モリブデン・チタン粉末の概要

モリブデン・チタン粉 は、モリブデンとチタンからなる金属粉末を指す。それぞれの元素の特性を併せ持ち、高強度、耐熱性、導電性を必要とする用途に適しています。

モリブデンチタンパウダーの主な詳細:

- 組成 – 一般的に20-80%モリブデン、残りはチタン

- 粒子サイズ – マイクロメートルからナノメートルスケールまで

- 製造方法 – 高エネルギーボールミリング、ガス/水アトマイズ、プラズマ回転電極プロセス

- 一般的な用途 – 積層造形、溶射皮膜、ろう付け合金

- 主要特性 – 高強度、優れた耐食性、導電性、低熱膨張率

モリブデンチタン粉末は、個々の金属のみと比較して強化された特性を提供します。組成を調整することにより、粉末の特性を様々な高性能用途に合わせて調整することができます。

種類

| タイプ | 構成 | 説明 |

|---|---|---|

| モリブデンが豊富 | 80% Mo, 20% Ti | 最高の硬度と強度、熱伝導性。チタンリッチ合金より耐酸化性が低い。 |

| チタンリッチ | 20%モリブデン、80%チタン | 優れた耐食性と有用な強度と導電性。モリブデンリッチタイプよりも延性が高い。 |

| 中級 | 40-60%Mo、バランスTi | モリブデンとチタンの特性をバランスよく配合。汎用合金。 |

| ナノコンポジット | MoとTiのナノ粒子 | 粒径が細かいため強度に優れる。高性能コーティングや構造物に使用される。延性は低い。 |

表1: モリブデン・チタン粉末の種類と代表的な組成

作曲と制作

モリブデンチタン粉末は20-80%のモリブデンを含み、残りはチタンです。ニッケル、クロム、アルミニウムのような他の合金元素は、特定の特性を変更するために少量添加されることがあります。

| 製造方法 | 説明 | 粒子特性 |

|---|---|---|

| 高エネルギーボール粉砕 | 粉砕メディアを用いた粉体粒子の冷間溶接と破砕の繰り返し | 幅広い粒度分布、不規則な形態、複合粒子 |

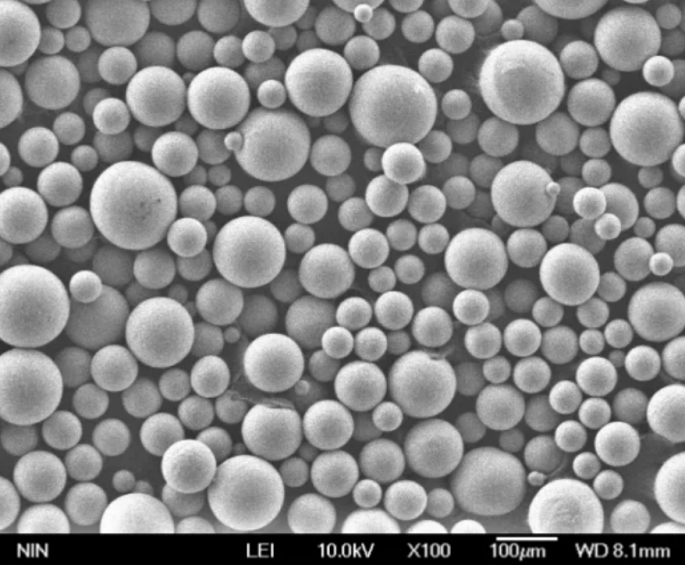

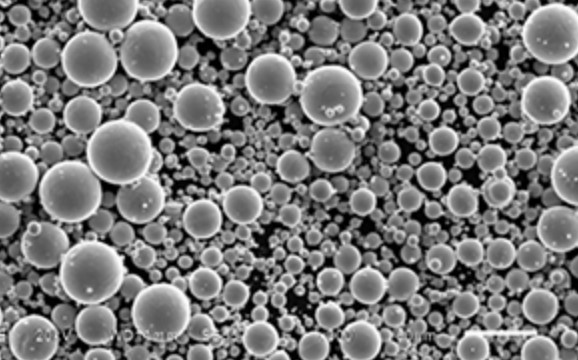

| ガス噴霧 | 高圧ガスによる溶融合金の急速冷却 | 球状形態、微細構造、タイトな粒度分布 |

| 水の霧化 | 噴霧化にガスの代わりにウォータージェットを使用 | ガスアトマイズに比べ球状粒子が少なく、粒径範囲が広い。 |

| プラズマ回転電極プロセス | 電極紡糸と急速溶融・凝固 | 粒度分布と形態の制御 |

表2: モリブデン・チタン粉末製造技術の概要

ガスアトマイズとプラズマ回転電極プロセスにより、粒度分布、形状、内部合金構造などの粉末特性を最大限に制御することができる。

モリブデン・チタン粉末の特性

| プロパティ | 貢献要素 | 詳細 |

|---|---|---|

| 強さ | モリブデン | モリブデンによる固溶体/分散強化で非常に高い降伏強度と引張強度を実現 |

| 硬度 | モリブデン | 成分によりロックウェル60HRCまで |

| 耐食性 | チタン | 表面の保護酸化物により、多くの酸や海洋環境などに対する優れた耐性 |

| 耐酸化性 | チタン | 約600℃まで酸化に耐える。モリブデンリッチ合金は耐性が低い。 |

| 熱伝導率 | モリブデン | 電極、熱管理部品などの高熱流束用途に有用 |

| 電気伝導率 | モリブデン | 特殊な導電性反応材料、溶射皮膜に使用される。 |

| 熱膨張 | チタン | 鋼鉄より約30%低膨張で、耐熱疲労性が向上 |

表3: モリブデン・チタン粉末の主要特性と寄与元素の概要

高強度は主にモリブデン固有の特性とチタンの固溶強化によるもので、チタンは有用な耐食性を付与する。組成を調整することで、抵抗、導電性、その他の特性をバランスさせることができる。

用途

モリブデン・チタン粉 は、その特殊な特性の組み合わせが必要とされる高度な用途に使用される:

| 申し込み | 用途と利点 |

|---|---|

| 付加製造 | 溶製材を超える強度を持つ高硬度部品。耐食性に優れる。 |

| 溶射コーティング | 耐摩耗性、導電性、耐熱性を備えた電気接点。 |

| ろう付けフィラー合金 | 膨張係数が一致するチタン合金または異種金属の組み合わせの接合。 |

| 焼結構造部品 | 物理的特性を調整したネットシェイプの高性能部品。 |

| 特殊反応材料 | テルミットまたは金属間反応性複合材料として配合された場合、高エネルギー出力が得られる。 |

表4: モリブデン・チタン粉末の用途と使用法の概要

高強度でカスタマイズ可能な形状を3Dプリントできることから、積層造形は大きな成長分野となっている。パウダーはまた、他の方法では容易に実現できない保護コーティングや高度な接合アプリケーションも可能にする。

モリブデン・チタン粉末の仕様

モリブデンチタン粉末は、様々な業界や国の仕様の下で利用可能です:

| スタンダード | 説明 |

|---|---|

| ASTM B939 | 溶射用モリブデン含有量50%のモリブデン合金をカバー |

| AMS 7758 | チタン-モリブデンブレンドを含むニッケル基合金粉末および加工標準 |

| MIL-PRF-32495 | モリブデンおよびモリブデン合金粉末の性能規格 |

| ISO 21818-1 | 積層造形用粉末の仕様、組成、サイズ、製造、試験 |

表5: モリブデン・チタン粉末の産業および軍事仕様

これらの仕様は、粉体の品質を標準化し、ミッションクリティカルな用途におけるバッチ間の一貫性を確保することを目的としています。これらの規格は、業界の需要に対応するために継続的に進化しています。

サプライヤーと価格

モリブデンチタン粉末は、主要な金属粉末サプライヤーや特殊添加剤製造会社から入手可能である:

| サプライヤー | kgあたりの開始価格 |

|---|---|

| サンドビック・オスプレイ | $450 |

| カーペンター・パウダー製品 | $200 |

| エラスティール | $250 |

| AP&C | $500 |

| アメリカの要素 | $3000 |

表6: モリブデン・チタン粉末サプライヤーの概要と参考価格

価格は、純度、粉末の特性、注文量によって大きく異なり、1kgあたり数百ドルから数千ドルになることもある。カスタム合金と粒子の最適化には、最低注文数量がある場合があります。

比較

モリブデンチタン粉末とモリブデン金属粉末の比較

| パラメータ | モリブデンチタン粉 | 純モリブデン粉末 |

|---|---|---|

| 密度 | 5-6 g/cc | 10g/cc |

| 強さ | 非常に高い(>1 GPa) | 高い |

| 耐酸化性 | チタン製で良好 | 悪い、保護雰囲気が必要 |

| 熱伝導率 | 中程度(~100W/m.K) | 非常に高い (140 W/m.K) |

| コスト | 高い(1kgあたり250~500ドル) | 低い(1kgあたり30~50ドル) |

表7: モリブデンチタン粉末と純モリブデン粉末との比較

モリブデンチタン粉末は、純粋なモリブデンに比べて耐食性と耐酸化性が非常に優れていますが、熱伝導性は若干低下します。また、チタンの添加は密度を低下させます。コストは高くなりますが、この合金のユニークな性能を必要とする用途には正当化できます。

モリブデンチタン粉末とステンレス鋼粉末の比較

| パラメータ | モリブデンチタン粉 | ステンレス鋼粉末 |

|---|---|---|

| 強さ | 非常に高い | ミディアム |

| 硬度 | ロックウェル60HRCまで | 最大ロックウェル 45 HRC |

| 耐食性 | 酸化チタン層により優れている | 300系ステンレス鋼に最適 |

| 熱伝導率 | 中程度(~100W/m.K) | 悪い(~20W/m.K) |

| コスト | 高い(1kgあたり250~500ドル) | 低価格(1kgあたり5~30ドル) |

表8: モリブデン・チタン粉末とステンレス鋼粉末の比較

モリブデン・チタン粉 は、標準的なステンレス鋼種に比べて高い強度と耐食性の両方を提供します。さらに、熱伝導率が非常に高いという利点もある。コストは高いが、特殊な用途には価値がある。

利点と限界

メリット

- 鍛造材を凌ぐ極めて高い強度

- モリブデンとチタンの比率を調整することで物理的特性を調整可能

- 酸化チタン保護層による優れた耐食性

- モリブデンからの有用な熱伝導性と電気伝導性

- 鋼鉄に比べて低熱膨張係数

- アディティブ・マニュファクチャリングと新興アプリケーションに最適

制限事項

- ステンレス鋼のような従来の合金よりも高価である。

- 純モリブデンより低い最高使用温度

- 脆いモリブデンリッチ組成は、延性/破壊靭性が低い。

- 溶融金属との反応性により、溶接/ろう付けの選択肢が制限される。

- モリブデン含有量の多い部品に必要な制御雰囲気処理

よくある質問

Q: 純金属粉末の代わりにモリブデンチタン粉末を使用する主な利点は何ですか?

A: モリブデンチタン粉末は、耐食性、高強度、有用な熱伝導性/電気伝導性、制御された膨張挙動など、個々の金属だけでは得られない相乗的な組み合わせを提供します。これにより、過酷な環境下での特殊な用途が容易になります。

Q:モリブデン・チタン粉末はどのように作られるのですか?

A: ガスアトマイズとプラズマ回転電極プロセスにより、粉末の特性を最大限に制御することができます。高エネルギーボールミリングは、原料を粉砕し、冷間溶接することで複合粉末を製造します。

Q: モリブデンチタン粉末はどのような産業で使用されていますか?

A: 航空宇宙、石油・ガス、化学処理、発電、医療用インプラントが、積層造形や焼結によって作られるモリブデンチタン部品の採用を後押ししています。ユニークな特性は、反応性材料や導電性コーティングのようなニッチな用途にも適しています。

Q: アディティブ・マニュファクチャリングが、これらの粉末の主な用途ですか?

A: アディティブ・マニュファクチャリングは、高性能部品を可能にするため、最も急成長しているアプリケーション分野です。しかし、モリブデンチタン粉末は、他の主要産業においても、溶射コーティングや特殊ろう付けフィラー合金としてかなりの用途があります。

Q: ステンレス鋼やタングステン合金のような一般的な代替品と比較した場合、コストはどうなりますか?

A: モリブデンチタン粉末は、単位質量あたりステンレス鋼グレードの5倍から20倍高価です。しかし、機械的特性や耐食性は飛躍的に向上します。タングステン合金の代替品として、原料コスト、完成部品コストの両面でより手頃な価格となっています。

Frequently Asked Questions (FAQ)

1) What particle size distribution is optimal for Molybdenum Titanium Powders in AM vs. thermal spray?

- AM (LPBF): typically 15–45 μm (or 20–63 μm by supplier); higher sphericity improves spreadability. Thermal spray often uses coarser cuts (45–106 μm) to match feed and deposition rates.

2) Gas-atomized vs. ball-milled Mo–Ti powders: which should I choose?

- Gas/plasma-atomized: spherical, tight PSD, best for LPBF and consistent flow. High-energy ball-milled: composite/lamellar particles, useful for reactive brazes or certain HVOF coatings; less ideal for LPBF due to irregular morphology.

3) How does composition (Mo/Ti ratio) affect corrosion and oxidation resistance?

- Ti-rich alloys (≤40% Mo) form robust TiO2 surface films, improving corrosion/oxidation up to ~600–700°C. Mo-rich grades (>60% Mo) boost strength/conductivity but require stricter atmospheres and may oxidize faster.

4) Can Molybdenum Titanium Powders be reused in AM workflows?

- Yes, with inert handling, sieving, and blend rules. Track O/N/H, PSD shift, flow, and density per ISO/ASTM 52907 and ASTM E1019. Typical practice supports 5–8 cycles before blending with virgin powder.

5) What post-processing is common for Mo–Ti AM parts?

- Stress relief, HIP (if density targets require), machining/EDM, and surface finishing. For corrosion-critical uses, consider passivation or thin ceramic/metallic barrier coatings depending on service environment.

2025 Industry Trends: Molybdenum Titanium Powders

- Application pull from high-temp tooling and corrosive process hardware drives demand for intermediate Mo–Ti compositions (40–60% Mo).

- Plasma spheroidization gains share to improve sphericity of milled or water-atomized feeds for LPBF.

- Digital material passports (PSD, O/N/H, tap/apparent density, reuse count) adopted for cross-site qualification.

- Sustainability: argon recovery and powder circularity programs reduce atomization gas use 20–35% and extend reuse windows.

- Standards maturation: broader use of ISO 21818-1 for AM powders and alignment with ASTM chemistry/flow tests for Mo–Ti blends.

2025 KPI Snapshot for Molybdenum Titanium Powders (indicative ranges)

| メートル | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| Sphericity (atomized AM grades) | 0.90–0.94 | 0.93–0.97 | Close-coupled atomization, plasma spheroidization |

| LPBF build rate (cm³/h per laser) | 20–35 | 28–50 | Multi-laser + path optimization |

| As-built relative density (optimized) | 98.0–99.4% | 98.5–99.7% | HIP to ≥99.9% when needed |

| Oxygen content, wt% (AM grade) | 0.05–0.12 | 0.04–0.10 | Improved inert handling |

| Reuse cycles before blend | 3–6 | 5–8 | With digital passports + sieving |

| Reported recycled feed fraction | Rare | 5–15% | Supplier sustainability disclosures |

References: ISO/ASTM 52907; ISO 21818‑1; ASTM E1019; ASTM B212/B213/B703; OEM atomizer notes; NIST AM‑Bench insights

Latest Research Cases

Case Study 1: Plasma-Spheroidized Mo–Ti Powder for LPBF Thin-Wall Consistency (2025)

Background: A chemical equipment OEM saw recoater streaks and porosity in 0.6–1.0 mm walls using water-atomized Mo–Ti (60/40).

Solution: Introduced plasma spheroidization to lift sphericity >0.94, implemented tighter PSD (20–53 μm), and optimized hatch/contour strategy; added inert closed-loop powder handling.

Results: Layer defects −40%; apparent density +0.30 g/cm³; as-built density +0.6% absolute; scrap rate −22% across three part families.

Case Study 2: Corrosion-Fatigue Improvement of Ti-Rich Mo–Ti AM Manifolds (2024)

Background: A process plant required chloride-resistant, lightweight manifolds with superior fatigue in wet service.

Solution: Printed Ti‑80/Mo‑20 manifolds, applied HIP and fine shot peening followed by tailored passivation; validated per ASTM G48 and rotating-bending tests.

Results: Pitting resistance equivalent number (PREN proxy) performance matched design targets; corrosion-fatigue life +25% vs 316L baseline at equal mass; weight −30% vs machined alloy alternative.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Documenting PSD, O/N/H, and reuse history via digital passports is essential to make Molybdenum Titanium Powders portable across platforms and sites.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “Intermediate Mo–Ti compositions are emerging as practical choices for LPBF where corrosion and strength must be co-optimized without resorting to heavier refractory systems.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Expect closer alignment of Mo–Ti powder QA with ISO 21818‑1 and broader adoption of standardized artifacts for qualification in regulated industries.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Feedstock characterization for AM powders

https://www.iso.org/standard/78974.html - ISO 21818‑1: Additive manufacturing — Test methods for metal powders

https://www.iso.org/ - ASTM standards: E1019 (O/N/H), B212/B213/B703 (density/flow)

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM validation

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Mo–Ti applications

https://senvol.com/database - HSE ATEX/DSEAR guidance for combustible metal powders handling

https://www.hse.gov.uk/fireandexplosion/atex.htm

Last updated: 2025-08-27

Changelog: Added five targeted FAQs, 2025 KPI table, two recent case studies, expert viewpoints, and authoritative tools/resources specific to Molybdenum Titanium Powders.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major OEMs release Mo–Ti parameter sets, or new datasets on powder circularity and corrosion performance are published.