1. Introduction: Why Maraging Steel Powder Matters in Modern Manufacturing

Maraging steel powder is a high-performance material widely used in aerospace, tooling, defense, and high-strength industrial applications. Known for its ultra-high strength, excellent toughness, and heat treatability without distortion, maraging steel is a top choice for additive manufacturing (AM) and powder metallurgy (PM) industries.

Key Benefits of Maraging Steel Powder

- Ultra-high tensile strength (up to 2,000 MPa)

- Good dimensional stability during heat treatment

- Excellent machinability in the annealed condition

- Superior weldability and corrosion resistance

- Ideal for additive manufacturing (3Dプリンティング) and metal injection molding (MIM)

Note for B2B Buyers: Maraging steel powder delivers a unique combination of strength and ductility, making it an ideal material for high-precision and load-bearing components.

Common Industries Using Maraging Steel Powder

| 産業 | 代表的な使用例 |

|---|---|

| 航空宇宙 | Engine components, landing gear, structural parts |

| 自動車 | High-stress gears, shafts, and drivetrain components |

| 工具 | Injection molds, die-casting tools, punches |

| ディフェンス | Missile components, structural reinforcements |

| Additive MFG | 3D printed molds, functional prototypes, and end-use parts |

2. Industrial Applications of Maraging Steel Powder

Maraging steel powder is uniquely suited for high-strength and high-precision applications. Its exceptional mechanical properties make it a mainstay in multiple industrial verticals.

Application Areas in Detail

航空宇宙

- Lightweight, high-strength structural components

- Jet engine parts requiring dimensional stability under thermal stress

- Tailor-made parts produced via 3D printing

Tool and Die Industry

- Injection mold cores and cavities for thermoplastics

- Hot and cold working tools

- Die-casting dies and high-wear punches

防衛・軍事

- Critical components for missiles and armored vehicles

- Wear-resistant parts exposed to extreme forces

アディティブ・マニュファクチャリング(3Dプリンティング)

- Functional end-use components

- Complex geometries for prototyping and production

- Customized, low-volume part fabrication

Benefits for Additive Manufacturing Suppliers

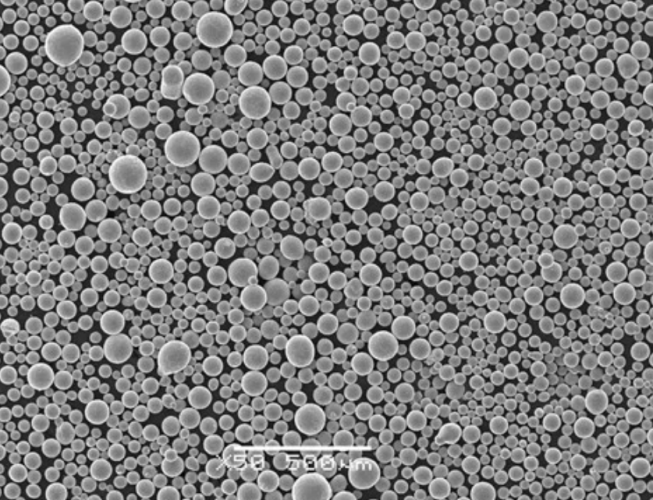

- High powder flowability and uniform particle size

- Excellent sintering and layering behavior

- Reduced post-processing due to minimal distortion

Maraging Steel Powder in 3D Printing

| 特徴 | Benefit for 3D Printing Manufacturers |

|---|---|

| Consistent particle morphology | Ensures even layer deposition and sintering |

| 狭い粒度分布 | Improves surface finish and mechanical properties |

| High purity and low oxygen content | Enhances final part integrity |

For more detailed specifications, visit our PMパウダー製品ページ.

3. Types and Grades of Maraging Steel Powder

Maraging steel powders are typically classified by grade, with the most common being 18Ni (300, 250, 200), indicating nickel content and strength levels. Each grade offers specific advantages tailored to industrial needs.

共通グレード

| グレード | ニッケル含有量 | UTS (MPa) | 主要物件 |

|---|---|---|---|

| 18Ni (300) | ~18% | ~2,000 | Highest strength, best for aerospace |

| 18Ni (250) | ~18% | ~1,700 | バランスの取れた強さとタフネス |

| 18Ni (200) | ~18% | ~1,400 | Good machinability, moderate strength |

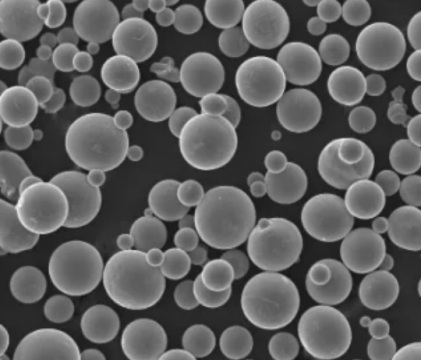

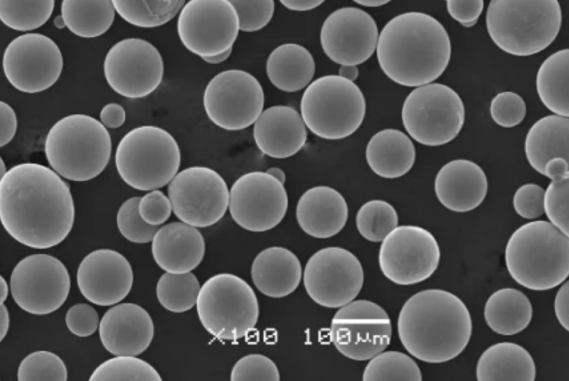

パウダー製造法

| 方法 | 説明 | 長所 |

|---|---|---|

| ガス噴霧 | Melts atomized by inert gas, forming spherical particles | High purity, excellent flowability |

| 水の霧化 | Water used to atomize molten steel into fine powders | Cost-effective, irregular particles |

| 複合霧化 | Hybrid of gas and water atomization | Customizable particle shapes |

At 上海Truer Technology Co., Ltd, we offer maraging steel powders produced via gas atomization and hybrid atomization techniques to meet the highest industry standards.

Customization for B2B Clients

- Custom particle size distributions (15–45μm, 45–105μm, etc.)

- オーダーメイドの合金組成

- Special packaging for moisture-sensitive applications

Truer Technology’s R&D team works closely with clients to develop powders suited for specific process parameters—ensuring optimal results for every application.

4. Market Trends and Growth Potential in Maraging Steel

Global Outlook

The maraging steel powder market is witnessing significant growth, driven by the rising adoption of additive manufacturing (AM) across aerospace, automotive, and defense sectors. The global AM market is projected to reach $35 billion by 2028, with high-strength metal powders like maraging steel taking center stage in high-performance applications.

Market Growth Drivers

- Increased Demand for 3D Printing in Aerospace

Lightweight, strong components made from maraging steel are replacing traditional machined parts. - Tooling Industry Modernization

Maraging steel powder enables faster turnaround for mold and die production using metal AM. - Defense Investments

Governments are investing heavily in advanced materials for high-performance military applications. - Asian Manufacturing Boom

China and Southeast Asia have become key manufacturing hubs, increasing regional demand for high-quality maraging steel powder.

Global Market Size Forecast

| 年 | Market Value (USD Billion) | 年平均成長率(%) |

|---|---|---|

| 2022 | 1.2 | - |

| 2025 | 2.4 | 16.2% |

| 2028 | 4.7 | 17.5% |

B2B Buyer Trends

- OEMs now prefer direct sourcing from powder manufacturers to reduce supply chain risk.

- 販売店 seek stable quality and custom packaging for resale in niche markets.

- E-commerce sellers are offering smaller batch sizes for research and prototyping labs.

📌 Related Read: Learn more about our company background and capabilities in high-performance powder metallurgy.

5. Key Factors When Choosing a Maraging Steel Powder Supplier

Choosing the right supplier is critical for ensuring consistent performance, timely delivery, and technical support. Here’s what B2B buyers, OEMs, and powder distributors should consider:

1.パウダーの品質と安定性

- 粒子の形態学: Should be spherical with minimal satellites.

- 純度: Low oxygen and nitrogen content for high mechanical performance.

- PSD (Particle Size Distribution): Should match machine specs (15–45μm for LPBF, 45–105μm for DED).

2.製造能力

- Does the supplier use gas atomization or hybrid atomization?

- Can they customize alloy compositions and particle size?

3. Certifications & Standards

| Standard/Certification | 説明 |

|---|---|

| ISO 9001 | General quality management |

| AS9100 | Aerospace quality standard |

| Material traceability | Required for defense and aerospace |

4. Technical Support & Customization

- In-house R&D team for tailored solutions

- Engineering support for AM process optimization

- Batch-specific data sheets and testing reports

5. Logistics & Packaging

- Moisture-controlled packaging

- Custom sizing for bulk or sample orders

- 輸出準備文書

B2B Tip:

Always request a COA (Certificate of Analysis) and PSD report before placing a large order. This reduces the risk of incompatibility with your AM machine or sintering process.

6. Top Global and Chinese Maraging Steel Powder Suppliers

Here are some of the key players in the global maraging steel powder supply chain:

Global Leaders

| サプライヤー名 | 国名 | 専門分野 |

|---|---|---|

| ヘガネスAB | スウェーデン | Wide range of PM and AM powders |

| カーペンター添加剤 | アメリカ | High-performance maraging steels |

| サンドビック・オスプレイ | 英国 | Gas-atomized metal powders |

| オベール&デュバル | フランス | Aerospace-grade AM powders |

中国の主要サプライヤー

| サプライヤー名 | 強み |

|---|---|

| 上海Truer Technology Co., Ltd | Wide maraging steel range, custom powders |

| CNPCパウダー | Large-scale production, cost-effective |

| Changsha Hualiu Metal Powder Co. | Specialty metal powders for AM |

Shanghai Truer Technology Co., Ltd – A Trusted Chinese Supplier

Established in 2009, 上海トゥルーア entered the additive manufacturing space in 2019. With a focus on R&D and customization, the company offers a full range of maraging steel powders produced through gas and hybrid atomization.

✅ ISO-Certified

✅ Custom particle size distribution

✅ Low oxygen and nitrogen content

✅ Widely used in aerospace, tooling, and defense

Product Range from Truer

| Maraging Steel Type | 製造方法 | Particle Size Options |

|---|---|---|

| 18Ni (300) | Gas / Hybrid Atomized | 15–45μm, 45–105μm |

| 18Ni (250) | ガスアトマイズド | カスタマイズ可能 |

| Custom Alloys | On Request | Based on customer specs |

トゥルーアはまた、次のようなサービスも提供している。 complete additive solutions, including lubricants, cutting agents, and magnetic additives—making them a one-stop solution for powder metallurgy clients.

👍 Explore the full range of PM powders available from Shanghai Truer.

7.中国メーカーに注目するバイヤーが増えた理由

In recent years, global buyers—including OEMs, distributors, and e-commerce sellers—have increasingly sourced maraging steel powder from Chinese suppliers. This trend is driven by a combination of technological advancements, cost efficiency, and improved quality control in China’s powder metallurgy industry.

Key Reasons B2B Buyers Prefer Chinese Suppliers

1.競争力のある価格設定

China offers significant cost advantages due to:

- Economies of scale in raw material processing

- Lower operational and labor costs

- Vertical integration among powder metallurgy manufacturers

2. Full Customization Capabilities

| カスタマイズ・オプション | 説明 |

|---|---|

| 粒度分布 | 15–45μm, 45–105μm, or customer-specified |

| 合金組成 | Custom Ni, Co, Mo, Ti content |

| パッケージング | Moisture-proof, nitrogen-filled, or OEM branded |

| 製造方法 | Choose between gas, water, or hybrid atomization |

3. Advanced Manufacturing Technologies

Chinese manufacturers such as Shanghai Truer Technology have invested heavily in R&D and automation. Their facilities often include:

- State-of-the-art gas atomization systems

- Real-time powder morphology analysis

- In-house metallurgy labs for QC and alloy development

4. Strong After-Sales and Technical Support

Chinese suppliers are now offering:

- English-speaking support teams

- Technical engineers for AM process optimization

- Fast response times and overseas warehousing options

📌 Learn more about Truer’s company focus and values on their 会社概要のページ.

8. Why Choose Shanghai Truer Technology

Shanghai Truer Technology Co., Ltd is a leading maraging steel powder manufacturer in China, with a strong reputation in the B2B market for precision powders, technical expertise, and responsive service.

会社概要

- Founded in: 2009

- AM Division launched: 2019

- Core focus: Powder Metallurgy & Additive Manufacturing

- Certifications: ISO 9001, RoHS, REACH compliant

トゥルアーの特徴

✅ Comprehensive Product Selection

Truer offers a wide variety of maraging steel and PM powders including:

- PM Bronze, Nickel Silver, Brass

- PM Iron, Steel, Copper-Steel

- Maraging Steel (18Ni-300, 250, 200 grades)

✅ Advanced Production Capabilities

| テクノロジー | 説明 |

|---|---|

| ガス噴霧 | Produces highly spherical, low-oxygen powders |

| 水の霧化 | Cost-effective option for standard grades |

| ハイブリッド霧化 | Combines benefits of gas and water methods |

✅ Tailored B2B Solutions

- Custom powder specs for AM and MIM applications

- Technical consulting and materials engineering

- Flexible MOQ for R&D to bulk production runs

- Private-label packaging for distributors

✅ Full Additives Division

In addition to steel powders, Truer also provides:

- Lubricants: Lube-W, SUW-8000

- Cutting agents: SME-100 (sulfur-free), TD-8

- 軟磁性添加剤QH-150

- Graphite products: TBC-400, TBC-1000

📌 View their full PMパウダー製品群 to explore available options.

9. How to Order Wholesale Maraging Steel Powder from China

Ready to source maraging steel powder in bulk? Here’s a step-by-step guide for B2B buyers looking to work with Shanghai Truer Technology.

ご注文の流れ

| ステップ | アクション | 備考 |

|---|---|---|

| 1 | Submit Inquiry via Website | を使用する。 お問い合わせページ |

| 2 | Share Technical Specs | Particle size, application, quantity, etc. |

| 3 | Receive Technical Datasheet (TDS) and COA | Review for compatibility |

| 4 | Sample Order (Optional) | For test runs or R&D |

| 5 | Confirm Bulk Order and Payment Terms | Usually 30% upfront, balance before shipment |

| 6 | Production and Quality Control | Lead time typically 7–14 days |

| 7 | Final Packaging and International Shipping | Export documents and MSDS included |

Accepted Payment Methods

- 銀行振込 (T/T)

- L/C (for large or long-term contracts)

- PayPal (for small sample orders)

配送オプション

- EXW, FOB Shanghai, or CIF to your port

- Air freight for urgent sample orders

- Sea freight for bulk orders

Truer offers full export support and can assist with customs documentation, certificates of origin, and HS code classification.

FAQs: Common Questions About Buying Maraging Steel Powder

Q1: What’s the minimum order quantity (MOQ) from Shanghai Truer?

A: MOQs are flexible. For standard grades, 10kg is accepted for testing or R&D. For customized powders, MOQ starts at 50kg.

Q2: Can I get a custom particle size distribution?

A: Yes. Truer offers PSDs such as 15–45μm for LPBF and 45–105μm for Directed Energy Deposition (DED). Custom sizes are available upon request.

Q3: What purity levels does Truer’s maraging steel powder offer?

A: Oxygen content is typically <0.02%, and nitrogen <0.01%, ideal for aerospace and tooling applications.

Q4: How do I ensure compatibility with my 3D printer or MIM process?

A: Truer provides technical datasheets, COA, and can recommend appropriate grades based on your equipment and end-use.

Q5: Does Shanghai Truer ship internationally?

A: Yes. Truer has shipped to North America, Europe, Southeast Asia, and the Middle East. Export packaging and documentation are included.

📌 Learn more about Truer’s full range of metal powders and additive solutions.

📩 Have a specific requirement? お問い合わせ お見積もりや技術的なご相談は