1. Introduction: Why Fe-Ni-Co Powder Matters in Advanced Manufacturing

Fe-Ni-Co powder—an alloy composed of iron (Fe), nickel (Ni), and cobalt (Co)—is a cornerstone material in precision industrial applications such as aerospace, magnetic components, electronics, and additive manufacturing. Its unique combination of thermal stability, magnetic permeability, and mechanical strength makes it a top choice for manufacturers demanding high-performance materials.

Why B2B Buyers Are Focusing on Fe-Ni-Co Powder

- High-temperature performance ideal for aerospace and automotive parts

- Excellent magnetic properties favored by electronics manufacturers

- Versatility in powder metallurgy (PM) and additive manufacturing (AM)

- Availability in various particle size distributions for tailored applications

📌 For a comprehensive overview of powder metallurgy materials, visit our PMパウダー製品ページ.

2. Applications of Fe-Ni-Co Powder in Industrial Sectors

Fe-Ni-Co powder plays a critical role in various high-tech and heavy industries. Here’s a breakdown of where and how this alloy is used:

航空宇宙産業

- High-temperature components for jet engines and turbines

- Structural parts requiring thermal expansion stability

- Engine parts with high fatigue resistance

電子・電気工学

- Magnetic cores and shielding components

- Transformer laminations

- Electromagnetic interference (EMI) shielding

医療機器

- MRI-compatible components

- Biocompatible surgical tools

- Precision implants requiring mechanical reliability

自動車産業

- Components in electric motors and hybrid drive systems

- Sensors and control systems needing magnetic sensitivity

| 申し込み | Benefits of Fe-Ni-Co Powder |

|---|---|

| 航空宇宙 | High strength, thermal stability |

| エレクトロニクス | Excellent magnetic permeability |

| メディカル | 耐食性、生体適合性 |

| 自動車 | High fatigue resistance, magnetic response |

3. Key Properties and Use Cases of Fe-Ni-Co Alloys

Fe-Ni-Co alloys are specifically engineered to deliver a unique set of physical and mechanical properties that support high-performance industrial applications.

主要物件

- 透磁率: High magnetic responsiveness for sensors and electronics

- 熱膨張係数: Low and stable across temperature ranges

- 耐食性: Suitable for harsh environments

- 機械的強度: High tensile strength and fatigue resistance

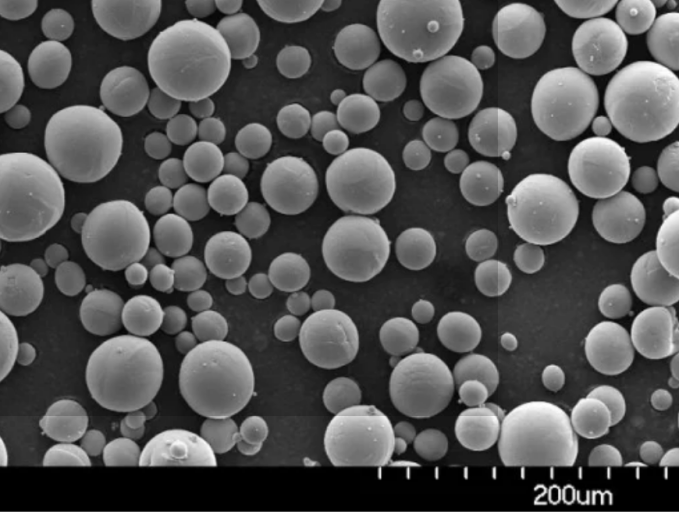

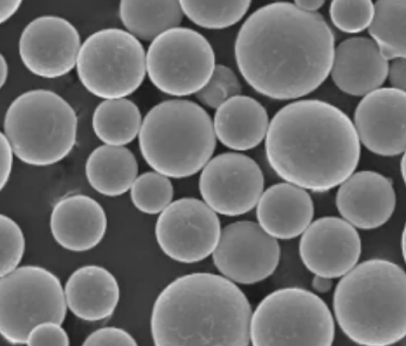

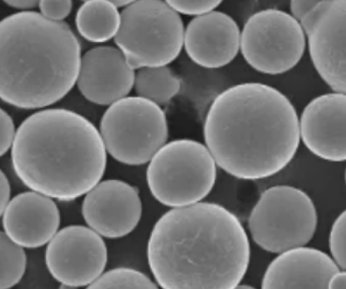

パウダー特性

| 特徴 | 詳細 |

|---|---|

| 粒子形状 | Spherical or irregular (depending on atomization method) |

| 粒子サイズ | 10–100 μm (customizable) |

| 純度 | >99.5% Fe-Ni-Co alloy |

| 生産方法 | Gas atomized, water atomized, carbonyl process |

代表的な使用例

- Additive manufacturing of aerospace brackets

- Powder compaction for magnetic sensors

- Sintering of medical device components

- Injection molding for micro-electronics

💡 Shanghai Truer Technology Co., Ltd specializes in producing high-quality Fe-Ni-Co powders using methods like gas atomization and carbonyl reduction, ensuring optimal particle uniformity and purity. Learn more about our company.

4. Global Market Trends for Fe-Ni-Co Powder

Increasing Demand from High-Performance Sectors

The Fe-Ni-Co powder market is experiencing robust growth, largely driven by the increasing demand for high-performance alloys in aerospace, electronics, and additive manufacturing.

主な市場促進要因:

- Aerospace growth: Demand for heat-resistant and lightweight parts is rising

- 電気自動車 (EVs): Increased usage in motor components and sensors

- Miniaturization in electronics: Need for high magnetic permeability materials

- 3Dプリンティング boom: Demand for advanced powders with uniform particle size

Market Size & Forecast

| 年 | Global Market Size (USD Million) | 年平均成長率(%) |

|---|---|---|

| 2021 | 245 | - |

| 2024 | 312 | 7.5 |

| 2028 | 420 | 7.9 |

Key Regions Showing Growth:

- North America: Focus on aerospace and defense

- Europe: Advancements in automotive and medical tech

- Asia-Pacific: Rapid industrialization and investment in additive manufacturing

新たなトレンド

- Shift toward customized powder blends

- Movement from traditional alloys to smart materials

- Integration of Fe-Ni-Co powders in magneto-electronic devices

5. How to Select a Reliable Fe-Ni-Co Powder Supplier

Choosing the right supplier is critical for manufacturers looking to maintain quality, consistency, and production efficiency. Here are essential criteria to evaluate:

考慮すべき主な要素

| 基準 | なぜ重要なのか |

|---|---|

| 粉末純度 | Impacts the final product’s performance and safety |

| 粒子径コントロール | Affects flowability and sintering behavior |

| 製造方法 | Determines morphology and chemical uniformity |

| 認証 | ISO, REACH, and RoHS compliance ensures quality |

| Supply Capability | Timely, high-volume delivery supports production schedules |

| テクニカルサポート | Assistance with application-specific customization |

サプライヤーに尋ねるべき質問

- Can you provide third-party purity test reports?

- What production methods do you use (e.g., water atomized, gas atomized)?

- Do you offer custom particle size distribution?

- What industries do you primarily supply to?

- Can you supply bulk orders consistently?

✅ Check out our Fe-Ni-Co Powder Product Range to explore ready-to-ship and customizable options.

6. Top Fe-Ni-Co Powder Manufacturers and Distributors Globally

Here are some of the most recognized suppliers of Fe-Ni-Co powder in the global market:

| 会社名 | 地域 | 専門性 |

|---|---|---|

| ヘガネスAB | スウェーデン | Metal powders for PM and AM |

| サンドビック・マテリアル | グローバル | ガスアトマイズ粉末 |

| 上海Truer Technology Co., Ltd | 中国 | High-purity PM and AM powders |

| カーペンター添加剤 | アメリカ | High-performance alloys for AM |

| GKN粉末冶金 | ドイツ | Fe-based alloy powders |

スポットライト上海泰爾科技有限公司

設立: 2009

AM Division Founded: 2019

Core Capabilities:

- Offers over 15 grades of PM and AM powders

- In-house production using water atomization, gas atomization, and carbonyl methods

- Supplies to aerospace, automotive, medical, and 3D printing sectors

- Products include PM bronze, PM nickel steel, PM infiltrated iron, and Fe-Ni-Co alloy powders

- ISO-certified and equipped for large-scale B2B distribution

Highlight Products:

- PM nickel steel (iron-nickel): Ideal for magnetic and structural applications

- Fe-Ni-Co powder: Customizable for sintering and 3D printing

- Diffusion alloyed PM powders: For complex engineering needs

🌐 Get in touch with our technical experts via our お問い合わせページ to discuss your Fe-Ni-Co powder requirements.

7. Why More Buyers Are Turning to Chinese Suppliers for Fe-Ni-Co

Over the past decade, Chinese manufacturers have increasingly become global leaders in the supply of high-performance metal powders—including Fe-Ni-Co alloy powders. From cost efficiency to technological innovation, Chinese suppliers offer a competitive edge that appeals to B2B buyers across sectors.

B2Bバイヤーが中国のサプライヤーを好む主な理由:

✅ Cost-Effective Production

- Lower manufacturing and labor costs allow Chinese suppliers to offer competitive pricing

- High-volume production capabilities reduce the unit cost in bulk orders

✅ Advanced Manufacturing Techniques

- Use of water atomization, gas atomization, and carbonyl reduction methods

- Ability to produce spherical particles ideal for additive manufacturing

- Consistent quality control using automated sieving and mixing systems

✅ End-to-End Supply Chain Management

- Integrated logistics and customs clearance support

- Fast turnaround times for both domestic and international orders

✅ カスタマイズと柔軟性

- Custom alloy formulations and particle size distributions

- Application-specific packaging and labeling

- OEM and ODM services available for enterprise clients

事例紹介上海泰爾科技有限公司

Shanghai Truer stands out as a leading Chinese manufacturer with over a decade of experience in powder metallurgy. The company is known for its:

- Full vertical integration—from powder production to additive solutions

- Broad portfolio, from Fe-Ni-Co to PM bronze, nickel silver, and hybrid alloys

- International client base in aerospace, medical, and automotive industries

🔗 Learn more about our advanced manufacturing capabilities on our 会社概要のページ.

8. Why Choose Shanghai Truer Technology Co., Ltd for Fe-Ni-Co Powder

Shanghai Truer Technology Co., Ltd is one of China’s most trusted suppliers of Fe-Ni-Co powder and other powder metallurgy materials. With strong R&D capabilities and vast experience in additive manufacturing, Truer offers a complete solution for B2B buyers.

What Sets Shanghai Truer Apart:

| 特徴 | B2Bバイヤーのメリット |

|---|---|

| 高純度パウダー | Ensures consistent performance in critical applications |

| Multiple Atomization Methods | Customized morphology for PM and AM needs |

| Broad Material Portfolio | One-stop sourcing for various alloy powders |

| R&D and Application Support | Technical consultation and formulation assistance |

| Global Shipping | Fast logistics and export documentation support |

Specialized Product Offering:

- Fe-Ni-Co Powder: Available in gas or water atomized forms for sintering, 3D printing, and thermal spraying

- カスタムブレンド: Tailored to match your mechanical, thermal, or magnetic property requirements

- Supporting Additives: Including graphite (TBC-400, TBC-1000), cutting agents (TD-8, SME-100), and lubricants (Lube-W, SUW-8000)

Industry Certifications:

- ISO 9001 Quality Management System

- Export-compliant with REACH, RoHS standards

- In-house lab testing and third-party validation reports available

📦 Explore our full range of PM and AM powders to find the right solution for your application.

9. FAQs: Buying Fe-Ni-Co Powder in Bulk for B2B Buyers

Q1: What is the standard particle size range for Fe-Ni-Co powder?

A: We offer particle sizes from 10 µm to 100 µm, depending on your application. Custom sieving is available on request.

Q2: Can I request a sample before placing a bulk order?

A: Yes, Shanghai Truer provides small-volume samples for industrial testing and evaluation. Contact our sales team to request a sample.

Q3: What is the minimum order quantity (MOQ) for wholesale Fe-Ni-Co powder?

A: Our MOQ starts at 25 kg for standard grades. For custom formulations, MOQ may vary depending on the complexity and material cost.

Q4: Do you offer technical support for additive manufacturing applications?

A: Absolutely. Our R&D and technical teams can assist you with powder selection, parameter optimization, and application-specific recommendations.

Q5: How long does it take to fulfill a bulk order?

A: Lead time typically ranges from 7 to 15 business days, depending on order volume and customization requirements.

📩 Ready to order or ask more questions? Visit our お問い合わせページ for direct assistance from our sales engineers.