1. Introduction: What Is Diffusion-Alloyed Powder and Why It Matters

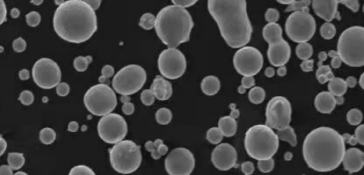

Diffusion-alloyed powder is a specialized powder metallurgy (PM) raw material where alloying elements are partially fused to the surface of iron powder particles through a high-temperature diffusion process. This method creates a hybrid powder with improved consistency, machinability, and mechanical properties, while still retaining the compressibility of premixed powders.

In the B2B manufacturing and metal fabrication world, diffusion-alloyed powders are vital for producing high-performance parts in industries such as:

- 自動車

- 航空宇宙

- 産業機械

- 工具と金型

- エレクトロニクス

These powders are especially popular among OEMs, tier-one suppliers, and contract manufacturers due to their exceptional balance between performance and cost-efficiency.

主要なB2Bキーワード

- Diffusion-alloyed powder supplier

- Wholesale diffusion-alloyed powder

- PM powder distributor

- Powder metallurgy alloys

- Industrial metal powder bulk buy

2. Industrial Applications of Diffusion-Alloyed Powder

Diffusion-alloyed powders are engineered to improve strength, compressibility, and dimensional accuracy in sintered parts. These powders are widely used across several sectors:

自動車産業

- トランスミッション部品

- ギアとスプロケット

- コンロッド

- カムシャフトプーリー

産業機械

- Hydraulic system parts

- Bearing housings

- Structural supports

- 耐摩耗コンポーネント

Power Tools & Hardware

- Drill components

- 切削工具インサート

- ロック機構

電気・電子

- 磁気コア

- Heat-dissipating casings

- Connectors and terminals

| 産業 | 共通コンポーネント | Benefits of Diffusion-Alloyed Powder |

|---|---|---|

| 自動車 | ギア、スプロケット、ロッド | Increased strength, wear resistance |

| 産業機械 | Housings, supports | Dimensional precision, durability |

| ツール&ハードウェア | Inserts, locks | 被削性、耐食性 |

| エレクトロニクス | Terminals, casings | Thermal stability, conductivity |

Diffusion-alloyed powders such as FD-0208 are especially favored in automotive parts due to their excellent hardenability and fatigue resistance.

For a deeper look into Shanghai Truer’s diffusion-alloyed powder offerings, visit our PMパウダー製品ページ.

3.主な特性と性能上の利点

Diffusion-alloyed powders blend the advantages of both prealloyed and admixed powders. Below are the standout performance characteristics that make them ideal for bulk industrial applications:

機械的特性

- 高いグリーン強度

- Enhanced sintered hardness

- 優れた寸法安定性

熱特性

- Excellent sinterability at lower temperatures

- Reduced thermal distortion

- Improved thermal conductivity for specific applications

加工の利点

- Better compressibility than fully prealloyed powders

- Uniform alloy distribution

- Lower segregation during handling

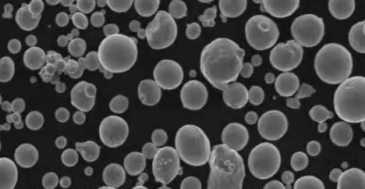

Typical Grades Available at Shanghai Truer:

- FD-0208: Diffusion alloyed copper and nickel

- FD-0200: Basic iron-copper alloy

- FX-2008: High strength hybrid alloy

| プロパティ | FD-0208 | FD-0200 | FX-2008 |

|---|---|---|---|

| 圧縮性 | 高い | ミディアム | 高い |

| Hardness (HB) | 80–100 | 60–80 | 100–120 |

| Sintered Density (g/cm³) | 6.8–7.2 | 6.5–6.9 | 7.0–7.3 |

| 引張強さ (MPa) | 600–800 | 350–500 | 750–900 |

These powders are especially suited for high-load components and applications where performance cannot be compromised.

If you’re interested in learning more about the technical capabilities and customizations available, reach out through our コンタクトページ.

4. Market Trends and Demand in Powder Metallurgy

The global powder metallurgy (PM) market has been experiencing steady growth, driven by increasing demand for lightweight, high-strength components across industries like automotive, aerospace, and industrial automation. Diffusion-alloyed powders, in particular, are gaining traction due to their unique balance of mechanical performance and cost-efficiency.

主な市場促進要因:

- Electrification of vehicles (EVs) requiring precision parts

- Growth in industrial automation and robotics

- Reduced material waste compared to traditional machining

- Rising demand for sustainable and energy-efficient manufacturing processes

Diffusion-Alloyed Powder Market Trends:

- Increased demand in Asia-Pacific due to automotive and industrial expansion.

- Customization of powder blends for specific mechanical properties.

- Shift from premix to diffusion-alloyed grades for better consistency and reduced segregation.

- Use of advanced atomization technologies to improve quality and purity.

| 地域 | Growth Trend | 需要を牽引する主要産業 |

|---|---|---|

| 北米 | Steady | Automotive, Aerospace, Defense |

| ヨーロッパ | 中程度 | Automotive, Green Energy |

| アジア太平洋 | Rapid | Automotive, Industrial Automation |

| ラテンアメリカ | エマージング | Mining Equipment, Tools Manufacturing |

According to industry reports, the global PM market is projected to reach USD 12 billion by 2028, with diffusion-alloyed powders comprising a growing share. This presents a significant opportunity for B2B buyers looking to source high-performance powders at scale.

5. How to Choose the Right Diffusion-Alloyed Powder Supplier

Sourcing the right diffusion-alloyed powder supplier is critical for manufacturers focused on quality, consistency, and cost management. Below are the key factors to consider when evaluating suppliers:

1. Technical Expertise & Certifications

- ISO 9001 certification and quality control systems

- In-house R&D and testing labs for custom powder development

- Long-standing experience in powder metallurgy and additive manufacturing

2. Product Range & Availability

- Availability of standard grades like FD-0208, FD-0200, FX-2008

- Customizable alloy compositions and particle size distributions

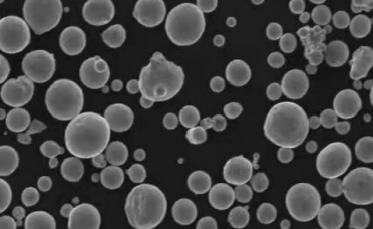

- Multiple production methods (water atomized, gas atomized)

3. Manufacturing Capabilities

- Advanced atomization technologies

- Strict consistency in powder particle distribution

- Clean production environments to avoid contamination

4. Logistics & Support

- グローバルな出荷能力

- Technical support for part design and sintering optimization

- Local warehousing or distribution networks

| Supplier Feature | B2Bバイヤーにとっての重要性 |

|---|---|

| ISO/TS Certifications | Ensures quality and reliability |

| Custom Powder Solutions | Matches specific part performance needs |

| Volume Flexibility | Supports both small batches and bulk orders |

| 競争力のある価格設定 | Better cost per unit for high-volume buyers |

For example, Shanghai Truer Technology Co., Ltd. has over 15 years of experience and offers both standard and custom diffusion-alloyed powders for global buyers. Learn more about our company’s background これ.

6. Top Suppliers of Diffusion-Alloyed Powders Worldwide

When sourcing diffusion-alloyed powders, it’s essential to know which suppliers offer the best combination of quality, customization, and global support. Here’s a list of some of the most recognized suppliers in the industry:

| サプライヤー名 | 地域 | Notable Products | 強み |

|---|---|---|---|

| Shanghai Truer Technology Co. Ltd. | 中国 | FD-0208, FX-2008, FD-0200 | Customization, full PM solutions |

| ヘガネスAB | スウェーデン | Astaloy, Distaloy grades | グローバルなプレゼンス、高度な研究開発 |

| リオティント・メタル・パウダーズ | カナダ | ATOMET, FL Series | High purity, automotive focus |

| GKNホエガネス | アメリカ | Ancorsteel grades | Long-standing reputation, innovation |

| カイメラ・インターナショナル | アメリカ | 特殊合金粉末 | Diverse PM product lines |

Why Shanghai Truer is a Top Choice in China:

- Offers a wide range of diffusion-alloyed powders including FD-0208 and FX-2008

- Integrates powder manufacturing with additive manufacturing services

- Provides tailored solutions for diamond tools, oil-impregnated bearings, and soft magnetic parts

- Supplies both water atomized and hybrid atomization powders

Shanghai Truer is not only a manufacturer but also one of the most professional additive suppliers in China’s powder metallurgy industry—supporting OEMs, tier-one suppliers, and global distributors.

To view our full list of diffusion-alloyed and PM powders, head over to our PMパウダーカタログ.

7. Why More Buyers Are Switching to Chinese Powder Metallurgy Suppliers

Global supply chains are undergoing a transformation, and more B2B buyers—including manufacturers, distributors, and e-commerce sellers—are sourcing directly from Chinese powder metallurgy suppliers. The reasons for this shift are rooted in cost-efficiency, scalability, and innovation.

Key Advantages of Chinese PM Suppliers

- 費用対効果の高い生産

Lower labor and material costs allow for highly competitive pricing—especially important for wholesale and high-volume buyers. - Advanced Manufacturing Technologies

Many Chinese manufacturers, like Shanghai Truer, have invested in advanced atomization and processing technologies, offering high-quality diffusion-alloyed powders that rival global brands. - カスタマイズと柔軟性

Chinese suppliers are often more agile in developing custom powder formulations tailored to specific B2B applications, including automotive, aerospace, and industrial components. - 統合サプライチェーン

With access to raw materials, logistics hubs, and technical resources, Chinese PM suppliers can fulfill large orders quickly and reliably.

| Benefits for B2B Buyers | 説明 |

|---|---|

| 競争力のある価格設定 | Lower cost per kilogram for bulk orders |

| Technical Customization | Powder blends tailored to your application |

| Fast Turnaround Times | Shorter lead times for global shipments |

| スケーラブルな生産 | Easily ramp up from trial batch to mass production |

Example: Why Shanghai Truer Is Leading the Shift

Shanghai Truer Technology Co., Ltd. exemplifies the strengths of Chinese PM suppliers:

- 14+ years in materials science and metallurgy

- Full integration of 3Dプリンティング powder equipment, PM powders, and additive solutions

- Offers diffusion-alloyed grades such as FD-0208, FX-2008, and FD-0200

- Provides lubricants, cutting agents, graphite additions, and sintering additives for full PM solutions

To explore how Shanghai Truer supports international buyers, visit our ホームページ.

8. Why Choose Shanghai Truer as Your Powder Metallurgy Partner

Shanghai Truer Technology Co., Ltd. is more than just a materials supplier—it’s a strategic partner for global B2B companies looking to scale their powder metallurgy operations.

トゥルアーの特徴

- ✅ 包括的な製品ライン

From PM iron, copper, and steel powders to diffusion-alloyed and prealloyed grades, Truer covers all your base material needs. - ✅ 高度な生産方式

Offers water atomization, gas atomization, and hybrid atomization to meet diverse technical requirements. - ✅ Turnkey Support for Manufacturers

Truer assists with application engineering, prototyping, powder selection, and performance testing. - ✅ Trusted by Global OEMs and Distributors

Exporting to North America, Europe, and Southeast Asia with excellent customer satisfaction and quality control.

Featured Diffusion-Alloyed Products

| 製品名 | Composition Type | 典型的な用途 |

|---|---|---|

| FD-0208 | Fe-Cu-Ni (diffused) | Gears, sprockets, structural parts |

| FX-2008 | Fe-Cu-Ni-Mo (hybrid) | High-strength automotive parts |

| FD-0200 | Fe-Cu (diffused) | General-purpose PM parts |

Additional Products from Truer

- 潤滑剤Lube-W、SUW-5000B

- Cutting Agents: SME-100 (sulfur-free), TD-8 (composite)

- Graphite Additives: QHP-330, TBC-400, TBC-1000

- Soft Magnetic Additives: QH-150

Whether you’re a component manufacturer, PM distributor, or OEM, Truer provides tailored support combined with technical expertise.

📩 For direct quotes or sample requests, お問い合わせはこちら.

9. FAQs: Buying Wholesale Diffusion-Alloyed Powder

Q1: What is the minimum order quantity (MOQ) for diffusion-alloyed powders at Shanghai Truer?

A: Our standard MOQ is 500 kg. However, for first-time buyers or R&D purposes, we can support smaller trial batches.

Q2: Can I request custom alloy compositions or particle size distributions?

A: Yes. Shanghai Truer specializes in customized powder solutions to meet specific performance or production requirements.

Q3: What quality certifications does Truer hold?

A: We operate under ISO 9001 quality management systems and offer full batch traceability and third-party testing on request.

Q4: Which atomization methods are available?

A: We offer water atomized, gas atomized, and hybrid (water + gas) powders to meet different applications and price points.

Q5: Do you export internationally?

A: Yes. We have a strong global logistics network and regularly ship to North America, Europe, Southeast Asia, and the Middle East.

Q6: 卸売りの注文方法は?

A: You can start by visiting our PMパウダーのページ and submitting an inquiry through the contact form. A representative will get in touch within 24 hours.

Q7: What industries benefit most from diffusion-alloyed powders?

A: Automotive, aerospace, industrial machinery, tool manufacturing, and electronics.

Q8: Can diffusion-alloyed powders be used in additive manufacturing (3D printing)?

A: While primarily used in PM parts, Truer also offers additive-grade powders. Contact us to learn more about our AM solutions.

✅ Internal Anchor Text Links Used in This Article:

By choosing Shanghai Truer as your diffusion-alloyed powder supplier, you’re partnering with a trusted, innovative, and globally recognized leader in powder metallurgy.

📞 Ready to source high-performance diffusion-alloyed powders in bulk? お問い合わせ for quotes, samples, or technical consultations.