1. What Is Corrax Powder and Why It Matters

Corrax powder is a premium-grade stainless tool steel specifically designed for additive manufacturing (AM) and powder metallurgy (PM) applications. Known for its excellent corrosion resistance, high strength, and superior polishability, Corrax powder is widely used in industries such as aerospace, medical, and tooling.

Chemical Composition of Corrax Powder (Typical):

| エレメント | 含有率(%) |

|---|---|

| Fe | バランス |

| Cr | 12–13 |

| Ni | 9–10 |

| Mo | 1.1–1.3 |

| Al | 1.5–1.8 |

| その他 | <1% |

Why Corrax Matters in Additive Manufacturing:

- Designed for tool and mold applications requiring high corrosion resistance.

- Heat-treatable to various hardness levels with minimal dimensional change.

- Excellent for complex geometries and near-net-shape production via AM.

- Delivers consistent performance in both prototyping and mass production.

B2B Buyer Insight:

For manufacturers in medical, dental, and tooling industries, Corrax powder provides a durable and reliable option for high-precision components. It offers a longer lifespan and less downtime, reducing total cost of ownership.

2. Industrial Applications of Corrax Powder

Corrax powder is particularly suitable for applications requiring high performance under harsh environments. Its unique properties make it ideal for industries that demand corrosion resistance and mechanical strength.

Key Industries Using Corrax Powder:

- Injection Molding Tools

Corrax is commonly used in the production of mold inserts, core pins, and tool cavities due to its high polishability and wear resistance. - Medical and Dental Devices

Its biocompatibility and corrosion resistance make it suitable for surgical tools, orthodontic devices, and implantable components. - 航空宇宙部品

Used in producing lightweight, corrosion-resistant parts with complex geometries. - 食品加工機器

Corrax’s rust resistance makes it ideal for components that come into contact with food or liquids.

Use Case Table:

| 産業 | Component Example | Benefits of Corrax Powder |

|---|---|---|

| メディカル | 手術器具、インプラント | 生体適合性、耐食性 |

| 工具 | Mold inserts, dies | High hardness, polishable surface |

| 航空宇宙 | Support brackets, ducts | Lightweight, strong, corrosion-resistant |

| 食品加工 | Machine parts, nozzles | Non-reactive, durable in wet environments |

Wholesale Insight:

Distributors and toolmakers need a material that reduces maintenance costs and extends product life. Corrax provides this advantage, especially when precision and hygiene are non-negotiable.

3. Key Properties and Use Cases in Additive Manufacturing

Additive manufacturing has revolutionized the way Corrax powder is used. Unlike traditional casting or forging, AM allows for the creation of complex geometries with minimal waste. Corrax is optimized for both powder bed fusion (PBF) and direct energy deposition (DED) processes.

Mechanical Properties (After Heat Treatment):

| プロパティ | 価値 |

|---|---|

| 硬度(HRC) | Up to 50 |

| 引張強度 | 1400–1600 MPa |

| 降伏強度 | ~1000 MPa |

| 破断伸度 | 8–10% |

| 密度 | 7.8 g/cm³ |

Advantages in AM Applications:

- Excellent dimensional stability during heat treatment.

- Low distortion after printing and post-processing.

- Reduced machining due to near-net-shape capabilities.

- High surface quality and polishability.

Common AM Use Cases:

- Injection mold cores for high-volume plastic parts.

- Customized dental devices and surgical guides.

- Lightweight aerospace brackets requiring high strength-to-weight ratio.

Pro Tip for Distributors:

Stocking Corrax powder in bulk ensures availability for high-mix, low-volume production. Consider partnering with a trusted supplier like Shanghai Truer to ensure consistent supply and technical support.

4. Market Outlook and Demand Trends for Corrax Powder

The global demand for Corrax powder is steadily increasing due to the rise in additive manufacturing and advanced tooling demands across multiple verticals. With Industry 4.0 accelerating digital production methods, manufacturers are seeking materials that offer high performance, scalability, and cost-efficiency—qualities Corrax powder delivers exceptionally.

Key Market Insights

| メートル | Value (2023) | Projected (2028) |

|---|---|---|

| Global AM Tooling Market Size | 19億ドル | $4.2 Billion |

| CAGR for Corrax Powder (2023–2028) | 14.2% | |

| Leading Demand Regions | Asia-Pacific, North America, Europe |

Driving Factors

- Growth in Additive Manufacturing: More companies are shifting from conventional manufacturing to AM, fueling demand for specialty powders like Corrax.

- Tooling Industry Expansion: With increasing need for high-precision molds in automotive and electronics, Corrax is becoming a preferred choice.

- Regulatory Push in Medical Sector: Standards for corrosion resistance and biocompatibility in surgical tools create strong pull for Corrax applications.

- Sustainability Movement: AM with Corrax enables reduced waste and energy efficiency, aligning with ESG goals.

B2B Takeaway:

For wholesale buyers and distributors, this growing demand offers a lucrative opportunity to expand product portfolios with high-margin, high-performance alloys like Corrax.

5. How to Choose a Reliable Corrax Powder Supplier

Choosing the right supplier is critical in ensuring consistent quality, timely delivery, and long-term partnership value. For B2B clients, the following criteria should be prioritized:

Key Evaluation Criteria for Corrax Powder Suppliers:

| 基準 | 説明 |

|---|---|

| Powder Quality Standards | ASTM, ISO, and internal quality control certifications |

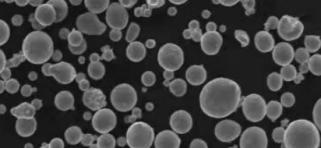

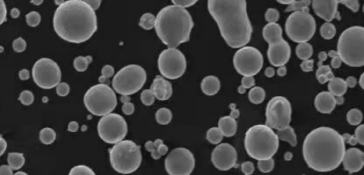

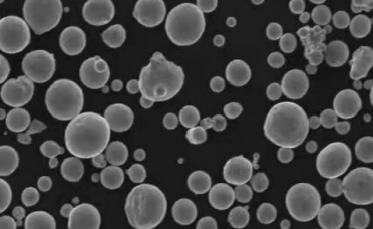

| 製造方法 | Gas atomization preferred for uniformity and purity |

| カスタマイズ能力 | Ability to adjust particle size distribution and packaging |

| Shipping and Lead Time | Fast turnaround and global logistics support |

| テクニカルサポート | Metallurgical consultation, application engineering |

| Price and MOQ | Competitive pricing with flexible minimum order quantities |

Checklist for B2B Procurement Teams:

- ✅ Request COA (Certificate of Analysis) with each batch

- ✅ Verify atomization method (gas atomized preferred for AM)

- ✅ Ask for sample lot prior to bulk order

- ✅ Evaluate after-sales technical support

Supplier Red Flags:

- Vague technical specifications

- Inconsistent lot quality

- No track record in additive manufacturing markets

📌 Insider Tip: For buyers seeking high-performance stainless steel powders, 上海Truer Technology Co., Ltd offers stringent quality control and a wide range of alloy options tailored for AM and PM.

6. Top Corrax Powder Suppliers in Asia and Globally

While Corrax powder is a niche material, there are several reputable suppliers globally. However, few combine quality, pricing, and customization like some of the top Asian manufacturers.

Top Global Corrax Powder Suppliers:

| 会社名 | 国名 | 強み |

|---|---|---|

| Uddeholm (voestalpine Group) | スウェーデン | Original developer of Corrax, high purity, premium pricing |

| カーペンター添加剤 | アメリカ | Advanced AM powders, strong R&D |

| 上海Truer Technology Co., Ltd | 中国 | Competitive pricing, wide PM & AM powder portfolio |

| ヘガネスAB | スウェーデン | Broad PM offerings, global reach |

| サンドビック積層造形 | スウェーデン | Integrated AM solutions, high-quality powders |

上海トゥルーアが際立つ理由

- Offers gas, water, and hybrid atomization options

- Supplies both standard and custom alloy compositions

- Specialized in stainless tool steels and additive powders

- Supports small batch orders for prototyping and mass orders for production

- Offers full technical consultation and post-sales support

👉 For product specifications, certifications, and custom order inquiries, visit the Shanghai Truer product catalog page.

7. Why More Buyers Are Shifting to Chinese Corrax Suppliers

As global supply chains evolve, more B2B buyers are turning to Chinese suppliers like Shanghai Truer for their Corrax powder needs—and for good reasons.

Key Advantages of Chinese Corrax Suppliers:

- コスト効率: Prices are often 20–30% lower than Western competitors without compromising quality.

- 製造規模: High capacity ensures shorter lead times and better inventory availability.

- イノベーション: Advanced metallurgy and in-house R&D teams support tailored solutions.

- 柔軟性: Accommodates both low- and high-volume orders, ideal for prototyping and scaling.

ケース・イン・ポイント上海泰爾科技有限公司

Established in 2009 and expanded into additive manufacturing in 2019, Shanghai Truer is now a leader in China’s powder metallurgy scene. The company offers:

- Corrax-equivalent stainless tool steel powders

- Custom atomization solutions (gas, water, hybrid)

- Full additive manufacturing support—from equipment to material supply

🧭 Learn more about their company history and mission これ.

Global Buyers’ Perspective:

| Concern | 欧米のサプライヤー | 中国のサプライヤー(トゥルーアなど) |

|---|---|---|

| Price per KG | $$$ | $$ |

| リードタイム | 4~6週間 | 1–2 weeks |

| MOQ | 高い | フレキシブル |

| テクニカルサポート | Limited to purchase | Ongoing metallurgical support |

| カスタムパウダー開発 | Rare | お問い合わせください。 |

📌 Summary for Distributors: If you’re expanding your AM material catalog or reducing sourcing costs, Chinese suppliers like Shanghai Truer offer unmatched value in terms of quality, support, and price.

8. Why Choose Shanghai Truer for Corrax Powder Supply

When it comes to selecting a reliable, high-quality supplier of Corrax-equivalent stainless tool steel powder, Shanghai Truer Technology Co., Ltd stands out as a trusted partner in the Chinese powder metallurgy and additive manufacturing industry.

会社概要

Shanghai Truer Technology Co., Ltd was established in 2009 and began expanding into additive manufacturing in 2019. The company is committed to developing and supplying advanced powder metallurgy materials and 3Dプリンティング solutions to global industrial users. It specializes in the production of various PM and AM powders, including Corrax-equivalent compositions.

🔗 Visit Shanghai Truer’s official product page for full powder specifications and available grades.

Key Advantages for B2B Buyers

| 特徴 | 上海トゥルーアドバンテージ |

|---|---|

| 製品範囲 | Comprehensive PM & AM powders including Corrax-equivalent |

| Atomization Methods | Gas, water, and hybrid atomization to suit different needs |

| グレード・オプション | Customizable grades: CT-1000, FL-4605, FD-0208, FN-5000, etc. |

| フレキシブルMOQ | Supports both small R&D batches and full-scale production |

| テクニカルサポート | Dedicated metallurgical consultants and product engineers |

| グローバル・ロジスティクス | Fast, reliable shipping to North America, Europe, Asia |

Customer Success Snapshot

A European mold tool manufacturer switched to Shanghai Truer’s Corrax-equivalent powder and reduced tooling turnaround time by 18%, while saving 27% on material costs. The customer cited Truer’s consistency, technical service, and flexible logistics as key factors in the transition.

9. How to Order Wholesale Corrax Powder from Shanghai Truer

Ordering Corrax powder in bulk from a reliable supplier like Shanghai Truer is straightforward. The company’s streamlined B2B procurement process ensures a smooth experience from consultation to delivery.

ご注文の流れ

- 最初のお問い合わせ

- Submit your requirements via the お問い合わせページ.

- Include desired alloy (e.g., Corrax or equivalent), particle size, quantity, and application.

- 技術相談

- Truer’s engineering team will verify your needs and recommend the most suitable powder solution.

- If needed, custom particle distributions or compositions can be arranged.

- Sample Evaluation (Optional)

- A trial batch can be sent for testing and validation prior to full order commitment.

- Quotation & Order Confirmation

- Receive a detailed quotation including price, lead time, and shipping options.

- Confirm order and arrange payment terms (LC, T/T, etc.).

- 生産管理、品質保証

- Powder produced under strict quality standards (ISO, ASTM compliance).

- Certificate of Analysis (COA) provided with every batch.

- 配送

- Global shipping available via air or sea freight, with optional customs support.

- アフターセールス・サポート

- Ongoing technical support for application optimization and future orders.

Required Documents for First-Time Buyers

- Business license or company registration

- Import/export certificate (if applicable)

- NDA or technical specification agreement (for custom formulations)

📌 For buyers seeking technical documentation or sample requests, start your inquiry here.

10. FAQs: Purchasing and Using Corrax Powder in Bulk

Q1: Is Corrax powder available in different particle sizes?

A: Yes. Shanghai Truer can supply Corrax-equivalent powder in customized particle size distributions, typically ranging from 15–45 µm for PBF and 45–150 µm for DED applications.

Q2: Can I request a sample before placing a large order?

A: Absolutely. Truer offers sample batches for testing and validation to ensure compatibility with your AM equipment and applications.

Q3: What’s the typical lead time for wholesale orders?

A: Standard lead time is 7–15 business days depending on order size and customization requirements.

Q4: Is technical support included after purchase?

A: Yes. Shanghai Truer provides full technical support, including application guidance, print parameter optimization, and troubleshooting.

Q5: Does Shanghai Truer ship internationally?

A: Yes. They have extensive experience shipping bulk powder orders to North America, Europe, Southeast Asia, and the Middle East.

Q6: What’s the shelf life of Corrax powder?

A: When stored properly in sealed containers under dry conditions, the powder has a shelf life of 12–18 months.

Q7: Is the powder certified for medical or aerospace use?

A: Certification depends on the specific batch and application. Truer can provide powders meeting ASTM and ISO requirements upon request.

Q8: Do you offer corrosion-resistant stainless steel alternatives to Corrax?

A: Yes. Truer supplies various grades of PM stainless steel that offer similar or enhanced corrosion resistance depending on the end-use requirement. Explore more on their 製品カタログ.