1. Introduction: Importance of Copper Phosphorus Alloy Powder in Industry

Copper phosphorus alloy powder, also known as Cu-P alloy powder, plays a vital role in various industrial applications, especially in brazing, powder metallurgy (PM), and the production of sintered components. These powders are designed to enhance the performance, strength, and conductivity of metal parts while offering cost-effective manufacturing methods.

In the powder metallurgy industry, copper phosphorus alloy powder is widely used due to its excellent diffusion qualities, corrosion resistance, and ability to form strong joints in brazed assemblies. The growing demand for durable, high-performance components in automotive, electrical, and HVAC industries has significantly increased the use of this alloy.

Key B2B Benefits of Copper Phosphorus Alloy Powder:

| 特徴 | Benefit for Manufacturers |

|---|---|

| High brazing performance | Ideal for joining copper and copper alloys |

| 耐食性 | Extended lifespan of components |

| 高い熱伝導性 | Efficient heat dissipation |

| 費用対効果 | Reduces material waste and production costs |

| Adaptable for PM | Compatible with sintered and 3D printed components |

With advanced technologies like additive manufacturing and hybrid sintering processes becoming mainstream, copper phosphorus alloy powder offers a scalable, high-quality option for mass production and high-performance parts.

2. Applications of Copper Phosphorus Alloy Powder in Manufacturing

Copper phosphorus alloy powders are extensively employed in multiple sectors due to their unique combination of mechanical strength and thermal properties. Below are some of the major industrial applications:

A. Brazing and Welding Industry

- Used for joining copper pipes, especially in HVAC systems, refrigeration, and plumbing.

- Acts as a self-fluxing alloy when brazing copper to copper.

- Improves joint integrity and reduces the need for additional flux.

B. Electrical and Electronics

- Used in manufacturing electrical connectors, switch contactsそして circuit breakers due to low electrical resistance.

- Provides excellent conductivity and oxidation resistance.

C. Powder Metallurgy (PM) Components

- Incorporated into sintered bushings, automotive partsそして rotor cores.

- Enhances 機械的強度, 耐摩耗性そして dimensional stability.

D. Additive Manufacturing

- Utilized in 3Dプリンティング of conductive components そして customized heat exchangers.

- Offers high resolution and precision in printed parts.

E. Diamond Tool Manufacturing

- Copper phosphorus powders are used as bonding agents in diamond tools.

- Provide uniform distribution of diamond particles and improved cutting performance.

Manufacturing Use-Case Table

| Industry Segment | 申し込み | Powder Benefit |

|---|---|---|

| HVAC & Plumbing | Brazing copper tubes | Self-fluxing, high joint strength |

| 自動車 | Sintered gear components | 耐摩耗性の向上 |

| エレクトロニクス | Switch contacts, connectors | High conductivity, corrosion resistance |

| ツール&ハードウェア | Diamond tool bonding | Uniform dispersion, durability |

| 3Dプリンティング | Customized conductive components | Precision and functional integration |

3. Key Properties and Use Cases of Copper Phosphorus Alloys

Copper phosphorus alloy powders are known for a unique set of physical and chemical properties that make them essential in several industrial use cases.

主要物件

- Phosphorus Content: Typically ranges from 5% to 15%, influencing hardness and melting point.

- Melting Range: 710°C–890°C depending on alloy composition.

- 電気伝導率: High, making it suitable for electronic applications.

- 熱伝導率: Excellent, ideal for heat-sensitive assemblies.

- 硬度: High hardness and wear resistance post-sintering.

- 耐食性: Excellent in most industrial environments.

Use Cases Based on Properties

| プロパティ | Value Provided | Ideal Use Case |

|---|---|---|

| 高い熱伝導性 | Fast heat transfer | Heat exchangers, brazed joints |

| Low melting point | Efficient brazing | Plumbing and HVAC systems |

| Phosphorus content | Increased strength and fluidity | Diamond tool bonding, sintered parts |

| 耐食性 | Extended service life | Outdoor electrical components |

Typical Grades and Specifications

| グレード | Composition (%P) | 粒子サイズ | アプリケーションエリア |

|---|---|---|---|

| CuP6 | 6.0 | -100メッシュ | General brazing |

| CuP10 | 10.0 | -200 mesh | Electrical & PM components |

| Diffused CuP | 可変 | カスタマイズ可能 | Diamond tools, sintered parts |

For a wide selection of copper phosphorus and other PM powders, you can explore our powder metallurgy offerings for detailed specifications and availability.

4. Global Market Trends & Growth Potential for Copper Phosphorus Powder

The global copper phosphorus alloy powder market is experiencing strong growth, driven by increasing demand in the HVAC, automotive, electronics, and additive manufacturing sectors. The rise of eco-friendly brazing materials and the shift toward cost-effective powder metallurgy solutions have made Cu-P powders more essential than ever.

主要市場ドライバー

- Growing demand for HVAC systems: The booming construction and infrastructure sector requires efficient copper-based brazing materials.

- Expansion of the EV and electronics industry: These industries require high-performance conductive materials, making Cu-P powders indispensable.

- Rising adoption of powder metallurgy and 3D printing: These manufacturing technologies rely on high-purity metal powders for performance and consistency.

- 環境規制: Phosphorus-based alloys reduce the need for external fluxes and lower environmental impact during brazing.

Market Growth Overview (2024–2030)

| 地域 | 年平均成長率(%) | Primary Driver |

|---|---|---|

| アジア太平洋 | 8.2% | Industrial growth, cost-effective supply |

| 北米 | 5.7% | High demand in automotive and HVAC |

| ヨーロッパ | 6.1% | Emphasis on green manufacturing |

| 中東 | 4.3% | Infrastructure projects |

Emerging Opportunities for Distributors and E-commerce Sellers

- Custom packaging for small-batch buyers

- OEM partnerships with HVAC and automotive manufacturers

- Private-label copper phosphorus powder for online B2B platforms

Forward-looking distributors are capitalizing on bulk pricing and consistent supply by partnering with trusted Chinese manufacturers like Shanghai Truer Technology.

5. How to Choose a Reliable Copper Phosphorus Powder Supplier

Choosing the right supplier is critical for maintaining product integrity, meeting project deadlines, and staying cost-competitive in B2B markets. The following factors are essential when evaluating a copper phosphorus alloy powder supplier:

主な評価基準

| 基準 | 何を見るべきか |

|---|---|

| 製品の一貫性 | Uniform particle size, phosphorus content, and flowability |

| 品質認証 | ISO 9001, REACH, RoHS, and other international quality standards |

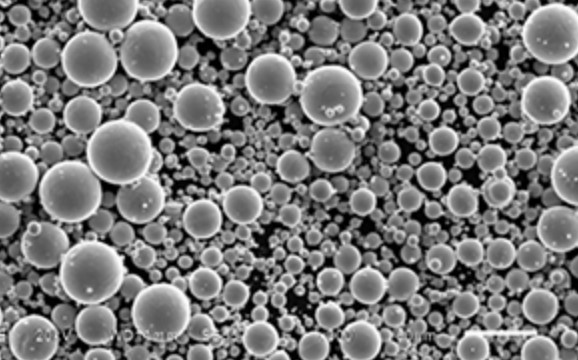

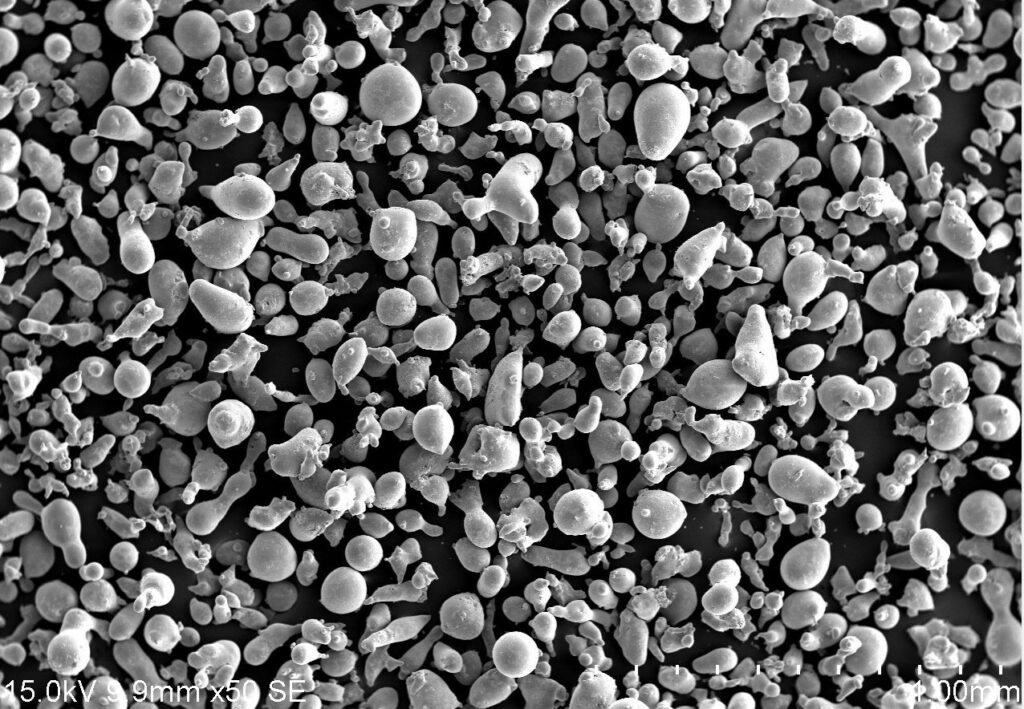

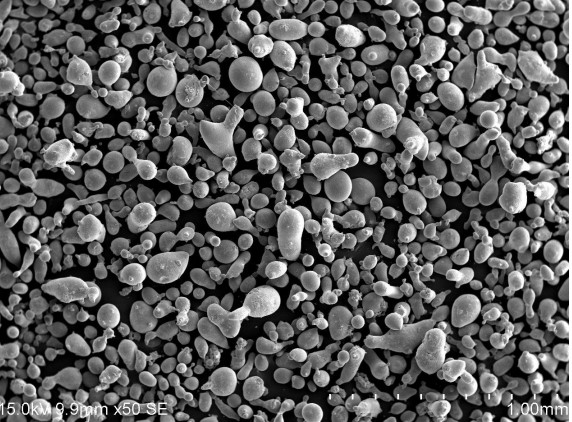

| 生産技術 | Water atomization, carbonyl reduction, or combined atomization methods |

| MOQとリードタイム | Flexible minimum orders and short turnaround for bulk shipments |

| テクニカルサポート | On-site consultation, application guidance, and powder customization |

| Global Shipping Capability | Logistics expertise and export documentation for international customers |

避けるべきレッドフラッグ

- No traceability or material certifications

- Inconsistent delivery timelines

- Limited technical support or application guidance

- No option for custom blends or packaging

Shanghai Truer Technology Co., Ltd. stands out with its 15 years of experience in powder metallurgy and additive manufacturing. The company’s copper phosphorus powders are made using advanced water and gas atomization techniques, ensuring top-tier quality and consistency. Learn more about the company’s capabilities on the 会社概要のページ.

6. Top 5 Copper Phosphorus Powder Suppliers in Asia

Asia is leading the global supply of copper phosphorus alloy powders, with China being the dominant player in production capacity, technology, and price competitiveness. Here are five top-rated suppliers based on product range, export capabilities, and client satisfaction:

1. Shanghai Truer Technology Co., Ltd. 🇨🇳

強みだ:

- Over 15 years in powder metallurgy

- Offers a wide range of Cu-P and hybrid PM powders

- Customization for diamond tools, sintered parts, and 3D printing

- Integrated services: powder production, packaging, shipping

Flagship Products:

- Diffused CuSn powder

- PM phosphorus iron

- CuP6, CuP10 powder

- Sintered bearing-grade powders

Website: 訪問 アム・マテリアル・ドット・コム to explore their full powder product line.

2. Mitsui Mining & Smelting Co., Ltd. 🇯🇵

強みだ:

- High-purity Cu alloy powders

- Advanced research in conductive materials

- Global logistics network

3. GGP Metal Powder Co., Ltd. 🇰🇷

強みだ:

- Focus on electronic-grade copper alloys

- Precise particle control

- Strong presence in the electronics market

4. CNPC Powder Group Co., Ltd. 🇨🇳

強みだ:

- Large-scale production

- Wide selection of PM powders

- 大量注文のための競争力のある価格

5. Kymera International 🇮🇳/🇺🇸

強みだ:

- Global footprint

- High-end brazing powders for aerospace and defense

- Strong technical support

| サプライヤー名 | 国名 | Strength Area | Website/Contact |

|---|---|---|---|

| 上海トゥルーア・テクノロジー | 中国 | PM applications, diamond tools | Truerにお問い合わせ |

| Mitsui Mining | 日本 | Electronics and brazing | Internal distributor network |

| GGPメタルパウダー | 韓国 | High-purity Cu alloys | Direct inquiry |

| CNPCパウダー | 中国 | Bulk PM powders | Distributor channels |

| カイメラ・インターナショナル | India/USA | 航空宇宙グレードの素材 | Global offices |

7. Why More Buyers Are Switching to Chinese Powder Manufacturers

Over the past decade, Chinese powder metallurgy suppliers have rapidly gained international trust due to their balance of quality, customization, and affordability. Copper phosphorus alloy powders are no exception.

Key Reasons Why Global Buyers Prefer Chinese Suppliers:

✅ 競争力のある価格設定

China offers significantly lower production costs, allowing wholesale buyers and distributors to increase margins.

✅ Advanced Manufacturing

Modern facilities use water and gas atomization, reduction methods, and hybrid approaches to match global quality standards.

✅ Flexible Order Volumes

From pilot batches to container loads, Chinese suppliers support a wide range of order sizes.

✅ Technical Support & Customization

Many suppliers, like Shanghai Truer Technology, offer engineering support, custom blends, and packaging tailored to client needs.

✅ Fast Global Shipping

Efficient export processes and relationships with freight partners ensure timely deliveries.

For businesses seeking a reliable, scalable source of copper phosphorus alloy powder or related PM materials, Truer’s powder metallurgy division is an ideal partner.

8. Why Choose Shanghai Truer Technology as Your Powder Supplier

Shanghai Truer Technology Co., Ltd. is one of China’s most trusted and advanced suppliers of copper phosphorus alloy powders and other powder metallurgy (PM) materials. Since its inception in 2009, Truer has consistently delivered high-quality, application-specific powder solutions for global OEMs, wholesalers, and industrial manufacturers.

トゥルアーの特徴

| 特徴 | 上海トゥルーアドバンテージ |

|---|---|

| 経験 | Over 15 years in powder metallurgy, additive manufacturing since 2019 |

| 製品範囲 | PM bronze, copper, brass, phosphorus iron, CuSn, stainless steel, and hybrid alloys |

| Manufacturing Technology | Water atomized, gas atomized, carbonyl and hybrid atomization methods |

| Custom Powders | Tailored phosphorus content, particle size, and blends for specific applications |

| 品質管理 | ISO-certified production, full traceability, and testing protocols |

| グローバルな輸出能力 | Proven track record of supplying clients in North America, Europe, and Southeast Asia |

| テクニカルサポート | Engineering consultation, material testing, sintering compatibility, and prototyping |

Recommended Products for Copper Phosphorus Applications

| 商品コード | 説明 | 申し込み |

|---|---|---|

| Diffused CuSn | Copper-tin-phosphorus powder | Diamond tools, high-strength sintering |

| PM Phosphorus Iron | Cu-P infused iron alloy powder | Bushings, rotors, sintered gears |

| CuP10 | 10% phosphorus copper alloy powder | Brazing, electronics, PM components |

Whether you’re a distributor looking to scale your product line or an OEM in need of high-performance powder, Truer offers the reliability and flexibility you need. You can learn more about Truer’s full capabilities on the company overview page.

9. How to Order Wholesale Copper Phosphorus Powder from China

Ordering copper phosphorus alloy powder in bulk from China is easier than ever—especially when working with established suppliers like Shanghai Truer Technology. Here’s a step-by-step guide to help wholesale buyers, distributors, and OEMs manage the process efficiently.

ご注文の流れ

- Define Product Requirements

- Specify grade (e.g., CuP6, CuP10)

- Indicate particle size (e.g., -100 mesh, -200 mesh)

- State application and performance requirements

- Request Quotation

- Contact the supplier via email or コンタクトフォーム

- Provide volume requirements, delivery terms (FOB, CIF), and packaging needs

- 技術相談

- Discuss custom blends or performance optimization

- Review technical data sheets and material compatibility

- Sample Evaluation (Optional)

- Receive material samples for testing and trial runs

- Confirm sintering, brazing, or bonding performance

- ご注文

- Confirm proforma invoice and payment terms (T/T, L/C, etc.)

- Establish lead times and shipping schedules

- Inspection & Quality Assurance

- Third-party inspection available upon request

- QA documentation and material traceability included

- 配送について

- Truer arranges international shipping with full export documentation

- Real-time logistics tracking and customer support

梱包オプション

| 包装タイプ | 説明 | Typical Quantity |

|---|---|---|

| Vacuum-sealed bags | Moisture-resistant, for small batch use | 5~25キロ |

| Steel drums | For bulk industrial orders | 50–200 kg |

| Custom-labeled cartons | Private label or OEM packaging | カスタマイズ可能 |

For full details on available materials and to request a quote, visit the PMパウダー製品ページ.

10. FAQs: Common Questions About Copper Phosphorus Alloy Powder

Q1: What is the typical phosphorus content in copper phosphorus alloy powder?

A: Common grades include CuP6 (6% phosphorus) and CuP10 (10% phosphorus). Custom phosphorus levels can be manufactured upon request.

Q2: Can copper phosphorus alloy powder be used in diamond tool manufacturing?

A: Yes, Truer’s diffused CuSn powder is ideal for diamond tool bonding, offering excellent wear resistance and uniform diamond dispersion.

Q3: Is your powder suitable for additive manufacturing and 3D printing?

A: Yes. Truer provides gas or hybrid atomized Cu-P powders with consistent particle size distribution for AM applications.

Q4: What industries commonly use Cu-P alloy powder?

A: HVAC, automotive, electronics, plumbing, and powder metallurgy industries are the largest consumers.

Q5: 輸出用のパウダーはどのように梱包されますか?

A: Truer offers vacuum-sealed bags, steel drums, or custom-labeled containers, all compliant with international shipping standards.

Q6: What is your minimum order quantity (MOQ)?

A: The MOQ varies by product but typically starts at 20–50 kg for standard grades. Custom orders may have different requirements.

Q7: Do you provide technical support or application guidance?

A: Yes, Truer offers full technical consultation, from product selection to sintering and application support.

Ready to Source High-Quality Copper Phosphorus Powder?

Shanghai Truer Technology is your one-stop solution for copper phosphorus alloy powder and other metal powders engineered for performance and consistency. Whether you’re sourcing for brazing, powder metallurgy, or diamond tool production, Truer offers the quality, customization, and global service your business needs.

📩 お問い合わせ をクリックして、見積もりまたは技術相談をご依頼ください。

🌐 Visit アム・マテリアル・ドット・コム to explore our full product catalog.

🔍 Learn more about our PM powder lineup.