1. Introduction: Why Brass Powder is Vital in Modern Manufacturing

Brass powder, a finely milled alloy of copper and zinc, plays a pivotal role in numerous industrial applications due to its excellent machinability, corrosion resistance, and thermal conductivity. For manufacturers, wholesalers, and distributors, brass powder is a highly demanded raw material that supports industries such as automotive, electronics, additive manufacturing, and decorative finishing.

Key Benefits of Brass Powder:

- 優れた耐食性

- 高い電気伝導性と熱伝導性

- Aesthetic gold-like appearance

- Superior machinability for PM and AM

- Recyclable and environmentally friendly

Brass powder is used in both traditional Powder Metallurgy (PM) and modern Additive Manufacturing (AM) processes. As global demand for lightweight and cost-efficient materials grows, brass powder has become a strategic material for B2B buyers focused on quality, performance, and price competitiveness.

2. Applications of Brass Powder in Key Industries

Brass powder is utilized by a broad spectrum of industries, and its versatility makes it suitable for both functional and aesthetic components. Here’s a breakdown of its major applications:

| 産業 | Application Use | ベネフィット |

|---|---|---|

| 自動車 | Bushings, bearings, gear parts | Wear resistance, anti-friction |

| エレクトロニクス | EMI shielding, connectors | 優れた導電性 |

| 付加製造 | Prototyping, decorative AM parts | High resolution & visual appeal |

| Jewelry & Crafts | Decorative coating, 3Dプリンティング | Aesthetic gold-like finish |

| 建設 | Architectural hardware | 耐食性 |

| ダイヤモンド工具 | Bond matrix material | Toughness and wear resistance |

B2B Buyers Commonly Include:

- OEM manufacturers

- Industrial component suppliers

- AM service bureaus

- Hardware distributors

- Artisanal and craft product resellers

The emergence of 3D printing has further expanded the use of brass powder in producing custom, complex components with both structural and decorative value.

3. Types and Grades of Brass Powder for Wholesale Buyers

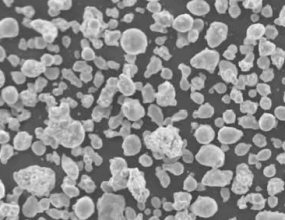

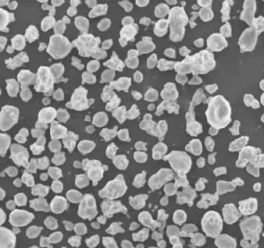

Understanding the different types and grades of brass powder is essential for procurement managers, engineers, and purchasing teams. The composition of brass powder can vary depending on zinc content, particle size, and production method.

Types of Brass Powder by Manufacturing Process:

| タイプ | 製造方法 | 特徴 |

|---|---|---|

| Atomized Brass Powder | Water/Gas Atomization | Spherical particles, high purity |

| Electrolytic Brass Powder | 電解 | Irregular shape, high surface area |

| Mechanical Alloyed Powder | Blending & Milling | Customizable composition |

Common Brass Powder Grades Offered by Shanghai Truer:

Shanghai Truer Technology Co., Ltd. offers high-performance PM brass powders tailored for industrial applications. Our powders are manufactured through water atomization, gas atomization, or a combination of both, ensuring consistency and performance.

| グレード | 構成 | 申し込み |

|---|---|---|

| CZ-1000 | Cu-Zn Alloy | General PM parts |

| カスタムグレード | Varying Zn content | Diamond tools, AM parts |

📌 For more information on our brass powder grades and technical specifications, visit our PMパウダー製品ページ.

Why B2B Buyers Trust Truer for Brass Powder:

- 一貫した粒度分布

- Customizable compositions for niche applications

- In-house production with strict QC

- Reliable bulk supply for continuous manufacturing

4. Market Trends & Demand Forecast for Brass Powder

The global brass powder market is witnessing steady growth driven by rising demand from industries such as automotive, electronics, additive manufacturing, and construction. B2B buyers are increasingly looking for reliable, cost-efficient, and high-performance brass powder suppliers to meet their production needs.

Key Market Trends Impacting Wholesale Brass Powder Demand:

- Growth in Additive Manufacturing (AM):

Brass powder is increasingly used in 3D printing for both functional and decorative applications. The aesthetic appeal of brass, coupled with its good printability, is driving demand from AM service providers and product design firms. - Demand from Automotive Sector:

The automotive industry requires brass powder for sintered bushings, bearings, and other wear-resistant parts. As electric vehicles (EVs) grow in popularity, the need for lightweight and conductive materials like brass will increase. - Expansion of Electronics and EMI Shielding Applications:

Brass powder is used in conductive coatings and electromagnetic interference (EMI) shielding. The surge in demand for consumer electronics and communication devices further boosts market growth. - Sustainability Initiatives:

Recyclable and non-toxic, brass powder aligns with green manufacturing trends. B2B buyers are increasingly prioritizing eco-friendly materials in the supply chain.

Global Market Forecast (2024–2030):

| 地域 | Estimated CAGR | 主要ドライバー |

|---|---|---|

| アジア太平洋 | 6.8% | Industrial manufacturing, low-cost production |

| 北米 | 5.2% | Growth in AM, precision engineering |

| ヨーロッパ | 4.9% | Green manufacturing, automotive sector |

| 中東・アフリカ | 3.5% | Infrastructure and construction |

These figures highlight the opportunity for wholesalers, distributors, and OEMs to capitalize on the rising demand for brass powder, particularly in Asia-Pacific where high-quality supply is increasing.

5. Key Factors to Consider When Choosing a Brass Powder Supplier

For industrial buyers, selecting the right brass powder supplier is critical to ensuring consistent quality, reliable delivery, and long-term cost efficiency. Here are the main factors to evaluate:

✔ Quality Assurance & Certifications

- ISO 9001、RoHS、REACH対応

- Traceable batch records

- In-house testing and analysis capabilities

✔ Particle Size & Morphology Control

- Consistent particle size distribution (PSD)

- Spherical vs. irregular particles based on application

- Low impurity levels for high-performance uses

✔ Production Capacity and Lead Time

- Ability to fulfill bulk orders

- Short lead time and reliable logistics

- Scalable capacity for future growth

✔ Customization Options

- Tailored composition (Cu-Zn ratio)

- Surface treatments or additive blends

- Specialized grades for diamond tools, AM, or PM

✔ Technical Support

- Application engineering assistance

- On-site trials or powder samples

- Technical documentation and MSDS provided

📌 To learn about Shanghai Truer’s integrated powder production system and quality control, visit our 会社概要のページ.

6. Top 5 Brass Powder Suppliers in Asia-Pacific

B2B buyers in Asia-Pacific often seek suppliers who offer a balance of quality, price, and delivery efficiency. Below are the leading brass powder manufacturers in the region:

| サプライヤー | 国名 | 主な強み |

|---|---|---|

| 上海Truer Technology Co., Ltd | 中国 | Integrated PM & AM powder manufacturing, custom grades, technical support |

| Mitsui Mining & Smelting Co., Ltd | 日本 | High-purity powders, electronics applications |

| ABCパウダー | インド | High-volume production, cost-effective |

| CNPC 粉末グループ | 中国 | Wide range of metal powders, strong logistics |

| 大同特殊鋼 | 日本 | Premium quality, strict QC |

上海トゥルーアが際立つ理由

- Offers PM brass powders produced via water and gas atomization

- In-house R&D and application support

- Flexible MOQs for distributors and OEMs

- Serves both traditional PM and emerging AM markets

Shanghai Truer has been a trusted name in powder metallurgy since 2009 and entered the additive manufacturing space in 2019. The company provides a full range of powders, lubricants, and additives tailored for professional industrial use.

📌 詳しくはこちら Shanghai Truer’s product offerings and how it supports OEMs, distributors, and AM service providers.

7. Why More Distributors Are Sourcing Brass Powder from China

China has emerged as a dominant hub for metal powder manufacturing, including brass powder, due to its advanced production capabilities, lower labor costs, and strong export infrastructure. For international B2B buyers and distributors, sourcing brass powder from China offers several strategic advantages.

Advantages of Sourcing Brass Powder from China:

- ✅ 競争力のある価格設定

Lower production and labor costs translate to better margins for buyers. - ✅ Advanced Manufacturing Technology

Chinese manufacturers like Shanghai Truer employ atomization, carbonyl, and hybrid techniques to produce high-quality powders. - ✅ Customization & Flexibility

Ability to accommodate small and large batch requirements with tailored compositions. - ✅ Strong Export Logistics

Fast and cost-efficient shipping options supported by mature logistics networks. - ✅ Wide Range of Alloys

Chinese suppliers offer not just brass, but also PM bronze, PM nickel silver, PM copper steel, and more.

By partnering with a reputable Chinese supplier, buyers can reduce costs while ensuring consistent quality and technical support.

📌 Ready to engage with a trusted Chinese powder manufacturer? Contact Shanghai Truer today to request a quote or product sample.

8. Why Choose Shanghai Truer as Your Brass Powder Supplier

Shanghai Truer Technology Co., Ltd. is one of China’s most trusted and specialized providers of metal powders, including high-performance PM brass powder. Since 2009, Truer has built a reputation for delivering consistent quality, technological innovation, and customized solutions for powder metallurgy and additive manufacturing industries.

✅ What Sets Shanghai Truer Apart?

| 特徴 | 説明 |

|---|---|

| Integrated Manufacturing | In-house atomization (water, gas, hybrid), blending, and QC |

| 業界経験 | 15+ years in PM, 5+ years in additive manufacturing |

| Custom Powder Solutions | Tailored Cu-Zn ratios, particle sizes, and special blends |

| フル添加剤ポートフォリオ | Lubricants, cutting agents, graphite, soft magnetic additives |

| グローバル・リーチ | Exporting to Asia, Europe, North America, and more |

Key Products from Truer for Brass Powder Buyers:

- PM Brass Powder (CZ-1000 and custom grades)

- PM Bronze, PM Nickel Silver, PM Copper Steel

- Hybrid low-alloy and pre-alloyed steel powders

- Atomization options: water, gas, combined

- Additives: Lube-W, SUW-5000B, QH-150, SME-100, TD-8

Shanghai Truer’s brass powders are processed with advanced atomization techniques to ensure uniform particle size, optimal flowability, and excellent sinterability — critical for applications in automotive, electronics, AM, and diamond tools.

📌 Learn more about our company history, mission, and capabilities on our About Page.

9. How to Order Wholesale Brass Powder from Shanghai Truer

Ordering brass powder in bulk from Shanghai Truer is a streamlined, professional process tailored for OEMs, distributors, and industrial procurement teams. Whether you’re sourcing for regular production or a large-scale project, Truer’s team is ready to support your needs.

🛒 Step-by-Step Wholesale Ordering Process:

- お問い合わせ

- Visit our お問い合わせページ

- Fill out the inquiry form or email our sales team directly

- Provide details: required grade, quantity, application, delivery timeline

- 技術相談(オプション)

- Our engineers will support you in selecting the right powder grade

- Customized options available based on particle size, Cu-Zn ratio, etc.

- 見積&サンプル請求

- Receive a formal quotation within 24–48 hours

- Request samples for testing and validation

- Order Confirmation & Payment

- Confirm specifications and commercial terms

- Choose from T/T, L/C, or other payment options

- Production & Quality Check

- Manufacturing begins under strict QC guidelines

- Batch testing and Certificate of Analysis (COA) provided

- 配送

- Global logistics via air, sea, or express courier

- Tracking information and customs assistance included

- アフターセールス・サポート

- Technical support available post-delivery

- Reordering and contract manufacturing options

📦 Minimum Order Quantities (MOQ):

| 製品タイプ | MOQ |

|---|---|

| Standard PM Brass Powder | 100キロ |

| Customized Grades | 300 kg |

| 添加物パッケージ | 25キロ |

📌 Explore our full list of metal powders and additives on our PMパウダーのページ.

10. FAQs: Common Questions About Buying Wholesale Brass Powder

Here are some of the most frequently asked questions from OEMs, procurement managers, and industrial buyers:

Q1: What is the lead time for wholesale brass powder orders?

A: Standard grades typically ship within 7–10 working days. Customized powders may require 2–3 weeks depending on composition and quantity.

Q2: Can I request a custom composition for specific applications?

A: Yes. Shanghai Truer offers fully customizable brass powder solutions tailored to your Cu-Zn ratio, particle size, and sintering needs.

Q3: What particle size ranges are available?

A: Common ranges include 0–45μm, 45–106μm, and 106–150μm. Spherical and irregular particles are both available depending on production method.

Q4: Do you offer technical support for new applications?

A: Absolutely. Our engineers provide consultation on powder selection, sintering parameters, and additive compatibility.

Q5: How do I get a sample before placing a large order?

A: Contact us via our お問い合わせページ and specify your testing needs. We’ll be happy to send a sample for evaluation.

Q6: Are your brass powders suitable for 3D printing?

A: Yes. We offer brass powders suitable for binder jetting, SLS/SLM, and other AM technologies. Particle morphology and flowability are optimized for printability.

Q7: What certifications do you provide?

A: Shanghai Truer complies with ISO 9001 and can provide RoHS, REACH, and custom inspection reports as needed.

Q8: Do you export internationally?

A: Yes, we ship to over 30 countries including the U.S., Germany, India, Brazil, and Southeast Asia.

🧭 Final Internal Links Recap

To support navigation and SEO, here are the 5 internal links embedded in this blog:

- PMパウダー製品ページ

- 上海トゥルーアについて

- Shanghai Truer Homepage

- お問い合わせページ

- PM Powder Product Page (Repeated for deep linking)

This comprehensive guide equips B2B buyers, OEMs, and industrial distributors with everything needed to source high-quality brass powder. From understanding applications to evaluating suppliers and placing orders, Shanghai Truer is your trusted partner in powder metallurgy and additive manufacturing.

👉 Ready to start sourcing? Contact us now for a customized quote or technical consultation.