Effect of Al2O3 nano-particles on properties of CoCrNi LPBF part

Experiment

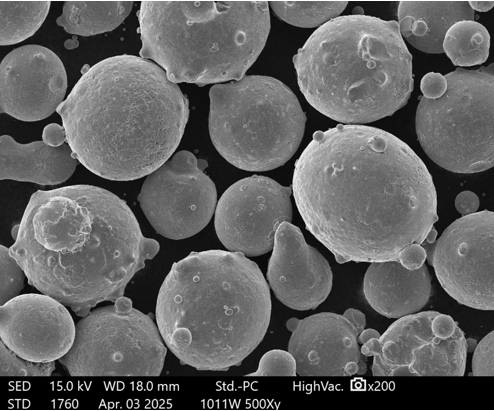

This study used CoCrNi alloy powder and Al₂O₃ powder as raw materials. CoCrNi alloy powder was prepared by vacuum gas atomization, and the powder particle size range was 15-53 μm. The particle size of Al₂O₃ powder was 38-74 μm. After the raw material powders were mixed, they were processed on the LPBF additive manufacturing system.

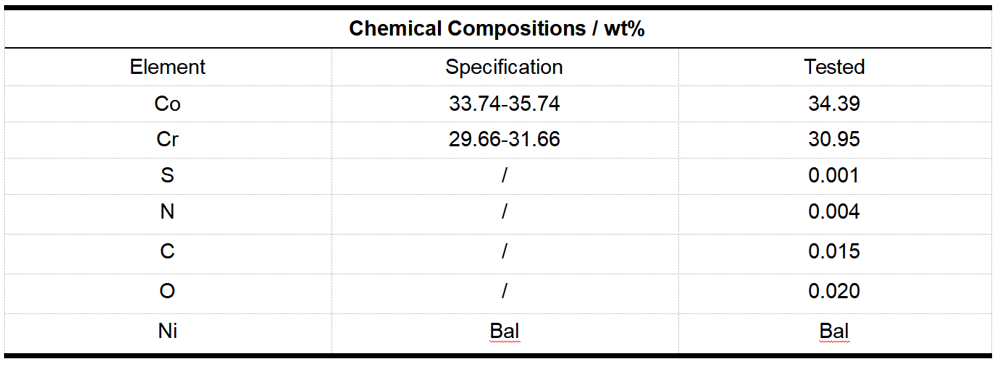

Chemical composition of CoCrNi:

Morphology of CoCrNi:

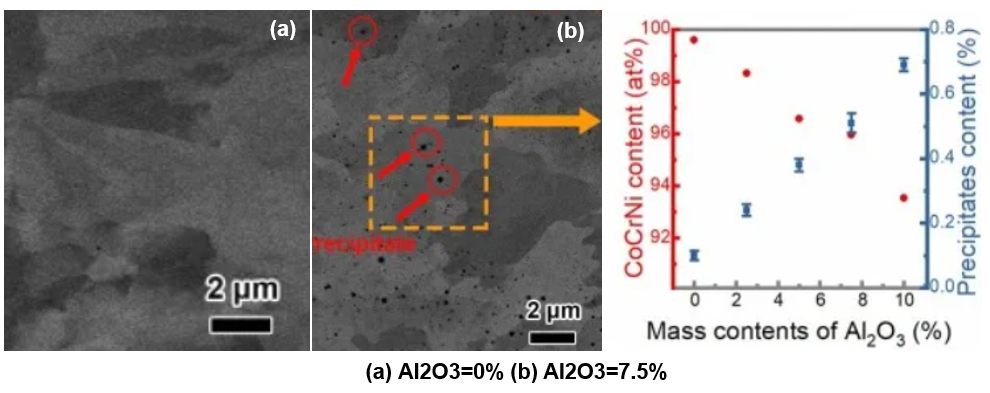

Microstructure analysis:

After adding Al2O2, the grains in the CoCrNi matrix are significantly refined, and a large number of nano-scale Al2O2 precipitates are formed. These precipitates are distributed along the boundaries and effectively hindering the movement of dislocations.

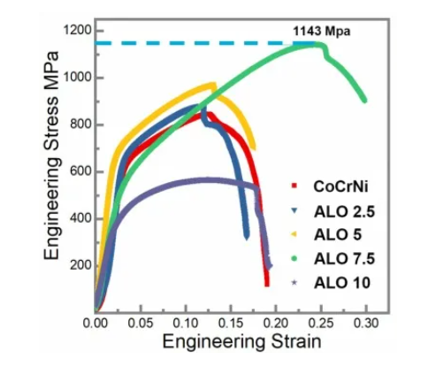

Mechanical properties:

Compression test results show that the ultimate compressive strength and hardness of CoCrNi parts increase significantly with the addition of Al₂O₃. In particular, when the Al₂O₃ content is 7.5 wt%, the ultimate compressive strength reaches 1143 MPa, the fracture strain is 29.8%, and the hardness is 300 HV. These performance improvements are mainly attributed to mechanisms such as grain refinement, dislocation strengthening, and second phase strengthening.

Conclusion:

In this study, Al₂O₃-reinforced CoCrNi metal matrix composites were successfully prepared by LPBF technology, and the effect of Al₂O₃ addition on the material microstructure evolution and mechanical properties was systematically studied. The results show that adding an appropriate amount of Al₂O₃ can significantly improve the mechanical properties of CoCrNi LPBF parts. This study provides a new way to develop high-performance metal matrix composites.

Other Mid- & High-Entropy Alloy Powders produced by TRUER:

CoCrNi, FeCoNiCr, FeCoNiCrMn, FeCoNiCrAl, FeCoNiCrMo, FeCoNiCrTi, FeCoNiCrV, FeCoNiCrCu