真空誘導溶解 (VIM)はSF小説から飛び出してきたように聞こえるかもしれないが、実は高品質の金属合金を製造するための最も先進的な方法のひとつである。航空宇宙、医療機器、高性能エンジンなど、最も重要な部品がどのようにして作られるのか、不思議に思ったことはないだろうか。この包括的なガイドでは、VIMの基本原理から特定の金属粉末モデルまで、その複雑さを掘り下げます。真空誘導溶解の魅力的な世界に飛び込んでみましょう!

真空誘導溶解の概要

真空誘導溶解(VIM)は、金属や合金を真空環境で溶解・精製するプロセスです。この技術は、ガスやその他の不純物による汚染を最小限に抑えることで、高純度材料の製造を保証します。VIMプロセスの主要コンポーネントには、誘導炉、真空チャンバー、およびさまざまな監視・制御システムが含まれます。

VIMの主な特徴

- 高純度:真空環境はコンタミネーションを減らす。

- 正確なコントロール:温度と組成の正確なコントロールが可能。

- 汎用性:幅広い金属と合金に適している。

- 効率性:従来の溶解方法と比較してエネルギー消費を削減。

VIMが加工する金属の種類

| メタル・タイプ | 構成 | プロパティ | 特徴 |

|---|---|---|---|

| チタン合金 | Ti、Al、V、Mo | 高強度、耐食性 | 軽量、高温性能 |

| ニッケル合金 | Ni、Cr、Fe、Mo、Al | 高い耐食性と耐熱性 | 過酷な環境に適している |

| ステンレス鋼 | Fe、Cr、Ni、Mo、C | 耐食性、強度 | 医療、自動車、航空宇宙分野で使用 |

| コバルト合金 | Co、Cr、W、Ni | 高い耐摩耗性、靭性 | 医療用インプラント、切削工具に最適 |

| 超合金 | Ni、Co、Fe、Cr、Mo、Al | 卓越した機械的強度 | ジェットエンジン、ガスタービンに不可欠 |

| 銅合金 | Cu、Zn、Sn、Pb | 良好な電気および熱伝導性 | 電気部品に広く使用 |

| アルミニウム合金 | Al、Cu、Mg、Si、Zn | 軽量、優れた耐食性 | 航空宇宙、自動車 |

| 貴金属 | Au、Ag、Pt、Pd | 高価値、優れた導電性 | 電子機器、宝飾品に使用 |

| 特殊合金 | 各種金属 | 特定の用途に合わせた特性 | 独自の産業ニーズに合わせてカスタマイズ可能 |

| 鉄合金 | Fe、C、Mn、Si | 高強度、磁気特性 | 建設、機械に不可欠 |

理解する 真空誘導溶解:プロセス

1.VIMの基本原則

VIMの核心は、真空下で電磁誘導を使って金属を溶かすことである。この方法では、金属に欠陥を生じさせる酸素、窒素、水素などのガスの存在を最小限に抑えることができる。

2.溶解プロセス

- 誘導加熱:金属は誘導炉内のるつぼに入れられる。るつぼを囲むコイルに交流電流が流れ、電磁場が発生して金属が加熱される。

- 真空環境:金属が加熱され溶け始めると、真空チャンバーは気圧を下げ、酸化や汚染を防ぐ。

- 精製:溶融金属は、合金元素の添加や不純物の除去によってさらに精錬することができる。

3.冷却と凝固

所望の組成と温度が達成されると、溶融金属は鋳型に流し込まれるか、インゴットに鋳造される。制御された冷却により、金属は欠陥を最小限に抑えて凝固し、高品質の製品が得られる。

の特徴 真空誘導溶解

VIMには、高性能金属を製造するための有力な選択肢となる、いくつかのユニークな特徴がある。

純度と品質

真空中で操業することにより、VIMはガスやその他の不純物による汚染を最小限に抑え、卓越した純度と品質の金属を生み出す。

精度とコントロール

このプロセスでは、温度と組成を正確に制御することができ、一貫した信頼性の高い結果が得られる。

汎用性

VIMは、一般的なステンレス鋼からエキゾチックな超合金や貴金属まで、幅広い金属や合金に適しています。

エネルギー効率

従来の溶解方法と比較して、VIMはエネルギー効率が高く、操業コストと環境への影響の両方を削減する。

真空誘導溶解の応用

VIMは、最高レベルの純度と精度が要求される高性能部品の製造に、さまざまな産業で使用されている。

| 産業 | 用途 | メリット |

|---|---|---|

| 航空宇宙 | タービンブレード、エンジン部品 | 高強度、耐熱性 |

| メディカル | インプラント、手術器具 | 生体適合性、耐食性 |

| 自動車 | 高性能エンジン部品 | 耐久性、効率性 |

| エレクトロニクス | 導電材料、コネクター | 高い導電性、信頼性 |

| 発電 | タービン部品、原子炉部品 | 耐熱性、機械的強度 |

| 石油・ガス | 掘削装置、海底部品 | 耐食性、靭性 |

| ディフェンス | 防具、武器部品 | 強さ、信頼性 |

| 産業機械 | 工具、耐摩耗部品 | 耐久性、耐摩耗性 |

| ジュエリー | 高額金属製品 | 美的品質、価値保持 |

| エネルギー貯蔵 | 電池部品、超伝導体 | 効率、パフォーマンス |

真空誘導溶解の等級

VIMで生産されるさまざまなグレードの金属は、さまざまな産業ニーズに対応しています。各グレードは、特定の用途に適した特定の特性を持っています。

| メタル・タイプ | グレード | 構成 | プロパティ | 用途 |

|---|---|---|---|---|

| チタン | グレード5 | Ti-6Al-4V | 高強度、軽量 | 航空宇宙、医療用インプラント |

| ニッケル | Inconel 718 | ニッケル-クロム-鉄-モリブデン | 高強度、耐酸化性 | タービンブレード、航空宇宙 |

| ステンレス鋼 | 316L | 鉄-クロム-ニッケル-モリブデン | 耐食性、生体適合性 | 医療機器、海洋アプリケーション |

| コバルト | CoCrMo | コバルト-クロム-モリブデン | 耐摩耗性、高強度 | 医療用インプラント、切削工具 |

| 超合金 | ルネ41 | ニッケル-コバルト-クロム-モリブデン | 高温強度、耐酸化性 | 航空宇宙、ガスタービン |

| 銅 | C18200 | 銅-クロム | 高い導電性、硬度 | 電気コネクター、抵抗溶接 |

| アルミニウム | 6061-T6 | Al-Mg-Si | 高強度、良好な加工性 | 航空宇宙、自動車 |

| 貴金属 | 24Kゴールド | オー | 高純度、導電性 | エレクトロニクス、ジュエリー |

| 特殊合金 | ヘインズ230 | ニッケル・クロム・モリブデン | 高温安定性、耐酸化性 | 化学処理、工業用加熱 |

| 鉄合金 | AISI 4140 | Fe-C-Mn-Si-Cr-Mo | 高い強度と靭性 | 建設、機械 |

サプライヤーと価格詳細

適切なサプライヤーを選択し、価格体系を理解することは、VIM生産金属の利用を検討している企業にとって極めて重要である。

| サプライヤー | 所在地 | 特産品 | 価格(1kgあたり) |

|---|---|---|---|

| カーペンター・テクノロジー | アメリカ | 高性能合金 | $50 – $200 |

| ATIメタルズ | アメリカ | 特殊金属および部品 | $40 – $180 |

| ヘインズ・インターナショナル | アメリカ | 高温合金 | $45 – $190 |

| アレゲニー・テクノロジーズ | アメリカ | チタンおよびニッケル基合金 | $55 – $220 |

| VSMPO-AVISMA | ロシア | チタン製品 | $60 – $210 |

| 大同特殊鋼 | 日本 | 特殊鋼、超合金 | $50 – $200 |

| サンドビック・マテリアル | スウェーデン | ステンレス鋼、特殊合金 | $45 – $185 |

| エリコン・メトコ | スイス | 表面ソリューション、先端材料 | $50 – $195 |

| 精密鋳造部品 | アメリカ | 複雑な金属部品 | $60 – $220 |

| プランゼーグループ | オーストリア | 耐火金属、高性能材料 | $55 – $215 |

長所と短所 真空誘導溶解

どのプロセスにも利点と限界がある。VIMの長所と短所を詳しく見てみよう。

| メリット | 制限事項 |

|---|---|

| 生産される金属の純度が高い | 高い初期設定費用 |

| 組成と温度を正確にコントロール | 熟練したオペレーターが必要 |

| 多様な金属加工に対応 | 小~中バッチサイズに限定 |

| エネルギー効率 | 真空装置のメンテナンス |

| コンタミネーションと欠陥の低減 | 処理時間が長い |

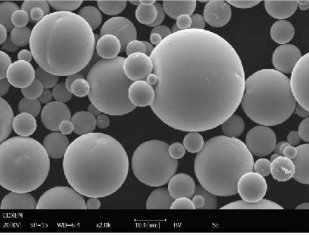

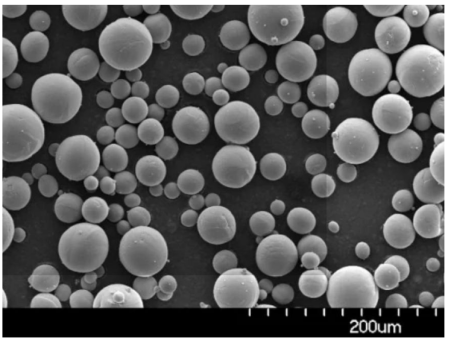

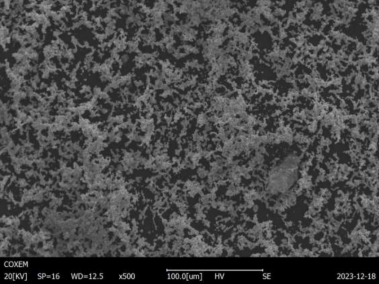

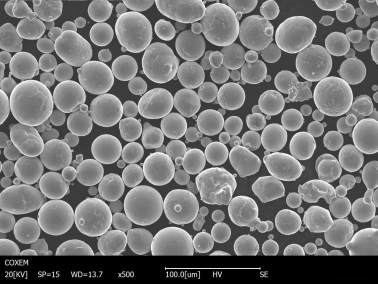

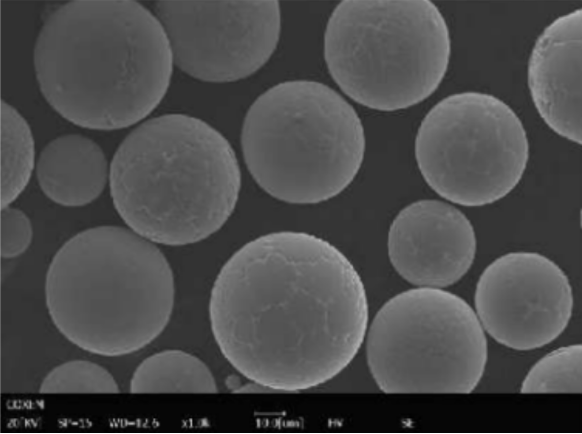

VIMが製作した金属粉末模型

VIMはまた、積層造形(3Dプリンティング)やその他の高度な用途向けの金属粉末の製造にも力を注いでいる。以下に具体的なモデルとその説明を紹介する:

- Ti-6Al-4Vパウダー

- 構成:チタン、アルミニウム、バナジウム

- 用途:航空宇宙、医療用インプラント

- プロパティ:高強度、軽量、耐食性

- インコネル625パウダー

- 構成:ニッケル、クロム、モリブデン、ニオブ

- 用途:航空宇宙、化学処理

- プロパティ:高強度、耐酸化性、耐食性

- 316L ステンレススチール粉

- 構成:鉄、クロム、ニッケル、モリブデン

- 用途:医療機器、船舶部品

- プロパティ:耐食性、生体適合性

- CoCrMoパウダー

- 構成:コバルト、クロム、モリブデン

- 用途:医療用インプラント、歯科用途

- プロパティ:高い耐摩耗性、生体適合性

- ルネ 41 パウダー

- 構成:ニッケル、クロム、コバルト、モリブデン

- 用途:航空宇宙、ガスタービン

- プロパティ:高温強度、耐酸化性

- 6061アルミニウム・パウダー

- 構成:アルミニウム、マグネシウム、シリコン

- 用途:航空宇宙、自動車

- プロパティ:高強度、良好な加工性

- ヘインズ 230 パウダー

- 構成:ニッケル、クロム、タングステン、モリブデン

- 用途:化学処理、工業用加熱

- プロパティ:高温安定性、耐酸化性

- C18200 銅粉

- 構成:銅、クロム

- 用途:電気コネクター、抵抗溶接

- プロパティ:高い導電性、硬度

- 24Kゴールドパウダー

- 構成:ゴールド

- 用途:エレクトロニクス、ジュエリー

- プロパティ:高純度、導電性

- AISI 4140 パウダー

- 構成:鉄、炭素、マンガン、ケイ素、クロム、モリブデン

- 用途:建設、機械

- プロパティ:高強度、高靭性

よくある質問

| 質問 | 回答 |

|---|---|

| 真空誘導溶解とは? | VIMは、電磁誘導を利用して真空環境で金属を溶解・精錬するプロセスである。 |

| なぜVIMでバキュームを使うのか? | 真空はガスやその他の不純物による汚染を最小限に抑え、高純度の金属を保証する。 |

| VIMで処理できる金属は? | チタン、ニッケル、ステンレス、コバルト、超合金、銅、アルミニウム、貴金属などの金属。 |

| VIMのメリットは? | 高純度、精密制御、多用途性、エネルギー効率などが主な利点である。 |

| VIMに制限はありますか? | セットアップコストが高いこと、熟練オペレーターが必要なこと、バッチサイズが限られていることなどが制限事項である。 |

| VIMは従来の溶解法と比べてどうですか? | VIMはより優れた純度とコントロールを提供するが、より高価で時間がかかる。 |

| どのような業界でVIMが使われているのか? | 航空宇宙、医療、自動車、エレクトロニクス、発電、石油・ガス、防衛など。 |

| VIMが製造している金属粉にはどのようなものがありますか? | Ti-6Al-4V、インコネル625、316Lステンレス鋼、CoCrMo、ルネ41、6061アルミニウム、ヘインズ230など。 |

| VIMはどのようにして高品質を確保しているのか? | 真空環境と、温度と組成の精密な管理は、高品質を保証するのに役立っている。 |

| VIM加工された金属はどこで購入できますか? | カーペンター・テクノロジー、ATIメタルズ、ヘインズ・インターナショナルなどのサプライヤーは、VIM加工金属を提供している。 |

結論

真空誘導溶解は、金属加工技術の進歩の証です。高純度で高性能な金属を生産するその能力は、品質と信頼性が最重要視される産業において不可欠なものとなっています。航空宇宙、医療、その他最高の材料を必要とするどの分野においても、VIMを理解することで優位に立つことができます。金属加工の未来はここにあり、それは真空誘導です!

ジェットエンジンの複雑な部品や医療用インプラントの精度に驚嘆するときは、それを可能にした驚くべきプロセスを思い出してほしい:真空誘導溶解法である。