1. Introduction: What Is Aermet 100 Powder and Why It Matters

Aermet 100 powder is a premium-grade, ultra-high-strength alloy powder used in critical applications requiring exceptional toughness, strength, and fatigue resistance. This maraging steel alloy contains iron, nickel, cobalt, molybdenum, and carbon—engineered to deliver performance under extreme conditions.

Initially developed for aerospace and military uses, Aermet 100 is now a go-to material in additive manufacturing (AM), metal injection molding (MIM), and powder metallurgy (PM) for parts that demand maximum fatigue resistance and fracture toughness.

Key B2B Benefits of Aermet 100 Powder:

- Ultra-high tensile strength (up to 280 ksi)

- Excellent fracture toughness (~100 ksi√in)

- 優れた耐疲労性

- Outstanding corrosion and stress-corrosion resistance

- High hardness after aging (>50 HRC)

- Ideal for additive manufacturing and PM parts

Target Industries:

- Aerospace (landing gear, actuators)

- Defense (armor, missile components)

- Oil and gas (drilling tools)

- Automotive performance parts

- Tooling and die manufacturing

2. Industrial Applications of Aermet 100 Powder

Due to its exceptional mechanical properties and ability to be processed via metal additive manufacturing, Aermet 100 powder is valued in sectors where performance cannot be compromised.

航空宇宙産業

- Landing gear components: High fatigue and impact resistance

- Actuators and shafts: Dimensional stability under dynamic loads

- Jet engine brackets: Lightweight and stress-resistant

Defense & Military Applications

- Armor-piercing ammunition

- Missile components

- Military-grade tooling

Oil & Gas Sector

- Downhole drilling tools

- High-stress couplings and valves

High-Performance Tooling

- Injection molding inserts

- 耐摩耗工具

- Die-casting molds

Additive Manufacturing & 3Dプリンティング

Aermet 100 powder is compatible with laser powder bed fusion (LPBF), direct energy deposition (DED), and electron beam melting (EBM). It enables on-demand manufacturing of complex, high-performance components.

Aermet 100 Powder Use Cases in Additive Manufacturing:

| 産業 | 使用例 | Benefits of Aermet 100 |

|---|---|---|

| 航空宇宙 | Actuator Brackets | 高い強度対重量比 |

| ディフェンス | Missile Guidance Components | Fracture toughness, precision |

| 工具 | 射出成形金型 | 高硬度、耐摩耗性 |

| Oil/Gas | Drill Sub Components | Corrosion & fatigue resistance |

For more information on available 3D printing powders including Aermet 100 and similar high-strength alloys, visit our product catalog.

3. Key Properties and Advantages of Aermet 100 Alloy

Aermet 100 powder is a maraging steel that offers a unique combination of ultra-high strength and superior toughness not easily matched by other alloys.

Chemical Composition (%):

| エレメント | Typical Content |

|---|---|

| Fe | バランス |

| Ni | 11.0 – 12.0 |

| Co | 13.0 – 14.0 |

| Mo | 5.0 – 5.3 |

| C | 0.01 – 0.03 |

| Cr | 0.1 – 0.3 |

Mechanical Properties (Aged Condition):

| プロパティ | 価値 |

|---|---|

| 極限引張強さ | 280 ksi (1,930 MPa) |

| 降伏強度 | 245 ksi (1,690 MPa) |

| 破壊靭性 | >100 ksi√in |

| 硬度 | >50 HRC |

| 伸び | ~10% |

B2Bバイヤーのメリット

- Reliability: Consistent mechanical performance for mission-critical applications

- 耐疲労性: Ideal for components under cyclic load

- Post-Processing Flexibility: Easy machining in annealed state, excellent response to aging

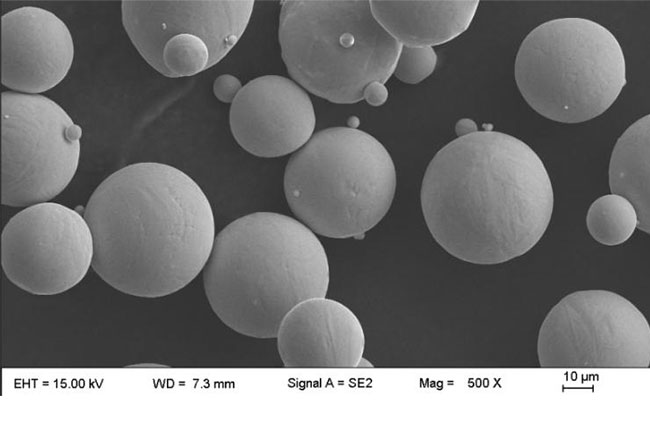

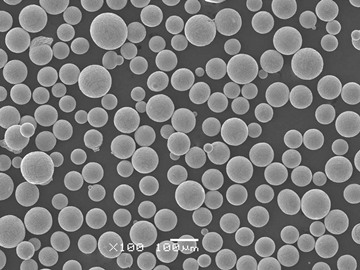

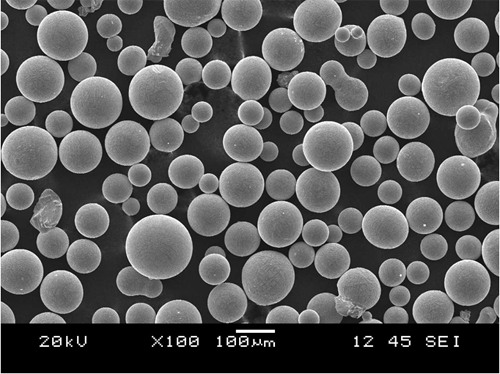

- Additive Manufacturing Compatibility: Spherical powder morphology for uniform flowability

Why Aermet 100 Is Superior to Conventional Stainless Steels:

| プロパティ | アーメット100 | 17-4PH Stainless Steel |

|---|---|---|

| 引張強度 | Up to 280 ksi | Up to 190 ksi |

| 破壊靭性 | >100 ksi√in | ~60 ksi√in |

| Machinability (Annealed) | 素晴らしい | 中程度 |

| AM Compatibility | 高い | 中程度 |

For a comprehensive overview of Shanghai Truer’s additive manufacturing capabilities and powder technology, visit our about page.

4. Market Trends and Demand for High-Strength Alloys

The global demand for ultra-high-strength alloys like Aermet 100 powder is seeing a significant uptrend, primarily driven by growth in aerospace, defense, and additive manufacturing sectors. As engineering requirements become more stringent, materials that can withstand extreme stress, fatigue, and environmental exposure are critical.

主な市場促進要因:

- Aerospace Modernization: The rise of electric aircraft, unmanned aerial vehicles (UAVs), and lighter airframes increases demand for high-strength alloys.

- Defense Spending: Global defense budgets are growing, leading to increased procurement of advanced materials for armor, weapons systems, and aircraft.

- Additive Manufacturing Growth: As 3D printing becomes mainstream, powders like Aermet 100 are in demand for functional, load-bearing components.

- Sustainability and Lightweighting: OEMs are seeking materials that reduce weight while maintaining or increasing strength.

Global Market Forecast (Aermet 100 and Similar Alloys):

| 地域 | カグル(2024-2030年) | 主要ドライバー |

|---|---|---|

| 北米 | 6.8% | Aerospace retooling, defense R&D |

| ヨーロッパ | 6.2% | Green aviation, AM adoption |

| アジア太平洋 | 8.3% | Military modernization, automotive innovation |

| 中東 | 5.9% | Oil & gas applications, aerospace expansion |

5. Criteria for Selecting a Reliable Aermet 100 Powder Supplier

Purchasing Aermet 100 powder for additive manufacturing or powder metallurgy applications demands careful supplier evaluation. Subpar quality or inconsistent batches can lead to catastrophic failure in critical components.

考慮すべき主な要素

- Powder Consistency & Purity

- Ensure particle size distribution and morphology are optimized for your AM platform.

- Check for low oxygen and carbon content to avoid brittleness and cracking.

- Manufacturing Technology

- Prefer suppliers using gas atomization or combined atomization techniques for superior powder sphericity and flowability.

- 品質認証

- ISO 9001, AS9100, or NADCAP certification is a must for aerospace-grade materials.

- Batch Traceability

- Each lot should include a certificate of analysis and full traceability.

- カスタマイズ・オプション

- Ability to tailor particle size ranges, packaging, and alloy variants.

- テクニカルサポート

- Suppliers should offer metallurgical consulting, AM compatibility testing, and post-processing advice.

- Lead Time and Logistics

- On-time delivery and robust export capabilities, particularly for global clients.

サプライヤー評価チェックリスト

| 基準 | 説明 | マストアイテム |

|---|---|---|

| 粉末純度 | <0.03% Carbon, <0.02% Oxygen | ✅ |

| 霧化技術 | Gas/Hybrid Atomization | ✅ |

| 3D Printing Compatibility | Tested on LPBF, DED, EBM | ✅ |

| カスタマイズ能力 | Size range, packaging, alloying | ✅ |

| 認証 | ISO 9001, AS9100 | ✅ |

| サプライチェーンの信頼性 | Global delivery, batch traceability | ✅ |

6. Top Global Suppliers of Aermet 100 Powder

Below is a brief overview of some of the most recognized suppliers of Aermet 100 powder, known for meeting stringent B2B requirements:

1. Carpenter Technology (USA)

- Pioneer developer of Aermet 100 alloy.

- Offers certified powders for AM and PM.

- Strong presence in aerospace and defense sectors.

2. Höganäs AB (Sweden)

- Leading global metal powder manufacturer.

- Supplies maraging steels, including Aermet-like variants.

- Strong R&D capabilities.

3. Sandvik Osprey (UK)

- Specializes in gas-atomized powders.

- Offers customized particle size distributions.

- High-quality feedstock for LPBF and DED processes.

4. Shanghai Truer Technology Co., Ltd (China)

- Emerging leader in high-performance PM and AM powders.

- Offers tailored Aermet 100 and similar maraging steel powders.

- Advanced hybrid atomization tech and full technical support.

- Competitive pricing with global logistics.

5. AMETEK Specialty Metal Products (USA)

- Produces high-purity, gas-atomized powders.

- Supplies to aerospace primes and defense contractors.

Comparison Table:

| サプライヤー名 | ガス噴霧 | カスタマイズ | Global Delivery | AM Compatibility | 認証 |

|---|---|---|---|---|---|

| カーペンター・テクノロジー | ✅ | ✅ | ✅ | ✅ | ISO, AS9100 |

| ヘガネスAB | ✅ | ✅ | ✅ | ✅ | ISO, AS9100 |

| サンドビック・オスプレイ | ✅ | ✅ | ✅ | ✅ | ISO, AS9100 |

| 上海トゥルーア・テクノロジー | ✅ | ✅ | ✅ | ✅ | ISO 9001 |

| アメテックSMP | ✅ | ✅ | ✅ | ✅ | ISO, NADCAP |

Truer offers a strong value proposition for companies seeking high-performance Aermet powders with technical support and competitive volumes. You can learn more about their additive manufacturing division これ.

7.中国メーカーに注目するバイヤーが増えた理由

With increasing pressure on OEMs and Tier 1 suppliers to reduce costs while improving performance, many B2B buyers are shifting their sourcing strategies towards high-quality Chinese manufacturers.

Key Reasons:

- Competitive Pricing: Lower labor and operational costs without compromising quality.

- 先進技術: Adoption of hybrid atomization and modern PM equipment.

- Customization Flexibility: Faster turnaround on tailored blends and particle sizes.

- Rapid Lead Times: Agile production and efficient export logistics.

- Expanding Certifications: Increasing number of ISO, AS9100, and NADCAP certified firms.

Strategic Advantages for Distributors & OEMs:

| メリット | Impact on Business |

|---|---|

| Lower Cost per Kg | Higher margins or cost savings |

| スケーラブルな生産 | Supports large-volume contracts |

| Global Logistics Capabilities | Faster to market |

| Technical Support in English | Seamless integration & collaboration |

Shanghai Truer Technology is a prime example of this trend, offering a wide range of 粉末冶金ソリューション for global clients in aerospace, defense, and automotive sectors.

8. Why Choose Shanghai Truer as Your Aermet 100 Supplier

Shanghai Truer Technology Co., Ltd. stands out among global powder metallurgy suppliers by offering high-performance Aermet 100 powder tailored for demanding B2B applications in aerospace, military, and industrial additive manufacturing.

Founded in 2009 and entering the 3D printing materials market in 2019, Truer has grown into one of China’s most professional and trusted suppliers of additive manufacturing powders and PM additives. With a deep understanding of powder production, Truer provides unmatched value to OEMs, 3D printing service bureaus, and industrial distributors.

What Makes Truer a Preferred Supplier for Aermet 100?

| 特徴 | Truer Benefit |

|---|---|

| 高度な霧化技術 | Gas, water, and hybrid atomization for optimal powder flow |

| Custom Particle Size Distribution | Tailored PSD for LPBF, DED, and MIM requirements |

| Proven Quality Control | ISO 9001-certified manufacturing and material traceability |

| Diverse Alloy Options | Full range of maraging steels and high-performance alloys |

| Industry Expertise | 15+ years in powder metallurgy, 5+ years in AM powders |

| Full Technical Support | Metallurgy consulting, AM process guidance, post-processing |

| グローバル・サプライチェーン | Fast shipping, export documentation, and volume pricing |

Truer’s Additive Manufacturing Alloy Grades Include:

- Aermet 100 and maraging steel variants

- PM 4600, PM 4200, FC-0208, FD-0208 (diffusion alloyed steel)

- PM nickel steel, iron-copper, FN-5000

- Stainless steel: gas- and water-atomized grades

- Diffusion CuSn powder for diamond tools and bearings

For a closer look at the alloys and powders available, please explore Truer’s 製品カタログ.

9. How to Order Wholesale Aermet 100 Powder from Truer

Ordering Aermet 100 powder in bulk from Shanghai Truer is designed to be seamless for global B2B partners, whether you’re an aerospace OEM, distributor, or additive manufacturing service provider.

ステップバイステップの注文プロセス:

- お問い合わせの送信

- Contact Truer via email or online form with your specifications:

- Desired alloy (e.g., Aermet 100)

- Particle size range (e.g., 15–45 μm for LPBF)

- Quantity (kg/tonnage)

- Application (AM, MIM, PM)

- Contact Truer via email or online form with your specifications:

- 技術相談(オプション)

- Truer’s technical team can assist with powder selection, compatibility testing, and process recommendations.

- 見積もりとリードタイム

- Receive pricing based on volume, shipping location, and customization.

- Typical lead time: 7–15 business days depending on order size.

- Sample Testing (If Required)

- Truer offers small sample batches for process validation.

- 支払い・物流

- Flexible payment terms for international buyers.

- Export documentation and customs support provided.

- 納品&アフターサービス

- Global shipping via air or sea.

- Post-delivery technical support and reorder assistance.

包装オプション:

| パッケージサイズ | 説明 |

|---|---|

| 5 kg Bottles | Ideal for R&D, testing, and prototyping |

| 25 kg Drums | Standard for mid-volume production |

| 500 kg Pallets | For high-volume OEM manufacturing |

For direct ordering inquiries, visit the コンタクトページ or email Truer’s export team.

10. FAQs: Common Questions About Buying Wholesale Aermet 100 Powder

Q1: What additive manufacturing methods are compatible with Aermet 100 powder?

Aermet 100 is suitable for:

- Laser Powder Bed Fusion (LPBF)

- Direct Energy Deposition (DED)

- 電子ビーム溶解(EBM)

- Binder Jetting (with post-sintering)

Q2: What particle size range is ideal for 3D printing?

For LPBF, a range of 15–45 µm is commonly used. For DED, larger particles (45–150 µm) are preferred.

Q3: Can I request customized powder composition or PSD?

Yes. Truer offers tailored chemical compositions, particle size distributions (PSD), and packaging to meet specific B2B project needs.

Q4: What quality certifications does Shanghai Truer have?

Truer operates under ISO 9001 standards and maintains strict QC protocols for powder metallurgy and additive manufacturing powders.

Q5: Is Aermet 100 powder available for international shipping?

Yes. Truer supports global delivery with all necessary export documentation and customs compliance.

Q6: Can I get a sample before placing a large order?

Yes. Truer provides small test samples for evaluation and compatibility testing.

Q7: Does Truer provide technical support for AM processes?

Absolutely. The Truer team includes metallurgists and AM specialists who offer support on powder selection, process optimization, and post-processing techniques.

If you’re ready to explore high-performance Aermet 100 powder for your B2B needs, we invite you to connect with our team. Learn more about Truer’s history, innovation, and mission by visiting our 会社概要のページ.