1. What Is MS1 Powder and Why It Matters in Manufacturing

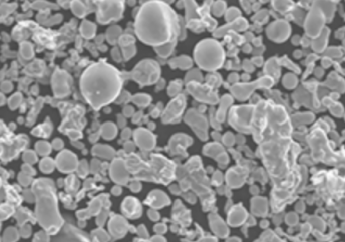

MS1 powder is a type of maraging steel powder widely used in additive manufacturing (AM), particularly in metal 3Dプリンティング. It is a pre-alloyed, gas-atomized powder made predominantly from iron, nickel, cobalt, molybdenum, and other alloying elements.

This material is especially known for its:

- 高強度

- 優れた熱安定性

- 良好な加工性

- 熱処理性

Chemical Composition of MS1 Powder

| エレメント | 構成比(%) |

|---|---|

| Fe | バランス |

| Ni | 18–19 |

| Co | 8.5–9.5 |

| Mo | 4.5–5.2 |

| Ti | 0.4–0.7 |

| Al | ≤0.1 |

| C | ≤0.03 |

Why MS1 Powder Matters for B2B Buyers

- 精密エンジニアリング: Ideal for tooling, molds, and aerospace parts that demand tight tolerances.

- High Yield Strength: Reduces material waste and improves product performance.

- カスタマイズ: Can be post-processed to enhance mechanical properties, making it valuable for prototyping and production.

B2B Use Cases:

- Injection molds for plastic and die-casting

- Aerospace structural components

- High-performance automotive parts

- Industrial tooling and fixtures

By leveraging MS1 powder, companies can significantly reduce lead times and costs compared to traditional subtractive manufacturing methods.

2. Industrial Applications of MS1 Powder in Additive Manufacturing

MS1 powder is engineered for high-stress, high-temperature, and high-precision applications. Its strength and versatility make it a preferred choice across industries.

Key Industries Using MS1 Powder

| 産業 | 応用例 |

|---|---|

| 航空宇宙 | Turbine blades, engine brackets, structural parts |

| 自動車 | Transmission components, engine parts, gear systems |

| 金型 | Injection molds, press tools, high-durability dies |

| 医療機器 | Surgical tools, orthopedic implants |

| ディフェンス | Custom weapon components, specialized armor parts |

Benefits of Using MS1 in AM vs Traditional Manufacturing

- ラピッドプロトタイピング: Reduce design-to-production cycle times.

- 複雑な幾何学: Produce intricate shapes without additional tooling.

- Low Waste: Material-efficient production with minimal scrap.

- On-Demand Manufacturing: Fulfill orders without large stockpiles.

Additive Manufacturing Processes Using MS1 Powder

- 選択的レーザー溶融(SLM)

- ダイレクトメタルレーザー焼結(DMLS)

- 電子ビーム溶解(EBM)

MS1 is compatible with leading industrial 3D printers like EOS M280, M290, and Concept Laser M2. It provides consistent layer adhesion, dimensional accuracy, and post-processing flexibility.

3. Key Properties and Advantages of MS1 Powder

MS1 is chosen for its mechanical strength, wear resistance, and ease of post-processing. These properties make it suitable for both functional prototypes and end-use parts.

Mechanical Properties (As-built and Heat Treated)

| プロパティ | As-built Value | Heat Treated Value |

|---|---|---|

| 極限引張強さ | ~1000 MPa | Up to 2000 MPa |

| 降伏強度 | ~900 MPa | ~1900 MPa |

| 破断伸度 | ~8% | ~3-5% |

| 硬度(HRC) | ~30 HRC | Up to 54 HRC |

Physical and Thermal Properties

- 密度: ~8.0 g/cm³

- 融点: ~1410–1450°C

- 熱伝導率: Moderate

- 耐食性: Moderate (can be improved with coating)

B2Bバイヤーのメリット

- Heat Treatable: Post-processing can double mechanical strength.

- Machinable: Easy to finish for high-precision parts.

- Long Tool Life: Excellent wear resistance increases part longevity.

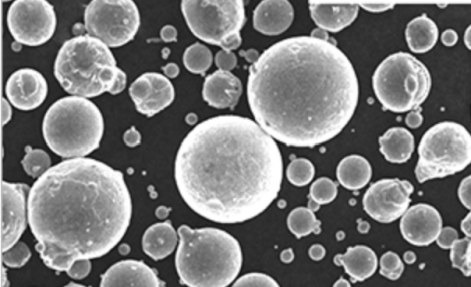

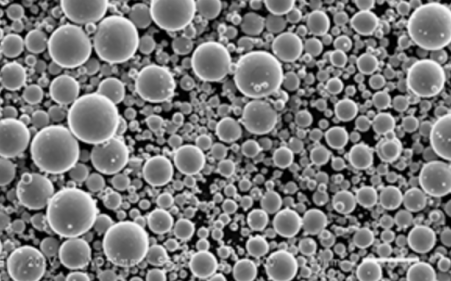

- バッチの一貫性: High-quality gas atomized powder ensures uniformity.

✅ If you’re sourcing for precision parts or custom tooling, MS1 offers a balance of strength and workability that few other AM materials can match.

👉 For more information on other 3D printing powders we offer, including stainless steel, brass, and bronze, visit our product catalog.

4. Global Market Trends and Demand for MS1 Powder

The global demand for MS1 powder is on the rise, driven by the increasing adoption of additive manufacturing (AM) across sectors like aerospace, automotive, medical, and industrial tooling. As industries shift toward high-performance, lightweight, and complex geometries, MS1 powder stands out as a premium maraging steel powder option.

Market Growth Overview

| 年 | Global MS1 Powder Market Size (USD Million) | 年平均成長率(%) |

|---|---|---|

| 2021 | 145 | 11.8% |

| 2023 | 182 | 12.5% |

| 2026 (F) | 260 | 13.1% |

| 2029 (F) | 352 | 12.8% |

成長の主な要因:

- Growth in Aerospace and Defense: Lightweight, strong materials like MS1 are critical for components.

- Tooling and Die Manufacturing: Shorter production cycles and improved durability.

- Shift from Subtractive to Additive: Lower production costs and waste reduction.

- Increased Customization Demand: Industries are pushing for more tailored, on-demand designs.

Regional Demand Insights

- 北米: Strong adoption in aerospace and defense sectors.

- ヨーロッパ: Rapid industrial digitization and government support for AM.

- アジア太平洋: Fastest growing region, driven by China’s and India’s expanding manufacturing bases.

📈 As demand surges, B2B buyers are increasingly looking for reliable, cost-effective suppliers who can meet tight tolerances and ensure consistent powder quality.

5. How to Choose a Reliable MS1 Powder Supplier

Selecting the right MS1 powder supplier is essential for ensuring consistent quality, supply chain reliability, and competitive pricing—especially for industrial buyers and OEMs.

考慮すべき主な要素

| 基準 | なぜ重要なのか |

|---|---|

| パウダーの品質と安定性 | Affects part performance and print repeatability |

| 霧化法 | Gas atomization yields better flowability and shape |

| Certification & Compliance | ISO, ASTM, and material traceability |

| カスタマイズ機能 | Tailored particle sizes or blends for specific printers |

| ロジスティクスとリードタイム | Essential for high-volume, just-in-time production |

| アフターセールス・サポート | Technical guidance, troubleshooting, and documentation |

Questions to Ask Your Supplier

- What is the particle size distribution (PSD) of your MS1 powder?

- Is your powder suitable for SLM/DMLS platforms like EOS or Concept Laser?

- Can you provide third-party test certificates (TPCs)?

- What kind of post-purchase technical support do you offer?

✅ Choosing a supplier with a proven track record, such as 上海Truer Technology Co., Ltd, ensures your business is backed by deep industry experience and robust R&D.

6. Top 5 MS1 Powder Suppliers in Asia-Pacific

The Asia-Pacific region is becoming a global hub for metal powder production, offering high-quality MS1 powder at competitive prices. Below are five leading suppliers known for their reliability and innovation.

Top 5 MS1 Powder Suppliers

| 会社概要 | 国名 | 主な強み |

|---|---|---|

| 上海トゥルーア・テクノロジー | 中国 | Full-service MS1 supplier with AM equipment integration |

| インドMIM | インド | Large-scale production, MIM & AM powders |

| JG Precision Metal | 中国 | Custom particle sizes for niche applications |

| 大同特殊鋼 | 日本 | High-purity maraging steel powders |

| POSCO Powder Tech | 韓国 | Advanced atomization technology and QC systems |

上海トゥルーアが際立つ理由

- Integrated Offerings: Not just powders—Truer also offers 3D printing equipment and technical services.

- Diverse Grades: Offers over 20 PM powder types including MS1, with options for water, gas, and hybrid atomization.

- Customized Solutions: Tailored blends and particle sizes for different printer platforms.

- Strong R&D Team: Continuous innovation in powder metallurgy and additive manufacturing.

🧩 If you’re a distributor or procurement manager looking to scale your AM operations, Shanghai Truer Technology offers unmatched value and flexibility. Learn more about who we are and how we support B2B customers globally.

7. Why More Distributors Are Turning to Chinese Manufacturers

In recent years, a growing number of global distributors, OEMs, and industrial buyers have shifted their sourcing strategies toward Chinese manufacturers—especially for high-performance powders like MS1. This shift is driven by several key advantages:

Key Benefits of Sourcing MS1 Powder from China

| メリット | 説明 |

|---|---|

| コスト効率 | Competitive pricing due to localized supply chain and advanced manufacturing |

| Large Production Capacity | Ability to meet high-volume B2B orders with short lead times |

| 技術の進歩 | Adoption of gas atomization and hybrid production technologies |

| カスタマイズ・オプション | Tailored particle sizes, compositions, and packaging for global clients |

| Government Support | Backed by national initiatives for AM and smart manufacturing |

Strategic Advantages for B2B Buyers

- Lower Procurement Costs: Chinese suppliers offer global quality at 20–30% lower prices than Western counterparts.

- Faster Scaling: With high-capacity facilities, they can fulfill bulk orders to support scaling operations.

- 統合されたサービス: Many Chinese suppliers now offer R&D, prototyping, and post-sales support.

Real-World Example

Shanghai Truer Technology, for instance, has become a go-to partner for international buyers due to its unique ability to provide not just MS1 powder, but also additive manufacturing equipment, technical guidance, and customized powder solutions—all under one roof.

🌍 For global distributors and industrial procurement teams, working with a trusted Chinese supplier offers a strategic edge in cost, quality, and delivery time.

8. Why Choose Shanghai Truer Technology as Your MS1 Powder Supplier

Shanghai Truer Technology Co., Ltd is one of China’s most established and trusted suppliers of metal powders for additive manufacturing. Founded in 2009, the company launched its additive manufacturing division in 2019, quickly becoming a leader in high-quality 3D printing powders and PM solutions.

トゥルアーの特徴

| 特徴 | B2Bバイヤーのメリット |

|---|---|

| 完全な垂直統合 | Offers both powder production and AM equipment for turnkey solutions |

| Wide Material Portfolio | MS1, PM stainless steel, bronze, nickel, brass, and specialized PM powders |

| 高度な生産方式 | Gas atomization, water atomization, and hybrid atomization |

| Custom Engineering Support | Tailors powder characteristics to match printer specs and performance goals |

| Fast Global Delivery | Well-developed logistics network for timely international shipping |

Truer’s PM Powder Expertise

Beyond MS1, Truer provides a full range of PM powders including:

- Pre-alloyed steels: PM4600, PM4200

- Copper-based alloys: PM Bronze, PM Brass, PM Copper Steel

- Stainless steels: Water and gas atomized

- Additives: Soft magnetic additives, graphite, cutting agents, lubricants

✅ Truer is also one of the few Chinese suppliers with a complete line of 粉末冶金ソリューション tailored for both traditional PM and additive manufacturing.

Client-Focused Services

- Custom powder grades and particle sizes

- Application consulting and material selection

- Sample testing and certification

- Dedicated B2B account managers

📞 Ready to explore a partnership? Reach out via our コンタクトページ をクリックして、お見積もりのご依頼やご相談のご予約をお願いいたします。

9. FAQs: Buying and Using MS1 Powder

Q1: What is the typical particle size range for MS1 powder in AM?

A: Standard ranges are 15–45 µm or 20–63 µm, depending on your specific 3D printer requirements.

Q2: Can MS1 powder be re-used in the printing process?

A: Yes, but with careful sieving and quality checks. Reusing powder beyond recommended cycles may affect mechanical properties.

Q3: Is MS1 powder compatible with all 3D printers?

A: MS1 is compatible with most laser-based powder bed fusion systems like EOS, SLM Solutions, and Concept Laser.

Q4: What certifications does Truer’s MS1 powder come with?

A: Truer provides full material data sheets, chemical analysis, and third-party test certification upon request.

Q5: 大量注文の場合、どのような梱包オプションがありますか?

A: Packaging ranges from 5kg vacuum-sealed pouches to 25kg drums and 500kg bulk containers, depending on order size and customer preference.

Q6: Does Shanghai Truer provide technical support for first-time users?

A: Absolutely. Truer offers full technical consultation, including powder selection, printer compatibility, and post-processing recommendations.

Q7: Is there a minimum order quantity (MOQ)?

A: Yes, the MOQ varies by product type but is generally flexible for new B2B clients looking to run trial batches.

✅ Ready to Source High-Quality MS1 Powder?

Whether you’re a precision tooling manufacturer, aerospace supplier, or 3D printing distributor, Shanghai Truer Technology offers a trusted, scalable solution for your metal powder needs.

👉 Explore our full range of products and services on the 公式サイト.

📩 For inquiries, technical consultation, or a customized quote, visit our お問い合わせページ 今日