1. Introduction: Understanding Y₂O₃ Powder

Y₂O₃ is a white, odorless inorganic compound that plays a crucial role in a variety of high-tech and industrial applications. As a rare earth metal oxide, Y₂O₃ is prized for its high melting point, thermal stability, and electrical insulating properties.

In the B2B and wholesale markets, Y₂O₃ powder is in demand across multiple industries, including:

- Additive manufacturing (AM)

- Ceramics production

- Optical coatings

- Luminescent materials

- Metallurgical additives

With increasing demand for advanced ceramics and high-temperature materials, Y₂O₃ is becoming a staple raw material for manufacturers seeking high-purity, reliable input materials.

Key Uses in B2B Sectors:

| Industry Segment | Application of Y₂O₃ Powder |

|---|---|

| 付加製造 | Used in ceramic 3Dプリンティング as a thermal barrier coating |

| 冶金学 | Acts as a stabilizer for high-temp superalloys |

| エレクトロニクス | Used in phosphors for display and LED technologies |

| Glass and Optics | Enhances durability in specialty and laser glasses |

| 航空宇宙・防衛 | Applied as thermal coatings in turbine and jet components |

If your business is involved in advanced ceramics, powder metallurgy, or AM processes, sourcing high-purity Y₂O₃ is critical. Shanghai Truer Technology Co., Ltd offers engineered solutions and consistent supply of Y₂O₃ powder tailored for industrial-scale operations.

👉 Learn more about the company’s background and mission in powder metallurgy and additive manufacturing.

2. Industrial Applications of Y₂O₃ Powder

Y₂O₃ powder’s unique properties make it a go-to material in several industrial applications. As industrial buyers, OEMs, and distributors seek high-performance materials, Y₂O₃ offers significant advantages in both performance and versatility.

Major B2B Applications of Y₂O₃ Powder

- アドバンスト・セラミックス

- High-purity Y₂O₃ is used to produce yttria ceramics with exceptional resistance to corrosion and high temperatures.

- Common in crucibles, kiln furniture, and sintered parts for chemical processing.

- Thermal Barrier Coatings (TBCs)

- Y₂O₃ is a component in yttria-stabilized zirconia (YSZ), widely used as a coating in jet engines and gas turbines.

- Protects metal components from thermal fatigue and oxidative damage.

- Sintering Additives for Powder Metallurgy

- Y₂O₃ improves densification and grain boundary strength in PM steels and alloys.

- Enhances performance of parts used in automotive and heavy machinery.

- Luminescent and Optical Materials

- Y₂O₃ doped with europium is used in red phosphors for LED and TV screens.

- Also used in fiber optics and laser technologies.

- Glass and Laser Applications

- Adds durability and thermal resistance in specialty glasses.

- Used in laser host materials and high-power laser components.

Application Overview Table

| アプリケーションエリア | Type of Use | Industry Benefiting |

|---|---|---|

| セラミックス | Substrate, crucible, corrosion-resistant parts | Chemical, Semiconductor |

| Thermal Coatings | Barrier layer in YSZ | 航空宇宙、エネルギー |

| 粉末冶金 | Sintering aid, grain control | Automotive, Heavy Machinery |

| Optical Displays | Phosphor material | Electronics, Displays |

| Laser Systems | Host for laser emission | Defense, Medical Devices |

3. Types and Properties of Y₂O₃ Powder

Y₂O₃ powder is available in several grades, particle sizes, and purities, depending on the intended industrial application. For B2B buyers, choosing the right specification is crucial to achieving optimal performance in end products.

Types of Y₂O₃ Powders by Manufacturing Method

| タイプ | 製造方法 | 一般的な用途 |

|---|---|---|

| High Purity (>99.99%) | Chemical precipitation | Optical, Electronics |

| Standard Industrial Grade | Thermal decomposition | Ceramics, Metallurgy |

| Nano Y₂O₃ Powder | Hydrothermal or Sol-Gel | Advanced coatings, sensors |

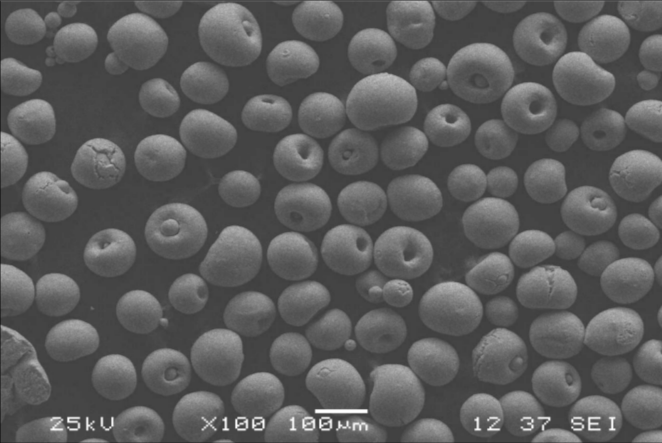

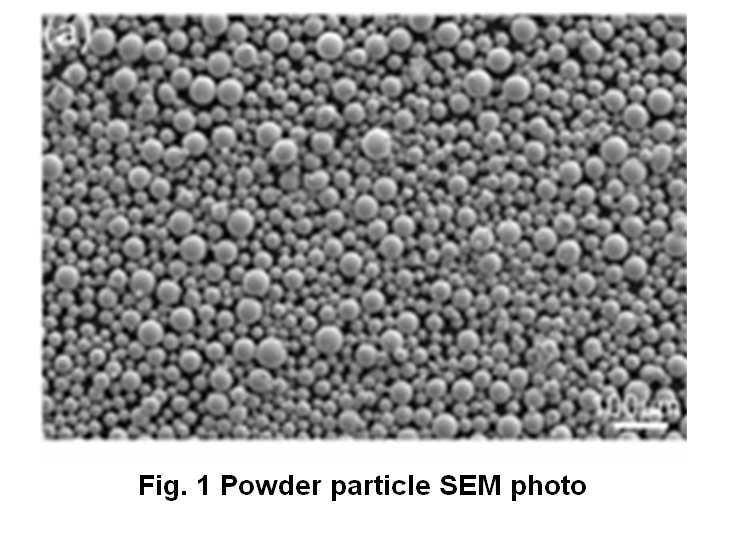

| Spherical Y₂O₃ Powder | プラズマ霧化 | Additive manufacturing, spraying |

物理的性質; 化学的性質

| プロパティ | 値/範囲 |

|---|---|

| 化学式 | Y₂O₃ |

| 分子量 | 225.81 g/mol |

| 外観 | White powder |

| 融点 | ~2,430°C |

| 純度レベル | 99.9% to 99.999% |

| 粒度分布 | 0.5 to 50 microns |

| 溶解度 | Insoluble in water, soluble in acids |

Key Considerations for B2B Buyers:

- 純度: High-purity grades are essential for electronics and optics.

- 粒子サイズ: Fine powders for coatings vs. coarse grades for ceramics.

- Agglomeration: Low-agglomerate powders preferred for AM and PM.

- 熱伝導率: Important for thermal barrier applications.

Shanghai Truer Technology provides customizable Y₂O₃ powder specifications, including nano and spherical forms, to meet advanced manufacturing requirements. Their integration of powder production and engineering services ensures consistency and cost-efficiency for bulk and repeat orders.

👉 Explore premium powder metallurgy materials for your next project.

4. Market Trends and Growth Potential for Y₂O₃ in Manufacturing

The Yttrium Oxide (Y₂O₃) powder market is experiencing robust growth, driven by expanding demand in high-performance ceramics, additive manufacturing, optical technologies, and advanced electronics. For B2B buyers, understanding these trends is essential for forecasting procurement needs and identifying long-term supplier partnerships.

主要市場ドライバー

- Rise of Additive Manufacturing (AM)

- 3D printing with ceramic and metal-ceramic composites is growing in aerospace, medical, and automotive industries.

- Y₂O₃ is being increasingly used in advanced AM applications due to its thermal and structural stability.

- Expansion in Electronics and Display Sectors

- Demand for LEDs, flat-panel displays, and laser devices is pushing consumption of Y₂O₃ as a phosphor material.

- Emerging applications in quantum dots and micro-LEDs are expected to further boost demand.

- Clean Energy and EV Adoption

- Y₂O₃ is used in high-temperature superconductors and solid oxide fuel cells (SOFCs), critical in renewable energy systems.

- The growth of electric vehicles (EVs) is stimulating interest in advanced ceramic components.

- Aerospace and Defense Applications

- YSZ coatings derived from Y₂O₃ are essential in turbines, jet engines, and propulsion systems.

- Government spending on defense R&D is increasing demand for rare earth oxides, including yttria.

世界市場の展望

| メートル | Value/Projection |

|---|---|

| Global Y₂O₃ Market Size (2023) | $198 Million USD |

| CAGR Forecast (2024–2030) | 7.5% |

| Top Regions by Demand | China, U.S., Germany, Japan |

| Leading Application Area | Ceramics and Coatings (~45% share) |

Challenges and Opportunities

- Supply Chain Risk: As a rare earth oxide, Y₂O₃ supply is sensitive to geopolitical factors and mining policies.

- Shift to Domestic Suppliers: Many manufacturers are now prioritizing local or regional sourcing to reduce lead times.

- Opportunity for Value-Added Services: Buyers increasingly prefer suppliers who offer technical support, customization, and logistics transparency.

👉 Looking for a supplier with proven expertise in high-purity metal powders? Contact the Shanghai Truer team for technical consultation and bulk pricing.

5. Key Considerations When Choosing a Y₂O₃ Powder Supplier

For procurement managers, OEMs, and distributors, selecting the right Y₂O₃ supplier is not just about price—it’s about long-term reliability, product consistency, and support for complex applications.

1. Purity and Consistency

Ensure the supplier can provide consistent purity levels (preferably ≥99.99%) across batches. This is especially important for applications in:

- Electronic components

- Optical coatings

- Sintered PM parts

2.生産能力

Inquire about the supplier’s manufacturing process (e.g., hydrothermal, thermal decomposition, plasma synthesis) and whether they can tailor:

- 粒度分布

- Morphology (spherical, nano, flake)

- Agglomeration levels

3. Technical Support

Does the supplier offer:

- Application engineering?

- Material compatibility guidance?

- Custom formulation services?

Suppliers like Shanghai Truer Technology go beyond powder sales by offering R&D support, application matching, and performance optimization for AM and PM industries.

4. Logistics and Lead Times

- Check whether the supplier maintains inventory for fast delivery.

- Ask about shipping options for bulk orders and international deliveries.

5. Quality Certifications

Ensure the supplier is certified or compliant with:

- ISO 9001

- RoHS

- REACH

- 製品安全データシート(MSDS)

Supplier Evaluation Checklist

| 評価基準 | Ideal Features |

|---|---|

| 製品の品質 | >99.99% purity, consistent particle size |

| Support Services | Technical consultation, material selection guidance |

| 柔軟性 | Customization, small-batch sampling, bulk scalability |

| ドキュメンテーション | COA, MSDS, ISO certification |

| 物流 | On-time delivery, global shipping, local inventory |

| 評判 | Verified clients, B2B references, industry recognition |

6. Top 5 Global and Chinese Y₂O₃ Powder Suppliers

For B2B buyers sourcing Y₂O₃ powder at scale, here are five reputable suppliers known for their quality, reliability, and support in the industrial and additive manufacturing sectors.

1. Shanghai Truer Technology Co., Ltd. – China

- ✅ Founded in 2009, AM division launched in 2019

- ✅ Offers a complete line of powder metallurgy and additive manufacturing powders

- ✅ Y₂O₃ powders tailored for ceramics, metallurgy, and AM

- ✅ Offers high-quality water atomized, gas atomized, and hybrid atomization powders

- ✅ Technical support for PM and AM applications

👉 Browse Truer’s extensive powder portfolio

2. Treibacher Industrie AG – Austria

- Specializes in rare earth oxides and advanced ceramics

- Supplies Y₂O₃ for glass, ceramic, and phosphor applications

- Offers high-purity grades and technical support

3. HEFA Rare Earth Canada Co. Ltd. – Canada/China

- Focuses on rare earth oxides with North American customer service

- Offers Y₂O₃ in bulk with global shipping

- Ideal for glass, electronics, and phosphors

4. American Elements – USA

- Offers one of the largest catalogs of rare earth compounds

- Provides nano, high-purity, and industrial-grade Y₂O₃

- Custom synthesis available for research and development

5. Sinocera (Jiangxi) – China

- Specializes in electronic ceramics and raw materials

- Supplies Y₂O₃ for capacitors, multilayer ceramic substrates, and more

- ISO-certified and REACH-compliant

Supplier Summary Table

| サプライヤー名 | 地域 | Purity Levels Offered | アプリケーション・フォーカス |

|---|---|---|---|

| 上海トゥルーア・テクノロジー | 中国 | 99.9% – 99.999% | PM, AM, Ceramics |

| トレーバッハ工業 | オーストリア | 99.99% | Ceramics, Glass, Phosphor |

| HEFA Rare Earth | Canada/China | 99.9% – 99.999% | Electronics, Optics |

| アメリカの要素 | アメリカ | 99.9% – 99.999% | R&D, Specialty Materials |

| Sinocera | 中国 | 99.95% – 99.999% | MLCC, Ceramics |

Shanghai Truer stands out due to its integrated services, ability to customize powder characteristics, and deep expertise in powder metallurgy. For OEMs and industrial buyers seeking a long-term, reliable Y₂O₃ partner, Truer offers unmatched value.

7. Why More Buyers Are Choosing Alternative Supply Sources

As global supply chains become more complex and vulnerable to disruption, B2B buyers are increasingly moving away from traditional sourcing models, especially when it comes to specialty and rare earth powders like Yttrium Oxide (Y₂O₃). Alternative sourcing models offer several advantages for wholesale buyers, OEMs, and distributors.

シフトの主な理由

- Global Supply Chain Volatility

- Trade restrictions, geopolitical tensions, and raw material shortages have impacted the availability of rare earth oxides.

- Buyers are diversifying suppliers across regions to mitigate risk.

- Rising Costs from Established Brands

- Many traditional suppliers in North America and Europe have significantly increased pricing due to energy, labor, and compliance costs.

- Emerging suppliers in Asia offer competitive pricing without compromising quality.

- Need for Customization and Technical Support

- Conventional suppliers often provide off-the-shelf solutions with limited support.

- New-generation suppliers like Shanghai Truer offer tailored solutions and engineering integration.

- Faster Delivery and Localized Inventory

- Alternative suppliers often keep regional stock and offer expedited shipping options.

- Reduced lead times mean lower inventory costs for buyers.

Comparison: Traditional vs. Alternative Supply Chain

| 特徴 | 伝統的サプライヤー | Alternative Supplier (e.g. Truer) |

|---|---|---|

| リードタイム | 4~6週間 | 1~3週間 |

| カスタマイズ・オプション | 限定 | 広範囲 |

| テクニカルサポート | 最小限 | Dedicated Engineering Team |

| 価格 | Premium | 競争的 |

| MOQ(最小注文数量) | 高い | フレキシブル |

| Delivery Models | Standard Freight | Express + Local Warehousing |

By partnering with agile, technically adept suppliers, B2B buyers can build more resilient and cost-effective sourcing strategies for Y₂O₃ and other specialty powders.

👉 Learn more about our flexible sourcing and support model on our 公式サイト.

8. Why Choose Shanghai Truer Technology as Your Y₂O₃ Supplier

Shanghai Truer Technology Co., Ltd is not just a material supplier — it’s a comprehensive solution provider for powder metallurgy and additive manufacturing. With a deep commitment to quality, customization, and technical partnership, Truer is one of China’s most trusted names in engineered metal powders.

会社概要

- ✅ Established in 2009, AM business launched in 2019

- ✅ ISO-certified production facilities

- ✅ Dedicated to high-quality PM and AM powders

- ✅ Offers full-service support from R&D to OEM integration

Why Truer Stands Out in the Y₂O₃ Supply Chain

- Custom Y₂O₃ Powder Formulations

- Particle sizes from nano to micron-scale

- Spherical, agglomerated, and high-purity options

- Tailored for ceramics, coatings, and AM applications

- Integrated Technical Services

- Application matching

- Composite powder development

- Powder testing and performance validation

- Broad Product Portfolio

In addition to Y₂O₃, Truer offers an extensive range of powders:- PM Bronze, PM Brass, PM Stainless Steel

- Diffusion alloyed steels (FD-0208, FL-4605, etc.)

- Additives: Lube-W, SUW-5000B, graphite TBC-400, cutting agents SME-100, TD-8

- New soft magnetic material QH-150

- Global Delivery and Support

- アジア、ヨーロッパ、北米への迅速な発送

- Multilingual support team

- Custom packaging and labeling for industrial clients

Client-Centric Benefits

| ベネフィット | 説明 |

|---|---|

| 一貫した品質 | Tight control over purity and particle morphology |

| Technical Partnership | Engineering team supports product integration and testing |

| 競争力のある価格設定 | Optimized for OEMs and distributors looking to scale |

| 柔軟なMOQ | From trial sampling to large-scale industrial supply |

| エンド・ツー・エンド・ソリューション | From powder to additive engineering and beyond |

✅ If you’re looking for a reliable, technically savvy Y₂O₃ supplier, Shanghai Truer is your ideal partner.

9. How to Order Wholesale Y₂O₃ Powder from Shanghai Truer

Ordering wholesale Yttrium Oxide (Y₂O₃) powder from Shanghai Truer is simple, transparent, and designed to support B2B procurement workflows. Whether you’re a manufacturer, distributor, or R&D lab, Truer offers a seamless ordering experience.

ご注文の流れ

- お問い合わせ・仕様

- Submit your requirements via the コンタクトフォーム.

- Include details like:

- Purity level (≥99.9%, 99.99%, 99.999%)

- Particle size/morphology

- Quantity (kg/tons)

- End-use application

- 技術相談

- Truer’s team will review your needs and suggest the right Y₂O₃ grade.

- You’ll receive:

- Technical datasheet (TDS)

- 分析証明書(COA)

- Sample availability (if requested)

- Quotation & Payment

- Receive a formal quotation including lead time, shipping options, and payment terms.

- Flexible payment options for bulk and repeat buyers.

- Production & Quality Check

- Manufacturing begins after order confirmation.

- Rigorous QC ensures consistency in every batch.

- 配送

- Global shipping via air or sea

- Expedited options available

- Tracking and documentation provided

- Post-Sale Support

- Application support, performance feedback, and reordering assistance

- Dedicated account manager for large-volume customers

Ordering Checklist

| 項目 | Required? |

|---|---|

| Technical Specification Sheet | ✅ |

| Delivery Address | ✅ |

| Quantity Needed | ✅ |

| Application Description | Optional |

| NDA or Supplier Agreement | Optional |

FAQs: Common Questions About Buying Wholesale Y₂O₃ Powder

Q1: What is the minimum order quantity (MOQ) for Y₂O₃ powder?

A: For standard grades, MOQ starts at 5 kg. For custom grades or nano powder, MOQ may vary.

Q2: Can I request a sample before placing a bulk order?

A: Yes, samples (typically 100g–500g) are available for evaluation. Shipping costs may apply.

Q3: Are Truer’s Y₂O₃ powders compatible with 3D printing?

A: Yes, Truer offers spherical and nano Y₂O₃ powders suitable for ceramic and hybrid AM systems.

Q4: Do you offer custom packaging for industrial buyers?

A: Yes, packaging can be customized by size (1kg, 5kg, 25kg) and labeling per client specs.

Q5: How do you ensure consistency across batches?

A: Each batch undergoes full QC analysis (COA provided), and Truer maintains strict internal quality protocols.

Q6: Can I integrate Y₂O₃ powder with other Truer PM materials?

A: Absolutely. Many clients use Y₂O₃ in combination with Truer’s diffusion alloyed steels and lubricants for enhanced sintering.

Internal Links Summary (Anchor Text with Embedded URLs)

Here are the internal links added throughout the article to improve user navigation and SEO:

- company’s background and mission

- premium powder metallurgy materials

- Contact the Shanghai Truer team

- 公式サイト

- Shanghai Truer is your ideal partner

By choosing Shanghai Truer Technology as your Y₂O₃ wholesale supplier, you gain access to world-class technical support, engineered powder solutions, and a reliable global logistics network. Whether you’re scaling up AM production or enhancing PM part performance, Truer delivers the quality and partnership your business needs.

準備はできたか? お問い合わせ for a free consultation or sample request.