1. Introduction: Why Aluminum Alloy Powder Is Reshaping Modern Manufacturing

Aluminum alloy powder has emerged as a cornerstone material in additive manufacturing, powder metallurgy (PM), automotive, aerospace, and electronics industries. Its high strength-to-weight ratio, corrosion resistance, and excellent thermal properties make it ideal for producing lightweight and durable components.

Why B2B Buyers Are Turning to Aluminum Alloy Powders:

- High mechanical performance with reduced weight

- Excellent formability and machinability

- Compatibility with 3Dプリンティング, metal injection molding (MIM), and PM

- Cost-effective for high-volume manufacturing

- Environmentally friendly with high recyclability

Bulk buyers, OEMs, and industrial distributors are increasingly sourcing aluminum powders to meet rising demand for sustainable and high-precision metal parts.

2. Industrial Applications of Aluminum Alloy Powder

Aluminum alloy powder is a versatile material used across various sectors. Below is a breakdown of its applications by industry:

| 産業 | 用途 | メリット |

|---|---|---|

| 自動車 | Engine blocks, brake components, transmission parts | Lightweight, fuel-efficient, corrosion-resistant |

| 航空宇宙 | Structural parts, frames, turbine housings | 高い強度対重量比、耐熱性 |

| エレクトロニクス | Heat sinks, housings, antennas | 優れた熱伝導性と電気伝導性 |

| 建設 | Decorative panels, structural joints | High durability, low maintenance |

| 付加製造 | 3D printed prototypes and end-use parts | High precision, material efficiency |

Powder Metallurgy (PM) Use-Cases:

- Gears and mechanical parts for industrial machinery

- Sintered aluminum components with high dimensional accuracy

- Porous materials for filtration systems

3. Types of Aluminum Alloy Powders and Their Properties

Choosing the right aluminum alloy powder depends on the intended application, manufacturing process, and required material properties. Aluminum powders are typically available in pure and alloyed forms and are produced by various atomization methods.

Common Aluminum Alloy Grades:

| 合金グレード | 構成 | 主要物件 | Manufacturing Use |

|---|---|---|---|

| AlSi10Mg | アルミ・シリコン・マグネシウム | High strength, good weldability | 3Dプリンティング、航空宇宙 |

| Al6061 | Aluminum-Magnesium-Silicon | 耐食性、機械加工性 | 自動車、構造物 |

| Al7075 | Aluminum-Zinc | 高い引張強度 | Aerospace, motorsports |

| AlSi7Mg | アルミ・シリコン・マグネシウム | Enhanced fluidity, casting suitability | Automotive, MIM |

| AlSi12 | High silicon content | Excellent castability | Die casting, PM |

Atomization Methods:

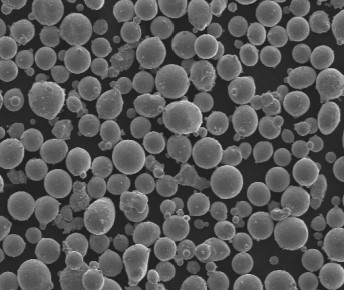

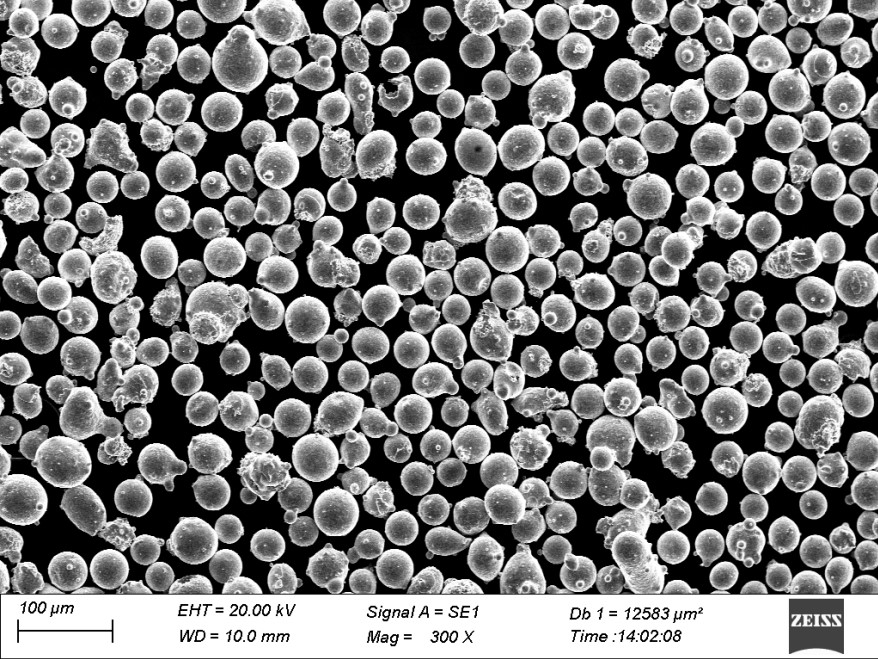

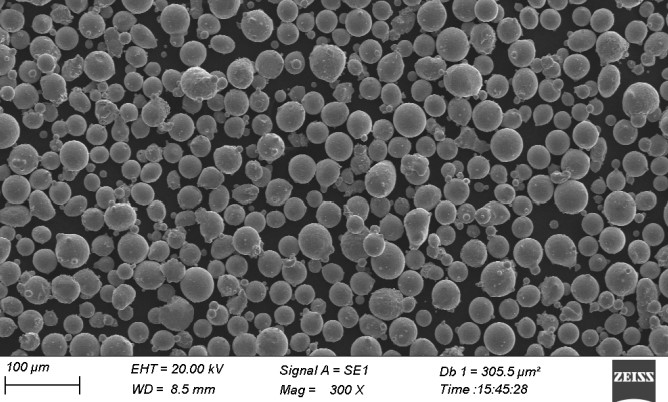

- Gas Atomization: Produces spherical particles with excellent flowability—ideal for 3D printing.

- Water Atomization: More economical, irregular shapes—suitable for PM and MIM.

- Combined Atomization: Hybrid approach for improved particle morphology and performance.

For a comprehensive range of metal powders, including aluminum alloy options suitable for additive manufacturing and PM, visit our 粉末冶金製品 ページを参照されたい。

4. Market Trends and Global Demand for Aluminum Alloy Powder

The global aluminum alloy powder market is experiencing significant growth, driven by the rapid expansion of additive manufacturing and the increasing demand for lightweight materials in automotive and aerospace industries. According to industry research, the aluminum powder market is projected to surpass USD 4 billion by 2030, with strong growth in Asia-Pacific and North America.

主な市場促進要因:

- 🌍 Growth in 3D printing and powder metallurgy (PM)

- 🚗 Lightweight automotive components for fuel efficiency and electrification

- ✈️ Aerospace innovation requiring high-strength, low-weight materials

- 🏭 Increased use in sintered components for industrial machinery

- ♻️ Push for sustainable and recyclable materials

B2B Buyer Insights:

- Distributors are stockpiling aluminum alloy powders with consistent particle size and flowability.

- OEMs and contract manufacturers are seeking long-term supply contracts to ensure production continuity.

- E-commerce sellers increasingly list metal powders for rapid prototyping and small-batch production.

5. Key Considerations When Choosing an Aluminum Alloy Powder Supplier

Selecting the right supplier for aluminum alloy powder in B2B markets involves more than just price. Here are essential factors to consider:

✅ Product Quality & Consistency

- Is the powder produced via gas, water, or hybrid atomization?

- Are particle size distribution and morphology consistent?

- Does the supplier offer technical data sheets and quality certifications?

✅ Supply Chain Reliability

- Can the supplier meet bulk order quantities consistently?

- What is the lead time for delivery and shipping?

- Are there warehousing or local distribution options?

✅ Customization Capabilities

- Can the supplier develop custom aluminum alloy compositions?

- Is there support for small-batch R&D or pilot-scale production?

✅ Technical Support & After-Sales Service

- Does the supplier provide metallurgical consulting or application advice?

- Are there field engineers or customer support teams for troubleshooting?

✅ Compliance & Safety

- Does the product meet RoHS, REACH, or other international standards?

- Are MSDS (Material Safety Data Sheets) provided?

Choosing a trusted partner like 上海Truer Technology Co., Ltd ensures that these critical factors are met with professionalism and technical accuracy.

6. Top 5 Aluminum Alloy Powder Suppliers in Asia

Here are five of the most reputable suppliers of aluminum alloy powders in Asia for B2B buyers and distributors:

| サプライヤー | 国名 | 主要製品 | 専門性 |

|---|---|---|---|

| 上海Truer Technology Co., Ltd | 中国 | Aluminum, Steel, Nickel, Bronze powders | High-quality PM and 3D printing powders |

| カイメラ・インターナショナル | 韓国 | Aluminum-based powders | Aerospace and electronics applications |

| CNPCパウダー | 中国 | Gas-atomized aluminum and copper powders | 積層造形 |

| 福田金属箔粉(株 | 日本 | Aluminum powders | Precision electronics and PM |

| Hoganas AB (Asia Branch) | インド | Aluminum and iron-based powders | PM and soft magnetic materials |

Shanghai Truer stands out for its comprehensive portfolio and dedication to powder metallurgy innovation. Truer provides a wide range of aluminum alloy powders produced through gas atomization, water atomization, and hybrid processes — tailored for both additive manufacturing and conventional PM.

7. Why More Distributors Are Sourcing Aluminum Alloy Powder from China

China has become a global leader in aluminum alloy powder production for several reasons:

🌐 Competitive Pricing

Thanks to economies of scale and advanced manufacturing infrastructure, Chinese suppliers offer high-quality metal powders at competitive prices — ideal for wholesale buyers and exporters.

⚙️ Advanced Manufacturing Techniques

Chinese producers invest heavily in R&D and have adopted cutting-edge atomization technologies, enabling them to supply powders with spherical morphology and tight particle size distributions.

🏭 Integrated Supply Chains

Many Chinese suppliers, including Shanghai Truer, offer one-stop solutions — from powder production to additive consultation and custom alloy development. This reduces lead times and simplifies logistics for B2B buyers.

📦 Flexible MOQs and Logistic Support

Chinese powder manufacturers typically offer:

- Low minimum order quantities (MOQs) for sampling

- Fast delivery timelines

- Global shipping and export licensing

Distributors and industrial buyers can also benefit from local warehousing, reducing transit time and customs costs.

For more details on how to connect with a Chinese supplier like Truer, visit our お問い合わせページ.

8. Why Choose Shanghai Truer as Your Aluminum Alloy Powder Partner

Shanghai Truer Technology Co., Ltd stands out as one of the most trusted and technically advanced suppliers of aluminum alloy powder in China. Established in 2009, Truer entered the additive manufacturing business in 2019 and has since become a leading provider of integrated solutions for powder metallurgy and 3D printing.

🏆 Why B2B Buyers Prefer Truer:

| 特徴 | 説明 |

|---|---|

| 🧪 Advanced Production Capabilities | Offers gas atomization, water atomization, and hybrid atomization to meet different manufacturing needs |

| 📊 Diverse Product Portfolio | Supplies PM aluminum alloys, bronze, nickel silver, iron-copper, stainless steel, and more |

| 🛠️ Engineering-Grade Quality | Powders optimized for additive manufacturing, sintering, MIM, and diamond tool production |

| 🌍 Global Export Experience | Trusted by international buyers in automotive, aerospace, and machinery industries |

| 📞 Professional Technical Support | Provides full technical consultation, application optimization, and after-sales service |

Truer’s aluminum alloy powders are engineered to provide consistent performance and meet the strictest quality standards. Grades like AlSi10Mg and Al6061 are available with tight particle size control, excellent flowability, and optimized for laser powder bed fusion and other AM technologies.

🔗 Learn more about Truer’s full capabilities on their 会社概要のページ.

9. How to Order Wholesale Aluminum Alloy Powder from Truer

Truer has streamlined the order process for distributors, OEMs, and industrial buyers. Here’s a step-by-step guide for how to source high-quality aluminum alloy powder in bulk:

📝 Step 1: Product Inquiry

- をご覧ください。 PM Powder Products page to explore available grades.

- Identify your application needs (e.g., particle size, alloy composition, manufacturing process).

- Contact Truer’s sales team with your specifications and estimated order quantity.

📄 Step 2: Receive Technical Data & Quotation

- Truer will provide:

- テクニカル・データ・シート(TDS)

- 製品安全データシート(MSDS)

- Pricing based on order quantity and delivery terms

- Custom alloy formulations available upon request

🔧 Step 3: Sample Testing (Optional)

- Truer can supply sample quantities for testing and qualification

- Samples are generally shipped via express courier within 3–5 business days

📦 Step 4: Place Bulk Order

- Confirm purchase order (PO)

- Agree on logistics (FOB, CIF, or DDP options available)

- Truer offers flexible MOQ depending on application and alloy type

🚚 Step 5: Delivery & After-Sales Support

- Orders are processed promptly with global shipping support

- Technical engineers available to guide application and troubleshoot issues

- Reorder and contract manufacturing options available for long-term partners

To initiate your order, contact the team directly via the お問い合わせページ.

10. FAQs: Buying Wholesale Aluminum Alloy Powder for Industrial Use

Here are some of the most frequently asked questions from B2B customers:

Q1: What is the minimum order quantity (MOQ) for aluminum alloy powder?

A: The MOQ varies by alloy and form. For standard grades, Truer can fulfill orders starting from 50 kg. Custom grades may require higher MOQs depending on the production run.

Q2: Can Truer supply powder suitable for 3D printing?

A: Yes. Truer specializes in additive manufacturing powders and offers gas-atomized aluminum alloy powders like AlSi10Mg optimized for 3D printing with uniform spherical particles and excellent flowability.

Q3: What particle sizes are available?

A: Truer offers a range of size distributions, including:

- 15–45 μm (ideal for LPBF/SLM 3D printing)

- 45–105 μm (for DED or PM processes)

- Custom sieve sizes per request

Q4: Are the powders certified?

A: Yes. All aluminum alloy powders come with full documentation, including:

- Certificate of Analysis (CoA)

- TDS and MSDS

- Compliance with RoHS, REACH, and international quality standards

Q5: Can Truer help with custom alloy development?

A: Absolutely. With a dedicated R&D team and over a decade of metallurgical experience, Truer can develop custom compositions tailored to your application needs.

🧩 Internal Links Summary for SEO & User Experience

To improve navigation and SEO, here are the internal links embedded throughout the article:

| アンカーテキスト | URL |

|---|---|

| 粉末冶金製品 | https://am-material.com/pm-powder/ |

| 会社概要のページ | https://am-material.com/about/ |

| お問い合わせページ | https://am-material.com/contact-us/ |

🚀 Whether you’re an OEM, distributor, or industrial buyer seeking a reliable source of aluminum alloy powder, Shanghai Truer is ready to be your long-term partner in innovation and performance. Explore the full range of solutions at アム・マテリアル・ドット・コム.