1. Introduction: Why Nimonic Powder is Vital for High-Performance Alloys

Nimonic is a family of nickel-based superalloys known for exceptional strength, high-temperature resistance, and oxidation resistance. These characteristics make Nimonic powder a popular choice for additive manufacturing (AM), powder metallurgy (PM), and critical engineering components in high-stress environments such as aerospace, automotive, and energy sectors.

For B2B buyers and procurement managers, sourcing high-quality Nimonic powder is essential for:

- Ensuring reliability in high-temperature applications

- Meeting demanding mechanical performance requirements

- Reducing long-term maintenance costs of critical components

Shanghai Truer Technology Co., Ltd is a trusted supplier of advanced metal powders, including Nimonic and other alloy powders. With over a decade of experience and a dedicated additive manufacturing division launched in 2019, Truer is helping global manufacturers integrate high-quality powders into their production workflows.

2. Industrial Applications of Nimonic Powder

Nimonic powder serves as a critical raw material in various industries that demand materials capable of withstanding extreme environments.

Key industrial applications include:

| 産業 | 申し込み | Benefit of Nimonic Powder |

|---|---|---|

| 航空宇宙 | Jet engine turbine blades, combustion chambers | High-temperature and creep resistance |

| 自動車 | Turbochargers, exhaust valves | 耐熱疲労性 |

| 発電 | ガスタービン、原子炉 | 耐酸化性と耐食性 |

| 付加製造 | 3D printed components for aerospace and medical | Complex geometries with high strength |

| 石油・ガス | Downhole tools, valves | Long-term corrosion resistance |

B2Bバイヤーのメリット

- Enables lightweight, high-performance components

- Reduces material failure in high-stress applications

- Supports innovation in AM and PM component development

3. Types and Compositions of Nimonic Powders

There are several grades of Nimonic powder, each formulated with varying amounts of chromium, cobalt, titanium, and aluminum to enhance specific performance traits.

Here’s a comparison of popular Nimonic grades:

| Nimonic Grade | 構成 | 主要物件 | ユースケース |

|---|---|---|---|

| Nimonic 75 | Ni (80%), Cr (20%) | Good corrosion resistance, moderate strength | Gas turbines, nuclear applications |

| Nimonic 80A | Ni (76.5%), Cr (19.5%), Ti, Al | High strength and oxidation resistance | Jet engines, exhaust valves |

| ニモニック90 | Ni (57%), Cr (19.5%), Co (18.5%), Ti, Al | Superior creep and fatigue resistance | Turbine discs, aerospace parts |

| Nimonic PE11 / PE16 | Ni base, with Mo, Cr, Co, Ti | Enhanced weldability and stress rupture resistance | Nuclear and aerospace components |

Powder Production Techniques:

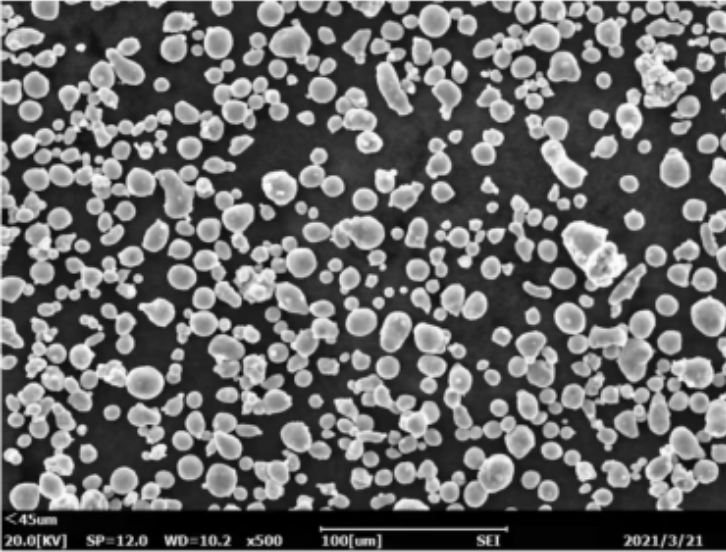

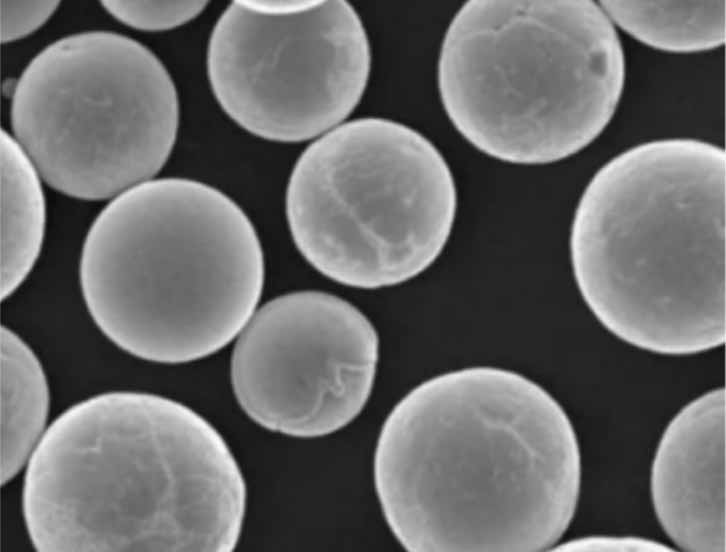

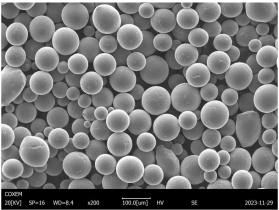

Shanghai Truer uses advanced atomization systems—including gas and water atomization—to ensure consistent particle morphology, flowability, and purity. Powder characteristics can be tailored based on the production method:

- Gas Atomization: Spherical particles, ideal for AM

- Water Atomization: Cost-effective, irregular shapes, suitable for PM

- Hybrid Atomization: Combines benefits of both methods

To explore Truer’s full range of metal powders, visit the PMパウダー製品カタログ.

4.世界市場の動向と成長の可能性

The demand for high-performance alloy powders like Nimonic is growing rapidly, driven by the expansion of additive manufacturing, aerospace modernization, and the push for higher efficiency in energy systems.

主な市場促進要因:

- Additive Manufacturing (AM) Growth: As aerospace OEMs and defense contractors adopt 3Dプリンティング for mission-critical parts, the demand for superalloy powders like Nimonic 80A and 90 is increasing.

- 高温アプリケーション: Industries are shifting toward materials that can withstand extreme thermal and mechanical stress.

- Sustainability and Lightweighting: Nimonic contributes to fuel efficiency and emissions reduction through lightweight, durable designs.

Market Forecast Highlights:

| 地域 | 予測CAGR (2024-2030) | Key Growth Driver |

|---|---|---|

| 北米 | 8.2% | Aerospace & defense investments |

| ヨーロッパ | 7.5% | Automotive electrification |

| アジア太平洋 | 9.8% | Industrial growth, AM adoption |

| 中東 | 6.0% | Energy and gas turbines |

B2B Opportunity Insight:

✅ OEMs and Tier-1 suppliers are increasingly sourcing customized Nimonic powders for specific applications.

✅ There’s a growing demand for shorter lead times and technical support from powder suppliers.

Shanghai Truer Technology Co., Ltd is positioned to meet this demand with its advanced facilities and responsive customer support. The company’s 会社概要のページ outlines its commitment to R&D and innovation in powder metallurgy.

5. Key Considerations When Choosing a Nimonic Powder Supplier

Sourcing Nimonic powder for industrial or additive applications involves more than just price. For B2B buyers, quality, consistency, and supply chain reliability are critical.

サプライヤー評価チェックリスト

- ✅ Powder Purity and Composition Consistency: Is the supplier certified and able to provide batch-level traceability?

- ✅ 生産技術: Does the supplier use gas atomization or other high-grade methods for spherical powders?

- ✅ カスタマイズ: Can the supplier tailor particle size distribution (PSD), flowability, and composition for your needs?

- ✅ Logistics and Lead Time: Are the powders delivered on time with appropriate packaging and documentation?

- ✅ テクニカルサポート: Does the supplier offer support for powder selection, testing, and application?

What to Look for in Technical Data Sheets:

- Particle Size Distribution (D10, D50, D90)

- Flow Rate (Hall/Carney)

- Tap Density and Apparent Density

- O, N, C, H Content (Gas analysis)

- SEM / Morphology Images

上海トゥルーアが際立つ理由

- Offers both gas atomized そして hybrid atomized パウダー

- 消耗品 spherical Nimonic powders tailored for AM and PM

- Provides full documentation and material traceability

- Strict quality control in accordance with ISO standards

For a technical consultation or custom order, feel free to contact Truer Technology directly.

6. Top Nimonic Powder Suppliers in Asia and Beyond

If you’re sourcing Nimonic powder for your production line or resale, here are some leading suppliers that B2B buyers often consider:

Top 5 Global Nimonic Powder Suppliers:

| 会社概要 | 地域 | 主なサービス | 専門分野 |

|---|---|---|---|

| 上海Truer Technology Co., Ltd | 中国 | Nimonic 75, 80A, 90, PE11, PE16 | Custom atomization, AM/PM integration |

| ヘガネスAB | スウェーデン | High-performance alloy powders | Large-scale PM solutions |

| サンドビック・オスプレイ | 英国 | Gas atomized superalloys | AM and aerospace focus |

| カーペンター添加剤 | アメリカ | ニッケル基超合金 | Aerospace and defense |

| テクナ | カナダ | Plasma atomized powders | Ultra-spherical nickel alloys |

Why Shanghai Truer is a Top Choice:

- Integrated supply chain: From powder production to custom packaging

- 強力な研究開発能力: Focused on alloy development

- 競争力のある価格設定: Ideal for bulk and repeat orders

- Fast logistics: Supports international shipping with proper documentation

Additionally, Truer’s メインサイト provides detailed product insights and downloadable material data sheets for decision-makers and engineers.

7. Why More Buyers Are Turning to Chinese Nimonic Powder Sources

In recent years, Chinese manufacturers have become increasingly competitive in the global market for high-performance metal powders—including Nimonic grades. B2B buyers are turning to Chinese suppliers for several strategic reasons.

Key Advantages of Sourcing from China:

| ベネフィット | 説明 |

|---|---|

| ✅ 競争力のある価格設定 | Lower production and labor costs make Chinese Nimonic powder more affordable without sacrificing quality. |

| 迅速なイノベーション | Chinese companies like Shanghai Truer are investing heavily in R&D and atomization technology. |

| ✅ Flexibility in Customization | Chinese suppliers are more agile in offering tailored compositions, PSDs, and packaging. |

| ✅ Scalable Production | Large-scale production lines ensure availability for high-volume industrial requirements. |

| 輸出経験 | Chinese firms have improved logistics, certifications, and compliance for global trade. |

Why Shanghai Truer Technology Co., Ltd Leads the Way:

Shanghai Truer has positioned itself as a leader in the export of specialty metal powders by focusing on three core pillars:

- Technological Expertise

With a dedicated additive manufacturing division since 2019, Truer combines metallurgical know-how with advanced powder processing. - Diversified Product Range

Besides Nimonic powder, Truer offers a wide range of PM powders, such as PM bronze, PM stainless steel, and PM nickel-based alloys, which you can explore on their PMパウダー製品ページ. - 顧客中心主義

Truer provides end-to-end customer support—from technical consultation to post-sale service—making them a trusted partner for buyers across aerospace, automotive, and energy sectors.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Nimonic Powder Partner

Shanghai Truer Technology Co., Ltd is one of China’s most recognized suppliers of powder metallurgy materials and additive manufacturing powders. For B2B buyers, engineers, and procurement managers, Truer is not just a powder provider—it’s a strategic partner in performance and reliability.

トゥルアーの特徴

| 特徴 | B2Bバイヤーのメリット |

|---|---|

| 完全な垂直統合 | From atomization to packaging—all in-house, ensuring quality control |

| カスタム合金開発 | Tailored Nimonic compositions to meet unique project needs |

| 高度な霧化技術 | Gas and water atomization ensure consistency in particle shape and size |

| グローバル・サプライチェーン | Export-ready with documentation and technical support |

| R&D Support | Work with Truer’s metallurgical team for new applications |

Product Grades Available:

- Nimonic 75

- Nimonic 80A

- ニモニック90

- PE11 / PE16 (Advanced Nimonic variants)

パウダーの特徴

- Particle Sizes: Typically 15–45 μm, 45–105 μm, or customized

- Morphology: Spherical (gas atomized), irregular (water atomized)

- Packaging: 5 kg, 25 kg, 100 kg drums (vacuum-sealed or inert gas-packed)

Truer also offers related additives and lubricants that improve sintering, machinability, and magnetic properties—ideal for component manufacturers looking for a complete solution.

➡️ Learn more about Truer’s company history and mission on their 会社概要のページ.

9. FAQs: Buying Wholesale Nimonic Powder

Here are some of the most frequently asked questions from industrial buyers and procurement teams regarding Nimonic powder sourcing:

Q1: What is the minimum order quantity (MOQ) for Nimonic powder?

A: Shanghai Truer generally offers flexible MOQs starting from 5 kg for sample orders, with bulk pricing available for orders above 100 kg.

Q2: Can Truer customize the particle size distribution (PSD)?

A: Yes. Truer offers tailored PSDs depending on the application—common ranges are 15–45 μm for AM, and 45–150 μm for PM.

Q3: Are Truer’s powders suitable for additive manufacturing?

A: Absolutely. Truer produces gas atomized Nimonic powders with spherical morphology and high purity, ideal for 3D printing.

Q4: What certifications does Truer hold?

A: ISO 9001-certified, Truer ensures strict quality control and provides material certificates (COA, SDS, TDS) with every shipment.

Q5: 卸売りの注文方法は?

A: Simply contact Truer’s sales team with your specifications. A technical consultant will assist with quotes, samples, and logistics.

🌐 Final Recommendations for B2B Buyers

Sourcing Nimonic powder for high-performance applications requires a supplier who can deliver consistency, customization, and technical support. Shanghai Truer Technology Co., Ltd offers:

- A broad portfolio of PM and AM powders

- State-of-the-art atomization processes

- Tailored solutions for aerospace, automotive, and energy industries

- Competitive pricing with global logistics support

To explore the full product line or request a quote, visit their 公式サイト.

🔗 Internal Links Summary for SEO Optimization:

- PMパウダー製品カタログ

- 上海トゥルーアについて

- Truer Contact Page

- Main Website Homepage

- PMパウダー製品カタログ (second mention under product range)

Stay ahead of the curve in advanced materials sourcing—partner with Shanghai Truer for reliable, high-performance Nimonic alloy powders.