1.はじめに現代の製造業で還元鉄粉が重要な理由

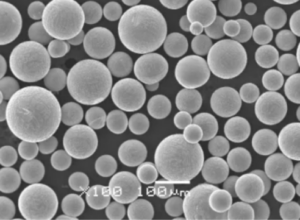

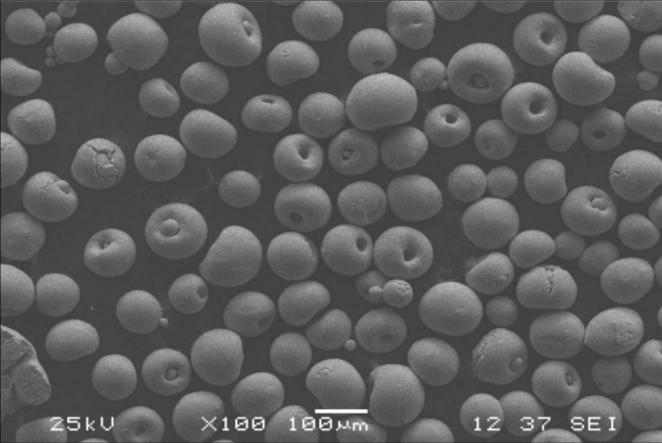

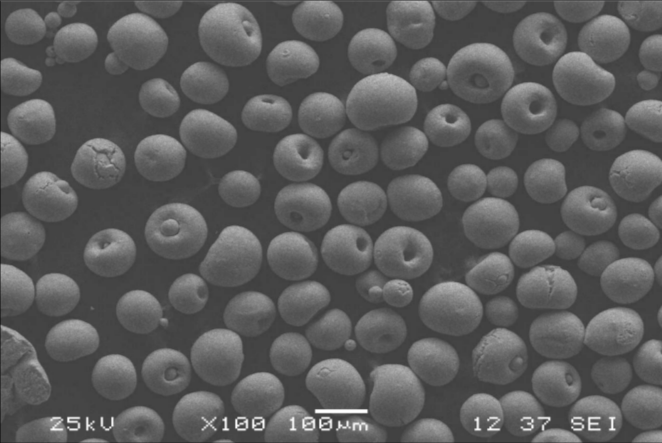

還元鉄粉はスポンジ鉄粉としても知られ、粉末冶金(PM)、磁性材料、溶接電極、摩擦部品、化学触媒など、さまざまな製造分野で重要な原料となっている。還元鉄粉は、鉄酸化物の還元反応によって製造される。 一酸化炭素 を還元剤として使用する。この工程により、非常に多孔質で反応性が高く、純度の高い鉄粉が得られる。

B2Bサプライチェーンや産業用途の文脈では、還元鉄粉はその価値が珍重される:

- 高い純度と一貫性

- 優れた圧縮性

- 優れた焼結挙動

- 低酸素

- 大量生産における費用対効果

これらの特性により、特に高性能のPM部品が必要とされる様々な分野で極めて重要な役割を果たしている。軽量で耐久性があり、コスト効率の高い金属部品に対する世界的な需要が高まるにつれ、還元鉄粉の関連性は高まり続けている。

B2Bのバイヤー、特に自動車、航空宇宙、製造業では、高品質の還元鉄粉を大量に確保するために、信頼できる卸売業者を利用するケースが増えています。適切な供給元を選択することで、安定した性能だけでなく、ISO 4491やMPIFなどの国際規格への準拠も保証されます。

2.還元鉄粉の工業的用途

還元鉄粉は汎用性が高く、多くの産業で使用されている。以下は、B2Bバイヤーとメーカー向けの主な産業用途の内訳です:

| 産業 | アプリケーションエリア | 還元鉄パウダーの利点 |

|---|---|---|

| 粉末冶金 | ギア、ブッシュ、構造部品 | 高い圧縮性、均一な微細構造 |

| 化学工業 | アンモニア合成および水素化反応用触媒 | 高い反応性と表面積 |

| 溶接業界 | 電極の充填材 | 適切な融合と強度を確保 |

| 磁性材料 | エレクトロニクスにおける軟磁性部品 | 低保磁力、高透磁率 |

| 摩擦材 | ブレーキパッド、クラッチプレート | 熱伝導性と強度を高める |

| ダイヤモンド工具 | 切削・研削工具用ボンドマトリックス | 高い硬度と耐久性 |

B2Bバイヤーにとって重要な理由:

- OEMおよびTier-1サプライヤー 自動車やエレクトロニクスの分野では、厳しい公差を満たす鉄粉が必要とされる。

- 化学メーカー 触媒反応のための高い表面活性を持つ鉄粉を求める。

- 流通業者および卸売業者 メーカーから直接調達することでコストを削減できる。

このような多業種の需要により、還元鉄粉は長期的な調達計画を立てるための戦略的材料となっている。

3.主な特性と技術的特徴

還元鉄粉の物理的・化学的特性を理解することは、用途に適した材料を選択する上で非常に重要です。以下は、B2Bバイヤーが評価すべき主要特性の技術比較です:

| プロパティ | 典型的な範囲 | アプリケーションにおける重要性 |

|---|---|---|

| 粒子径(µm) | 20-200 | 流動性、充填性、焼結性に影響する。 |

| 見かけ密度 (g/cm³) | 2.2-3.0 | 金型充填と部品の均一性に影響 |

| 純度(%) | >98.5 | 安定したパフォーマンスを保証 |

| 酸素含有量(%) | 0.5 | 低酸素は焼結性と延性を向上させる |

| 炭素含有量(%) | 0.1 | 冶金学的安定性に不可欠 |

| 圧縮率 (MPa) | 550 | 圧力下での成形性を示す |

| 流量(秒/50g) | 25-35 | プレスの自動給紙には欠かせない |

利用可能な還元鉄粉のグレード

上海泰爾科技股份有限公司は、多様な用途向けに幅広い還元鉄粉グレードを提供しています。グレード例

- F-0000:精密部品のための超高純度

- FD-0200:優れた機械的特性を持つ拡散合金鋼粉

- FD-0208:強度と密度が要求される焼結構造部品用

これらのパウダーは様々な粒度分布があり、均一性と品質を保証するために高度な還元技術を用いて製造されています。

PMパウダーの全製品をご覧になりたい方は、以下をご覧ください。 PMパウダー製品ページ 詳細な仕様とダウンロード可能なデータシートはこちら。

4.世界市場の概要と成長動向

世界の還元鉄粉市場は、粉末冶金、自動車、エレクトロニクス、化学産業など、さまざまな業種からの需要増加に後押しされ、過去10年間で大きな成長を遂げてきた。B2Bバイヤーにとって、市場ダイナミクスを理解することは、長期的な調達とソーシング戦略にとって不可欠です。

世界市場規模&予測

最近の市場調査によると

- 2023年 市場規模:21億米ドル

- カグル(2024-2030年): 5.8%

- 2030年の市場規模予測:32億米ドル

主要市場ドライバー

- 自動車生産台数の増加:EVや低燃費車における焼結部品の需要の増加。

- アディティブ・マニュファクチャリングの拡大:3DプリンティングとPMベースのプロトタイピングの成長。

- 化学業界の需要:還元鉄粉の触媒や浄水システムへの利用。

- 持続可能な製造:鉄粉は、廃棄物の少ない、ネットシェイプに近い製造方法を可能にする。

地域別市場インサイト

| 地域 | 市場シェア(%) | 注目すべきトレンド |

|---|---|---|

| アジア太平洋 | 45% | 中国とインドの主要生産拠点、コスト効率に優れた製造業 |

| 北米 | 25% | 自動車および航空宇宙セクターからの旺盛な需要 |

| ヨーロッパ | 20% | グリーン製造と高性能PM部品に注力 |

| ラテンアメリカ | 5% | 鉱業と重工業による新興市場の可能性 |

| 中東 | 5% | 石油・ガス産業アプリケーションの成長 |

について アジア太平洋地域特に 中国中国は、製造コストの低さ、先進的な還元技術、堅調なPM産業により、圧倒的な生産量を誇っている。このため、国際的な販売業者やOEMにとって、中国からの調達は非常に魅力的なものとなっている。

5.正しい還元鉄粉サプライヤーの選択

安定した品質、適切な文書化、タイムリーな納品を必要とするB2Bバイヤーにとって、信頼できるサプライヤーを選ぶことは非常に重要です。以下は、考慮すべき重要な要素のチェックリストです:

サプライヤー評価の主な検討事項

| 基準 | なぜ重要なのか |

|---|---|

| 製造方法 | 純度、粒子形状、性能に影響 |

| 認証(ISO、MPIF) | 品質と国際コンプライアンスの確保 |

| カスタマイズ・オプション | 粒子径、密度、合金組成を調整する能力 |

| 物流・梱包 | 信頼性の高い輸出梱包とグローバルな出荷能力 |

| テクニカルサポート | アプリケーション・アシスタンスのための研究開発およびエンジニアリング・チームへのアクセス |

| MOQとリードタイム | 少量注文から大量注文まで柔軟に対応 |

サプライヤーへの質問

- 各バッチの分析証明書(COA)を提供してもらえますか?

- 特定の用途向けにカスタムブレンドやプレアロイ粉末を提供していますか?

- リードタイムと輸出能力は?

- 新製品開発のための技術的支援を提供できますか?

上海 Truer Technology Co., Ltd.は、これらの条件をすべて満たし、産業界のバイヤー向けに調整された還元鉄粉および添加剤材料の完全なスイートを提供しています。同社の技術チームは、標準的な粉末冶金と高度な粉末冶金の両方のアプリケーションをサポートするための設備が整っています。

6.アジアの還元鉄粉サプライヤー トップ5

還元鉄粉を大量に調達している場合、これらは製品範囲、輸出能力、業界の評判に基づいて、アジアのトップメーカーとサプライヤーです。

| サプライヤー名 | 国名 | 主な強み |

|---|---|---|

| 上海Truer Technology Co., Ltd | 中国 | 幅広いPMパウダーポートフォリオ、カスタムグレード、強力な研究開発サポート |

| JFEスチール株式会社 | 日本 | 自動車・エレクトロニクス用高純度鉄粉 |

| ホガナスAB(中国子会社) | スウェーデン/中国 | グローバルブランド、高性能パウダー、プレミアム価格 |

| CNPCパウダー | 中国 | 溶接、PM、摩擦コンポーネント用の費用対効果の高いパウダー |

| 建徳新新粉末製造有限公司 | 中国 | 強力な国内プレゼンス、標準的なPMグレード |

そのうちのひとつだ、 上海Truer Technology Co., Ltd は、品質、技術サポート、価格のバランスで際立っている。2009年に設立されたTruerは、2019年に積層造形分野に参入し、以来、高品質の3DプリンティングパウダーとPM材料のサプライヤーとして信頼されている。同社の還元鉄粉は、高度な還元と霧化プロセスを用いて設計されており、さまざまな用途で安定した性能を発揮する。

上海トゥルーアと提携する理由

- 標準グレードとカスタマイズされたパウダーグレードの両方を提供

- 完全なドキュメントと技術データシートを提供

- 競争力のある価格で大量注文をサポート

- 迅速な配達と輸出準備の整った梱包を提供

- 10年にわたるPM革新の経験に裏打ちされたもの

卸売価格についてのお問い合わせやサンプルのご請求は、Truer社までご連絡ください。 お問い合わせページ.

7.中国メーカーを選ぶバイヤーが増えている理由

近年、中国は還元鉄粉の生産と輸出における世界的リーダーとして台頭してきた。グローバル・ディストリビューターからOEMメーカーに至るB2Bバイヤーは、いくつかの戦略的・経済的理由から、中国のサプライヤーにますます目を向けるようになっている。

中国の還元鉄粉サプライヤーの主な利点:

| メリット | 説明 |

|---|---|

| コスト効率 | スケールメリットと人件費削減による競争力のある価格設定 |

| 先進製造業 | 最新の還元・噴霧・混合技術の使用 |

| 幅広い製品レンジ | 様々な産業向けの標準グレードとカスタムグレード |

| 迅速なターンアラウンドと輸出ロジスティクス | 成熟したサプライチェーンとグローバルな出荷能力 |

| 研究開発およびカスタマイズ | お客様のご要望に合わせたオーダーメイドのパウダーを開発する能力 |

ケース・イン・ポイント上海泰爾科技有限公司

上海トゥルーアは、中国のサプライチェーンの強みを体現している。2009年に設立された同社は、中国で最も信頼される粉末冶金サプライヤーのひとつへと発展した。同社は 粉末冶金部門トゥルーアは、還元鉄粉や添加剤を含む包括的な製品群を提供しています:

- PMアイアン

- PMスチール

- PM 銅-スチール (Fe-Cu)

- PMニッケル鋼(Fe-Ni)

- PM浸透鉄

- FD-0208、FL-4605、FN-5000などの拡散合金およびハイブリッド・パウダー

これらのパウダーは、還元法、水アトマイズ法、複合アトマイズ法を用いて製造され、高い純度レベルと安定したバッチ品質を保証している。

グローバルバイヤーからの信頼

トゥルアーの国際的評価は、おかげさまで高まり続けている:

- 輸出対応認証(ISO9001、ROHSなど)

- 英語によるB2Bサポートとドキュメンテーション

- 自動車、エレクトロニクス、化学業界のバイヤーとの長年にわたる関係

地政学的な変化やサプライチェーンの再評価が進む中、多くのグローバル・バイヤーは中国のサプライヤーを単なる低コスト・プロバイダーとしてではなく、戦略的な長期的パートナーとして見ている。

8.上海泰爾科技有限公司を選ぶ理由

B’B2Bのバイヤー、代理店、またはOEMが還元鉄粉の信頼できるソースを探している場合、上海Truer Technology Co.その理由は以下の通りです:

1.フルサービスのPM材料ソリューション

トゥルーアは単なる粉体メーカーではなく、ソリューション・プロバイダーです。その専門知識は多岐にわたります:

- 金属粉製造(鉄、銅、鋼、合金)

- 潤滑剤、切削剤、軟磁性添加剤などの添加材

- 高度なアプリケーションのためのカスタムパウダー処方

2.高度な生産能力

トゥルーアは、還元、水噴霧化、ガス噴霧化の技術を組み合わせて粉体を製造しています:

- 高い圧縮性

- 低酸素

- 均一な粒度分布

- 自動化プロセスのための優れた流動性

3.実績

粉末冶金業界で15年以上、積層造形で5年以上の経験を持つトゥルーアは、この分野で強固な基盤を築いてきた:

- 産業研究開発

- OEMコラボレーション

- 輸出物流

- 規制遵守

4.B2Bにフォーカスしたカスタマーサポート

Truerは、自動車部品製造のための大量ロットでも、プロトタイピングのための少量ロットでも、お客様のご要望にお応えします:

- 迅速な対応

- 多言語サポート

- 技術コンサルティング

- 柔軟なMOQ

プロジェクトのニーズについてご相談ですか?訪問 トゥルアーのコンタクトページ セールス・エンジニアとつながる。

9.よくある質問還元鉄粉のまとめ買いについて

還元鉄粉の調達について、B2Bバイヤーからのよくある質問です:

Q1:還元鉄粉とアトマイズ鉄粉の違いは何ですか?

- 還元鉄粉 は、水素または一酸化炭素を使用して酸化鉄を還元することによって製造され、その結果、多孔質のスポンジ状の粒子が得られる。

- アトマイズ鉄粉 は、溶融した鉄をチャンバー内に噴霧して球状の粒子を形成する。流動性に優れるが、コストが高い。

Q2: 特注の粒子サイズやプレアロイ組成を要求できますか?

上海トゥルーアは、粒度分布、合金組成、流量、圧縮性など、お客様の用途に合わせてカスタマイズしたソリューションを提供します。

Q3: 大量注文のリードタイムはどのくらいですか?

リードタイムは数量とカスタマイズの要件によって異なります。標準的な大量注文の場合、多くの場合 7~10 営業日以内に出荷できます。Truerでは、各見積もりに詳細な納期を記載しています。

Q4: どのようなパッケージ・オプションがありますか?

トゥルーアは、輸出グレードのパッケージングを提供しています:

- 25kg 真空パック

- 1トンバルクコンテナ

- 湿気バリア付きパレット積み貨物

Q5: 大量注文の前にサンプルは入手できますか?

Truerでは、テストおよび検証用にサンプル量を提供しています。営業チームへのお問い合わせは 会社ウェブサイト をクリックして、サンプルとデータシートをご請求ください。

埋め込み内部リンクの概要

以下は、シームレスなナビゲーションのために記事に埋め込まれた内部リンクである:

- PMパウダー製品ページ - パウダー・グレードと仕様の詳細

- Truerについて - 会社の背景と能力

- お問い合わせページ - お問い合わせ・ご注文

- ホームページ - 製品とサービスの概要

- PMパウダー製品ページ - 利用可能なグレードを強調するために再利用

この調達ガイドに従って、上海Truer Technologyのような信頼できるメーカーを検討することで、B2Bバイヤーは産業ニーズに合わせた高品質の還元鉄粉を確保することができます。世界的な競争力、卓越した技術力、信頼できるサポートにより、Truerは世界のPM業界において一流のサプライヤーとして際立っています。