概要 FeCoNiCrMo-1粉末

FeCoNiCrMo-1粉末は、その卓越した機械的特性、耐食性、構造安定性により、先端製造業や材料科学の分野で支持を得ている高エントロピー合金(HEA)です。FeCoNiCrMo-1のようなHEAは、構成元素の割合がほぼ等モルであることが特徴であり、従来の合金と比較してユニークな特性を有しています。

なぜこの粉が重要なのか?FeCoNiCrMo-1粉末は、靭性、柔軟性、耐性を兼ね備えた金属粉末のスーパーヒーローです。先進的な製造方法を模索している場合でも、過酷な条件下での構造性能を向上させたいと考えている場合でも、FeCoNiCrMo-1粉末は最適なソリューションとなるでしょう。

FeCoNiCrMo-1粉末の組成

FeCoNiCrMo-1粉末の組成は、従来の金属合金とは一線を画しています。鉄(Fe)、コバルト(Co)、ニッケル(Ni)、クロム(Cr)、モリブデン(Mo)の5つの中心元素がほぼ等しい比率で混合されており、優れた性能を保証する。

| エレメント | 組成(概算) | 合金での役割 |

|---|---|---|

| 鉄(Fe) | ~20% | 合金マトリックスを強化する。 |

| コバルト | ~20% | 耐摩耗性を高める。 |

| ニッケル(Ni) | ~20% | 延性と靭性を向上させる。 |

| クロム(Cr) | ~20% | 耐食性を高める。 |

| モリブデン (Mo) | ~20% | 優れた硬度と耐クリープ性を持つ。 |

FeCoNiCrMo-1粉末の特性

FeCoNiCrMo-1粉末は、様々な用途に汎用的に使用できる一連の特性を誇っています:

- 並外れた強さとタフネス: マルチエレメント設計により、この粉末は驚くべき強度対重量比を示し、航空宇宙および防衛用途に適している。

- 耐食性: クロムとモリブデンは、腐食性の高い環境での耐性に貢献している。

- 熱安定性: その組成は、高温でも低温でも安定性を保証する。

- 耐摩耗性: コバルトは、時間の経過とともに機械的摩耗に耐える能力を強化する。

- カスタマイズ可能な微細構造: 3Dプリンティングやその他の積層造形技術に適している。

応用例 FeCoNiCrMo-1粉末

その素晴らしい特性のおかげで、FeCoNiCrMo-1粉末は多くの産業で使用されています。簡単に紹介しよう:

| 産業 | 用途 |

|---|---|

| 航空宇宙 | タービンブレード、構造部品、ヒートシールド |

| 自動車 | 高性能エンジン部品、耐摩耗ギア |

| メディカル | 補綴物、歯科インプラント、手術器具 |

| ディフェンス | 装甲板、ミサイル部品 |

| エネルギー | 原子炉部品、海洋掘削リグ |

| 付加製造 | 高精度が要求される3Dプリント部品 |

FeCoNiCrMo系粉末の特定モデル

ここでは、FeCoNiCrMo系粉末の注目すべきモデルを、その特徴とともに紹介する:

1. FeCoNiCrMo-1スタンダード

- 説明 強度、耐食性、熱安定性のバランスが取れたベースライン・パウダー。

- 最適: 一般産業用途および研究目的。

2.FeCoNiCrMo-1 HTP

- 説明 過酷な熱条件下での使用に最適化された高温性能バリアント。

- 最適: 航空宇宙およびエネルギー産業。

3.FeCoNiCrMo-1 XR

- 説明 モリブデン含有量の増加により、耐摩耗性と耐腐食性が向上。

- 最適: 海洋およびオフショア用途。

4.FeCoNiCrMo-1フレックス

- 説明 強度を損なうことなく、柔軟性と延性を重視。

- 最適: 医療用インプラントと補綴物

5.FeCoNiCrMo-1ナノ

- 説明 高度な3Dプリンティング精度を実現するナノスケールの粉末粒子。

- 最適: エレクトロニクスと航空宇宙における積層造形。

6.FeCoNiCrMo-1 AM

- 説明 アディティブ・マニュファクチャリング用に特別に設計され、優れた印刷適性を提供する。

- 最適: ラピッドプロトタイピング。

7.FeCoNiCrMo-1 ウルトラ

- 説明 超高耐食性が特徴。

- 最適: 化学処理装置

8.FeCoNiCrMo-1 HP

- 説明 コバルト含有量を増やし、耐摩耗性を向上させた高性能タイプ。

- 最適: 高負荷の機械部品。

9.FeCoNiCrMo-1ライト

- 説明 密度を落とした軽量バージョン。

- 最適: 航空宇宙および自動車の重量に敏感な部品。

10.FeCoNiCrMo-1バイオ

- 説明 医療用に設計された生体適合性パウダー。

- 最適: 外科用インプラントと歯科用アプリケーション。

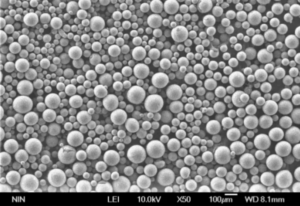

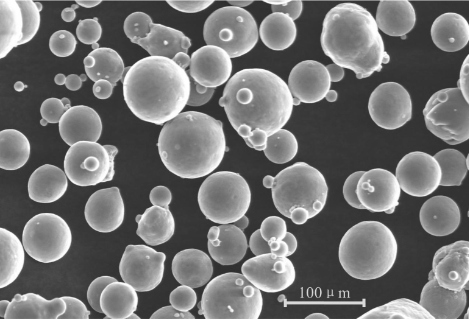

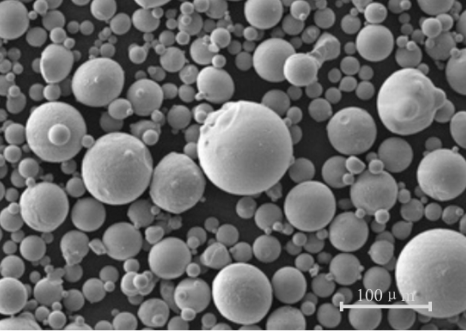

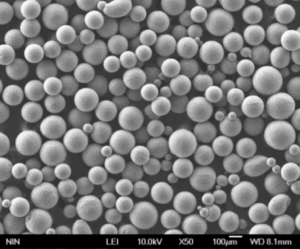

仕様 FeCoNiCrMo-1粉末

| 仕様 | 詳細 |

|---|---|

| 粒子サイズ | 10~45μm(カスタマイズ可能) |

| 密度 | ~7.8 g/cm³ |

| 融点 | ~1300-1400°C |

| 硬度 | 300-400 HV |

| 規格 | ASMB212、ISO9001 |

| 梱包オプション | 1キロ、5キロ、10キロ |

サプライヤーと価格情報

| サプライヤー | 地域 | 価格(USD/kg) | 備考 |

|---|---|---|---|

| アドバンスド・アロイズ社 | 北米 | $150-$180 | 一括割引を提供。 |

| 株式会社メタルワークス | ヨーロッパ | $140-$170 | カスタム・コンポジションも可能。 |

| アジアアロイ社 | アジア太平洋 | $120-$160 | 競争力のある価格設定。 |

| グローバル金属トレーダー | ワールドワイド | $130-$175 | 世界中に迅速に発送。 |

のメリットとデメリット FeCoNiCrMo-1粉末

| メリット | デメリット |

|---|---|

| 優れた耐食性と耐摩耗性。 | 従来の合金に比べてイニシャルコストが高い。 |

| 極端な温度でも優れた性能を発揮。 | 地域によっては入手できない。 |

| 多様な用途に対応。 | 加工には専用の装置が必要。 |

| 高い安定性と耐久性。 | 複数の要素による複雑なリサイクルプロセス。 |

よくある質問

| 質問 | 回答 |

|---|---|

| FeCoNiCrMo-1粉末は何に使用されますか? | 航空宇宙、自動車、医療、エネルギー、3Dプリンティング。 |

| FeCoNiCrMo-1は鋼よりも優れているのですか? | 耐食性、耐摩耗性、温度安定性に優れている。 |

| 3Dプリントは可能ですか? | はい、多くのモデルは積層造形に最適化されています。 |

| 高いですか? | 従来の合金よりも高価だが、優れた特性を発揮する。 |

| 主要サプライヤーは? | Advanced Alloys Inc.、MetalWorks Co. |