先端素材の世界では、 NiTi50(ニチノール)粉末 は、そのユニークな特性で際立っている。形状記憶効果や超弾性について聞いたことがあるかもしれないが、この粉末はそれらの特徴をはるかに超えている。では、NiTi50が航空宇宙、医療機器、ロボット工学などの産業でゲームチェンジャーとなるのはなぜか?その詳細に飛び込もう。

NiTi50(ニチノール)粉末の概要

NiTi50ニッケル・チタン合金の粉末で、一般的には次のように知られている。 ニチノール.それは 形状記憶合金(SMA)つまり、変形しても元の形状を記憶し、熱にさらされると元の形状に戻る。この特性により、ニチノールは、永久的な損傷を与えることなく大きな変形を受けることができる材料を必要とする用途において、非常に貴重な存在となっている。

しかし、それだけではない!ニチノールはまた 超弾性つまり、永久変形することなく大きなひずみを回復することができ、他の金属に比べて非常に弾力性に富んでいる。さらに、耐腐食性、生体適合性、優れた疲労寿命といった要素もあり、以下のような分野で高い人気を誇っている。 生体医工学、航空宇宙、ロボット工学.

NiTi50(ニチノール)粉末の組成

では、具体的な話をしよう。 NiTi50粉末 は主に以下から成る。 ニッケル そして チタンこの2つの元素は、ほぼ等しい原子割合(Ni50%、Ti50%)を持つ。この2つの元素が組み合わさって、並外れた特性を持つ金属合金が形成される。

典型的な構成の内訳は以下の通り:

| エレメント | パーセント(%) |

|---|---|

| ニッケル(Ni) | 50 ± 1 |

| チタン(Ti) | 50 ± 1 |

| その他の不純物 | 0.2 |

少量の不純物は製造工程によって異なるが、一般的にパウダーの高純度と効果を維持するために最小限に抑えられている。

の特徴 NiTi50(ニチノール)パウダー

NiTi50粉末の特徴を語るとき、他の素材と何が違うのかに注目することが不可欠である。

主な特徴

- 形状記憶効果(SME): NiTi50は変形後、ある温度以上に加熱すると元の形状に戻る。

- 超弾性: この素材は、熱を必要とせず、ほとんど瞬時に大きな変形を回復させることができる。そのため、耐久性と柔軟性に優れ、ダイナミックな用途に最適です。

- 生体適合性: NiTi50は生体適合性が高いため、ステントや整形外科用インプラントなどの医療機器に広く使われている。

- 耐食性: チタン含有により、NiTi50は体液や航空宇宙環境などの過酷な環境下でも腐食に強い。

- 疲労寿命: NiTi50は数百万回の変形サイクルに耐えることができるため、長期間の使用にも高い信頼性を発揮する。

詳細特性表:

| 特徴 | 説明 |

|---|---|

| 密度 | 6.45 g/cm³ |

| 融点 | 1240 – 1310°C |

| 変形温度 | Ni-Ti比による(通常-50℃~100) |

| 弾性係数 | 28-41 GPa (オーステナイト相) |

| 熱伝導率 | 18 W/m-K |

| 電気抵抗率 | 82-100 µΩ-cm |

| 硬度 | 180-300 HV(ビッカース硬度) |

| 形状回復ストレイン | 最大8 |

NiTi50(ニチノール)粉末トップ10モデル

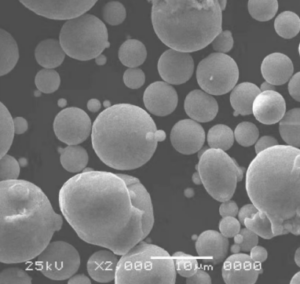

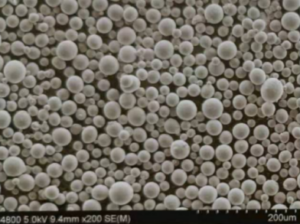

NiTi50粉末にはいくつかのバリエーションがあり、それぞれが特定の用途に合わせて調整されている。以下は、市場で入手可能な最も一般的なモデルの一部である。 粒子径, 純度そして 使用目的.

1.NiTi50 P1 – 医用グレード

- 純粋さ: 99.9%

- 粒子径: 15-53 µm

- アプリケーション ステントや整形外科用スクリューなどの医療用インプラントの3Dプリントに最適。

2.NiTi50 P2 – 航空宇宙グレード

- 純粋さ: 99.8%

- 粒子径: 20-63 µm

- アプリケーション アクチュエーターやスプリングなどの航空宇宙部品に適している。

3.NiTi50 P3 –ファインパウダー

- 純粋さ: 99.95%

- 粒子径: 5-25 µm

- アプリケーション 複雑な3Dプリンティング用途やマイクロデバイス製造に最適。

4.NiTi50 P4 – 超弾性グレード

- 純粋さ: 99.85%

- 粒子径: 45-105 µm

- アプリケーション ロボット工学やオートメーションなど、高い弾力性が要求される用途に使用される。

5.NiTi50 P5 – 超高純度

- 純粋さ: 99.99%

- 粒子径: 10-50 µm

- アプリケーション 血管ステントなど、高精度の医療用途に不可欠。

6.NiTi50 P6 – 高温グレード

- 純粋さ: 99.8%

- 粒子径: 25-75 µm

- アプリケーション ジェットエンジンのような高温にさらされる環境用に設計されている。

7.NiTi50 P7 – 低変態温度

- 純粋さ: 99.9%

- 粒子径: 30~60 µm

- アプリケーション 低温変成が必要な極低温用途に使用される。

8.アクチュエータ用粉末 NiTi50 P8 –

- 純粋さ: 99.8%

- 粒子径: 20-60 µm

- アプリケーション 自動車システムの精密アクチュエーターや形状記憶部品に最適。

9.NiTi50 P9 –積層造形グレード

- 純粋さ: 99.85%

- 粒子径: 20-70 µm

- アプリケーション アディティブ・マニュファクチャリングおよび金属3Dプリンティング用途に最適化されている。

10.NiTi50 P10 – 耐食性

- 純粋さ: 99.9%

- 粒子径: 15-50 µm

- アプリケーション 海洋工学や化学処理のような腐食環境での用途に最適。

応用例 NiTi50(ニチノール)パウダー

NiTi50粉末は汎用性が高いため、さまざまな産業で使用されている。その用途を探ってみよう:

| 産業 | 申し込み |

|---|---|

| 医療機器 | ステント、ガイドワイヤー、整形外科用インプラント、手術器具 |

| 航空宇宙 | アクチュエータ、温度に敏感なファスナー、振動減衰部品 |

| ロボット工学 | 形状記憶アクチュエータ、フレキシブルジョイント、グリッパー |

| 自動車 | エンジン部品、温度調節システム、センサー |

| コンシューマー・エレクトロニクス | フレキシブルフォンフレーム、アンテナ、ヘッドフォン |

| 海洋工学 | 耐腐食性部品、フレキシブル水中装置 |

| 建設 | 耐震構造、スマートセンサー |

仕様、サイズ、グレード

ここでは、NiTi50粉末の標準仕様と利用可能な等級を簡単に見てみましょう:

| 仕様 | グレード/タイプ | 粒子径範囲 (μm) | 申し込み |

|---|---|---|---|

| ASTM F2063 | メディカルグレード | 15-53 µm | バイオメディカル |

| AMS 5382 | 航空宇宙グレード | 20-63 µm | 航空宇宙 |

| ASTM B348 | 工業用グレード | 25-75 µm | インダストリアル |

| ASTM F2516 | 超弾性グレード | 45-105 µm | ロボット工学 |

| アストマ F2063/ISO 5832-11 | 付加製造 | 20-70 µm | 3Dプリンティング |

サプライヤーと価格

価格は、購入するモデル、純度、数量によって異なります。以下は、主要サプライヤーに基づく典型的な価格設定の詳細です:

| サプライヤー | モデル | 価格(kgあたり) | 最小注文数量 | リードタイム |

|---|---|---|---|---|

| ABCマテリアル | NiTi50 P1 | $850 | 5 kg | 2週間 |

| XYZメタルズ | NiTi50 P2 | $800 | 10キロ | 3週間 |

| プレミアムパウダー株式会社 | NiTi50 P3 | $950 | 2 kg | 1週間 |

| ニチノールサプライ | NiTi50 P4 | $920 | 8キロ | 2週間 |

| アドバンスド・メタルワークス | NiTi50 P5 | $970 | 1 kg | 4週間 |

の利点 NiTi50(ニチノール)パウダー

NiTi50がさまざまな業界で人気を博しているのには理由がある。

.

- 耐久性がある: NiTi50は超弾性特性を持ち、変形しにくいため、従来の金属よりも耐久性がある。

- 汎用性がある: NiTi50は、そのユニークな特性により、医療機器から航空宇宙まで、さまざまな分野で応用されている。

- 生体適合性: 人体内で使用しても副作用がなく、安全に使用できる数少ない金属のひとつ。

- 耐食性: このパウダーは過酷な環境でも性能を発揮するため、長期にわたって信頼できる。

利点と限界:

| メリット | 制限事項 |

|---|---|

| 形状記憶と超弾性 | 高い材料費 |

| 耐食性と耐疲労性 | 機械加工が難しい |

| 生体適合性 | 変換温度範囲の制限 |

| 動的アプリケーションにおける高い回復力 | 特定の環境条件(熱)を必要とする |

よくある質問

| 質問 | 回答 |

|---|---|

| NiTi50粉末は何に使われるのですか? | NiTi50は、医療機器、航空宇宙部品、ロボット工学、自動車部品、家電製品などに使用されている。 |

| NiTi50の特徴は? | その形状記憶効果と超弾性は、他の合金と比較してユニークなものである。 |

| NiTi50は生体適合性がありますか? | はい、NiTi50は生体適合性が高く、バイオメディカル用途に広く使用されています。 |

| NiTi50粉末の価格は? | 価格は様々だが、NiTi50は一般的に従来の金属よりも高価で、1kgあたり800ドルから970ドルである。 |

| NiTi50粉末はどのような産業で最も使用されていますか? | 医療、航空宇宙、ロボット産業がNiTi50粉末の最大のユーザーである。 |

結論

結論として NiTi50(ニチノール)粉末 は、さまざまな高度な用途に適したユニークな特性を持つ驚くべき材料です。生命を救う医療機器や最先端の航空宇宙技術に使用されるにせよ、NiTi50は、他の材料にはほとんどない多様性と性能を提供します。

その組み合わせは 形状記憶性、超弾性、耐食性、生体適合性 は、今後もさまざまな分野で価値ある材料であり続けるだろう。しかし、コストが高く、特殊な加工が必要なため、これらの特性が本当に必要なハイエンドの用途に限定されるかもしれない。

次のプロジェクトでNiTi50粉末の使用を検討している場合は、その利点と限界を比較検討し、適切かどうかを判断してください。この材料の可能性は非常に大きいが、そのコストと特殊な取り扱い要件から、特殊で高性能な用途に最も適している。