概要

アトマイズ後の治療 金属粉末の製造は、航空宇宙から医療機器に至るまで、様々な産業の製造プロセスにおいて極めて重要である。この処理によって金属粉末の特性が向上し、特定の用途により適したものとなる。この処理には通常、粒度分布、形態、化学組成を改善するためのアニール、ふるい分け、表面改質などの工程が含まれる。

アトマイズ後の治療とは?

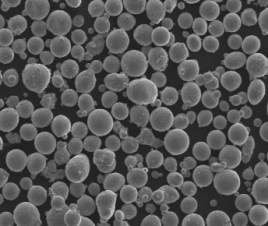

アトマイズ後処理とは、アトマイズによって製造された後の金属粉末に適用される様々な方法を指す。アトマイズは、溶融金属を微細な液滴に分解し、凝固させて粉末粒子にするプロセスである。アトマイズ後の処理は、粉末の特性を高め、一貫性を確保し、最終用途での性能を向上させるために不可欠です。

金属粉末の種類と組成

金属粉には様々な種類があり、それぞれ特定の用途に合わせたユニークな組成と特性を持っています。ここでは、最も一般的に使用される金属粉末とその組成をご紹介します:

| 金属粉 | 構成 | プロパティ |

|---|---|---|

| ステンレススチール316L | Fe、Cr、Ni、Mo | 耐食性、高張力 |

| チタン Ti6Al4V | Ti、Al、V | 高い強度対重量比、耐食性 |

| アルミニウム6061 | Al、Mg、Si | 軽量、優れた機械的特性 |

| コバルト・クロム合金 | Co、Cr、Mo | 高い耐摩耗性、優れた生体適合性 |

| ニッケル合金625 | Ni、Cr、Mo、Nb | 高強度、優れた耐食性 |

| マルエージング鋼 18Ni300 | Fe、Ni、Co、Mo | 高強度、優れた靭性 |

| 銅合金 C18150 | Cu、Cr、Zr | 高い導電性、優れた耐摩耗性 |

| 炭化タングステン | WC、Co | 極めて高い硬度、耐摩耗性 |

| Inconel 718 | Ni、Cr、Fe、Nb、Mo | 高強度、良好な耐酸化性 |

| 青銅合金 CuSn12 | 銅、錫 | 良好な耐食性、優れた加工性 |

後処理用パウダーの特徴

ポストアトマイズ処理は、金属粉末の様々な特性を向上させるために設計されています。ここでは、いくつかの重要な特性を見てみましょう:

| 特徴 | 説明 |

|---|---|

| 粒度分布 | 均一性を確保し、流動性と充填密度に影響を与える。 |

| 形態学 | 流れやパッキングに影響を与える球状や不規則な形状 |

| 表面積 | 反応性と焼結挙動に影響 |

| 純度 | 高純度レベルが汚染リスクを低減 |

| 流動性 | 取り扱いや加工のしやすさに影響 |

| 見かけ密度 | パッキングと焼結効率に影響 |

| 酸化レベル | より低い酸化が高温用途での性能を高める |

パウダーの用途 アトマイズ後の治療

ポストアトマイズ金属粉末の強化された特性は、幅広い用途に適している:

| 申し込み | 説明 |

|---|---|

| 航空宇宙 | 高強度、軽量コンポーネント |

| 自動車 | エンジン部品、トランスミッション部品 |

| 医療機器 | インプラント、手術器具 |

| エネルギー部門 | タービンブレード、燃料電池 |

| エレクトロニクス | 導電性インク、熱管理 |

| 工具 | 切削工具、金型 |

| アディティブ・マニュファクチャリング(3Dプリンティング) | カスタム、複雑形状、プロトタイピング |

仕様、サイズ、等級、規格

アトマイズ後処理用の金属粉末を選択する際には、仕様、サイズ、グレード、規格を考慮することが重要です。参考までに詳細な表を示します:

| パウダータイプ | サイズ範囲 (µm) | グレード | 規格 |

|---|---|---|---|

| ステンレススチール316L | 15-45, 45-105 | AISI 316L | ASM276、AMS5653 |

| チタン Ti6Al4V | 15-45, 45-90 | グレード5 | ASMB348、AMS4928 |

| アルミニウム6061 | 20-63, 63-125 | AA 6061 | アストマムB209、アムス4027 |

| コバルト・クロム合金 | 10-45, 45-90 | ASTM F75 | ISO 5832-4 |

| ニッケル合金625 | 15-53, 53-150 | UNS N06625 | ASMB446、AMS5666 |

| マルエージング鋼 18Ni300 | 10-45, 45-105 | グレード300 | AMS6514、ASM538 |

| 銅合金 C18150 | 20-53, 53-150 | UNS C18150 | ASTM B606、RWMAクラス2 |

| 炭化タングステン | 5-15, 15-45 | ISO9001認証取得 | ISO 9001、ASM B777 |

| Inconel 718 | 15-45, 45-105 | UNS N07718 | ASMB637、AMS5662 |

| 青銅合金 CuSn12 | 20-63, 63-150 | UNS C90700 | ASMB505、AMS4880 |

サプライヤーと価格詳細

高品質の金属粉末を入手するには、適切なサプライヤーを選ぶことが重要です。ここでは、いくつかのサプライヤーとその価格詳細を見てみよう:

| サプライヤー | 所在地 | 金属粉 | 価格(USD/kg) |

|---|---|---|---|

| ヘガネスAB | スウェーデン | ステンレススチール316L | $50 – $70 |

| LPWテクノロジー | 英国 | チタン Ti6Al4V | $300 – $400 |

| カーペンター・テクノロジー | アメリカ | アルミニウム6061 | $25 – $40 |

| アルカムAB(GEアディティブ) | スウェーデン | コバルト・クロム合金 | $250 – $350 |

| サンドビック | スウェーデン | ニッケル合金625 | $100 – $150 |

| GKNホエガネス | アメリカ | マルエージング鋼 18Ni300 | $150 – $200 |

| アメテック・スペシャリティ・メタル | アメリカ | 銅合金 C18150 | $30 – $50 |

| ケナメタル | アメリカ | 炭化タングステン | $70 – $90 |

| 金属粉末とプロセス | アメリカ | Inconel 718 | $200 – $250 |

| 金属粉末の製造 | 英国 | 青銅合金 CuSn12 | $20 – $35 |

後処理用パウダーの長所と短所

どの金属粉にもそれぞれの利点と限界がある。ここではその比較を見てみよう:

| 金属粉 | メリット | 制限事項 |

|---|---|---|

| ステンレススチール316L | 耐食性、高強度 | 他の鋼鉄に比べ高コスト |

| チタン Ti6Al4V | 軽量、高強度 | 高価で加工が難しい |

| アルミニウム6061 | 軽量、優れた機械的特性 | 鋼鉄に比べて強度が低い |

| コバルト・クロム合金 | 高い耐摩耗性、生体適合性 | 高価、機械加工が難しい |

| ニッケル合金625 | 優れた耐食性、高強度 | 高価、高密度 |

| マルエージング鋼 18Ni300 | 高強度、優れた靭性 | 高価、熱処理が必要 |

| 銅合金 C18150 | 高導電性、耐摩耗性 | 酸化しやすく、鋼鉄より強度が低い。 |

| 炭化タングステン | 非常に硬く、耐摩耗性 | 脆い、高価 |

| Inconel 718 | 高強度、良好な耐酸化性 | 高価、機械加工が難しい |

| 青銅合金 CuSn12 | 良好な耐食性、機械加工可能 | 他の合金に比べて強度が低い |

後処理用パウダーの利点

ポストアトマイズ処理には、金属粉末の品質と性能を向上させる数多くの利点があります。ここでは、その利点について詳しくご紹介します:

粒度分布の向上

ふるい分けや分級といったアトマイズ後の処理は、均一な粒度分布の達成に役立つ。これは、積層造形や粉末冶金などの用途で安定した性能を発揮するために極めて重要である。

改良されたモルフォロジー

アニールや熱処理などの処理は、粉末粒子の形態を改善し、より球状にすることができる。球状の粒子は流動性がよく、より効率的に充填され、より高品質の完成品となる。

汚染の低減

コンタミネーションを最小限に抑えた高純度パウダーは、医療機器や航空宇宙部品などの用途に不可欠です。アトマイズ後の処理により、粉体は厳しい純度要件を満たすことができます。

最適化された流動性

良好な流動性は、3Dプリンティングや金属射出成形のようなプロセスにとって非常に重要である。

アトマイズ後の処理は、粉体の流動特性を向上させ、スムーズで信頼性の高い処理を保証します。

制御された酸化レベル

金属粉末の酸化レベルを制御することは、高温用途に不可欠です。アトマイズ後の処理は酸化を抑制し、最終製品の性能と寿命を向上させます。

粉末の規格、サイズ、等級、基準 アトマイズ後の治療

適切な金属粉末を選択するには、さまざまな仕様、サイズ、等級、規格を考慮する必要があります。以下はその詳細な内訳である:

| 金属粉 | サイズ範囲 (µm) | グレード | 規格 |

|---|---|---|---|

| ステンレススチール316L | 15-45, 45-105 | AISI 316L | ASM276、AMS5653 |

| チタン Ti6Al4V | 15-45, 45-90 | グレード5 | ASMB348、AMS4928 |

| アルミニウム6061 | 20-63, 63-125 | AA 6061 | アストマムB209、アムス4027 |

| コバルト・クロム合金 | 10-45, 45-90 | ASTM F75 | ISO 5832-4 |

| ニッケル合金625 | 15-53, 53-150 | UNS N06625 | ASMB446、AMS5666 |

| マルエージング鋼 18Ni300 | 10-45, 45-105 | グレード300 | AMS6514、ASM538 |

| 銅合金 C18150 | 20-53, 53-150 | UNS C18150 | ASTM B606、RWMAクラス2 |

| 炭化タングステン | 5-15, 15-45 | ISO9001認証取得 | ISO 9001、ASM B777 |

| Inconel 718 | 15-45, 45-105 | UNS N07718 | ASMB637、AMS5662 |

| 青銅合金 CuSn12 | 20-63, 63-150 | UNS C90700 | ASMB505、AMS4880 |

比較分析:アトマイズ後処理用パウダーの種類

それでは、さまざまな金属粉の詳細な比較を掘り下げてみよう:

ステンレス鋼316LとチタンTi6Al4Vの比較

ステンレススチール316L はその耐食性と強度で知られている。しかし チタン Ti6Al4V は軽量で強度対重量比が高いため、重量が重要な要素となる航空宇宙用途や医療用途に最適である。

アルミニウム6061対コバルト・クロム合金

アルミニウム6061 の耐摩耗性や生体適合性には及ばない。 コバルト・クロム合金これは医療用インプラントや歯科用途に好まれる。

ニッケル合金625とマルエージング鋼18Ni300の比較

ニッケル合金625 は耐酸化性に優れているため、高温や腐食性の環境に適している。一方 マルエージング鋼 18Ni300 は卓越した強度と靭性を備えており、工具や構造用途に適している。

銅合金C18150と超硬合金の比較

銅合金 C18150 は導電性と耐摩耗性に優れ、電気接点に最適である。これに対して 炭化タングステン は、比類のない硬度と耐摩耗性を誇り、切削工具や摩耗部品に最適です。

インコネル718と青銅合金CuSn12の比較

Inconel 718 は、高い強度と過酷な環境下での優れた耐酸化性から好まれている。 青銅合金 CuSn12機械加工性と耐食性に優れ、ベアリングやブッシュによく使用される。

専門家の意見と研究

研究や専門家の意見は、金属粉末の所望の特性を達成する上で、アトマイズ後の処理の重要性を補強している。研究によると、最適化された粒度分布とモルフォロジーは、積層造形やその他の用途における粉末の性能に大きく影響する。

例えば、米国材料試験協会(ASTM)の研究では、3Dプリント部品の気孔率を低減し機械的特性を向上させる上で、アトマイズ後の処理が果たす役割を強調しています。同様に、金属粉末工業連盟(MPIF)の専門家は、航空宇宙や医療機器などの重要な用途における高純度粉末の必要性を強調しています。

よくある質問

| 質問 | 回答 |

|---|---|

| アトマイズ後の治療とは? | アトマイズ後の処理とは、アトマイズ後の金属粉末の特性を向上させるために、アニール、ふるい分け、表面改質などの処理を施すことを指す。 |

| なぜ粒度分布が重要なのか? | 均一な粒度分布は、3Dプリンティングや粉末冶金などの様々な用途において、安定した流動性、充填密度、総合的な性能を保証します。 |

| 球状粉末の利点は何ですか? | 球状のパウダーは、不規則な形状のパウダーに比べ、流動性が良く、より効率的に充填され、最終製品の品質が高くなります。 |

| アトマイズ後の処理はどのように汚染を減らすのですか? | ふるい分けや熱処理などの処理により、不純物や汚染物質を除去し、重要な用途に適した高純度の粉末を確保します。 |

| 航空宇宙用途に最適な金属粉末は? | チタンTi6Al4Vは、その高い強度対重量比と優れた耐食性で好まれ、航空宇宙部品に最適です。 |

| ニッケル合金625を使用する主な利点は何ですか? | ニッケル合金625は、特に高温で腐食性の高い環境において、高い強度と優れた耐食性を発揮します。 |

| 金属粉末の流動性はどのようにして向上するのか? | ふるい分けやアニールなどのアトマイズ後の処理は、粉体の流動特性を改善し、取り扱いや加工を容易にする。 |

| 金属粉の酸化レベルはどのような意味を持つのか? | 酸化レベルが低いことは、最終製品の性能と寿命を向上させるため、高温用途にとって極めて重要である。 |

| アトマイズ後の処理は機械的特性を改善できるか? | そう、焼きなましや熱処理のような処理は、金属粉末の機械的特性を向上させ、特定の用途により適したものにすることができる。 |

| 医療用インプラントに最適な金属粉末は? | コバルトクロム合金は、その高い耐摩耗性と優れた生体適合性により、医療用インプラントに一般的に使用されている。 |