銅合金粉 とは、銅と他の合金元素の組み合わせから作られる粉末のことで、特殊な特性を持つ材料を製造するためのものです。この粉末は、プレスや焼結のような粉末冶金技術や積層造形技術によって高性能の部品を製造するのに使われます。

銅合金粉末の概要

銅合金は、強度、導電性、耐食性、機械加工性、その他の特性を非常によく兼ね備えているため、最も広く使わ れているエンジニアリング・マテリアルのひとつです。銅に亜鉛、錫、ニッケル、シリコン、アルミニウムなどの合金元素を混ぜ合わせることで、特定の用途に合わせて特性を細かく調整した様々なブレンドが生まれます。

粉末冶金は、自動車、電気、電子、産業機械などの産業で使われる複雑な部品に成形し、焼結することができる微細な銅合金の粉末を利用します。粉末冶金では凝固速度が速いため、混じり合わない元素を混ぜ合わせることができ、インゴット冶金では不可能なユニークな微細構造を形成することができます。

銅合金粉が好まれる理由には次のようなものがある:

- 混合粉体における化学組成の優れた制御

- 急冷凝固による微細構造の精密化

- 多孔質で密度制御された部品の製造能力

- 複雑な形状を製造するためのシンプルな加工

- インゴット鋳造時によく見られる偏析の防止

- 材料、エネルギー、労働力の削減による大幅なコスト削減

先進的な積層造形では、最新の金属粉末を使用して、従来の方法を上回る微細な粒径と機械的特性を持つ高度な部品を3Dプリントする。

銅合金粉末の種類

銅は、様々な用途に適した材料を作るために、様々な元素と合金化することができます。一般的な粉末には以下のようなものがあります:

| タイプ | 構成 |

|---|---|

| 真鍮 | 銅-亜鉛(Cu-Zn) |

| ブロンズ | 銅錫(Cu-Sn) |

| キュプロニッケル | 銅-ニッケル(Cu-Ni) |

| 銅-鉄 | 銅鉄(Cu-Fe) |

| 銅ベリリウム | 銅ベリリウム(Cu-Be) |

これらのベースパウダーは、特性を向上させるために、クロム、シリコン、コバルトなどの他の元素を少量添加することでさらに改良することができる。組成は、強度、耐食性、耐摩耗性、熱特性、摩擦、潤滑性などの特性に直接影響します。粉末サプライヤーはしばしば、用途に特化した配合でオンデマンドのカスタマイズ合金を開発する。

の特徴 銅合金粉末

銅合金は、物理的・化学的特性の魅力的な組み合わせを示し、工業部品やコンポーネントに有用です。特筆すべき特性は以下の通りです:

| プロパティ | 特徴 |

|---|---|

| 強さ | 黄銅や青銅のような銅合金は、1200MPaを超える引張強度を達成することができます。 |

| 導電率 | 電気伝導率と熱伝導率は純銅より低いが、鉄の代替品よりはかなり高い。 |

| 耐食性 | 不動態化処理により、水分、酸など様々な環境下で優れた耐食性を発揮。 |

| 加工性 | 鉛青銅のような快削銅合金は、鋼よりも加工しやすい。 |

| 耐摩耗性 | 銅-コバルトや銅-クロムなどの特殊組成は、硬度~150 BHNの摩耗部品用に開発された。 |

| 摩擦係数 | 摩擦係数は、潤滑合金の0.2から、特定の用途に合わせた高摩擦材料の1.0の範囲である。 |

| 透過性 | 比透磁率は、合金によってオーステナイト系ステンレス鋼の10倍から10000倍。 |

実現可能な材料特性の多様性により、銅合金は構造部品だけでなく、接点、リードフレーム、ブッシュ、溶接チップ、真空、高温用途などにも適しています。

銅合金粉末の用途

導電性、耐食性、摩擦特性、機械加工性など、さまざまな銅合金のユニークな組み合わせにより、幅広い産業分野で使用されています:

| 産業 | 用途 |

|---|---|

| 自動車 | ブッシング、ワッシャー、溶接チップ、コネクター、ファスナー、スイッチ、リレー |

| 電気 | コンタクトストリップ、端子、コネクタ、リードフレーム、ヒューズ、抵抗素子 |

| エレクトロニクス | リードフレーム、コネクター、ヒートシンクやヒートスプレッダーなどの熱管理部品 |

| エンジニアリング | ベアリング、ブッシング、ギア、摩耗部品 |

| 産業機械 | ブッシング、プランジャーチップ、バルブ部品、パウダー/トナーアプリケーション部品 |

| 医療と歯科 | 生体適合性によるピン、スクリュー、プレート用インプラント |

| 軍事・防衛 | 撃針、薬莢、弾丸ジャケット |

| 石油・ガス | バルブ、ポンプ、海底および坑内コンポーネント |

強度、延性、摩耗性能、複雑な形状の組み合わせが可能なため、銅合金はさまざまな産業の小、中、大の構造部品に適しています。

銅合金粉末の仕様

銅合金粉末は、組成限界、粉末サイズ、粒度分布、見かけ密度値、タップ密度値などの特性を定義する、国際的および地域的な規格の範囲に従って製造されます。主な規格は以下の通りです:

| スタンダード | グレード | エレメンツ・リミテッド |

|---|---|---|

| EN ISO 3522 | CuP2、CuP3、CuP4など。 | Pb、As、Cd、Niなど。 |

| ASTM B177 | CDA金メッキ、ブロンズCDA 854、C97300など | S、Se、Te、Sbなど |

| DIN 8513 | MF-CuSn8、MF-CuSn12、MFCuCr1など。 | S、Pなど。 |

| GB/T 4337 | HB61、HB62、HB63など | Zn、Ni、Alなど |

| AWS A5.7 | ERCuNi、ERCuZn-Cなど。 | S、P、Oなど。 |

これらは粉体を調達する際の品質、一貫性、信頼性の基準を定めるものです。許容限界は、潜在的に有害な不純物を管理するのに役立ちます。

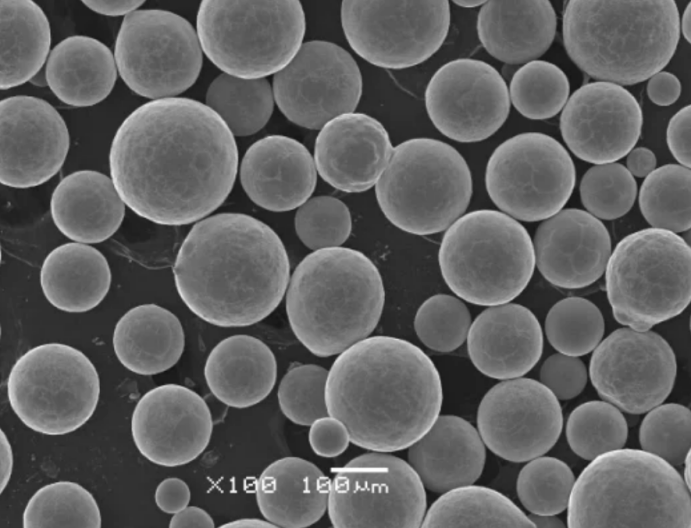

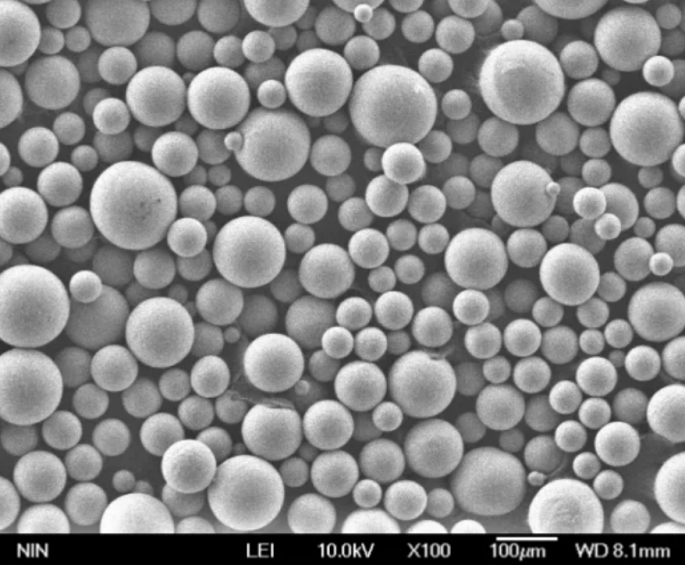

銅合金粉末のサイズ

100 ミクロン以下の微細な銅合金粉末は、焼結時の高密度化を促進し、最終部品の機械的特性を最大限に引き出します。また、表面仕上げや細部の特徴もよくなります。しかし取り扱いは難しくなります。150ミクロン以上の粗い粒子は粉塵の問題を軽減しますが、焼結密度は低くなります。したがって、実用的な範囲は

| パラメータ | 一般的なサイズ範囲 |

|---|---|

| 最大粒子径 | 150 μm |

| 最小粒子径 | 15-20 μm |

| 平均粒子径 | 45-75 μm |

銅合金粉末グレード

銅合金粉末は、組成と粉末の特性に基づいて、次のようなグレード・グループに分類される:

| グレード | 作曲 | 一般的なアプリケーション |

|---|---|---|

| 自由加工 | Cu-Zn-Pb、Cu-Sn-Pbのような鉛入り黄銅と青銅 | チップコントロールが必要な切削加工部品 |

| 高い導電性 | Cu-Ni、Cu-Fe | エレクトロニクス– リードフレーム、コネクター等 |

| 耐摩耗性 | Cu-Cr、Cu-Co | ベアリング、ブッシング、プランジャー |

| 強さ | Cu-Ni-Si-Crのような複雑なCu合金 | 高強度構造部品 |

銅合金粉末の製造工程

工業用の銅合金粉末を製造する一般的な技術には次のようなものがある:

- 霧化:溶融金属の流れが微細な液滴に分解され、急速に凝固して粉末になる。

- 電解:合金成分が層ごとに共蒸着される電気化学製造

- カルボニルプロセス:金属カルボニル蒸気の熱分解による微粒子の生成

これらの方法の利点は、精密な化学的性質を持つ超微粒子、球状/不規則な形状の粉末です。また、潤滑剤とのレディー・トゥ・プレスブレンドも成形プロセスの原料として供給することができます。これらの粉末の高純度、高密度、高流動性により、高品質の焼結部品が得られます。

銅合金粉末のサプライヤー

銅粉や合金粉の世界的な主要メーカーには以下のようなものがある:

| 会社概要 | ブランド | 生産能力 |

|---|---|---|

| ホーガナス | ホーガナス | 20万トン |

| GKNホエガネス | ホエガネス、北米ヘガネス | 18万トン |

| 金属粉末の製造 | メイキン | 20,000トン |

| CNPC 粉末グループ | 中国石油天然気集団公司 | 10万トン |

これらの企業は、オンデマンドで材料を調整できる合金設計能力と、少量の研究開発から大量の商業生産まで供給できる生産能力を持っている。

銅合金粉末の価格

料金は、以下の条件によって異なる:

| パラメータ | 価格設定への影響 |

|---|---|

| 作曲 | Cr、Be、Coなどの合金元素が増えると高価になる。 |

| パウダーの純度/品質 | 最も高価な高純度医歯薬用グレード |

| 注文数量 | 数量割引あり |

| 地域需要 | アジアの価格は欧州/米国より30%低いこともある |

一般的な価格帯は以下の通り:

| 合金タイプ | 価格帯 |

|---|---|

| 真鍮粉 | kgあたり15-25ドル |

| 青銅粉 | kgあたり25-45ドル |

| 銅-ニッケル-クロム | kgあたり50ドル以上 |

価格もまた、粒度分級、レディ・トゥ・プレス混合、特殊梱包など、プロバイダーが提供できる追加サービスによって異なる。

銅合金粉末の比較

異なる銅合金を並べて分析すると、こうなる:

| 真鍮 | ブロンズ | 銅-鉄 | 銅-ニッケル | |

|---|---|---|---|---|

| 強さ | 中程度 | 高い | 高い | 中程度 |

| 導電率 | 高い | 中程度 | 非常に高い | 高い |

| 耐食性 | 中程度 | 中程度 | 低い | 非常に高い |

| 耐摩耗性 | 中程度 | 低い | 低い | 中程度 |

| コスト | 低い | 中程度 | 中程度 | 高い |

そのため、重要な性能要件に基づいて適切な銅合金を選択することができます。

銅合金粉末の利点

バルク合金と比較して有用な利点は以下の通りである:

- 均一性:ミクロ偏析がなく、均一なミクロ構造

- 等方性:異方性を持つ鋳造製品とは異なる。

- 細粒:急速冷却により粒子が非常に細かくなり、強度が向上。

- 作業性:複雑で緻密な形状への容易な成形性

- カスタマイズ:ご要望に応じた化学的性質、粒度分布

- 生産性:スクラップ・ロスを最小限に抑えた自動化された大量生産

- 品質:バッチ間の一貫性が鋳造品のばらつきを上回る

の限界 銅合金粉末

いくつかの欠点がある:

- バルク合金より高コスト

- 他のフォームに比べ、サイズや形状が限られている

- 圧縮後の熱伝導率と電気伝導率が低い

- 焼結時に保護雰囲気が必要な場合がある

- 不適切な焼結による粒成長の可能性

- 酸化を防ぐために特別な取り扱いと容器が必要

Frequently Asked Questions (Supplemental)

1) Which Copper Alloy Powder is best for high‑conductivity and heat‑sink applications?

- Oxygen‑free Cu and CuCrZr powders offer high electrical/thermal conductivity; for LPBF, use green/blue‑laser compatible, highly spherical powders (D10/50/90 ≈ 15/30/45 μm) with very low oxide.

2) How do I choose between brass, bronze, and cupronickel powders?

- Brass (Cu‑Zn): good conductivity and machinability, lower cost; Bronze (Cu‑Sn): better strength/wear; Cupronickel (Cu‑Ni): superior corrosion resistance (marine) with moderate conductivity. Match to corrosion, conductivity, and cost targets.

3) What powder specs matter most for AM vs press‑and‑sinter?

- AM (PBF/BJ): sphericity, narrow PSD, low oxygen (<0.08 wt% for Cu/Cu alloys), high apparent/tap density, low satellites. Press‑and‑sinter: flowability, consistent PSD (45–75 μm typical), controlled lubricant blends, and deoxidizing sintering atmospheres.

4) Can recycled Copper Alloy Powder be blended without hurting properties?

- Yes, with strict sieving, oxide/spatter removal, and “powder passports” tracking PSD, O/H, and flow. Typical validated blend‑back for PBF: 10–30%; for SLS/BJ: follow OEM refresh ratios and verify conductivity and density.

5) What atmospheres are recommended for sintering copper alloys?

- High‑purity hydrogen or dissociated ammonia (dew point ≤ −40°C) for maximum conductivity; nitrogen‑hydrogen blends for brasses/bronzes; avoid oxidizing atmospheres to prevent oxide films and loss of conductivity.

2025 Industry Trends and Data

- Green/blue laser adoption accelerates dense copper and Cu alloys in PBF for EV busbars and thermal management.

- ESG disclosure: Recycled copper content (15–40%) and Environmental Product Declarations increasingly required in RFQs.

- Binder jet + HIP maturation enables complex bronzes with high density and fine detail at lower cost-per‑part.

- AI‑assisted powder classification improves lot‑to‑lot PSD and flow consistency.

- Corrosion‑focused alloys (Cu‑Ni, Cu‑Ni‑Cr) see growth in desalination and offshore wind balance‑of‑plant components.

| KPI (Copper Alloy Powder & Use), 2025 | 2023 Baseline | 2025 Typical/Target | Application area | Why it matters | Sources/Notes |

|---|---|---|---|---|---|

| PBF Cu/CuCrZr as‑built density (%) | 98.5–99.4 | 99.5–99.9 | メタルAM | Mechanical, conductivity | OEM/peer‑reviewed data |

| Conductivity vs. wrought (IACS) | 80–90% | 90–95% | Cu/CuCrZr PBF | Electrical performance | Machine + alloy improvements |

| Oxygen in AM‑grade Cu powders (wt%) | 0.08–0.12 | 0.03–0.08 | AM powder | Porosity, spatter | ASTM E1019; supplier QC |

| Binder‑jetted bronze final density (%) | 96–98 | 98.5–99.5 (post‑HIP) | Binder jet | Reliability, machinability | BJ + HIP workflows |

| Disclosed recycled Cu content (%) | 限定 | 15–40 | All | ESG, cost stability | EPD/LCA reports |

| Sintering atmosphere dew point (°C) | −20 to −30 | ≤ −40 | Press‑sinter | Conductivity retention | Furnace best practices |

Authoritative resources:

- ISO/ASTM 52907 (metal powder characterization), 52904 (PBF practice): https://www.iso.org

- ASTM B822/B214 (PSD), B212/B213 (density/flow), B923 (true density), E1019 (O/N/H): https://www.astm.org

- NIST AM Bench datasets: https://www.nist.gov/ambench

- Copper Development Association application data: https://www.copper.org

Latest Research Cases

Case Study 1: Blue‑Laser PBF of CuCrZr Heat Spreaders for Power Electronics (2025)

- Background: An inverter manufacturer needed compact, high‑conductivity heat spreaders with internal lattices.

- Solution: Highly spherical CuCrZr powder (PSD 15/30/45 μm; O = 0.04 wt%); blue‑laser PBF with optimized hatch and contour; stress‑relief + aging; surface finishing of flow channels.

- Results: Density 99.7%; thermal conductivity 360–380 W/m·K; part count consolidation 5→1; module temperature −7°C at equal load; scrap rate 4% (was 11%).

Case Study 2: Binder‑Jetted Tin Bronze Bushings with Sinter‑HIP (2024)

- Background: An industrial OEM sought cost‑effective, oil‑impregnated bushings with complex lubrication features.

- Solution: Fine bronze powder (Cu‑Sn, D50 ≈ 25 μm); binder jetting; debind + H2 sinter; HIP; controlled porosity zones via green density tuning; oil impregnation.

- Results: Final density 98.8–99.3% in load regions; tailored porosity 5–8% in lube zones; wear rate −22% vs. machined bronze; unit cost −15% at 10k/yr.

Expert Opinions

- Dr. Brandon Lane, Research Engineer, NIST

- Viewpoint: “Linking powder oxygen and PSD from Copper Alloy Powder passports to in‑situ melt‑pool metrics improves first‑time‑right builds for conductive parts.”

- Prof. Iain Todd, Professor of Metallurgy, University of Sheffield

- Viewpoint: “Laser wavelength matching for copper—especially blue and green—has moved Cu and CuCrZr from ‘difficult’ to production‑ready in PBF.”

- Dr. Christina Friedrichs, Head of Powder R&D, industrial metals manufacturer

- Viewpoint: “For press‑and‑sinter, furnace atmosphere control—dew point and gas purity—dominates conductivity outcomes more than minor alloy tweaks.”

Affiliation links:

- NIST AM: https://www.nist.gov

- University of Sheffield (Materials): https://www.sheffield.ac.uk

Practical Tools/Resources

- Standards/QC: ISO/ASTM 52907; ASTM B212/B213/B214/B822; ASTM B923; ASTM E1019

- Design/simulation: Ansys/Simufact Additive for scan/path; nTopology for lattice heat‑spreaders; Thermo‑Calc/DICTRA for Cu‑alloy aging

- Databases: Senvol Database (https://senvol.com/database); Copper Development Association (https://www.copper.org); MatWeb (https://www.matweb.com)

- Metrology: Four‑point probe for resistivity; DSC/DMTA for alloy temper behavior; CT for porosity; SEM/XPS for oxide films

- Safety: NFPA 484 guidance for combustible metals; supplier SDS; inert gas handling best practices

Last updated: 2025-08-22

Changelog: Added 5 supplemental FAQs tailored to Copper Alloy Powder selection, specs, and processing; introduced a 2025 KPI table and trend insights; provided two case studies (CuCrZr heat spreaders via blue‑laser PBF; binder‑jet bronze bushings with HIP); included expert viewpoints with affiliations; compiled standards, simulation, databases, and safety resources.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards update, major OEMs publish new copper AM parameter sets, or significant EPD/ESG requirements for copper powders change.