1. Introduction: Why Ti64 Powder is Dominating Advanced Manufacturing

Titanium alloy Ti6Al4V (commonly referred to as Ti64) powder has emerged as a cornerstone material for advanced manufacturing sectors such as aerospace, biomedical, automotive, and industrial tooling. The alloy’s unique combination of high strength, low density, corrosion resistance, and excellent biocompatibility makes it ideal for both additive manufacturing (AM) and powder metallurgy (PM).

For B2B buyers, especially those in aerospace or medical device production, Ti64 powder offers:

- Propriétés mécaniques améliorées

- Lightweight component design

- Compatibility with various 3D printing technologies (SLM, EBM, DED)

- Long-term cost efficiency via near-net-shape manufacturing

As demand for 3D-printed titanium components continues to grow, sourcing high-quality Ti64 powder from reliable suppliers becomes critical to maintaining competitive advantage in the market.

2. Industrial Applications of Ti64 Powder in Additive Manufacturing and PM

Ti64 powder is a key enabler in the production of high-performance parts across multiple industries. Below is a breakdown of its primary applications:

| L'industrie | Applications | Avantages |

|---|---|---|

| Aérospatiale | Turbine blades, structural brackets, engine components | Rapport résistance/poids élevé, résistance à la fatigue |

| Biomédical | Orthopedic implants, dental implants, surgical tools | Biocompatibilité, résistance à la corrosion |

| Automobile | Lightweight engine parts, heat exchangers | Weight reduction, thermal stability |

| L'énergie | Offshore components, heat exchangers | Corrosion and temperature resistance |

| Défense | Missile components, armor systems | High impact strength, durability |

Key advantages for manufacturers and OEMs include:

- Ability to create complex geometries without machining

- Reduction in material wastage

- Improved supply chain efficiency

- Customization at scale

For wholesale buyers and distributors, Ti64 powder represents a high-margin product with growing demand across sectors.

3. Types and Grades of Ti64 Powder for B2B Buyers

Understanding the types and grades of Ti64 powders is essential for procurement teams, engineers, and product managers sourcing for industrial use.

Common Ti64 Powder Types by Production Method:

| Méthode de production | Description | Utilisation typique |

|---|---|---|

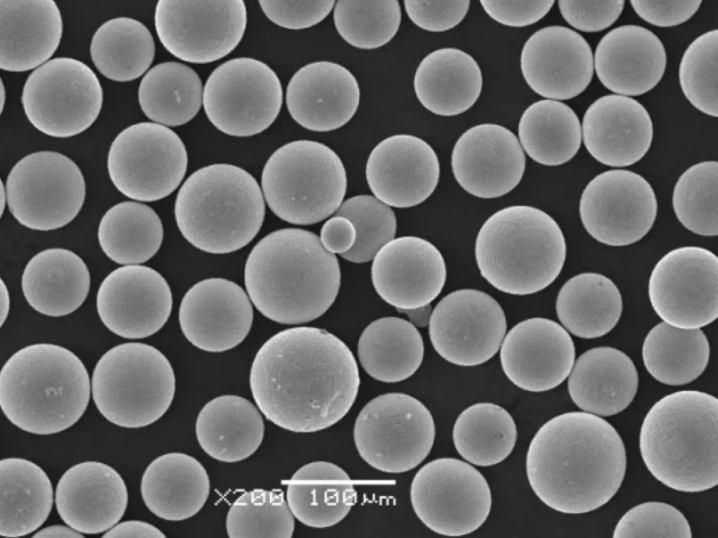

| Gaz Atomisé | Produces spherical particles with high flowability | Preferred for additive manufacturing |

| Plasma atomisé | Ultra-spherical, low oxygen content | Ideal for aerospace and medical |

| EIGA (Electrode Induction Gas Atomization) | High purity, fine particle control | High-end aerospace and biomedical applications |

| Hydride-Dehydride (HDH) | Irregular particles, cost-effective | Used in PM and some AM processes |

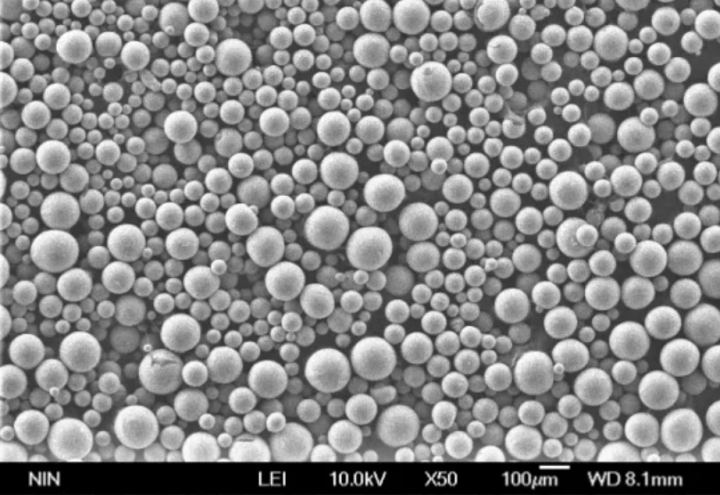

Distribution de la taille des particules :

| Taille des mailles | application |

|---|---|

| 15–45 µm | Laser Powder Bed Fusion (LPBF) |

| 45–106 µm | Fusion par faisceau d'électrons (EBM) |

| 106–250 µm | Directed Energy Deposition (DED), Cold Spray |

Key Material Properties:

- Composition: ~90% Titanium, 6% Aluminum, 4% Vanadium

- Density: 4.43 g/cm³

- Melting Point: 1604–1660°C

- Oxygen Content: < 0.2% (critical for aerospace/medical)

Buyers must ensure consistency in particle size, flowability, and purity to meet regulatory and performance standards.

4. Global Market Trends and Growth Potential of Titanium Alloy Powders

The global market for titanium alloy powders, particularly Ti64, is experiencing robust growth driven by the expansion of additive manufacturing and the increasing adoption of lightweight materials across industries.

Market Overview

| Métrique | Value (2023) | Projected (2028) | CAGR |

|---|---|---|---|

| Global Ti64 Powder Market Size | USD 387 million | USD 912 million | 18.6% |

| Aerospace Industry Share | 42% | 47% | - |

| Medical Devices Share | 21% | 25% | - |

Principaux facteurs de croissance

- Aerospace Demand: Aircraft OEMs are shifting to 3D-printed Ti64 parts to reduce weight and fuel consumption.

- Medical Sector Expansion: Increased use of custom orthopedic and dental implants made with Ti64.

- Rise of AM & Impression 3D: Laser and electron beam technologies prefer spherical Ti64 powders.

- L'action en faveur du développement durable: Ti64 enables near-net-shape parts, reducing waste and energy use.

Regional Opportunities

- Asie-Pacifique: Rapid industrialization and government-backed 3D printing initiatives in China and India.

- Amérique du Nord: Dominated by aerospace and defense applications.

- L'Europe: Strong adoption in biomedical R&D and automotive lightweighting.

Buying Ti64 powder now positions B2B buyers and distributors to ride the wave of industrial transformation. Early access to stable, scalable sources will be key to long-term profitability.

5. Key Considerations When Selecting a Ti64 Powder Supplier

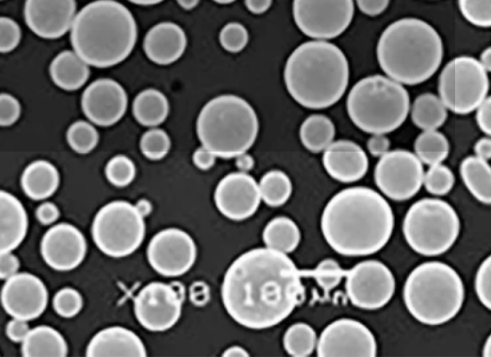

With increased demand comes a crowded supplier landscape. B2B buyers must evaluate Ti64 powder vendors based on a mix of technical, logistical, and business factors.

Critical Evaluation Criteria

| Facteur | Pourquoi c'est important | Ce qu'il faut rechercher |

|---|---|---|

| Morphologie des particules | Affects flowability and print quality | Spherical, low porosity grains |

| Pureté chimique | Impacts mechanical performance | Low oxygen, nitrogen, and hydrogen content |

| Méthode de production | Determines consistency and cost | Gas or plasma atomization preferred |

| Certifications | Obligatoire pour les industries réglementées | ISO 13485, AS9100, ASTM F2924 compliance |

| Personnalisation | Enables diverse applications | Ability to tailor particle size or chemistry |

| Capacité d'approvisionnement | Supports scalability | Monthly output >500 kg preferred |

| Logistique | Affects lead times and cost | Regional warehouses, fast export service |

Drapeaux rouges à éviter

- Lack of third-party quality certifications

- No technical documentation (e.g., PSD, SEM images, COA)

- Inconsistent particle sizes

- Poor customer service or communication delays

For a comprehensive introduction to Shanghai Truer’s capabilities and company background, click here.

6. Top 5 Ti64 Powder Suppliers in Asia-Pacific Region

Asia-Pacific has become a hotspot for Ti64 production, driven by cost advantages and rapid industrialization. Below are some of the top-performing suppliers in the region.

1. Shanghai Truer Technology Co. Ltd (Chine)

- Établi: 2009

- 3D Printing Division: Since 2019

- Points forts: Full-spectrum production (gas atomized, water atomized, hybrid), customizable grades, strong R&D

- Produit: Ti64 for AM and PM, plus full range of PM additives

- Certifications: ISO-compliant, technical documentation available

- Site web: www.am-material.com

2. AP&C (Canada, APAC Distributor Network)

- Spécialité: Plasma atomized Ti64 powders for high-end aerospace

- Points forts: Ultra-spherical particles, high purity

- Limitation: High cost, longer lead times in Asia

3. TLS Technik (Germany/Asia)

- Spécialité: EIGA-based powders for medical implants

- Points forts: Low oxygen levels, tight particle control

- Limitation: Limited availability for smaller buyers

4. Western Superconducting Technologies (China)

- Points forts: In-house titanium sponge production

- Applications: Used by Chinese aerospace and defense contractors

- Limitation: Primarily focused on domestic market

5. Toho Titanium (Japan)

- Spécialité: HDH and gas atomized Ti64

- Points forts: Reliable quality, long-standing reputation

- Limitation: Higher cost structure

When comparing suppliers, Shanghai Truer stands out for its flexibility, expertise techniqueet Prix compétitifs, making it an ideal partner for B2B buyers and distributors.

7. Why More Distributors Are Shifting to Chinese Ti64 Powder Manufacturers

Over the past decade, China has rapidly emerged as a global leader in advanced materials manufacturing, including titanium alloy powders like Ti64. Increasingly, international B2B buyers, distributors, and OEMs are turning to Chinese suppliers for several strategic reasons.

Key Advantages of Chinese Suppliers

| Avantage | Explication | B2B Benefits |

|---|---|---|

| Rentabilité | Lower production and labor costs | Competitive pricing at scale |

| Advanced Production | China has invested in gas atomization and EIGA tech | Comparable quality to Western companies |

| Stable Supply Chain | Local access to titanium sponge and alloys | Shorter lead times, fewer disruptions |

| Scalable Output | High-volume manufacturing capacity | Supports large contracts and long-term demand |

| Government Support | National initiatives to support AM and PM sectors | Incentives for R&D, innovation, and export |

Major Export Hubs

- Shanghai

- Guangdong

- Jiangsu

- Sichuan

These regions host certified facilities equipped for high-purity metal powder production.

Strategic Procurement Tip:

Many global buyers are now engaging in dual sourcing — combining a Western supplier for specialty needs and a Chinese supplier for bulk orders — to ensure cost and supply chain balance.

For buyers exploring alternative sourcing options, Shanghai Truer’s product portfolio of PM and AM powders offers a reliable and high-quality gateway into China’s advanced powder metallurgy sector.

8. Why Choose Shanghai Truer Technology Co., Ltd for Ti64 Powder

Shanghai Truer Technology Co., Ltd is not just a manufacturer — it’s a trusted partner for B2B buyers seeking reliability, quality, and technical expertise in Ti64 powder and other PM materials.

Présentation de l'entreprise

- Fondée: 2009

- AM Division Launched: 2019

- Focus Areas: 3D printing powders, powder-making equipment, PM additives

- Site web: am-material.com

Ti64 Powder Capabilities

| Fonctionnalité | Détails |

|---|---|

| Processus de fabrication | Gas atomization, water atomization, hybrid atomization |

| Taille des particules | 15–45 µm, 45–106 µm, 106–250 µm |

| Purity Control | Low oxygen, nitrogen, and hydrogen content |

| Support technique | Application consulting, COA, SEM analysis |

| Personnalisation | Tailored grades for LPBF, EBM, DED applications |

Additional Product Offerings

Besides Ti64, Truer offers a comprehensive range of powder metallurgy solutions y compris :

- PM Bronze, PM Nickel Silver, PM Stainless Steel

- Prealloyed Steels (e.g., FD-0208, FL-4605)

- Soft magnetic powders and custom additives

- Cutting agents and lubricants like SUW-8000 and SME-100

Why Truer is Preferred by B2B Clients

- ✔️ ISO-certified production

- ✔️ Fast response time

- ✔️ Detailed technical documentation

- ✔️ Competitive pricing for bulk orders

- ✔️ International logistics capability

Whether you’re a distributor, OEM, or contract manufacturer, Truer’s flexible production and high-quality assurance make it an ideal long-term partner.

📌 For a deep dive into our company’s mission, values, and manufacturing strengths, visit our About page.

9. FAQ: Common Questions About Buying Wholesale Ti64 Powder

Here are the most frequently asked questions by B2B buyers and procurement teams when sourcing Ti64 powder:

Q1: What is the minimum order quantity (MOQ) for Ti64 powder?

A : Most suppliers, including Shanghai Truer, offer flexible MOQs starting from 1 kg for sampling. Bulk pricing usually starts at 50 kg or more.

Q2: What certifications does Truer offer for Ti64 powder?

A : Truer provides full COA (Certificate of Analysis) and can meet ASTM F2924 et ISO 13485 standards upon request.

Q3: Can I request customized particle size distributions?

A : Yes. Truer offers tailored sieving services for specific AM processes like LPBF (15–45 µm) or EBM (45–106 µm).

Q4: How does Truer ensure the chemical purity and morphology of Ti64 powder?

A : Truer uses advanced gas atomization under inert argon atmosphere and conducts strict QC, including SEM imaging, oxygen/nitrogen testing, and flowability analysis.

Q5: Do you support OEM and private-label packaging?

A : Yes. Truer supports OEM labeling, white-label packaginget custom branding for distributors and resellers.

Q6: What is the lead time for international orders?

A : Standard lead time is 7–10 business days for in-stock powders. Custom batches may require 2–3 weeks. Truer supports international air and sea shipping.

Q7: How do I place an order or request a sample?

A : You can reach Truer directly via their contact us page, where a technical expert will assist you with quotes, sample requests, or technical questions.

🔗 Internal Link Summary

Below are the internal anchors used throughout the blog to enhance SEO and navigation:

- Powder Metallurgy Product Page – Ti64 & More

- À propos de Shanghai Truer Technology Co

- Contact Us for Samples or Orders

- Homepage – Explore Products & Services

- Ti64 Powder Product Page (PM Powder Section)

This comprehensive guide ensures that B2B buyers, procurement managers, and technical sourcing teams are equipped with the knowledge they need to make informed decisions about Ti64 powder sourcing for additive manufacturing and powder metallurgy applications. Shanghai Truer Technology Co., Ltd offers the ideal combination of quality, flexibility, and reliability in the evolving global titanium alloy market.

Ready to discuss volume pricing or get technical specs? Contact our team now for fast support and expert consultation.