1. Introduction: Why Ti6242 Powder Is Gaining Traction in High-Performance Industries

Ti6242 is a high-temperature titanium alloy composed primarily of titanium (Ti), aluminum (Al), tin (Sn), zirconium (Zr), and molybdenum (Mo). Its nominal composition is:

| Élément | Poids (%) |

|---|---|

| Ti | Balance |

| Al | 6 |

| Sn | 2 |

| Zr | 4 |

| Mo | 2 |

This alloy—often referred to simply as Ti-6Al-2Sn-4Zr-2Mo—is widely known for its excellent high-temperature strength, oxidation resistance, and long-term stability. These properties make it ideal for critical aerospace and automotive components.

Caractéristiques principales :

- High tensile strength up to 550°C

- Excellente résistance à la fatigue

- Superior creep resistance over standard titanium alloys

- Outstanding oxidation resistance

- Compatibility with additive manufacturing methods like SLM, EBM, and DED

With the advancement of additive manufacturing and powder metallurgy, demand for Ti6242 powder has surged. Manufacturers require specialized powders that offer both high thermal performance and processability—two areas where Ti6242 excels.

2. Industrial Applications of Ti6242 Powder in Aerospace, Automotive, and Medical

Ti6242 powder is engineered for high-performance environments where temperature and load conditions are extreme. The alloy is most commonly used in the following sectors:

Industrie aérospatiale

- Turbine engine components (e.g., discs, shafts, blades)

- Afterburner casings

- Airframe structural components

Industrie automobile

- Racing engine parts

- Turbocharger rotors

- Valve train components

Secteur médical

- Implants orthopédiques (for high-load-bearing applications)

- Outils chirurgicaux (where thermal resistance is crucial)

Energy and Industrial Applications

- High-temperature reactors

- Équipement de traitement chimique

- Échangeurs de chaleur

| Secteur | Exemple d'application | Benefit of Ti6242 Powder |

|---|---|---|

| Aérospatiale | Disques de turbine | High fatigue & creep resistance |

| Automobile | Turbo Rotors | Thermal stability at high RPMs |

| Médical | Implants | Biocompatibility + fatigue strength |

| L'énergie | Échangeurs de chaleur | Corrosion + heat resistance |

In additive manufacturing, Ti6242 powder enables the production of complex geometries that would be difficult or impossible to machine from solid billet. It reduces material waste and allows for lightweight component design without compromising strength.

3. Technical Properties and Advantages of Using Ti6242 in Additive Manufacturing

When used in metal additive manufacturing (AM), the Ti6242 alloy powder delivers exceptional performance. Its mechanical and thermal properties are well-suited for powder-bed fusion and directed energy deposition processes.

Mechanical Properties (As-Built from AM Process)

| Propriété | Valeur (typique) |

|---|---|

| Résistance ultime à la traction | 950–1050 MPa |

| Limite d'élasticité | 880–950 MPa |

| Élongation | 10–14% |

| Dureté (HV) | 320–350 |

| Densité | 4,5 g/cm³ |

Propriétés thermiques

- Service temperature: up to 550°C

- Thermal conductivity: 6.7 W/m·K

- Coefficient of thermal expansion: 8.6 μm/m·K

Advantages for AM Users:

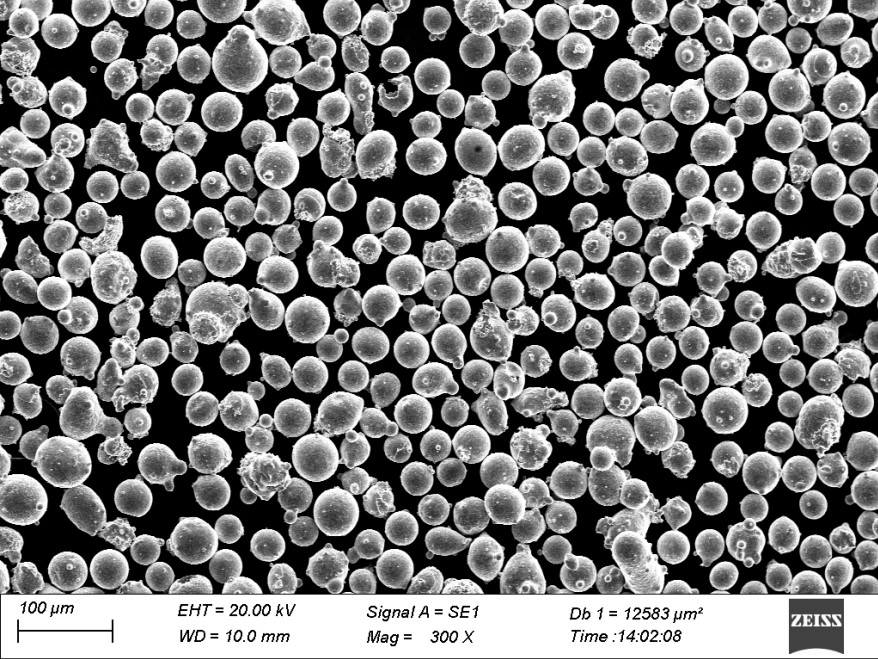

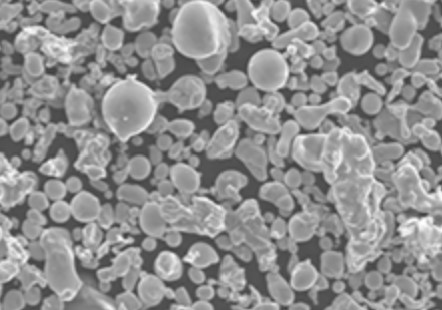

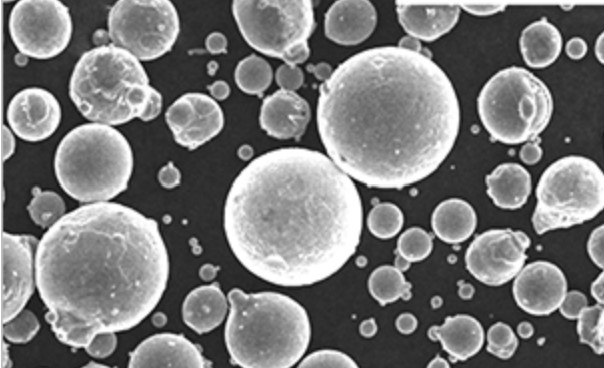

- Consistent Flowability: Spherical particle morphology for uniform recoating during SLM process

- Haute pureté: Low oxygen and hydrogen content ensures ductility

- Custom Particle Size Distribution: Available in ranges like 15–45 μm, 45–105 μm for specific AM technologies

Compatible AM Technologies:

- Fusion sélective par laser (SLM)

- Fusion par faisceau d'électrons (EBM)

- Direct Energy Deposition (DED)

At Shanghai Truer Technology Co., Ti6242 powder is produced using advanced atomisation du gaz methods to ensure spherical morphology, high purity, and excellent flowability—essential qualities for AM applications.

4. Global Market Trends and Demand Forecast for Ti6242 Alloy Powder

The global market for titanium-based powders, and especially advanced alloys like Ti6242, is witnessing rapid growth due to increased adoption of additive manufacturing (AM) and powder metallurgy (PM) in high-performance industries.

Principaux facteurs de croissance :

- Aerospace Expansion: Rising demand for lightweight, high-strength materials in jet engines and structural components.

- AM Proliferation: Surge in metal Impression 3D across automotive, medical, and industrial sectors.

- Innovation matérielle: Shift toward high-temperature alloys for next-gen propulsion systems.

Market Forecast (2024–2030):

| Région | Market CAGR (Est.) | Key Sectors Driving Demand |

|---|---|---|

| Amérique du Nord | 7.8% | Aerospace, Defense, Medical |

| L'Europe | 8.3% | Automotive, Energy, AM Research |

| Asie-Pacifique | 10.5% | Industrial Manufacturing, Aerospace |

| Moyen-Orient | 6.1% | Oil & Gas, Energy Infrastructure |

Emerging Trends:

- Use of Ti6242 in hypersonic aerospace programs

- Growth in custom implant production via AM

- Hybrid manufacturing combining AM and subtractive methods

As OEMs and Tier 1 suppliers continue investing in titanium AM applications, sourcing high-quality Ti6242 powder is becoming a strategic imperative. Companies that secure reliable, scalable, and high-performance powder sources now will have a significant advantage in the future.

5. Key Selection Criteria for Choosing a Reliable Ti6242 Powder Supplier

For buyers, distributors, and manufacturers sourcing Ti6242 powder in bulk, selecting the right supplier is critical to ensure product quality, consistency, and regulatory compliance. Below are essential criteria to evaluate:

1. Qualité et consistance de la poudre

- Spherical morphology with good flowability

- Tight control over particle size distribution (PSD)

- Low oxygen, nitrogen, and hydrogen content

- Repeatable performance across batches

2. Manufacturing Method

- atomisation du gaz preferred for AM-grade powders

- Inert atmosphere processing to avoid contamination

- Capability to offer customized PSDs for different AM systems

3. Certifications and Compliance

- ISO 9001, AS9100 (for aerospace-grade materials)

- Full traceability of raw materials

- Batch-level test reports (chemical & mechanical)

4. Logistics and Scalability

- Ability to handle bulk orders or recurring supply

- Local/regional warehousing options

- Export experience and documentation support

5. Technical Support & Customization

- Guidance on AM process parameters

- Material customization based on client needs

- Post-sale technical support

| Facteur de sélection | Best Practice |

|---|---|

| Morphologie des poudres | Spherical, gas-atomized |

| Contrôle de la taille des particules | 15–45μm or 45–105μm based on application |

| Niveaux de pureté | O < 0.2%, H < 0.01%, N < 0.05% |

| Certifications | ISO 9001, AS9100, material traceability |

| Supplier Experience | 5+ years in AM powder production |

Shanghai Truer Technology Co., Ltd meets and exceeds these benchmarks, offering high-quality Ti-based PM powders tailored for demanding AM and PM applications. Their experience, quality control, and technical customization make them a trusted supplier in the global market.

6. Top 5 Ti6242 Powder Manufacturers and Distributors Globally

Finding a reliable Ti6242 powder supplier can be challenging due to the technical complexity and high purity requirements of this alloy. Below are five globally recognized suppliers offering Ti6242 powder at industrial scale:

| Nom du fournisseur | Région | Caractéristiques principales |

|---|---|---|

| Shanghai Truer Technology | Chine | Gas atomized Ti6242, custom PSDs, AM/PM expertise |

| AP&C (GE Additive) | Canada | Aerospace-grade powders, high-volume production |

| TLS Technik | Allemagne | Ti alloys for AM, tight PSD control, ISO certified |

| Oerlikon AM | Suisse | Full AM supply chain, powder + printing services |

| Additif pour charpentier | ÉTATS-UNIS | High-purity Ti6242, advanced lab testing capabilities |

Why Shanghai Truer is a Standout:

- Over a decade in PM and additive materials

- Advanced atomization technologies (gas, water, and hybrid)

- Offers not only Ti6242 powder, but also a full suite of PM additives and lubricants

- Deep R&D capabilities for custom alloy development

For buyers looking to source from Asia or expand their supplier base in China, Shanghai Truer Technology Co. stands out as a strategic partner offering both quality and flexibility.

7. Why More Buyers Are Turning to Chinese Suppliers for Ti6242 Powder

The global supply chain has shifted significantly in recent years due to rising material costs, geopolitical uncertainty, and innovation in regional manufacturing. As a result, more B2B buyers are turning to Fournisseurs chinois for high-performance metal powders like Ti6242.

Key Advantages of Chinese Suppliers:

- Price competitiveness due to localized raw materials and processing

- Advanced manufacturing infrastructure in powder metallurgy

- Des délais plus courts for Asia-Pacific and Middle Eastern buyers

- Growing R&D investment in additive materials

Shanghai Truer has become one of the most trusted names in this space, offering:

- Spherical, gas-atomized Ti6242 powder for AM

- Custom production capabilities for specific particle size needs

- ISO-compliant quality systems and full traceability

- Extensive experience in powder metallurgy and additive manufacturing

As one of the leading Chinese suppliers, Truer provides a compelling value proposition for global buyers looking for both reliability and cost-efficiency. Their technical data sheets, client support, and ability to scale production make them a preferred choice for many distributors and manufacturers.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Ti6242 Powder Partner

Shanghai Truer Technology Co., Ltd has established itself as one of China’s most reliable and technically advanced manufacturers of powder metallurgy materials and additive manufacturing powders. Since launching its additive manufacturing division in 2019, Truer has rapidly expanded its product portfolio to serve global B2B customers in aerospace, automotive, medical, and industrial sectors.

Key Advantages of Partnering with Truer:

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Technologie d'atomisation avancée | Gas, water, and hybrid atomization for optimal powder quality |

| Customizable PSDs | Tailored powder sizing for specific AM systems (SLM, EBM, DED) |

| Wide Alloy Availability | In addition to Ti6242, Truer offers PM bronze, nickel silver, stainless steel, and more |

| Complete Additive Solutions | Lubricants, cutting agents, and soft magnetic additives for PM |

| Global Export Capabilities | Efficient logistics, documentation, and customer support |

| Certifications de qualité | ISO standards, full material traceability, and batch-level testing |

Truer’s Ti6242 powder is gas atomized in an inert atmosphere, ensuring excellent sphericity, flowability, and ultra-low oxygen content (<0.15%). This makes it ideal for high-precision additive manufacturing applications in regulated industries like aerospace and medical.

Ce qui distingue Truer :

- Over a decade in powder metallurgy innovation

- In-house R&D for material customization

- Responsive technical support for AM process optimization

- Competitive pricing and scalable production volumes for wholesale buyers

For more on Truer’s additive manufacturing capabilities, visit their site officiel.

9. How to Order Wholesale Ti6242 Powder from Shanghai Truer

Ordering high-quality Ti6242 powder from Shanghai Truer is a streamlined process optimized for international B2B buyers, distributors, and OEM manufacturers.

Processus de commande étape par étape :

- Enquête initiale

- Visitez le site Page de contact and submit your inquiry form

- Provide details: desired alloy (Ti6242), quantity, particle size range, application, shipping location

- Consultation technique

- Truer’s sales and engineering teams will follow up with technical specs, MSDS, and TDS

- Customization options available for particle size or packaging

- Quotation and Lead Time

- Receive a formal quotation with price, minimum order quantity (MOQ), lead time, and shipping terms (FOB, CIF, etc.)

- Test d'échantillons (optionnel)

- Small quantities (1–5 kg) can be ordered for testing before bulk order

- Purchase Order and Payment

- Send PO and confirm payment (wire transfer, L/C, or other agreed method)

- Production and Quality Control

- Batch production begins with full QC measures (chemical, PSD, flowability, oxygen/nitrogen tests)

- Shipping and Documentation

- Truer handles export documents (COA, MSDS, packing list, invoice)

- Global delivery via air freight or sea freight

- Support après-vente

- Truer offers ongoing support for powder usage, AM processing, and future orders

Options d'emballage :

- Vacuum-sealed aluminum bags (1 kg, 5 kg, 10 kg)

- Steel drums with inert gas backfill for bulk orders (25 kg, 50 kg)

- Custom packaging upon request

| Type de commande | MOQ | Délai d'exécution | Sample Available? | Bulk Discount? |

|---|---|---|---|---|

| Sample | 1 kg | 3–5 days | Oui | Non |

| Bulk | 25+ kg | 7-14 jours | Optional | Oui |

| OEM Custom | 100+ kg | 15–20 days | Oui | Oui |

Ready to get started? Reach out via the formulaire de contact pour demander un devis ou un échantillon.

10. FAQs: Common Questions About Sourcing and Using Ti6242 Powder

Q1: What is the typical particle size range available for Ti6242 powder?

A: Shanghai Truer offers Ti6242 powder in ranges such as 15–45 μm for SLM and 45–105 μm for DED/EBM. Custom PSDs are available on request.

Q2: Is Truer’s Ti6242 powder suitable for aerospace-grade components?

A: Yes. The powder is gas atomized in an inert atmosphere, ensuring high purity and consistency required for aerospace and high-temperature applications.

Q3: Can I get a small sample before placing a bulk order?

A: Yes. Truer provides 1–5 kg samples for qualification and testing purposes.

Q4: What is the oxygen content in Truer’s Ti6242 powder?

A: Typically <0.15%, which meets the requirements for additive manufacturing and aerospace industry standards.

Q5: How do I ensure compatibility with my AM machine?

A: Truer’s engineers provide technical guidance and can recommend the appropriate PSD and process parameters for your specific AM system.

Q6: Does Truer provide other titanium or PM powders?

A: Yes. In addition to Ti6242, Truer offers a broad range of Poudres PM including PM stainless steel, bronze, copper alloys, steel alloys, and soft magnetic materials.

Q7: What’s the typical lead time for a 100 kg order?

A: Approximately 10–14 business days, depending on customization and logistics.

Q8: Can I request custom packaging or labeling?

A: Yes. Truer offers custom packaging solutions and private labeling for distributors and OEMs.

Internal Links Summary (5 Anchored URLs):

- Ti-based PM powders – embedded in Part 2, Section 5

- Site officiel – embedded in Part 3, Section 8

- Page de contact – embedded in Part 3, Section 9

- Formulaire de contact – embedded in Part 3, Section 9

- Poudres PM – embedded again in FAQ, showcasing variety

By choosing Shanghai Truer Technology Co., Ltd as your Ti6242 powder supplier, you’re partnering with a company that combines technical excellence, global logistics capabilities, and a strong commitment to supporting your additive manufacturing or powder metallurgy operations.

For inquiries, technical specifications, or sample requests, visit the page de contact and connect with Truer’s expert team today.