1. Introduction : Pourquoi la poudre SS-410L est-elle cruciale pour la fabrication moderne ?

Dans le paysage en évolution de la fabrication additive (AM) et de la métallurgie des poudres (PM), acier inoxydable les poudres d'acier inoxydable comme le SS-410L sont de plus en plus prisées par les équipementiers, les vendeurs en ligne et les fabricants de composants industriels. Le SS-410L, un acier inoxydable martensitique à faible teneur en carbone, offre un équilibre entre la résistance à la corrosion, la résistance mécanique et la rentabilité, ce qui le rend particulièrement adapté aux pièces structurelles, aux filtres frittés et aux composants automobiles.

Mots-clés de recherche B2B :

- Vente en gros de poudre d'acier inoxydable SS-410L

- Acheter de la poudre SS-410L en vrac

- Poudre SS-410L pour la fabrication additive

- Fournisseurs de poudre SS-410L pour l'impression 3D

- Distributeurs industriels de poudres d'acier inoxydable

Pourquoi le SS-410L atomisé est-il important ?

- Permet d'obtenir des pièces frittées de haute densité

- Amélioration de la fluidité dans les processus AM et PM

- Adapté à la production à haut débit

- Réduction des coûts de post-traitement grâce à un meilleur état de surface

Shanghai Truer Technology Co., Ltd, l'un des principaux fournisseurs de poudres d'acier inoxydable en Chine, a été un innovateur clé dans cet espace. Depuis 2019, sa division de fabrication additive a développé des poudres de haute qualité adaptées aux applications AM et PM. Grâce à des techniques avancées d'atomisation à l'eau et au gaz, Truer fournit de la poudre SS-410L de qualité supérieure à des clients B2B mondiaux.

👉 En savoir plus sur Shanghai Truer Technology

2. Applications de la poudre SS-410L dans les secteurs industriels

La polyvalence de la poudre SS-410L la rend idéale pour diverses utilisations industrielles. Sa résistance à la corrosion et ses performances mécaniques sous l'effet de la chaleur et des contraintes sont particulièrement appréciées dans les secteurs suivants :

| L'industrie | Exemples d'application | Avantages de l'utilisation de la poudre SS-410L |

|---|---|---|

| Automobile | Composants de freinage, bagues, pièces d'engrenage | Grande résistance à l'usure, rentabilité |

| Aérospatiale | Supports structurels, boîtiers | Stabilité dimensionnelle, résistance à la corrosion |

| Pétrole et gaz | Filtres, pièces de pompes | Résistance aux fluides corrosifs |

| Dispositifs médicaux | Outils orthopédiques, supports chirurgicaux | Biocompatibilité, excellente finition de surface |

| Appareils ménagers | Eléments chauffants, pièces d'appareils | Résistance à la chaleur, formabilité |

Avantages pour les acheteurs en gros :

- Facilement extensible pour les grands volumes de production

- Compatible avec le moulage par injection de métal (MIM) et la fusion sélective par laser (SLM)

- Conforme aux normes internationales de gestion de la maintenance telles que MPIF et ISO

Shanghai Truer soutient les acheteurs de produits en vrac par un approvisionnement régulier, une assistance technique et des options de personnalisation pour des applications spécifiques. Consultez leur Gamme de poudres SS-410L pour plus de détails.

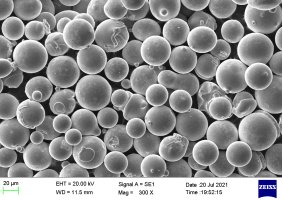

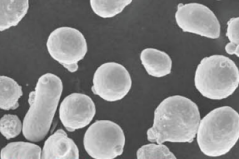

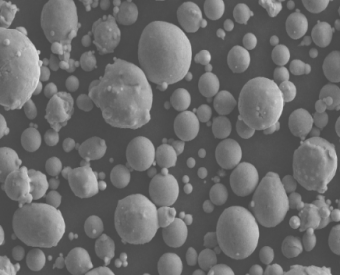

3. Propriétés physiques et mécaniques de la poudre atomisée de SS-410L

La poudre d'acier inoxydable SS-410L est disponible en différentes distributions granulométriques et peut être personnalisée en fonction du processus de frittage utilisé par l'acheteur. Shanghai Truer propose des versions atomisées à l'eau et au gaz, chacune adaptée à des besoins de fabrication différents.

| Propriété | Valeurs typiques |

|---|---|

| composition chimique | Fe : Équilibre, Cr : 11.5-13.5%, C : <0.03%, Si : <1% |

| Distribution de la taille des particules | D50 : 30-60 µm (personnalisable) |

| Débit (Hall, s/50g) | 25-35 |

| Densité apparente | 2.5-3,2 g/cm³ |

| Densité frittée | Jusqu'à 7,3 g/cm³ |

| Dureté (HRB) | 70-85 |

| Résistance à la traction | 480-620 MPa |

Caractéristiques de la poudre atomisée SS-410L :

- Excellente fluidité pour les procédés AM

- Faible teneur en oxygène pour de meilleurs résultats de frittage

- Une morphologie cohérente garantit des performances uniformes

- Réduction des impuretés pour une meilleure fiabilité

Options de personnalisation chez Truer :

- Réglage de la taille des particules pour le MIM, le SLM ou la projection de liant

- Optimisation des mélanges d'alliages

- Étiquetage et emballage OEM pour les distributeurs

🔍 Explorez d'autres spécifications de la poudre d'acier inoxydable sur AM-Material.com

4. Tendances du marché et demande mondiale de poudres d'acier inoxydable

Le marché mondial des poudres d'acier inoxydable connaît une tendance à la hausse significative, stimulée par l'adoption rapide dans les industries de la fabrication additive (AM), de la métallurgie des poudres (PM) et du moulage par injection de métal (MIM). La poudre atomisée SS-410L, en particulier, a vu sa demande augmenter en raison de son équilibre entre la résistance à la corrosion, l'accessibilité financière et la résistance mécanique.

📊 Aperçu des principaux marchés :

| Métrique | 2023 Estimation | prévisions pour 2028 |

|---|---|---|

| Taille du marché mondial de la poudre d'inox | 1,3 milliard de dollars | 2,1 milliards de dollars |

| CAGR (2023-2028) | 9.2% | |

| Principaux secteurs de croissance | Automobile, aérospatiale, AM | Énergie, Dispositifs médicaux |

| Principaux marchés régionaux | Chine, États-Unis, Allemagne, Japon | Inde, Corée du Sud, Brésil |

🔎 Les tendances B2B stimulent la demande :

- Localisation de la chaîne d'approvisionnement: Les équipementiers et les fournisseurs de niveau 1 diversifient leurs sources d'approvisionnement afin de réduire leur dépendance à l'égard de marchés particuliers.

- Passer à la fabrication durable: La recyclabilité du SS-410L s'aligne sur les objectifs de développement durable.

- Demande de personnalisation: Les utilisateurs finaux recherchent des solutions de poudres sur mesure pour des géométries de pièces spécifiques.

Aperçu du commerce de gros: Les distributeurs et les acheteurs en gros privilégient de plus en plus les relations directes avec des fabricants tels que Shanghai Truer Technology pour garantir le contrôle de la qualité, des délais de livraison plus courts et une assistance technique.

👉 Découvrez nos capacités en matière de métallurgie des poudres sur notre site web page d'accueil

5. Facteurs à prendre en compte lors du choix d'un fournisseur de poudre SS-410L

Le choix du bon fournisseur de poudre atomisée SS-410L est essentiel pour garantir la cohérence du produit, l'efficacité de la production et la conformité réglementaire dans les flux de production B2B.

liste de contrôle pour l'évaluation des fournisseurs :

| Critères d'évaluation | Pourquoi c'est important pour les acheteurs B2B |

|---|---|

| Qualité des poudres & ; Composition | Impacts sur la performance des pièces, le succès du frittage |

| Technologie d'atomisation | Détermine la morphologie et la fluidité des poudres |

| Cohérence des lots | Essentiel pour la production de grands volumes et la répétabilité |

| Certifications | Conformité ISO, RoHS et REACH pour l'exportation |

| Capacités de personnalisation | Possibilité de modifier la distribution des tailles ou la teneur en alliages |

| Délais et logistique | Affecte la planification de la production et le contrôle des stocks |

| Support technique | Essentiel pour le dépannage et l'optimisation des applications |

| Conditions de prix et de quantité | Impact sur la budgétisation et la compétitivité de votre chaîne d'approvisionnement |

🌟 Shanghai Truer Technology Advantage :

- Processus de double atomisation (gaz + eau) pour répondre à divers besoins de fabrication

- Recherche et développement en interne pour des mélanges de poudres sur mesure

- Production et traçabilité certifiées ISO

- Qualité constante d'un lot à l'autre

- MOQ flexible pour les distributeurs et les OEM

🔗 Voir notre offre complète de produits en Poudres d'acier inoxydable PM

6. Principaux fournisseurs mondiaux de poudre SS-410L

Lors de l'approvisionnement en poudre SS-410L en vrac, les entreprises doivent évaluer non seulement le prix, mais aussi la capacité, l'expertise technique et la portée mondiale du fournisseur. Voici une comparaison des fournisseurs de premier plan qui s'adressent aux acheteurs B2B :

| Nom de l'entreprise | Pays | Spécialité | Technologie d'atomisation | Services B2B proposés |

|---|---|---|---|---|

| Shanghai Truer Technology | Chine | PM & ; Poudres pour l'impression 3D | Gaz & ; Eau | Personnalisation OEM, approvisionnement en vrac, conseil technique |

| Hoganas AB | Suède | Poudres métalliques de haute pureté | L'eau | Distribution mondiale, recherche et développement avancés |

| Additif pour charpentier | ÉTATS-UNIS | Poudres pour la fabrication additive | Gaz | Ingénierie d'application, soutien logistique |

| Sandvik Additive | Suède | Poudres AM & ; MIM de qualité supérieure | Gaz | Poudres ultrafines, services d'impression internes |

| Pometon S.p.A. | Italie | Poudres PM de qualité industrielle | L'eau | Fourniture de pièces détachées de qualité automobile, formation technique |

Pourquoi Shanghai Truer se démarque :

- L'un des fournisseurs d'additifs les plus professionnels de Chine dans l'industrie des particules

- Offre une solution complète : production de poudres + équipement + soutien à l'application

- Forte présence sur les marchés asiatique, européen et nord-américain

- Des prix compétitifs et une livraison plus rapide grâce à une production localisée

📞 Prêt à vous connecter avec nous ? Contacter l'équipe Truer pour les demandes de renseignements concernant le commerce de gros.

7. Pourquoi de plus en plus d'acheteurs choisissent les fabricants chinois pour la poudre SS-410L

Au cours de la dernière décennie, la Chine est devenue une force dominante dans la chaîne d'approvisionnement mondiale de la métallurgie des poudres (PM) et de la fabrication additive (AM). De plus en plus d'acheteurs B2B - des équipementiers aux distributeurs de matériaux - s'approvisionnent en poudres d'acier inoxydable, comme le SS-410L atomisé, auprès de fournisseurs chinois en raison de plusieurs avantages stratégiques.

📈 Principales raisons pour lesquelles les acheteurs s'approvisionnent en Chine :

- Rentabilité

- La baisse des coûts des matières premières et de la main-d'œuvre réduit le coût total de production.

- Des prix compétitifs permettent de dégager de meilleures marges pour les revendeurs et les équipementiers.

- Échelle de production & ; Capacité

- Des fabricants chinois comme Shanghai Truer exploitent des lignes d'atomisation à grande échelle.

- Capable de répondre à des commandes de gros volumes avec une qualité constante.

- Progrès technologiques

- Utilisation de technologies d'atomisation hybrides (gaz et eau) pour optimiser les propriétés.

- La recherche et le développement en interne permettent de mettre au point rapidement des alliages sur mesure.

- Des délais plus courts

- Une logistique nationale solide et des réseaux d'expédition internationaux.

- Réduction des délais de mise sur le marché, en particulier pour les acheteurs de l'Asie de l'Est et du Pacifique.

- Conformité réglementaire

- Les principaux fournisseurs chinois respectent les normes ISO 9001, RoHS et REACH.

- Traçabilité et documentation pour la distribution mondiale.

💡 Conseil de pro pour les distributeurs :

Lorsque vous vous approvisionnez en Chine, choisissez des entreprises établies qui ont fait leurs preuves en matière d'exportation, telles que Shanghai Truer Technologyafin de garantir la fiabilité et l'assistance technique.

8. Pourquoi choisir Shanghai Truer Technology comme partenaire pour la poudre SS-410L ?

Shanghai Truer Technology Co, Ltd s'est imposée comme l'un des fournisseurs de métallurgie des poudres les plus fiables de Chine. Depuis son entrée dans l'industrie de la fabrication additive en 2019, Truer a développé un solide portefeuille de poudres métalliques, notamment le SS-410L atomisé de haute pureté.

🏆 Ce qui distingue Shanghai Truer :

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Atomisation double (gaz + eau) | Une fluidité et une densité adaptées aux besoins de l'AM & ; de l'PM |

| Large gamme de grades | Du CT-1000 au FD-0208 et aux mélanges personnalisés SS-410L |

| Recherche et développement internes | Développement rapide de compositions d'alliage personnalisées |

| Production & ; Intégration des équipements | Solution AM complète : poudre + équipement + assistance |

| OEM et distributeurs | QMo flexible, emballage en marque blanche et expédition rapide |

✔ Assurance de la qualité des produits :

- Morphologie cohérente des particules: Assure un comportement de frittage prévisible.

- Contamination par l'oxygène: Améliore les performances mécaniques des pièces finales.

- Cohérence d'un lot à l'autre: Essentiel pour la production à grande échelle de MIM/SLM.

🔧 Un service complet d'assistance :

- Conseil technique pour l'optimisation des applications

- Distribution granulométrique personnalisée

- Documentation d'exportation et soutien logistique

Découvrez la gamme complète de poudres métalliques et d'additifs Truer sur leur site Internet page produit

9. FAQs : Acheter en gros de la poudre atomisée SS-410L

Q1 : Quel est le MOQ pour les commandes en gros de poudre SS-410L de Shanghai Truer ?

A : La quantité minimale de commande est flexible, à partir de 100 kg pour les commandes d'essai. Des tarifs de gros sont disponibles pour les commandes supérieures à 500 kg.

Q2 : Quelles sont les industries qui bénéficient le plus de la poudre SS-410L ?

A : Les industries de l'automobile, de l'aérospatiale, de l'énergie, de la médecine et de la fabrication générale utilisent couramment le SS-410L en raison de sa grande solidité et de sa résistance à la corrosion.

Q3 : Puis-je demander une distribution granulométrique personnalisée ?

A : Truer offre une personnalisation basée sur les exigences de votre processus de frittage ou d'impression (SLM, MIM, Binder Jetting, etc.).

Q4 : Les poudres Truer sont-elles certifiées ?

A : Absolument. Toutes les poudres sont accompagnées d'un COA et sont conformes aux normes ISO 9001. La documentation RoHS et REACH est également disponible pour les exportations mondiales.

Q5 : Comment passer une commande en gros ?

A : Vous pouvez nous contacter directement via le site Page de contact pour obtenir un devis, demander des échantillons ou commencer les achats.

✅ Vous êtes prêt à vous procurer de la poudre SS-410L de haute qualité ?

Shanghai Truer Technology est votre partenaire de confiance pour la poudre atomisée SS-410L haute performance. Que vous soyez un OEM, un distributeur ou un fournisseur de commerce électronique, Truer offre une qualité constante, une expertise technique et des prix compétitifs pour répondre à vos exigences de production.

🔗 Visite AM-Material.com pour consulter notre gamme complète de produits ou prendre contact avec notre équipe dès aujourd'hui.

📌 Liens internes utilisés dans ce blog :

- https://am-material.com/about/ - “Shanghai Truer Technology” ;

- https://am-material.com/pm-powder/ - “Gamme de produits en poudre SS-410L” ;

- https://am-material.com/pm-powder/ - “Poudres d'acier inoxydable PM” ;

- https://am-material.com/contact-us/ - “Contacter l'équipe Truer 𔄭 ;

- https://am-material.com/ – “AM-Material.com”

Faites-nous part du prochain sujet que vous souhaitez explorer !