1. Introduction : Pourquoi la poudre de bronze PM est-elle importante dans la fabrication moderne ?

La poudre de bronze issue de la métallurgie des poudres joue un rôle essentiel dans les composants industriels de haute performance. Alors que la demande de pièces durables, efficaces et rentables augmente, les fabricants des secteurs de l'automobile, de l'aérospatiale, de la marine et des machines industrielles se tournent de plus en plus vers la poudre de bronze de la métallurgie des poudres en raison de ses propriétés :

- Résistance supérieure à l'usure

- Excellente conductivité thermique et électrique

- Haute résistance à la corrosion

- Compatibilité avec divers procédés de frittage

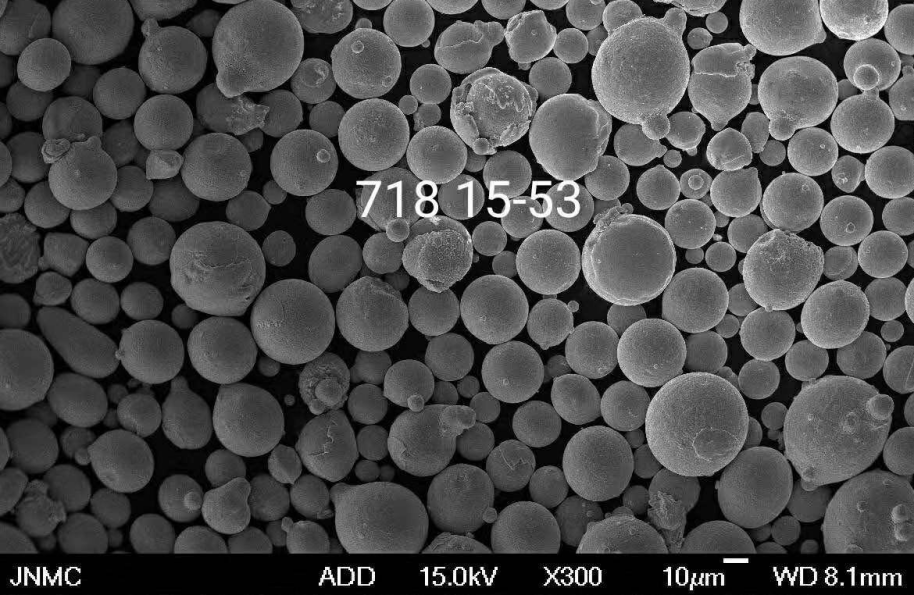

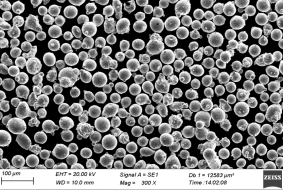

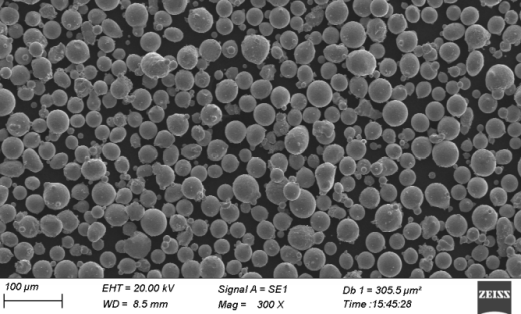

La poudre de bronze PM est généralement produite à l'aide de techniques d'atomisation, notamment l'atomisation à l'eau et l'atomisation au gaz. Ces méthodes permettent un contrôle précis de la taille, de la forme et de la distribution des particules, qui sont des facteurs critiques pour la production de pièces frittées de haute qualité.

La poudre de bronze PM est une matière première de choix pour la fabrication à grande échelle et les applications OEM, en particulier dans les environnements B2B, où la cohérence, l'évolutivité et la fiabilité de la chaîne d'approvisionnement sont importantes.

2. Principales applications industrielles de la poudre de bronze PM

La poudre de bronze PM est largement utilisée dans les industries qui ont besoin de composants présentant à la fois une résistance mécanique et des propriétés autolubrifiantes. Voici les principales applications :

⚙️ Cas d'utilisation courants

| L'industrie | application | Description |

|---|---|---|

| Automobile | Bagues et paliers | Bagues en bronze imprégnées d'huile pour des performances durables |

| Aérospatiale | Guides de soupapes | Pièces à haute résistance, résistantes à la corrosion |

| Électricité | Contacts et connecteurs | Excellentes propriétés de conductivité et d'anticorrosion |

| Marine | Bagues d'hélice | Résiste à la corrosion due à l'eau salée |

| Machines industrielles | Engrenages et pièces structurelles | Composants solides et résistants à l'usure pour les machines à forte charge |

🧪 Avantages fonctionnels

- Autolubrification: La poudre de bronze est souvent utilisée dans les roulements frittés imprégnés d'huile, ce qui la rend idéale pour les assemblages sans entretien.

- Précision dimensionnelle: La métallurgie des poudres permet un contrôle étroit des tolérances, ce qui est essentiel pour les systèmes automatisés et robotisés.

- Efficacité des matériaux: Un minimum de déchets pendant la production permet de réduire le coût unitaire, ce qui est important pour les acheteurs en gros et les OEM.

3. Types de poudres de bronze PM et leurs propriétés

Les poudres de bronze PM sont classées en fonction de leur composition, de leur méthode de production et des caractéristiques des particules. Les types de bronze les plus courants sont les suivants

🔬 Compositions communes

| Type | Cuivre (%) | Étain (%) | Additifs | Propriétés |

|---|---|---|---|---|

| Bronze standard | 90 | 10 | Aucun | Excellente résistance à l'usure, usage général |

| Bronze phosphoreux | 89 | 10 | 1% Phosphore | Amélioration de la rigidité et de la résistance à la fatigue |

| Bronze imprégné d'huile | 90 | 10 | Lubrifiants | Autolubrifiant, idéal pour les coussinets |

| Bronze au plomb | 85 | 5 | 10 % d'avance | Usinabilité améliorée, applications antifriction |

⚗️ Méthodes de production

- Vaporisation de l'eau: Idéal pour produire de grands volumes de particules de forme irrégulière, adaptées aux applications structurelles.

- atomisation du gaz: Produit des particules sphériques, préférées pour les applications nécessitant une plus grande fluidité et une meilleure densité de tassement.

🏭 Grades disponibles à Shanghai Truer

Shanghai Truer Technology Co. propose des poudres de bronze PM spécialisées pour diverses applications industrielles. Ces poudres sont disponibles en plusieurs qualités et méthodes de production, notamment :

- Options de pulvérisation d'eau et de gaz

- Poudre de bronze de haute pureté avec une distribution granulométrique cohérente

- Compositions sur mesure pour des applications spécialisées

Vous pouvez consulter des informations plus détaillées sur les produits sur leur site web Page produit PM Powder.

4. Tendances du marché et opportunités de croissance dans la métallurgie des poudres de bronze

Le marché mondial de la métallurgie des poudres de bronze connaît une forte dynamique, tirée par la demande des secteurs de l'automobile, de l'électronique et des machines industrielles. Alors que l'ingénierie de précision et la fabrication écologique gagnent du terrain, la poudre de bronze PM devient un matériau stratégique pour les acheteurs B2B.

📊 Perspectives de croissance du marché

| Métrique | 2023 | 2028 (projeté) | CAGR |

|---|---|---|---|

| Taille du marché mondial du bronze PM | 1,2 milliard de dollars | 1,9 milliard de dollars | 8.9% |

| Part de l'Asie-Pacifique | 45% | 50%+ | Région à plus forte croissance |

🔥 Facteurs clés

- Électrification des véhicules: Utilisation accrue du bronze PM dans les moteurs électriques et les roulements.

- Développement durable: La métallurgie des poudres réduit les déchets de matériaux, ce qui est conforme aux objectifs ESG.

- Fabrication avancée: Fabrication additive et Impression 3D intègrent des matériaux PM pour créer des composants légers et durables.

🛠️ Applications émergentes

- Équipements pour l'énergie verte (par exemple, éoliennes, moteurs de panneaux solaires)

- Entraînements et actionneurs électriques

- Capteurs industriels intelligents et robotique

🌍 Tendances régionales

- Chine et Asie du Sud-Est: L'essor de la fabrication locale et le soutien des pouvoirs publics à la technologie des particules.

- L'Europe: Forte adoption dans les secteurs de l'automobile et de l'aérospatiale en raison des objectifs de performance et de durabilité.

- Amérique du Nord: L'accent est mis de plus en plus sur la relocalisation et l'approvisionnement local en matières premières.

5. Choisir le bon fournisseur de poudre de bronze PM : Principaux éléments à prendre en compte

La sélection du bon fournisseur de poudre de bronze PM est essentielle pour les acheteurs B2B, en particulier ceux qui gèrent des opérations de fabrication ou d'OEM à grande échelle. Voici les facteurs essentiels à évaluer :

liste de contrôle pour l'évaluation des fournisseurs

| Critères | Pourquoi c'est important |

|---|---|

| Consistance de la poudre | Assurer la fiabilité des produits sur l'ensemble des cycles de production |

| Méthode de production | Affecte la morphologie, la fluidité et la frittabilité des poudres |

| Capacités de personnalisation | Capacité à répondre à des besoins spécifiques en matière d'alliage ou de taille des particules |

| Logistique et délais | Essentiel pour les acheteurs de JIT ou de gros volumes |

| Certifications et contrôle de la qualité | Conformité ISO, RoHS, REACH pour le commerce international |

| Support technique | Permet d'optimiser les paramètres de traitement et de réduire les taux de défaut |

🧩 Défis communs en matière d'approvisionnement B2B

- Des tailles de particules incohérentes entraînant des problèmes de frittage

- Retards dus à une capacité de production limitée

- Manque de flexibilité pour répondre aux exigences des alliages personnalisés

- Absence de documentation technique ou de traçabilité des matériaux

Shanghai Truer répond à ces préoccupations en proposant :

- Une large gamme de compositions et de nuances d'alliages

- Méthodes d'atomisation au gaz et à l'eau

- Recherche et développement en interne et assistance technique pour les partenaires B2B

- Installations de production certifiées ISO

Pour en savoir plus sur les antécédents et les capacités de l'entreprise, visitez le site web de la Commission européenne A propos de nous.

6. Les 5 premiers fournisseurs de poudre de bronze PM en Asie-Pacifique

Pour les distributeurs B2B, les OEM et les responsables des achats industriels, le choix d'un fournisseur fiable dans la région Asie-Pacifique garantit des prix compétitifs et un approvisionnement régulier. Voici les cinq principaux fournisseurs :

🏆 Principaux fournisseurs de bronze PM

| Entreprise | Pays | Principaux points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Large gamme de poudres de bronze et d'alliage PM, atomisation avancée, axée sur la R & D |

| Fukuda Metal Foil & Powder Co. Ltd | Japon | Bronzes spéciaux pour l'électronique et l'automobile |

| GKN Hoeganaes | Chine/Japon | Une présence mondiale, une expertise métallurgique étendue |

| POLEMA | Russie | Poudres de bronze de haute pureté pour applications spécialisées |

| Poudre CNPC | Chine | Diversité des poudres PM, fortes capacités d'exportation |

🤝 Pourquoi Shanghai Truer sort du lot

- Établi en 2009, avec plus d'une décennie d'expertise en matière de gestion de projets

- Lancement d'une division de fabrication additive en 2019

- Offre des qualités de poudre de bronze PM standard et sur mesure

- Les services comprennent l'équipement de production de poudres, l'assistance et les solutions d'additifs

- Reconnu comme l'un des principaux fournisseurs d'additifs dans l'industrie chinoise des MP

Les produits en bronze de Shanghai Truer sont idéaux pour les acheteurs qui recherchent une qualité constante dans des volumes de gros. Leurs processus de fabrication avancés garantissent des poudres de haute performance adaptées aux normes automobiles, électroniques et industrielles.

Vous pouvez explorer toutes leurs capacités et les contacter directement par l'intermédiaire de leur site web Page de contact.

7. Pourquoi de plus en plus d'acheteurs se tournent vers les fabricants chinois de poudre de bronze PM

Ces dernières années, de nombreux distributeurs, grossistes et OEM du monde entier se sont tournés vers les fournisseurs chinois pour s'approvisionner en poudre de bronze PM, et ce pour de bonnes raisons. L'industrie chinoise de la métallurgie des poudres a considérablement évolué, offrant une combinaison unique de prix, de qualité et de capacités techniques.

🌐 Principaux avantages de l'approvisionnement en poudre de bronze PM en Chine

| Avantage | Description |

|---|---|

| Prix compétitifs | Réduction des coûts de production et économies d'échelle |

| Une gamme de produits diversifiée | Large choix de compositions de bronze et de tailles de particules |

| Installations modernes | Technologies avancées d'atomisation de l'eau et du gaz |

| Capacités de R & D | Des fournisseurs comme Shanghai Truer investissent dans l'innovation des produits |

| Délai d'exécution rapide | Délais plus courts pour les expéditions mondiales et les commandes en gros |

📦 Idéal pour les acheteurs B2B

- Distributeurs: Accès à des prix de gros et à une qualité constante pour la revente

- Fabricants OEM: Des qualités personnalisables et des chaînes d'approvisionnement fiables

- Vendeurs de commerce électronique: Approvisionnement compétitif pour soutenir les marchés en ligne

- Ingénieurs industriels: Documentation technique et échantillons pour le prototypage

🏭 Pourquoi Shanghai Truer est un choix privilégié

Shanghai Truer Technology Co., Ltd jouit d'une confiance croissante de la part des acheteurs internationaux à la recherche d'un partenaire B2B à long terme. Voici pourquoi :

- Équipe interne de recherche et développement pour personnaliser les poudres de bronze pour des applications spécifiques

- Flexibilité de production avec des méthodes d'atomisation à l'eau, au gaz ou hybrides

- Expérience confirmée avec des acheteurs dans les secteurs de l'automobile, de l'électricité et des pièces frittées

- Gamme complète de produits PM

8. Pourquoi choisir Shanghai Truer comme fournisseur de poudre de bronze PM ?

Shanghai Truer s'est positionné en tant que leader de l'industrie chinoise des particules. Pour les entreprises qui s'approvisionnent en poudre de bronze PM en gros, l'entreprise offre une valeur inégalée en termes d'expertise technique, de diversité des produits et d'assistance à la clientèle.

🏢 Présentation de l'entreprise

| Attribut | Détails |

|---|---|

| Établi | 2009 |

| Lancement de l'entreprise PM | 2019 |

| Spécialisation | Equipement PM, Poudre de bronze, Additifs |

| Méthodes de production | Atomisation à l'eau, atomisation au gaz, atomisation combinée |

| Clients cibles | OEM, distributeurs, fabricants d'additifs |

🔍 Points forts du produit

- Poudre de bronze PM dans des qualités adaptées à :

- Roulements imprégnés d'huile

- Contacts électriques

- Bagues marines

- Formulation d'alliages personnalisés sur demande

- Poudre de bronze disponible en différentes tailles de particules

🧪 Solutions additives

Truer propose également une solution complète d'additifs pour les clients PM :

- Lubrifiants tels que Lube-W, SUW-8000

- Agents de coupe tels que SME-100, TD-8

- Graphites (TBC-400, TBC-1000)

- Additifs magnétiques doux (QH-150, QHP-330)

Shanghai Truer n'est donc pas seulement un fournisseur de poudres de bronze, mais aussi un partenaire technologique complet dans le domaine de la métrologie légale. Pour en savoir plus sur l'ensemble de ses capacités, consultez le site Web de Shanghai Truer site web principal.

9. FAQs : Acheter de la poudre de bronze PM en gros

Voici les réponses aux questions les plus fréquentes posées par les acheteurs B2B et les spécialistes des achats :

❓ Quelle est la quantité minimale de commande (MOQ) pour la poudre de bronze PM ?

- Les MOQ varient en fonction de la qualité, mais commencent généralement à partir de 100 kg pour les compositions standard. Les commandes personnalisées peuvent avoir des exigences différentes.

❓ Puis-je demander des compositions d'alliage personnalisées ?

- Oui, Shanghai Truer prend en charge l'alliage personnalisé et la distribution de la taille des particules en fonction des besoins de votre application.

❓ Quelles sont les certifications de qualité de Shanghai Truer ?

- L'entreprise respecte les normes ISO et fournit des fiches techniques, des fiches de données de sécurité et des rapports d'inspection de la qualité avec chaque envoi.

❓ Comment la poudre est-elle expédiée ?

- Les poudres sont emballées dans des sacs scellés sous vide ou remplis d'azote et expédiées dans des fûts ou des caisses, en fonction de la taille de la commande et de la destination.

❓ Proposez-vous une assistance technique ?

- Truer offre une assistance technique complète, y compris des conseils sur le frittage, des directives sur la manipulation des poudres et le développement d'applications.

❓ Comment obtenir un devis ou un échantillon ?

- Vous pouvez demander un échantillon ou un devis directement par l'intermédiaire de la page d'accueil Page de contact. Un ingénieur commercial vous assistera dans les 24 à 48 heures.

En s'approvisionnant en poudre de bronze PM auprès d'un fournisseur de confiance comme Shanghai Truer, les acheteurs B2B peuvent garantir la qualité, la cohérence et la rentabilité de chaque lot. Que vous soyez un OEM, un distributeur ou un vendeur en ligne, Truer offre la fiabilité et l'assistance technique nécessaires pour rester compétitif dans le paysage industriel actuel.