1. Introduction : Qu'est-ce que la poudre de laiton PM et pourquoi est-elle importante dans la fabrication ?

La poudre de laiton PM (Powder Metallurgy) est un alliage de cuivre et de zinc finement broyé, conçu pour être utilisé dans les composants frittés et la fabrication additive. Par rapport aux méthodes conventionnelles de moulage ou d'usinage, la poudre de laiton PM permet de produire des pièces complexes de manière plus efficace et avec peu de déchets. La poudre de laiton PM est devenue une matière première essentielle à mesure que la demande de composants de forme presque nette augmente dans des secteurs tels que l'automobile, l'électronique et l'aérospatiale.

Pourquoi les acheteurs B2B doivent-ils être attentifs ?

- ✔️ Coût-efficacité pour la production de masse

- ✔️ Grande recyclabilité et faibles pertes de matériaux

- ✔️ Permet une fabrication de précision

- ✔️ Idéal pour les géométries complexes

Les principaux acteurs du secteur B2B, tels que les fabricants OEM, les distributeurs et les producteurs de pièces en métallurgie des poudres, s'approvisionnent de plus en plus en ce matériau afin d'améliorer les performances des produits et de minimiser les coûts de production.

2. Applications de la poudre de laiton PM dans les secteurs industriels

La poudre de laiton PM est utilisée dans de nombreux secteurs en raison de ses excellentes propriétés mécaniques, de sa conductivité thermique et de sa résistance à la corrosion. Voici les principales industries qui utilisent la poudre de laiton PM dans leurs lignes de production :

| L'industrie | Cas d'utilisation de l'application |

|---|---|

| Automobile | Anneaux de synchronisation, bagues, engrenages et sièges de soupapes |

| Électricité et électronique | Broches de connecteur, bornes, dissipateurs thermiques et blindage EMI |

| Outils et machines | Roulements, cames et composants de soupapes |

| Aérospatiale | Composants de précision légers |

| Biens de consommation | Accessoires décoratifs, pièces de serrure, accessoires de plomberie |

Avantages pour les distributeurs B2B et les équipementiers :

- Personnalisation en vrac selon des rapports d'alliage spécifiques (Cu/Zn)

- Taille constante des particules pour un meilleur frittage

- Disponibilité sous forme d'atomes d'eau et d'atomes de gaz

Pour un aperçu détaillé des poudres PM disponibles, y compris le laiton, voir notre catalogue de poudres PM.

3. Propriétés clés et cas d'utilisation de la poudre de laiton PM

La compréhension des propriétés matérielles de la poudre de laiton PM aide les acheteurs B2B à prendre des décisions éclairées en matière d'approvisionnement. Vous trouverez ci-dessous une ventilation des propriétés critiques :

| Propriété | Description |

|---|---|

| Distribution de la taille des particules | La fourchette est généralement comprise entre 25 et 150 microns |

| Débit | Excellente fluidité pour un compactage uniforme |

| Température de frittage | 800-900°C selon la composition de l'alliage |

| Densité | Densité réalisable jusqu'à 7,0 g/cm³ |

| Résistance mécanique | Haute résistance et ductilité après frittage |

| Résistance à la corrosion | Excellent dans les environnements humides et légèrement acides |

Cas d'utilisation dans la fabrication interentreprises :

- ✔️ Bagues en laiton PM pour les applications à grande vitesse

- ✔️ Filtres en laiton fritté dans les systèmes de chauffage, de ventilation et de climatisation et les systèmes de fluides

- ✔️ Composants de blindage EMI dans le matériel de télécommunication

- ✔️ Pièces décoratives en laiton par fabrication additive

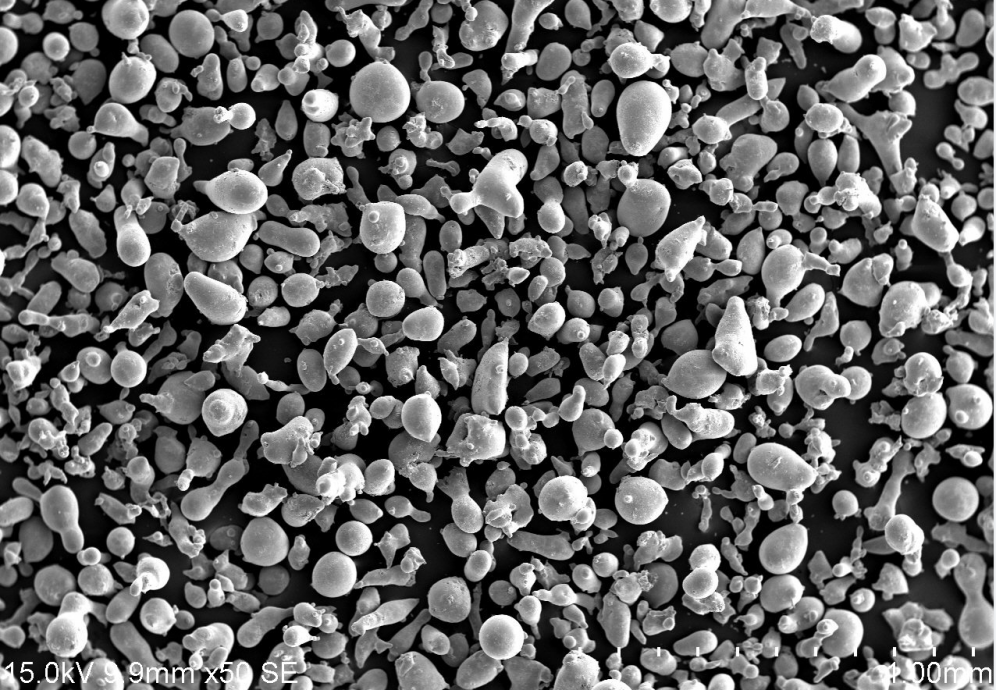

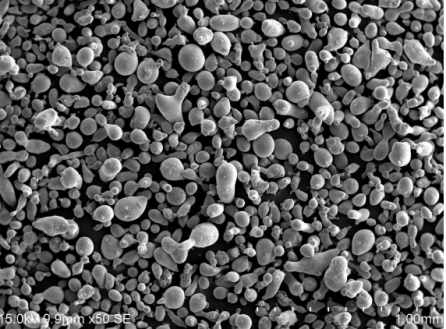

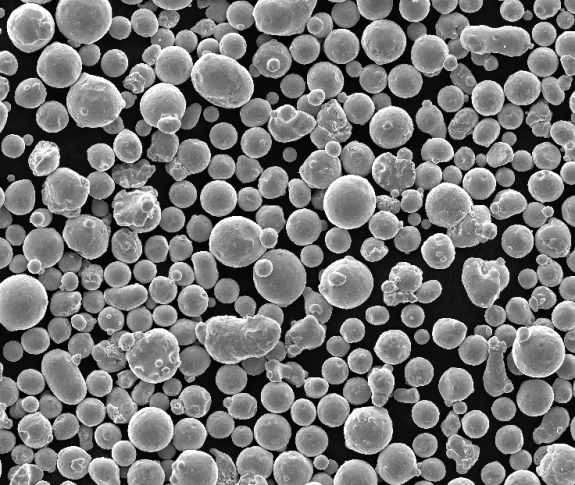

Shanghai Truer Technology Co. propose des poudres de laiton PM fabriquées à l'aide de techniques avancées d'atomisation à l'eau. Ces poudres offrent une excellente fluidité et une grande résistance à l'état vert, ce qui les rend idéales pour les applications traditionnelles de PM et de Impression 3D et les applications. Pour en savoir plus sur la mission de l'entreprise et ses capacités de production, visitez le site web de l'entreprise A propos de nous.

4. Tendances du marché et potentiel de croissance dans le segment des poudres de laiton

Le marché de la poudre de laiton PM connaît une forte croissance, stimulée par l'essor de la fabrication additive, l'électrification des véhicules et l'adoption croissante de la métallurgie des poudres dans les composants de précision. Selon de récents rapports industriels, le marché mondial de la métallurgie des poudres devrait atteindre 12,9 milliards USD d'ici 2028, les poudres non ferreuses comme le laiton jouant un rôle central.

Principaux moteurs de la croissance

- 📈 Expansion des composants de véhicules électriques (VE) à l'aide de pièces PM

- 🏗️ La croissance des infrastructures stimule la demande de raccords de plomberie et de mécanique

- 🔧 Utilisation accrue du laiton dans les composants frittés résistants à l'usure

- 🌍 Passage à la fabrication durable et à l'efficacité des matériaux

Perspectives pour les acheteurs en gros B2B

| Tendance | Impact sur les acheteurs |

|---|---|

| Passage à une fabrication proche de la forme d'un filet | Réduction de l'usinage et des déchets, amélioration des marges |

| Développement d'alliages sur mesure | Exige une collaboration plus étroite avec les fournisseurs de poudres |

| Croissance dans la région Asie-Pacifique | Accroissement de la concurrence et de la complexité de la chaîne d'approvisionnement |

| L'accent mis sur la stabilité de la chaîne d'approvisionnement | Encourage les contrats à long terme avec des fournisseurs fiables |

Shanghai Truer Technology Co. Ltd répond à ces tendances en proposant des solutions sur mesure et en maintenant la fiabilité de la chaîne d'approvisionnement. Sa gamme de poudres de laiton PM atomisées est conçue pour répondre aux besoins évolutifs des fabricants mondiaux, en particulier dans les secteurs de l'automobile et de l'électronique.

5. Comment évaluer les fournisseurs de poudre de laiton PM pour les achats en gros

Le choix du bon fournisseur est essentiel pour garantir la qualité, la cohérence et la rentabilité de votre processus de production. Vous trouverez ci-dessous une liste de contrôle que les acheteurs B2B doivent prendre en compte lorsqu'ils évaluent les fournisseurs de poudre de laiton PM :

Critères d'évaluation des fournisseurs

| Critères | Ce qu'il faut rechercher |

|---|---|

| Qualité de la poudre | Taille constante des particules, grande pureté, bonne compressibilité |

| Technologie de production | Atomisation à l'eau, atomisation au gaz ou méthodes d'atomisation hybrides |

| Support technique | Développement d'alliages sur mesure, essais de matériaux et assistance au frittage |

| Certifications | Conformité ISO, RoHS, REACH pour les marchés internationaux |

| MOQ et délai d'exécution | Quantités minimales de commande flexibles et livraison rapide |

| Logistique et emballage | Emballages anti-oxydation, conteneurs sous vide, documentation prête à l'exportation |

Questions à poser à un fournisseur potentiel

- Pouvez-vous fournir une fiche technique et une fiche de données de sécurité pour la poudre de laiton ?

- Quelles sont les températures de frittage et les durées de maintien recommandées ?

- Proposez-vous des rapports d'alliage personnalisés (par exemple, Cu:Zn 65:35, 60:40) ?

- Quels sont les délais de livraison standard pour les commandes en gros ?

Pour les acheteurs à la recherche d'un partenaire fiable à long terme, Shanghai Truer propose non seulement une large gamme de poudres PM, mais aussi des solutions d'additifs complètes, notamment des lubrifiants et des agents de coupe qui améliorent les performances de frittage et d'usinage. Pour en savoir plus sur leur gamme complète de produits, consultez leur site web page d'accueil.

6. Principaux fournisseurs mondiaux de poudre de laiton PM pour les équipementiers et les distributeurs

Pour aider les acheteurs à s'y retrouver dans le paysage des fournisseurs, voici quelques-unes des principales sources mondiales de poudre de laiton PM de haute qualité :

| Nom du fournisseur | Région | Principaux points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Large gamme d'alliages, options d'atomisation eau/gaz, solutions personnalisées |

| Hoganas AB | Suède | Présence mondiale, recherche et développement importants, prix élevés |

| GGP Poudre métallique | Allemagne | Normes européennes, poudres non ferreuses spécialisées |

| Kymera International | ÉTATS-UNIS | Poudres de laiton de haute pureté, très utilisées dans l'aérospatiale |

| Fukuda Metal Foil & Powder Co. Ltd. | Japon | Poudres de précision pour l'électronique et l'outillage fin |

Pourquoi Truer est-il le premier choix des acheteurs internationaux ?

- 🌐 Une logistique et une documentation prêtes pour l'exportation

- 🧪 Solutions personnalisées comprenant des additifs PM et des matériaux magnétiques doux

- 🏭 Plus d'une décennie d'expérience dans le domaine de la maintenance et de la fabrication additive

- 📦 Souplesse d'utilisation pour les petits lots et les commandes en vrac

Les distributeurs et les équipementiers à la recherche d'un partenaire d'approvisionnement stratégique en Asie peuvent bénéficier de la connaissance approfondie de l'industrie et des capacités de production fiables de Truer. Truer propose également des conseils sur la sélection des matériaux et l'amélioration des processus de frittage. Pour des demandes directes ou des demandes d'échantillons, visitez le site Web de Truer Page de contact.

7. Pourquoi les fabricants se tournent vers les sources chinoises de poudres de laiton PM

Ces dernières années, les acheteurs B2B - y compris les OEM, les grossistes et les fabricants sous contrat - se sont de plus en plus tournés vers les fournisseurs chinois de poudre de laiton PM. Cette évolution s'explique par plusieurs avantages stratégiques que les fabricants de poudre chinois apportent au marché mondial.

Principales raisons de ce changement

- 💰 Rentabilité: La baisse des coûts opérationnels et de main-d'œuvre permet de réduire le prix des matières premières sans compromettre la qualité.

- 🏭 Échelle de production: Des installations de pointe avec une production à haut volume garantissent un approvisionnement constant pour les commandes en gros.

- 🧪 Capacités de personnalisation: Les fabricants chinois proposent des compositions d'alliages de laiton sur mesure pour des applications spécifiques.

- 🚛 Amélioration de la logistique: Amélioration des capacités d'expédition à l'échelle mondiale grâce à un emballage et à des certifications adaptés à l'exportation.

- 📊 Investissement technologique: L'investissement continu dans les technologies d'atomisation et la recherche et le développement permettent de proposer des produits compétitifs.

Cas d'utilisation B2B : approvisionnement des équipementiers européens en Chine

| Défi | Fournisseur traditionnel | Fournisseur chinois (par exemple, Shanghai Truer) |

|---|---|---|

| Coûts élevés des matières premières | 9,50 $/kg | 6,80 $/kg |

| Délai d'exécution | 5-6 semaines | 3-4 semaines |

| Flexibilité de l'alliage sur mesure | Limitée | Disponible |

| Support technique | Modéré | Ingénieurs spécialisés dans le domaine de la maintenance |

Shanghai Truer Technology Co. est un exemple majeur de cette transformation. Ses poudres de laiton PM sont fabriquées par atomisation de précision à l'eau et au gaz, ce qui permet un contrôle étroit de la taille des particules et une grande compressibilité. Les protocoles d'assurance qualité et les capacités d'expédition mondiale de Truer en font un fournisseur privilégié pour les entreprises qui recherchent un équilibre entre la qualité, le prix et la fiabilité.

Pour un aperçu complet de leurs poudres de laiton et d'alliage de cuivre, visitez le site web Poudre PM page produit.

8. Pourquoi choisir Shanghai Truer Technology Co. comme fournisseur de poudre de laiton ?

Shanghai Truer est l'un des noms les plus fiables de l'industrie chinoise de la métallurgie des poudres. Depuis son entrée sur le marché de la fabrication additive en 2019, l'entreprise s'est rapidement forgé une réputation de fournisseur de solutions PM complètes, notamment d'équipements de fabrication de poudres, de poudres de haute qualité et de conseils techniques.

Pourquoi Truer se démarque

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Large gamme de produits | Alliages de laiton, de maillechort, de bronze, d'acier et de cuivre disponibles |

| Des installations ultramodernes | Lignes d'atomisation pour la production d'eau, de gaz et d'hybrides |

| Développement d'alliages sur mesure | Compositions sur mesure (par exemple, Cu-Zn 60:40, 65:35, 70:30) |

| Expertise en matière d'additifs PM | Gamme complète de lubrifiants, d'agents de coupe et d'améliorateurs de frittage |

| Soutien de bout en bout | De la sélection des matériaux à l'intégration additive et à la performance des pièces |

Industries de soutien

- Fabricants de pièces automobiles

- Equipementiers électriques et électroniques

- Fournisseurs de composants pour la métallurgie des poudres

- Grossistes en import-export

- fournisseurs de services d'impression 3D

L'engagement de Truer en matière de précision, de personnalisation et de fiabilité en fait un partenaire idéal à long terme pour les acheteurs mondiaux. Sa division additifs propose également des matériaux uniques tels que les lubrifiants SUW-5000B et les agents de coupe sans soufre SME-100 pour améliorer l'efficacité du traitement des particules.

Pour en savoir plus sur la mission et la philosophie de fabrication de l'entreprise, consultez le site Web de l'entreprise A propos de nous.

9. FAQs : Questions courantes concernant l'achat de poudre de laiton PM en gros

Q1 : Quels sont les alliages de poudre de laiton PM disponibles chez Shanghai Truer ?

A1 : Truer propose une large gamme de rapports Cu-Zn, tels que 60:40, 65:35, et des mélanges personnalisés. Leurs poudres conviennent aux applications frittées et imprimées en 3D.

Q2 : Quelle est la distribution standard de la taille des particules ?

A2 : Truer fournit des poudres de laiton PM dans des tailles de particules allant de 25 µm à 150 µm, avec des options de tamisage personnalisé sur demande.

Q3 : Proposez-vous une assistance technique pour le frittage et le compactage ?

A3 : Oui. L'équipe d'ingénieurs de Truer offre des conseils sur les courbes de frittage, la pression de compactage et la sélection des additifs afin de garantir une performance optimale des pièces.

Q4 : Quelles sont les options d'emballage disponibles pour les envois internationaux ?

A4 : La poudre de laiton PM est scellée sous vide dans des sacs anti-oxydation et emballée dans des fûts ou des cartons de qualité export, en fonction de la taille de la commande.

Q5 : Comment puis-je passer une commande en gros auprès de Shanghai Truer ?

A5 : Vous pouvez facilement poser une question ou demander un devis en remplissant le formulaire sur leur site web Page de contact.

Q6 : Puis-je demander un échantillon avant de passer une commande en gros ?

A6 : Oui. Truer fournit des échantillons de matériaux aux acheteurs B2B qualifiés à des fins d'évaluation et de test.

Q7 : Quelles sont les certifications de vos poudres ?

A7 : Les poudres Truer sont fabriquées dans le cadre de systèmes de gestion de la qualité ISO et sont conformes aux normes RoHS et REACH pour les marchés internationaux.

En s'approvisionnant en poudre de laiton PM auprès de Shanghai Truer Technology Co., Ltd, les acheteurs B2B ont accès à une solution matérielle fiable, rentable et hautement personnalisable, conçue pour la fabrication avancée. Que vous soyez un OEM, un distributeur ou un fabricant d'additifs, Truer offre l'expertise et la gamme de produits nécessaires pour soutenir votre croissance.

🔗 Explorez la gamme complète de poudres PM et de solutions d'additifs sur le site officiel de la Commission européenne Site web AM-Matériel.