1. Introduction: Why Inconel 600 Powder is in High Demand

Inconel 600 powder is a high-performance nickel-chromium-iron alloy widely used for its exceptional resistance to heat, corrosion, and oxidation. As industries prioritize high-strength materials for complex engineering and additive manufacturing, Inconel 600 powder has emerged as a go-to solution for components operating in extreme environments.

Key Reasons Driving Demand:

- Stabilité thermique: Performs under high temperatures up to 1093°C (2000°F)

- Résistance à la corrosion: Excellent in oxidizing and reducing environments

- Additive Manufacturing Compatibility: Ideal for Impression 3D and PM (powder metallurgy)

- Longévité: Significant lifecycle advantages in aggressive industrial conditions

Inconel 600 powder is especially critical for B2B buyers in aerospace, nuclear, marine, and chemical processing sectors who require durable materials that meet stringent safety and performance standards.

2. Industrial Applications of Inconel 600 Powder

Inconel 600 powder is a versatile material tailored for harsh industrial environments. Its unique mechanical and chemical stability makes it indispensable across several sectors.

Principaux domaines d'application :

| L'industrie | application | Bénéfice |

|---|---|---|

| Aérospatiale | Engine components, exhaust ducts, and turbine blades | High temperature resistance and mechanical strength |

| Traitement chimique | Heat exchangers, reaction vessels, and acid tanks | Corrosion resistance to acids and chlorides |

| L'énergie nucléaire | Fuel element cladding and reactor vessels | Radiation and oxidation resistance |

| 3D Printing/Additive Manufacturing | Custom parts and prototypes | High precision, low porosity, and thermal stability |

| Génie maritime | Pump shafts, valves, and heat exchangers | Resistance to saltwater corrosion |

For companies in these sectors, sourcing Inconel 600 powder in bulk or custom blends can significantly improve product reliability and performance.

3. Key Properties and Advantages of Inconel 600 Alloy Powder

The performance of Inconel 600 powder lies in its distinctive alloy composition and microstructure, optimized for extreme industrial conditions.

Chemical Composition of Inconel 600

| Élément | Pourcentage |

|---|---|

| Nickel (Ni) | ≥ 72% |

| Chrome (Cr) | 14% – 17% |

| Fer (Fe) | 6% – 10% |

| Other elements (C, Mn, S, Si, Cu) | < 2% |

Mechanical & Physical Properties

- Densité: 8.47 g/cm³

- Plage de fusion: 1354–1413°C

- Résistance à la traction: 655 MPa

- Limite d'élasticité: 310 MPa

- Élongation: 40%

- Dureté: 85 HRB

Avantages pour les acheteurs B2B :

- ✅ Excellent resistance to oxidation and carburization

- ✅ Maintains mechanical integrity under thermal cycling

- ✅ Non-magnetic and suitable for electric heating applications

- ✅ Compatible with additive manufacturing technologies

- ✅ Long service life in aggressive chemical environments

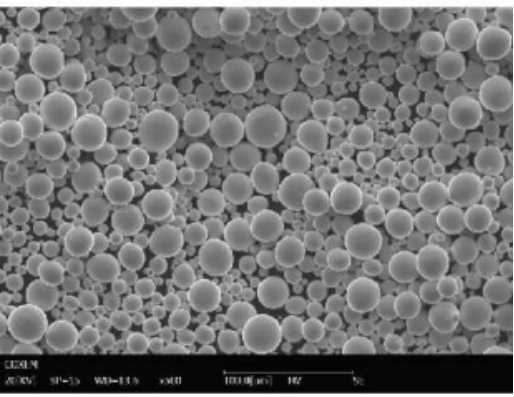

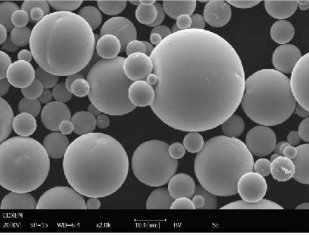

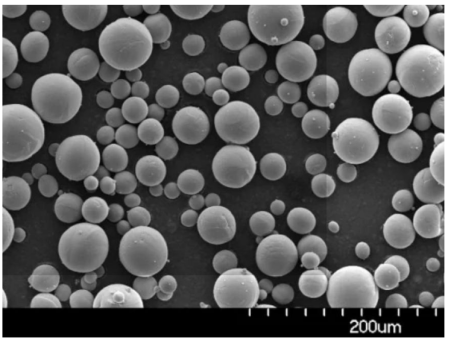

Shanghai Truer Technology Co., Ltd offers Inconel-grade powders produced using advanced atomization technologies — ensuring spherical morphology, controlled particle size distribution, and minimal oxygen content. These features are essential for ensuring powder flowability and uniform sintering in PM and AM processes.

To explore other high-performance powders for additive manufacturing, visit the Page produit PM Powder.

4. Global Market Trends and Growth Forecast for Inconel Powders

The global demand for high-performance alloy powders like Inconel 600 is growing rapidly, driven by the expansion of advanced manufacturing technologies such as additive manufacturing (AM) and powder metallurgy (PM). As industries seek materials that can withstand extreme conditions, Inconel 600 continues to gain traction.

Market Overview

| Métrique | 2023 Estimation | prévisions pour 2028 | CAGR (2023-2028) |

|---|---|---|---|

| Global Inconel Powder Market Value | USD 420 Million | USD 720 Million | 11.2% |

| Share from Additive Manufacturing | 35% | 50% | - |

| Asia-Pacific Market Share | 38% | 45% | - |

Principaux facteurs de croissance :

- Expansion of AM and PM in Aerospace & Defense

Lightweight and heat-resistant alloys like Inconel 600 are vital for 3D-printed engine and turbine parts. - Stringent Environmental and Safety Regulations

Inconel’s resistance to oxidation and toxic environments makes it a preferred material in nuclear and chemical processing. - Rise in Energy Sector Projects

Applications in hydrogen production, geothermal energy, and oil & gas are driving demand for corrosion-resistant alloy powders. - Increased Investment in R&D

Companies are innovating new alloy formulations and powder production techniques to meet custom industrial needs.

In summary, the Inconel 600 powder market is positioned for strong growth across various high-tech, high-temperature industries. B2B buyers should consider securing long-term supply contracts to hedge against future price increases and limited availability.

5. How to Choose a Reliable Inconel 600 Powder Supplier

For B2B buyers, the choice of supplier can significantly influence the performance and reliability of the final product. Here’s how to evaluate a trusted Inconel 600 powder supplier:

Critères d'évaluation clés :

| Critères | Pourquoi c'est important |

|---|---|

| Méthode de production | Impacts powder morphology, flowability, and purity. Look for gas atomized or plasma atomized powders. |

| Contrôle de la taille des particules | Important for additive manufacturing precision and sintering uniformity. |

| ISO & Industry Certifications | Ensures quality control and compliance with international standards. |

| Options de personnalisation | Ability to tailor particle size, composition, and quantity for specific applications. |

| Delivery Lead Times | Affects project timelines and supply chain reliability. |

| Support technique et documentation | Essential for troubleshooting and process optimization. |

Red Flags to Watch For:

- Lack of traceability or material verification certificates

- Inadequate technical support or post-sale service

- Inconsistent batch quality or poor packaging

Shanghai Truer Technology Co., Ltd meets all the above criteria by offering high-purity Inconel and other alloy powders with tight quality control. Truer has over a decade of experience in powder metallurgy and additive manufacturing, making it a trusted partner for large-scale industrial buyers.

To learn more about Truer’s capabilities and certifications, visit the À propos de nous.

6. Top Inconel 600 Powder Suppliers in Asia

Asia has emerged as a major hub for alloy powder production due to its advanced manufacturing infrastructure and cost-effective supply chains. Here are five leading suppliers of Inconel 600 powder in the region:

| Nom du fournisseur | Localisation | Caractéristiques principales |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Offers gas and water atomized Inconel powders, excellent B2B support, fast lead times |

| Sandvik Asia | Inde | Known for high-quality AM powders including Inconel grades |

| Acier Daido | Japon | Offers premium-grade nickel-based alloy powders |

| Poudre CNPC | Chine | Large-scale production, variety of particle size distributions |

| Nippon Yakin Kogyo | Japon | Specialist in high-performance alloys including Inconel series |

Why Choose Shanghai Truer:

- ✅ In-house powder atomization technology (gas & water)

- ✅ Full range of PM and AM-grade Inconel, stainless steel, and alloy powders

- ✅ Dedicated R&D and technical support team

- ✅ ISO-certified production facility

- ✅ Competitive pricing and flexible packaging for bulk orders

Their ability to integrate powder production with additive manufacturing services makes Truer one of the most comprehensive suppliers in the region. Learn more on the Official Website.

7. Why More Buyers are Sourcing Inconel 600 Powder from China

China has become a global powerhouse for the production of specialty metal powders, including Inconel 600, due to its robust supply chain, skilled labor, and competitive pricing.

Key Advantages of Chinese Suppliers:

- Rentabilité: Lower production and labor costs translate to better pricing for bulk orders.

- Production modulable: Suppliers like Truer can handle both small prototype batches and large-scale commercial volumes.

- Des délais plus courts: Regional supply hubs and advanced logistics support faster delivery to Asia-Pacific, Europe, and North America.

- Custom Engineering Solutions: Chinese manufacturers often provide additive and alloy development services tailored to specific industries.

Example Use Case:

A European aerospace firm switched to a Chinese supplier for Inconel 600 powder, cutting costs by 25% while maintaining ASTM and ISO quality standards. Reduced lead time also accelerated their R&D to production transition.

Shanghai Truer Technology Co., Ltd is a leading example of this transformation. They offer:

- High-purity Inconel 600 powders (gas atomized)

- Custom packaging and logistics solutions for international clients

- Fast response customer service to support sourcing and QA teams

Want to request a quote or sample? Contact Truer Here.

8. Why Choose Shanghai Truer Technology Co., Ltd as Your Inconel Powder Supplier

Shanghai Truer Technology Co., Ltd has established itself as a leading manufacturer and supplier of high-quality metal powders for additive manufacturing (AM) and powder metallurgy (PM). For B2B buyers sourcing Inconel 600 powder, Truer offers a unique combination of quality, customization, and technical expertise.

Why Truer Stands Out in the Inconel Market:

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| Advanced Powder Production | Offers both gas and water atomization, ensuring round, uniform particles ideal for AM and PM |

| Wide Material Portfolio | Inconel 600, PM stainless steels, PM copper alloys, hybrid low-alloy steels, and more |

| Flexible Order Quantities | From small R&D samples to large-scale industrial supply, with consistent quality |

| Rapid Delivery | Efficient logistics and short lead times across Asia, Europe, and North America |

| Dedicated B2B Support | Technical consultation, documentation (MSDS, COA), and post-sale assistance |

| Custom Engineering Solutions | Ability to tailor particle sizes, alloy compositions, and additive blends for specific applications |

Truer’s Alloy Powder Grades Include:

- Inconel 600, 625, and 718 (available upon request)

- PM Bronze, PM Nickel Silver, PM Brass

- PM Stainless Steels (Water/Gas Atomized)

- Prealloyed and Hybrid Low-Alloy Steels (e.g., FD-0208, FL-4605)

- Specialized additive powders: graphite, cutting agents, lubricants

All powders are processed in ISO-certified facilities with full traceability and quality checks.

Looking for more than just Inconel? Explore their full range of powder metallurgy materials and additives on the Page produit PM Powder.

9. How to Order Wholesale Inconel 600 Powder from China

Placing a wholesale order for Inconel 600 powder from Shanghai Truer Technology Co., Ltd is a streamlined process designed for efficiency and customization.

Processus de commande étape par étape :

- Enquête initiale

Fill out the contact form on the Page de contact or send an email with your required quantity, particle size, and application. - Consultation technique

Truer’s engineers will review your specifications and suggest the most suitable grade and production method (gas atomized preferred for AM). - Demande de devis et d'échantillon

Receive a detailed quotation (FOB/CIF options), lead time, and optional test sample for evaluation. - Order Confirmation & Payment

Confirm order details, sign the supply agreement, and proceed with payment via T/T or L/C as per contract terms. - Production & ; Assurance qualité

Truer will produce your batch under strict QA standards, including particle size distribution analysis, chemical composition verification, and flowability testing. - Expédition et livraison

Orders are packed in air-tight, moisture-resistant containers and shipped via air or sea, depending on urgency. - Support après-vente

Receive full documentation (MSDS, COA, test reports) and access to Truer’s technical team for any post-delivery questions.

Documents Provided with Every Order:

- Certificat d'analyse (COA)

- Fiche de données de sécurité (FDS)

- Particle Size Distribution Report

- Packing List and Customs Docs

Truer can also help with REACH and RoHS compliance for buyers in Europe.

10. FAQs: Common Questions About Buying Inconel 600 Powder Wholesale

Q1: What is the minimum order quantity (MOQ) for Inconel 600 powder?

A1: The MOQ typically starts from 5 kg for trials and 100 kg for wholesale pricing. Truer offers flexibility based on application.

Q2: What particle size ranges are available?

A2: Standard sizes include 15–45 µm (ideal for SLM/3D printing), 45–105 µm (for PM applications), and custom sizes upon request.

Q3: Is the powder suitable for Selective Laser Melting (SLM)?

A3: Yes. Truer’s gas atomized Inconel 600 powder is optimized for high flowability and spherical shape, making it ideal for SLM and other AM technologies.

Q4: Can you provide test samples before placing a large order?

A4: Absolutely. Truer encourages sample testing to verify compatibility with your AM or PM equipment.

Q5: How do you ensure consistent quality between batches?

A5: Every batch is tested and documented with full traceability. Truer uses advanced sieving, drying, and blending systems to ensure uniformity.

Q6: Do you export Inconel 600 powder to Europe and North America?

A6: Yes. Truer has extensive international shipping experience and provides all necessary export documentation.

Q7: What’s the typical lead time for bulk orders?

A7: 7–15 business days depending on volume and customization requirements.

Q8: Can Truer customize chemical composition or add trace elements?

A8: Yes. Truer offers custom alloy development services for R&D and specialized industrial needs.

Q9: How can I learn more about Shanghai Truer’s capabilities?

A9: Visit the official À propos de nous to explore Truer’s history, technology, and certifications.

Q10: Is technical support available after delivery?

A10: Yes. Truer provides ongoing technical support to help clients optimize powder use in their manufacturing processes.

By choosing Shanghai Truer Technology Co., Ltd as your Inconel 600 powder supplier, you’re partnering with one of the most trusted names in the Chinese powder metallurgy industry. Whether you’re producing aerospace components, chemical processing parts, or AM prototypes, Truer ensures quality, consistency, and value at scale.

🔗 Ready to discuss your Inconel 600 powder needs? Contactez Truer dès aujourd'hui