Introduction: What is FeSiB Powder and Why It Matters to Industry

FeSiB (Iron-Silicon-Boron) powder is a high-performance alloy powder used extensively in various powder metallurgy (PM) and additive manufacturing (AM) applications. Comprised primarily of iron, silicon, and boron, this material offers outstanding soft magnetic properties, corrosion resistance, and thermal stability, making it an ideal choice for energy-efficient motor cores, magnetic sensors, and transformer components.

Why FeSiB Powder is Gaining B2B Attention

- ✔️ Increasing demand for high-efficiency electrical components

- ✔️ Rising adoption of soft magnetic composite (SMC) materials in EVs and wind turbines

- ✔️ Growing reliance on powder metallurgy for cost-effective, high-volume part production

- ✔️ Compatibility with both conventional PM and cutting-edge additive manufacturing systems

Composition of FeSiB Alloy Powder

| Élément | Contenu typique (%) |

|---|---|

| Fe | Balance |

| Si | 3–6% |

| B | 0.5–2.0% |

| C, N, O | <0.1% (controlled) |

With its unique chemical structure and magnetic properties, FeSiB powder is becoming a critical raw material across automotive, aerospace, and electronics industries.

Applications of FeSiB Powder in Powder Metallurgy and Additive Manufacturing

FeSiB powder is valued for its role in producing soft magnetic components that require high electrical resistivity and low core losses. Its applications span multiple industrial sectors, especially where magnetic flux density and efficiency are paramount.

Core Applications by Industry

| L'industrie | Exemples d'application |

|---|---|

| Automobile | Electric motor stators, inductors, torque sensors |

| Power Electronics | Transformers, chokes, magnetic cores |

| Industrie | High-speed motors, magnetic shielding components |

| Aérospatiale | Lightweight SMC parts for avionics |

Benefits in Powder Metallurgy (PM)

- Haute compressibilité pour les géométries complexes

- Microstructure uniforme après frittage

- Faibles pertes par courants de Foucault

- Excellent rapport résistance/poids

Benefits in Additive Manufacturing (AM)

- Compatible with selective laser melting (SLM) and binder jetting

- Enables rapid prototyping of magnetic parts

- High dimensional accuracy and minimal post-processing

- Réduction des déchets de matériaux

Learn more about the types of PM powders available for industrial use and how FeSiB fits within Truer’s extensive product catalog.

Key Properties and Performance Advantages of FeSiB Alloy Powders

FeSiB powder is engineered to meet the demanding requirements of modern applications. It combines magnetic efficiency with thermal stability, making it suitable for both low- and high-frequency devices.

Magnetic & Mechanical Properties

| Propriété | Valeur typique |

|---|---|

| Résistivité électrique | >100 µΩ·cm |

| Magnetic saturation (Bs) | ~1.5–1.7 T |

| Coercivity (Hc) | <100 A/m |

| Density (as compacted) | ~7,1 g/cm³ |

| Température de Curie | >500 °C |

Additional Technical Benefits

- 📌 Low hysteresis loss = Higher energy efficiency

- 📌 Excellent thermal conductivity for temperature-sensitive environments

- 📌 Stable magnetic performance across a broad temperature range

- 📌 Suitable for high-speed sintering and multi-axis AM builds

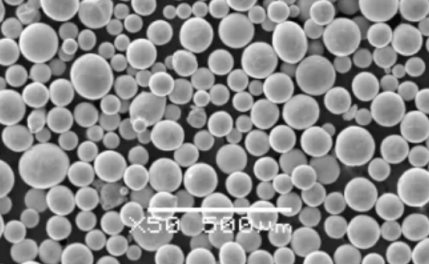

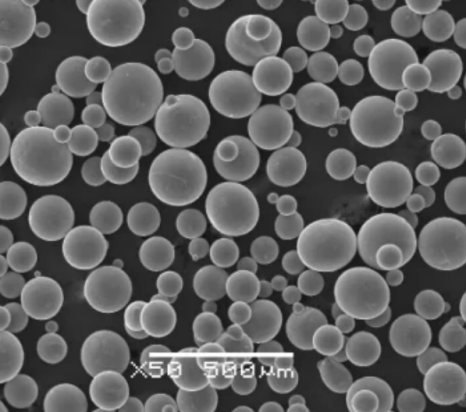

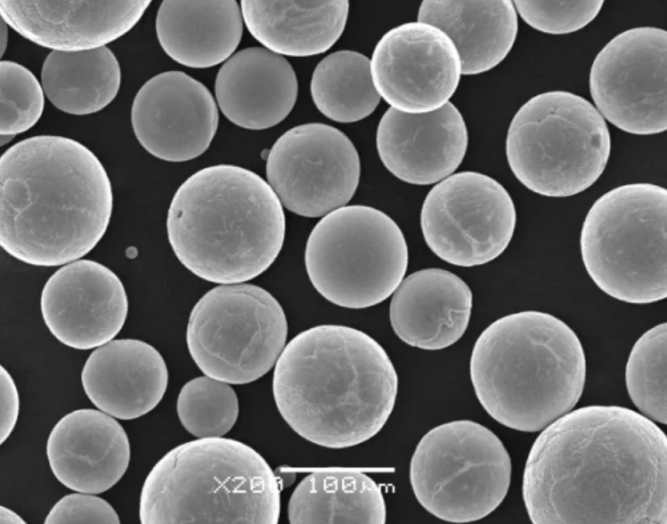

FeSiB powders produced through gas atomization and hybrid atomization (water + gas) ensure uniform particle size distribution, enhancing flowability and packing density.

Shanghai Truer Technology Co., Ltd uses advanced atomization techniques to manufacture FeSiB powder with high sphericity, excellent purity, and consistent magnetic performance—ideal for demanding B2B applications.

Top FeSiB Powder Manufacturers and Suppliers in China

China has emerged as a global leader in powder metallurgy and additive manufacturing materials, including advanced soft magnetic powders like FeSiB. For B2B buyers, sourcing from reliable Chinese manufacturers offers cost-efficiency, technical support, and fast delivery times.

Key Evaluation Criteria for FeSiB Suppliers

When selecting a FeSiB powder supplier, especially in China, businesses should consider the following:

- ✅ Production capacity and consistency

- ✅ Purity and particle size control

- ✅ Compliance with international standards (e.g., ISO, RoHS)

- ✅ Technical support for PM and AM applications

- ✅ Customization options for alloy compositions

- ✅ Logistics and export readiness

Top-Rated FeSiB Powder Suppliers in China (2024)

| Nom du fournisseur | Points forts | Localisation |

|---|---|---|

| Shanghai Truer Technology Co. | High-purity, customizable FeSiB powder; PM and AM expertise; global shipping | Shanghai |

| GKN Sinter Metals (China) | Global leader in PM; advanced R&D laboratories | Yizheng, Jiangsu |

| CNPC Powder Material Co. Ltd. | Offers gas atomized FeSiB and other soft magnetic powders | Anhui |

| Changsha Hualiu Metallurgical | Offers FeSiB and FeSi powders for motor core applications | Hunan Province |

| Jilin Songjiang Tech | Focused on soft magnetic powder production for electronics and energy | Jilin Province |

Shanghai Truer Technology Co., Ltd stands out with its integrated capabilities in powder manufacturing and additive materials engineering, making it an ideal partner for B2B procurement professionals.

Why More Distributors Are Sourcing FeSiB Powder from China

The shift toward Chinese powder suppliers in global B2B markets isn’t just about cost — it’s about innovation, agility, and access to advanced materials like FeSiB that meet modern industry demands.

Key Drivers Behind the Trend

- 📈 Increased local investment in R&D and powder metallurgy automation

- 📦 Strong domestic logistics networks supporting fast exports

- ⚙️ Lower production and operation costs compared to Western competitors

- 🌐 Customization and OEM-friendly production models

- 📊 Growing recognition of Chinese quality standards in global certifications

Advantages for International Distributors

| Avantage | Description |

|---|---|

| Prix compétitifs | Margin-friendly pricing for large-volume orders |

| Flexible MOQ Policies | Minimum order quantities tailored to business needs |

| Technical Documentation | Data sheets, MSDS, and compliance certificates readily available |

| Global Distribution Support | Efficient handling of cross-border logistics and customs |

En savoir plus sur Shanghai Truer Technology Co., Ltd’s background and capabilities to understand why global buyers trust their FeSiB powder.

Why Choose Shanghai Truer Technology Co., Ltd for FeSiB Powder

Shanghai Truer Technology Co., Ltd has been a pioneer in China’s powder metallurgy supply chain since 2009. Since launching its additive manufacturing division in 2019, Truer has expanded its product portfolio to include premium FeSiB powders optimized for both PM and AM applications.

What Sets Truer Apart in the Powder Market

- 🔬 Advanced atomization equipment for water, gas, and hybrid atomization

- ⚙️ In-house engineering support for AM prototyping and PM sintering

- 📌 Quality assurance with batch-level testing and material traceability

- 🌍 Export-ready packaging and compliance with international standards

- 🧪 Custom alloy development for specific magnetic and mechanical properties

FeSiB Powder Solutions Offered by Truer

| Type de produit | Méthode d'atomisation | Target Application |

|---|---|---|

| FeSiB Magnetic Powder | Gas or hybrid atomized | Electric motors, sensors |

| Alliages magnétiques doux | Eau pulvérisée | Transformers, EMI shielding |

| SMC-Grade FeSiB Powders | Custom blended | Magnetic powder cores |

Truer also offers a complete lineup of additives, including soft magnetic agents like QH-150 and QHP-330, that can be combined with FeSiB to fine-tune performance characteristics.

Ready to explore Truer’s full PM and AM powder catalog? Visit their page officielle du produit for detailed specifications and datasheets.

How to Order Wholesale FeSiB Powder from Shanghai Truer

Sourcing premium FeSiB powder in bulk requires a streamlined procurement process, especially for distributors, component manufacturers, and additive manufacturing companies. Shanghai Truer Technology Co., Ltd simplifies this process with a professional, B2B-friendly ordering system designed to meet global buyer expectations.

Processus de commande en gros, étape par étape

Here’s how international buyers can place an order for FeSiB powder from Shanghai Truer:

- Enquête initiale

- Contact Truer via their formulaire de contact officiel ou par courriel

- Provide details such as quantity, desired composition, application, and delivery timeline

- Product Specification & Quotation

- Truer’s technical team will provide a tailored quote

- Material data sheets, test reports, and compliance documentation are shared upon request

- Sample for Approval (Optional)

- Small batch samples can be shipped for testing before bulk order

- Includes powder morphology, flowability, and magnetic performance reports

- Confirmation de commande

- Upon sample approval and price agreement, buyers issue a purchase order (PO)

- Truer confirms lead time, shipping terms (FOB, CIF, DDP), and payment method

- Production & ; Contrôle de la qualité

- Powder is produced using gas or hybrid atomization

- Each batch undergoes QC for particle size, chemical composition, and magnetic performance

- Emballage et logistique

- Export-grade packaging (moisture-proof, anti-static)

- Shipping via sea, air, or rail with full tracking support

- Support après-vente

- Technical guidance for PM and AM applications

- Ongoing product development collaboration for repeat buyers

Packaging Options Available

| Type d'emballage | Weight per Unit | Convient pour |

|---|---|---|

| Foil-sealed aluminum bag | 1–5 kg | Sample or R&D orders |

| Fiber drum (sealed) | 25–50 kg | Pilot-scale production or small batch |

| Fût en acier avec doublure | 100–250 kg | Bulk industrial production |

For direct inquiries or to request a quote, visit the page de contact and connect with Truer’s international sales team.

FAQs: Common Questions About Buying Wholesale FeSiB Powder

To assist engineers, procurement teams, and distributors, here are answers to the most frequently asked questions about sourcing FeSiB powder from Shanghai Truer:

1. What applications is FeSiB powder best suited for?

FeSiB is ideal for soft magnetic components such as:

- Electric motor stators

- Magnetic sensors

- Transformer cores

- Magnetic shielding for electronics

- Soft magnetic composites (SMCs)

2. What is the minimum order quantity (MOQ)?

- MOQs vary based on product type and customization level.

- Standard MOQ for FeSiB powder is typically 25 kg, but Truer can accommodate smaller R&D orders.

3. Can I request custom alloy compositions?

Yes. Truer supports custom formulations based on specific magnetic, mechanical, or thermal requirements. Their R&D team can provide consultation and samples.

4. What certifications does Truer provide?

- Material test reports (MTR)

- ISO quality management system certification

- RoHS and REACH compliance (upon request)

- Third-party SGS or BV inspection (optional)

5. How long does shipping take?

- Domestic China: 3–5 working days

- Asia-Pacific: 7–10 days

- Europe/North America: 12–15 days by air; 25–40 days by sea

Truer offers logistic support with Incoterms like EXW, FOB, and CIF.

Conclusion: FeSiB Powder is a Strategic Advantage for B2B Manufacturers

FeSiB powder is a next-generation material that’s unlocking new performance levels in soft magnetic applications. From electric vehicles to renewable energy systems, this alloy is empowering manufacturers to innovate with efficiency, precision, and reliability.

For wholesale buyers, selecting the right supplier is critical. Shanghai Truer Technology Co., Ltd stands out as a trusted partner with:

- ✅ Over 15 years of powder metallurgy experience

- ✅ Advanced atomization and powder processing capabilities

- ✅ A comprehensive product catalog for PM and AM industries

- ✅ Global delivery and technical support

Whether you’re a distributor, OEM, or end-user, Truer offers the technical depth, product reliability, and supply flexibility B2B buyers need in 2024 and beyond.

Discover the full range of Truer’s additive manufacturing materials and explore their premium powder solutions for your next project.

Internal Links Summary (Anchor Text Hyperlinks):

- types of PM powders available for industrial use

- Shanghai Truer Technology Co., Ltd’s background and capabilities

- page officielle du produit

- formulaire de contact officiel

- explore their premium powder solutions

📩 Ready to get started? Contact Shanghai Truer today to request a quote or sample for FeSiB powder and power your next magnetic innovation.