1. What Is 2205 Powder and Why It Matters in Industrial Manufacturing

2205 powder refers to a duplex stainless steel powder, primarily composed of approximately 22% chromium, 5% nickel, and 3% molybdenum. It combines the benefits of both austenitic and ferritic stainless steels, offering high strength and excellent corrosion resistance. In powder form, 2205 is widely used in additive manufacturing (AM), metal injection molding (MIM), and powder metallurgy (PM) applications by OEMs, metal part manufacturers, and industrial fabricators.

Composition of 2205 Duplex Stainless Steel

| Élément | Contenu (%) |

|---|---|

| Chrome (Cr) | ~22 |

| Nickel (Ni) | ~5 |

| Molybdène (Mo) | ~3 |

| Azote (N) | ~0.14 |

| Manganèse (Mn) | ≤2 |

| Carbone (C) | ≤0.03 |

Why Manufacturers Choose 2205 Powder:

- Superior corrosion resistance, especially in chloride-rich environments

- High yield strength (twice that of standard austenitic acier inoxydables)

- Excellent fatigue and stress corrosion cracking resistance

- Cost-effective alternative to high-nickel alloys

2205 powder is highly suitable for environments involving aggressive chemicals, high pressure, and high mechanical stress—making it a preferred material among B2B buyers in chemical processing, oil & gas, marine, and pulp & paper sectors.

2. Key Applications of 2205 Duplex Stainless Steel Powder

The versatility of 2205 powder makes it applicable across a wide range of industries. B2B buyers, especially those in engineering, fabrication, and component manufacturing, source 2205 powder for the following uses:

Fabrication additive (impression 3D)

- Production of corrosion-resistant parts for marine environments

- Printing of pressure vessels and piping systems

- Manufacturing of structural components for offshore rigs

Métallurgie des poudres (PM)

- Fabrication of high-strength components in automotive and aerospace industries

- Creation of wear- and corrosion-resistant parts

- Production of mechanical seals, fasteners, and pump components

Moulage par injection de métal (MIM)

- Small, intricate parts for electronic housings and surgical tools

- Cost-efficient production of high-volume metal components

- Excellent surface finish and dimensional accuracy

Autres utilisations industrielles

- Heat exchanger tubes and fittings

- Flanges and valves for chemical processing

- Food processing equipment requiring high hygiene standards

📌 Interested in high-performance PM powders for these applications? Check out Truer’s PM powder offerings for a complete list of available stainless steel grades.

3. Properties and Advantages of 2205 Powder for OEMs and Fabricators

2205 powder offers a combination of mechanical strength, corrosion resistance, and processability that makes it ideal for OEMs and contract manufacturers.

Propriétés mécaniques

| Propriété | Valeur (typique) |

|---|---|

| Résistance à la traction | ≥620 MPa |

| Limite d'élasticité | ≥450 MPa |

| Allongement à la rupture | ~25% |

| Dureté | ~250 HB |

Résistance à la corrosion

- Highly resistant to pitting and crevice corrosion (PREN > 35)

- Excellent resistance to chloride stress corrosion cracking

- Suitable for seawater, acidic, and oxidizing environments

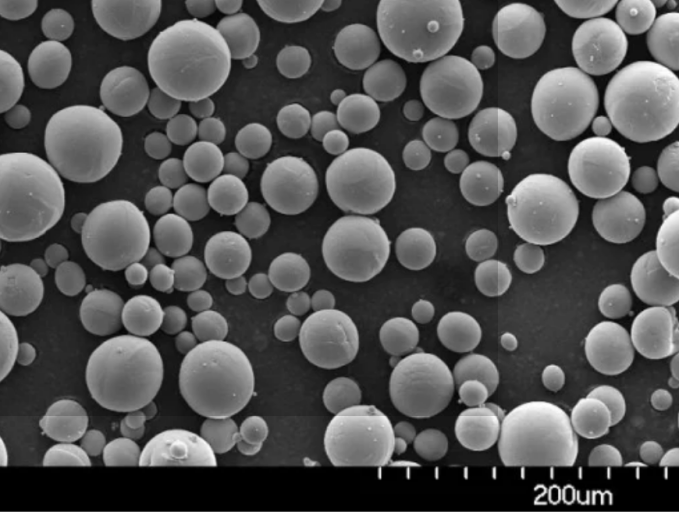

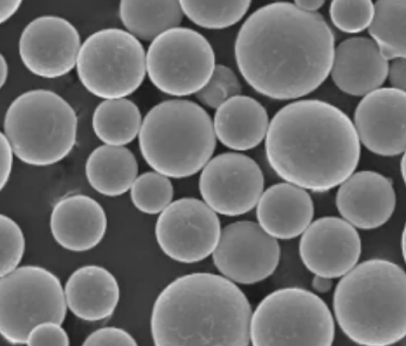

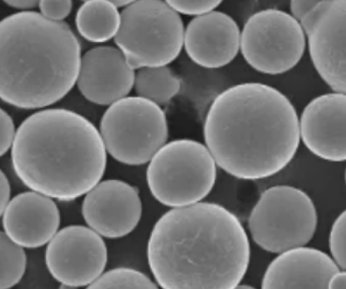

Avantages de la transformation

- Compatible with water or gas atomization processes

- Uniform particle size distribution for consistent flowability

- Suitable for sintering, laser powder bed fusion, binder jetting, and direct energy deposition

Benefits for B2B Buyers

- Lower material costs compared to high-nickel alloys

- Enhanced part life leads to reduced maintenance costs

- Meets global standards like ASTM A790, UNS S32205, and ISO certifications

Performance Summary Table

| Fonctionnalité | 2205 Powder Performance |

|---|---|

| Résistance à la corrosion | Excellent |

| Résistance mécanique | Haut |

| Résistance à la fatigue | Haut |

| Rentabilité | Medium-High |

| Soudabilité | Modéré |

| Printability (AM) | Haut |

🔍 Learn more about our company’s advanced stainless steel powder capabilities on our A propos de nous.

4. Global Market Trends and Demand Forecast for 2205 Powder

The demand for 2205 duplex stainless steel powder is experiencing significant growth worldwide, primarily driven by the expansion of additive manufacturing, renewable energy sectors, and the need for corrosion-resistant components in aggressive environments.

Principaux moteurs du marché

- Growth in Additive Manufacturing (AM): The global AM market is projected to reach over $50 billion by 2030, with metal powders accounting for a major share. 2205 powder is increasingly preferred for printing high-strength, corrosion-resistant parts.

- Infrastructure & Energy Sectors: Projects in offshore wind energy, chemical processing, and marine infrastructure are boosting demand for duplex stainless steel components.

- Environmental Regulations: Stricter emission and corrosion standards are pushing OEMs and fabricators toward more durable materials like 2205 duplex stainless steel.

Forecast: 2024–2030

| Région | CAGR (2024-2030) | Les industries clés qui stimulent la croissance |

|---|---|---|

| Asie-Pacifique | 8.4% | Automotive, Marine, Energy |

| Amérique du Nord | 6.9% | Oil & Gas, Aerospace, AM |

| L'Europe | 7.5% | Chemical Processing, Infrastructure |

| Moyen-Orient et Afrique | 6.2% | Water Treatment, Oil & Gas |

Market Insights for B2B Buyers

- Supply Chain Diversification: Distributors are increasingly sourcing from Asia, especially China, for cost-effective and high-quality powders.

- Customization in Demand: OEMs are requesting tailor-made powders with specific grain sizes, flowability, and compositions.

- Environmental Certifications: End-users prefer suppliers with ISO 14001 and REACH-compliant production.

5. Choosing the Right 2205 Powder Supplier: Key Evaluation Criteria

For B2B buyers, selecting a reliable 2205 powder supplier goes beyond just price. Quality consistency, technical support, and logistics efficiency are critical.

Checklist for Evaluating a 2205 Powder Supplier

| Facteur d'évaluation | Ce qu'il faut rechercher |

|---|---|

| Méthode de fabrication | Water atomized, gas atomized, or hybrid atomization |

| Powder Certification | ISO 9001, ASTM, REACH, RoHS |

| Distribution de la taille des particules (PSD) | Consistency, typically 15–45 µm or 45–105 µm |

| Emballage et logistique | Safe, moisture-proof drums or vacuum packaging |

| Support technique | Metallurgical experts, application engineers |

| Capacité de personnalisation | Ability to tailor chemical composition and PSD |

| Fiabilité de la chaîne d'approvisionnement | On-time delivery, inventory buffer, MOQ flexibility |

Technical Considerations

- Fluidité : Critical for AM and MIM processes

- Purity & Homogeneity: Impacts mechanical and corrosion performance

- Sphéricité : Affects powder bed density and print quality in 3D printing

📞 Need help selecting the right powder specification? Reach out via our Page de contact for expert consultation.

6. Top 5 Global Suppliers of 2205 Powder for B2B Buyers

If you’re sourcing 2205 powder in bulk, these are the most recognized suppliers offering high-quality materials globally:

1. Shanghai Truer Technology Co. Ltd (Chine)

- Points forts :

- Over 10 years in powder metallurgy

- Offers water, gas, and hybrid atomized stainless steel powders

- Specializes in PM, MIM, and AM applications

- In-house R&D and customization services

- Certifications : ISO 9001, REACH

- Flagship Products: PM stainless steel powders (CT-1000, FD-0200, SBF2218)

🔗 Learn about Truer’s full PM powder portfolio ici

2. Sandvik Additive Manufacturing (Sweden)

- Offers gas-atomized duplex stainless steel powders

- Strong in aerospace and medical sectors

- Excellent R&D and material innovation

3. Carpenter Additive (USA)

- Known for high-purity, spherical powders

- Strong technical documentation and AM compatibility

- Premium pricing for high-end sectors

4. Höganäs AB (Sweden)

- One of the largest PM powder producers globally

- Offers diffusion alloyed and pre-alloyed steels

- Used widely in automotive sintered components

5. EOS GmbH (Germany)

- Specialist in AM powders

- Offers 2205 and other stainless steel grades

- Provides integrated software and hardware for AM lines

Tableau de comparaison

| Fournisseur | Région | Type d'atomisation | Personnalisation | Flexibilité du MOQ | Industry Focus |

|---|---|---|---|---|---|

| Shanghai Truer | Chine | Water/Gas/Hybrid | Oui | Oui | PM, MIM, AM |

| Sandvik | Suède | Gaz | Limitée | Moyen | Aérospatiale, Médical |

| Additif pour charpentier | ÉTATS-UNIS | Gaz | Oui | Haut | Aérospatiale, Énergie |

| Höganäs | Suède | L'eau | Oui | Haut | Automotive, PM |

| EOS GmbH | Allemagne | Gaz | Limitée | Moyen | Fabrication additive |

7. Why More OEMs Are Sourcing 2205 Powder from China

In recent years, China has emerged as a dominant force in the global powder metallurgy market. Here’s why:

Rentabilité

- Lower production costs due to domestic raw materials and economies of scale

- Prix compétitifs pour les commandes de gros volumes

- Flexible MOQ policies ideal for both SMEs and large enterprises

Progrès technologiques

- Adoption of advanced atomization technologies

- Integration of AI and automation in powder grading

- Quality standards on par with European and US manufacturers

Supply Chain Strength

- Robust logistics infrastructure for global shipping

- Quick lead times and warehousing options

- Government-backed export incentives

Case Study: Shanghai Truer Technology Co., Ltd

Shanghai Truer is a model of China’s manufacturing excellence. Established in 2009, Truer has evolved into one of the most trusted names in 2205 stainless steel powder supply.

- Additive Manufacturing Division created in 2019

- Offers both standard grades and custom formulations

- Renowned for its diffusion CuSn powder used in diamond tools and sintered bearings

- Developed cutting-edge additives like SUW-8000 and QH-150

👨🏭 Learn more about Truer’s innovative product lines on our page d'accueil

8. Why Choose Shanghai Truer Technology as Your 2205 Powder Supplier

For B2B buyers, reliability, quality assurance, and technical expertise are non-negotiable when sourcing specialty powders like 2205 duplex stainless steel. Shanghai Truer Technology Co., Ltd stands out as a preferred supplier due to its integrated capabilities, high-quality powder offerings, and dedication to engineering innovation.

Présentation de l'entreprise

- Founded: 2009

- AM Division Established: 2019

- Core Specialization: Manufacturing and supplying metal powders for additive manufacturing (AM), powder metallurgy (PM), and various industrial applications

- Méthodes de production : Water atomization, gas atomization, carbonyl, and hybrid methods

- Certifications : ISO 9001, REACH, and industry-specific quality standards

Why Truer Is a Trusted 2205 Powder Supplier

| Bénéfice | Détails |

|---|---|

| Expérience dans l'industrie | 15+ years in powder metallurgy |

| Expertise technique | In-house R&D and metallurgical team |

| Flexibilité de la personnalisation | Tailored PSD, chemical composition, and additive blends |

| Large gamme de produits | Duplex stainless steel, PM steel, bronze, brass, copper, soft magnetic |

| Logistics & Fulfillment | Global shipping, MOQ flexibility, safe packaging |

| Client Support | Pre-sales engineering consultation and post-sales technical guidance |

Flagship Products Related to 2205 Powder

- PM stainless steel powders: FD-0200, FD-0208, SBF2218

- Hybrid low-alloy steels: FX-2008, FX1005

- Proprietary additives: SME-100 (sulfur-free cutting agent), Lube-W, QH-150 (soft magnetic additive)

🌐 Want to explore Truer’s full line of metal powders? Visit our Page produit PM Powder for technical data and application insights.

9. How to Order Wholesale 2205 Powder from Shanghai Truer

Ordering 2205 powder in bulk from a trusted supplier like Truer is a simple and streamlined process designed for B2B convenience. Here’s how you can initiate and manage your procurement with confidence.

Processus de commande étape par étape

| Étape | Description |

|---|---|

| 1 | Demande de renseignements – Contact Truer via website or email with product specs |

| 2 | Consultation technique – Receive assistance in selecting the correct grade and PSD |

| 3 | Devis et délais – Get a formal quote with shipping and MOQ details |

| 4 | Demande d'échantillon (facultatif) – Request a trial sample for testing & evaluation |

| 5 | Confirmation de commande – Finalize your PO and confirm payment terms |

| 6 | Production et assurance qualité – Powder is manufactured, tested, and packed according to spec |

| 7 | Global Shipping – Truer manages secure, tracked shipping to your facility |

Documentation fournie

- Fiche de données de sécurité (FDS)

- Certificate of Analysis (CoA)

- Technical Data Sheet (TDS)

- Export compliance documents

Payment and Shipping Terms

- Payment: T/T, L/C, or negotiated terms for long-term buyers

- Shipping: FOB, CIF, DDP available globally

- MOQ : Flexible, depending on grade and packaging requirements

📩 Ready to get started? Submit your custom inquiry on our Page de contact and one of our engineers will reach out within 24 hours.

10. FAQs: Common Questions About Buying Wholesale 2205 Powder

Q1: What is the typical particle size distribution (PSD) for 2205 powder?

A: The most common PSD ranges are 15–45 µm and 45–105 µm, ideal for additive manufacturing and PM applications, respectively. Truer can customize PSD based on customer requirements.

Q2: Is Truer’s 2205 powder compatible with 3D printing?

A: Yes. Truer offers highly spherical 2205 powder produced using gas or hybrid atomization, ensuring excellent flowability and print quality for laser-based AM technologies.

Q3: Can I request a small sample before placing a bulk order?

A: Absolutely. Truer provides sample quantities for testing and validation, especially for OEMs and R&D teams evaluating new materials.

Q4: Does Truer offer technical support for new applications?

A: Yes. Truer’s in-house metallurgists and engineers consult with clients to optimize material selection, sintering parameters, and additive blends.

Q5: What industries commonly use 2205 powder?

A: 2205 powder is widely used in oil & gas, marine, chemical processing, additive manufacturing, automotive, and energy industries due to its high strength and corrosion resistance.

Q6: How does Truer ensure powder quality?

A: Every batch undergoes rigorous quality control including chemical analysis, particle size testing, morphology inspection, and mechanical property validation.

Q7: What is the lead time for wholesale orders?

A: Standard lead times range from 2–4 weeks, depending on the product volume and customization required. Expedited shipping options are available.

Final Notes & Call to Action

As global demand for corrosion-resistant, high-strength materials continues to rise, 2205 duplex stainless steel powder has become a strategic purchase for manufacturers, distributors, and component makers across industries. Whether you’re in additive manufacturing, powder metallurgy, or MIM production, choosing the right supplier is critical.

Shanghai Truer Technology Co., Ltd offers a unique value proposition with:

✅ Decades of powder metallurgy expertise

✅ Full-spectrum powder production capabilities

✅ Customized solutions for demanding applications

✅ Proven quality, global shipping, and technical support

🔗 Learn more about our company history, values, and innovation journey on our A propos de nous

📞 If you’re ready to improve your supply chain with reliable stainless steel powder, contact our sales team today for a custom quote or technical consultation.