1. Introduction: What Is 2.4668 Powder and Why It Matters

2.4668 powder is the designation for a high-performance nickel alloy known as UNS N07718 or Inconel 718. This nickel-chromium-based superalloy exhibits exceptional strength, corrosion resistance, and thermal stability, making it a top choice for powder metallurgy and additive manufacturing (AM) applications.

Key Industrial Names for 2.4668:

- Inconel 718

- UNS N07718

- Alloy 718

Why It Matters in B2B Supply Chains:

- ✅ High-performance replacement for standard stainless steel powders

- ✅ Widely used in aerospace, automotive, and energy sectors

- ✅ Supports complex geometries in additive manufacturing

- ✅ Ideal for high-temperature and high-stress environments

This alloy powder is especially critical in industries where component failure is not an option. Its widespread use in mission-critical systems makes it a high-demand product among OEMs, Tier 1 suppliers, and contract manufacturers.

2. Industrial Applications of 2.4668 Alloy Powder

2.4668 powder is used across a variety of high-performance industries. The powder form allows for precise application in both additive manufacturing (AM) and traditional powder metallurgy (PM) processes.

Major Sectors Using 2.4668 Powder:

| L'industrie | Applications |

|---|---|

| Aérospatiale | Turbine blades, combustors, fuel nozzles, structural parts |

| Automobile | Turbocharger wheels, exhaust valves, high-stress engine parts |

| L'énergie | Nuclear reactor components, gas turbines, heat exchangers |

| Pétrole et gaz | Downhole tools, valves, pump shafts |

| Dispositifs médicaux | Surgical tools, orthopedic implants (select uses) |

| Fabrication additive | Custom geometries, topology-optimized parts |

Why It’s Preferred:

- Stable at temperatures over 700°C

- Exceptional fatigue resistance

- Low creep and high tensile strength

- Weldable and formable

B2B Buyers:

- OEMs looking for AM-compatible materials

- Distributors seeking advanced PM powders

- Tier 1 aerospace/automotive suppliers

- Contract manufacturers for defense and energy sectors

3. Properties and Technical Specifications of 2.4668 Powder

For effective supplier evaluation and procurement, understanding the technical specs of 2.4668 powder is essential.

Key Chemical Composition (Typical)

| Élément | Pourcentage (%) |

|---|---|

| Nickel (Ni) | 50–55 |

| Chrome (Cr) | 17–21 |

| Fer (Fe) | Balance |

| Niobium (Nb) | 4.75–5.5 |

| Molybdène (Mo) | 2.8–3.3 |

| Titane (Ti) | 0.65–1.15 |

| Aluminium (Al) | 0.2–0.8 |

Propriétés physiques et mécaniques

| Propriété | Valeur |

|---|---|

| Densité | 8,19 g/cm³ |

| Point de fusion | 1260–1336°C |

| Résistance à la traction | > 1240 MPa |

| Limite d'élasticité | > 1035 MPa |

| Élongation | ~12% |

| Dureté (Rockwell C) | 36–44 |

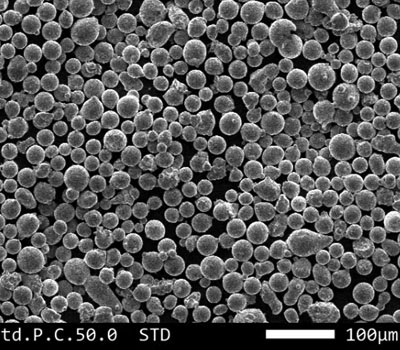

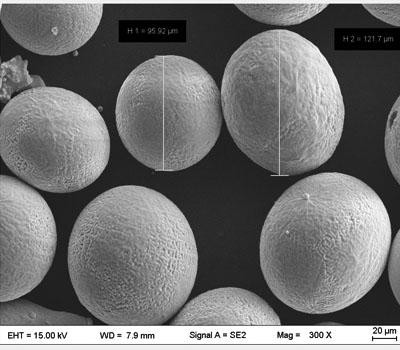

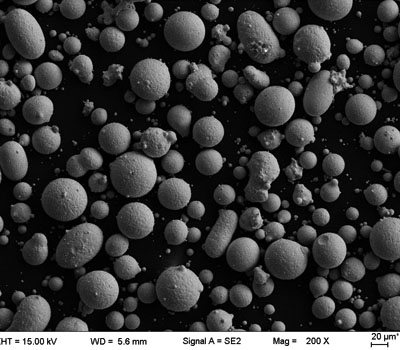

Available Forms and Particle Sizes

| Forme | Gamme de taille des particules (μm) |

|---|---|

| Gas Atomized Powder (GA) | 15–45, 15–53, 45–105 |

| Water Atomized Powder (WA) | 45–150 |

| Spherical for AM & HIP | 15–45, 45–105 |

Powder Metallurgy (PM) Use Cases:

- Pressage isostatique à chaud (HIP)

- Moulage par injection de métal (MIM)

- Jetting de liant

- Fusion sélective par laser (SLM)

- Electron beam melting (EBM)

For a more detailed overview of powder metallurgy grades including 2.4668 and other advanced alloys, visit our Page produit PM Powder.

Why B2B Buyers Prefer This Alloy:

- Rapport résistance/poids élevé

- Long lifecycle performance

- AM compatibility enables rapid prototyping and customization

- Suitable for high-volume manufacturing with minimal waste

4. Global Market Demand and Growth Opportunities

The market for high-performance metal powders like 2.4668 (Inconel 718) is experiencing rapid growth, driven by the expansion of additive manufacturing (AM), aerospace advancements, and the global push toward lightweight, heat-resistant components in high-stress applications.

📈 Global Market Trends

| Tendance | Détails |

|---|---|

| Growth of Additive Manufacturing | Metal AM is projected to grow >25% CAGR through 2030 |

| Aerospace Industry Expansion | Rising demand for fuel-efficient aircraft drives usage of 2.4668 parts |

| Shift Toward Sustainable Manufacturing | Powder-based processes reduce material waste and energy consumption |

| Localization of Supply Chains | OEMs seeking reliable domestic and regional suppliers |

🌍 Regional Demand Insights

| Région | Key Driving Sectors | Demand Outlook |

|---|---|---|

| Amérique du Nord | Aerospace, Energy, Medical | Haut |

| L'Europe | Automotive, Aerospace, Defense | Haut |

| Asie-Pacifique | Additive manufacturing, Oil & Gas | Très élevé |

| Moyen-Orient | Petrochemicals, Energy | Modéré |

Key B2B Opportunities:

- Tier-1 suppliers looking to localize procurement of AM-grade powders

- Distributors seeking to add high-margin specialty alloys like 2.4668

- E-commerce players building B2B marketplaces for metal powders

- OEMs requiring custom particle size distributions for different AM machines

The rise of distributed manufacturing has made high-quality, certified 2.4668 powder a mission-critical input for thousands of suppliers globally.

5. How to Choose a Reliable 2.4668 Powder Supplier

When sourcing industrial powders like 2.4668, choosing the right supplier is not just a matter of price—it impacts production quality, regulatory compliance, and delivery timelines. Here are the key factors to evaluate.

✅ B2B Supplier Evaluation Checklist

| Critères | Ce qu'il faut rechercher |

|---|---|

| Méthode de production des poudres | Gas atomization preferred for AM; water atomization for cost-effective PM |

| Quality Certification | ISO 9001, AS9100, REACH, RoHS, and material traceability |

| Distribution de la taille des particules | Consistent 15–45μm, 45–105μm as per AM/PM needs |

| Packaging & Handling | Vacuum-sealed, inert gas packaging, anti-contamination protocols |

| MOQ & ; Délai de livraison | Flexible MOQ for R&D to large-scale production; short lead times |

| Support technique | Application engineers, data sheets, and on-site consultation available |

🔍 Key Questions to Ask Your Supplier

- Do you provide gas atomized or water atomized 2.4668 powder?

- Can you provide full chemical and mechanical property certification?

- Do you offer custom particle sizes for AM platforms like EOS or Renishaw?

- What is your typical lead time for bulk orders?

- Can you support logistics and export documentation?

To learn more about a supplier that meets these critical standards, check out Shanghai Truer Technology’s Company Profile.

6. Leading 2.4668 Powder Suppliers in Asia and Europe

Here we highlight five reputable companies known for supplying industrial-grade 2.4668 powder to OEMs, distributors, and AM service providers.

🌟 Top 5 Global Suppliers of 2.4668 Powder

| Nom du fournisseur | Région | Points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Custom atomization, full PM/AM support, wide product range |

| Hoganas AB | Suède | Large-scale PM production, strong R&D |

| Technologie LPW (additif pour charpentier) | ROYAUME-UNI/ÉTATS-UNIS | Aerospace-grade AM powders, traceable supply chain |

| Fabrication additive Sandvik | Suède | High-purity powders for AM, strong innovation |

| EOS GmbH | Allemagne | Certified AM powders for EOS machines |

Pourquoi la technologie Shanghai Truer se démarque-t-elle ?

Shanghai Truer Technology is one of China’s most trusted names in powder metallurgy and additive manufacturing materials. With a focus on advanced powder production, they provide:

- ✅ Custom gas and water atomized 2.4668 powders

- ✅ Full support for powder metallurgy applications

- ✅ Certified grades for both AM and PM processes

- ✅ In-house material scientists and technical support

- ✅ Export experience and short lead times

Industries Served: Aerospace, automotive, tooling, energy, and medical sectors.

Available Grades: CT-1000, F0008, FL-4605, FD-0200, and customer-specific blends.

For buyers seeking a dependable supplier of high-performance metal powders, Shanghai Truer Technology offers a complete solution with global service capabilities.

7. Pourquoi de plus en plus d'acheteurs se tournent vers les fabricants chinois

In the last decade, B2B industrial buyers have increasingly turned to Chinese manufacturers for sourcing high-performance alloy powders like 2.4668. This shift is driven by a combination of technological advancement, supply chain flexibility, and cost-effectiveness.

🔍 Key Reasons for the Shift

| Facteur | Advantages Offered by Chinese Suppliers |

|---|---|

| Prix compétitifs | Lower production costs without compromising quality |

| Customized Manufacturing | Ability to produce custom grades and particle sizes for AM/PM |

| Des délais plus courts | Rapid production cycles and flexible MOQ options |

| Export-Ready Infrastructure | Expérience de la logistique internationale et de la conformité |

| Investment in R&D | Growing focus on innovation, especially in additive manufacturing sector |

Case in Point: Shanghai Truer Technology

Shanghai Truer Technology Co., Ltd exemplifies the new generation of Chinese powder metallurgy suppliers. Established in 2009, Truer entered the additive manufacturing space in 2019 and quickly became a trusted name for:

- Gas and water atomized 2.4668 powder

- A wide portfolio of PM and AM-compatible alloy powders

- Technical consultation for specific engineering applications

- Reliable export and logistics support for wholesale buyers

Learn more about their company background and capabilities.

Testimonials from International Buyers:

“Truer’s 2.4668 powder met all our aerospace-grade requirements. Their support team helped us fine-tune particle size distribution for our SLM machines.”

— Procurement Manager, Aerospace Component Manufacturer, Germany

“We switched to their powder for our oil & gas tools and found it more consistent and cost-effective than our previous European supplier.”

— B2B Distributor, UAE

8. Why Shanghai Truer Technology Is a Trusted Supplier

Shanghai Truer Technology is recognized as one of China’s most professional and reliable suppliers of powder metallurgy materials and additive manufacturing powders—including 2.4668.

🏆 Competitive Advantages of Shanghai Truer Technology

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| In-house Atomization Facilities | Full control over powder quality and consistency |

| Large gamme de produits | Includes PM iron, stainless steel, copper, brass, and Inconel grades |

| Custom Powder Solutions | Particle size, morphology, and composition tailored to buyer needs |

| Support technique et recherche et développement | Application engineers and lab support for part design and prototyping |

| Expédition et logistique mondiales | Export-ready documentation and short delivery times |

🧪 Available Powder Grades

Truer supplies a comprehensive range of prealloyed, hybrid, and diffusion-alloyed PM powders, including:

- PM 4600 steel (prealloyed)

- PM 4200 steel (hybrid)

- PM stainless steel (gas or water atomized)

- FX-2008, FD-0208, FN-5000, and more

- Diffusion CuSn powder for diamond tools and sintered bearings

Truer’s full PM powder catalog can be explored ici.

B2B Ordering Solutions Provided by Truer

- Bulk ordering with volume discounts

- OEM/ODM services for private label or custom grades

- Technical consultation to match powder to your AM/PM equipment

- After-sales support including test reports and performance data

9. FAQ: Buying Wholesale 2.4668 Powder

❓ What is 2.4668 powder used for?

2.4668 (Inconel 718) powder is widely used in aerospace, automotive, energy, and additive manufacturing applications due to its excellent mechanical strength and corrosion resistance at high temperatures.

❓ What types of atomization does Truer use for 2.4668?

Shanghai Truer offers both gas and water atomized 2.4668 powder. Gas atomization is recommended for additive manufacturing, while water atomized powder is better suited for traditional PM applications.

❓ Can I order custom particle sizes?

Yes. Truer provides customized particle size distributions such as 15–45μm or 45–105μm to meet specific AM platform requirements (e.g., EOS, Renishaw, SLM Solutions).

❓ Do you provide certificates and material data sheets?

Absolutely. Each batch of 2.4668 powder comes with full chemical composition, mechanical properties, and quality assurance certificates.

❓ How do I place an order?

You can get in touch with the sales team directly through the formulaire de contact, or email Truer with your volume, grade, and spec requirements. A technical representative will assist you through every step of the procurement process.

❓ Is there a minimum order quantity (MOQ)?

Truer offers flexible MOQs, especially for R&D and new product development projects. For regular production, bulk discounts are available.

🔗 Internal Links Summary (Anchor Texts)

- Page produit PM Powder

- Profil de l'entreprise

- Shanghai Truer Technology

- Formulaire de contact

- Full PM Powder Catalog

This blog was crafted to help wholesale buyers, distributors, and OEMs understand the technical and commercial value of 2.4668 powder, and why Shanghai Truer Technology is a top-tier supplier in the global market. If you’re ready to source high-quality 2.4668 powder for your business, contact us today pour demander un devis ou une consultation technique.