1. Introduction: What is 18Ni300 Powder and Why It Matters in Manufacturing

18Ni300, also known as Maraging Steel 300, is a high-strength, low-carbon, iron-nickel-based alloy powder widely used in additive manufacturing (AM) and powder metallurgy (PM). It boasts exceptional mechanical properties, including ultra-high strength, excellent toughness, and outstanding dimensional stability after heat treatment.

Key Features of 18Ni300 Powder:

- Composition: Iron, Nickel (~18%), Cobalt, Molybdenum, Titanium, Aluminum

- Méthodes de production: Gas atomization (for spherical morphology), water atomization (cost-effective)

- Compatibilité: Ideal for Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Metal Injection Molding (MIM)

Its excellent weldability and minimal distortion during printing make it a preferred material for high-performance parts in industries like aerospace, tooling, automotive, and defense.

📌 18Ni300 powder is critical for manufacturing parts that demand both precision and strength.

2. Key Industrial Applications of 18Ni300 Powder

18Ni300 is used extensively across multiple high-performance sectors due to its unique properties. Below are the most notable applications:

Industrie aérospatiale

- Composants de la turbine

- Landing gear parts

- Structural aircraft components

Automotive & Motorsport

- Gears and shafts

- High-stress engine components

- Performance-critical parts in racing cars

Tool & Die Industry

- Injection molding tools

- Die-casting molds

- Forming dies

Defense & Military

- Missile components

- Firearm parts

- Armor-piercing tools

Dispositifs médicaux

- Instruments chirurgicaux

- Orthopedic implants (non-biocompatible applications)

| L'industrie | Common Parts Made with 18Ni300 | Benefit of Usage |

|---|---|---|

| Aérospatiale | Aubes de turbine, supports | Rapport résistance/poids élevé |

| Automobile | Gears, engine components | Fatigue resistance, durability |

| Outils et matrices | Moules, matrices | Precision and toughness |

| Défense | Firearm components | Strength and dimensional stability |

| Dispositifs médicaux | Surgical tools (non-implant) | Excellente usinabilité |

3. Properties and Benefits of 18Ni300 for Additive Manufacturing

18Ni300 powder offers a combination of physical and mechanical properties that make it ideal for additive manufacturing (AM).

Propriétés physiques :

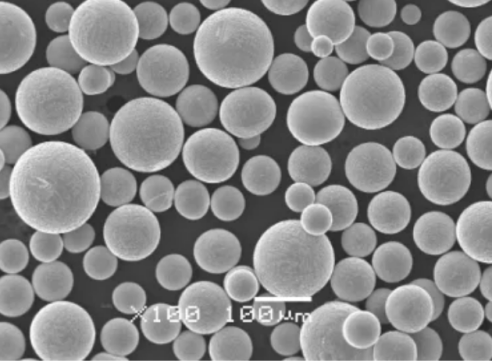

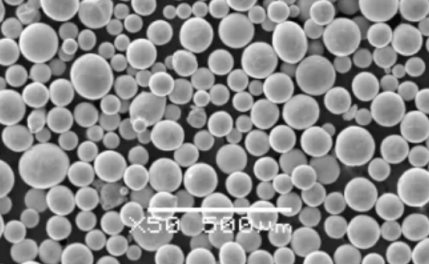

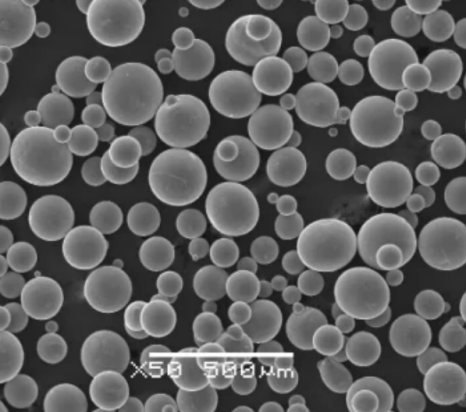

- Taille des particules: 15–45 µm (SLM grade), 45–105 µm (EBM grade)

- Morphologie: Spherical (preferred for AM)

- Densité: ~8.1 g/cm³

- Point de fusion: ~1413°C

Mechanical Properties (Post Heat-Treatment):

- Résistance ultime à la traction (UTS): >2000 MPa

- Limite d'élasticité: >1800 MPa

- Élongation: ~5–10%

- Dureté: ~54 HRC

Key Benefits:

- Minimal shrinkage and distortion during sintering or printing

- Excellent surface finish

- Haute résistance à l'usure

- Corrosion resistance in non-aggressive environments

- Superior weldability compared to traditional tool steels

Additive Manufacturing Advantages:

- Liberté de conception: Enables production of complex geometries

- Réduction des déchets: Powder can be recycled in closed-loop AM systems

- Prototypage rapide: Speeds up development cycles

- Coût-efficacité: Eliminates the need for expensive tooling

Here’s a comparative summary of 18Ni300 vs. traditional tool steel in AM:

| Propriété | Poudre 18Ni300 | Traditional Tool Steel |

|---|---|---|

| La force | Very High (>2000 MPa) | High (~1200–1500 MPa) |

| Usinabilité | Excellent | Modéré |

| Printability (SLM/EBM) | Excellent | Modéré |

| Post-processing Needs | Heat-treatment only | Très large |

| Qualité de l'état de surface | Haut | Modéré |

🔗 Learn more about Shanghai Truer’s Produits en poudre PM that include high-performance alloys like 18Ni300.

4. Global Market Demand and Trends for 18Ni300 Powder

As the demand for high-performance metal powders grows, 18Ni300 remains one of the most sought-after materials in the additive manufacturing (AM) and powder metallurgy (PM) sectors. Its superior strength, printability, and heat-treatment response make it a preferred choice for mission-critical components.

Tendances du marché mondial

- Additive Manufacturing Boom

The global metal AM market is projected to reach over USD 18 billion by 2030, with maraging steel powders like 18Ni300 playing a key role in aerospace and tooling segments. - Aerospace & Defense Demand Surge

Increased military budgets and the need for lightweight, high-strength components are accelerating adoption across NATO countries and Asia-Pacific. - Chaînes d'approvisionnement localisées

Disruptions from COVID-19 and geopolitical tensions have driven OEMs to seek more reliable, local suppliers of high-strength powders like 18Ni300. - Durabilité et recyclage

The recyclability of 18Ni300 powder in AM systems supports greener manufacturing goals, making it favorable for environmentally conscious OEMs.

Market Growth Forecast (2024–2030)

| Région | CAGR (2024-2030) | Facteurs clés |

|---|---|---|

| Amérique du Nord | 13.8% | Aerospace, defense, and automotive innovation |

| L'Europe | 12.5% | Tooling and AM standardization |

| Asie-Pacifique | 15.6% | Industrial expansion and local AM adoption |

📈 The growth of industries like aerospace, automotive, and tooling directly fuels demand for reliable, high-performance powders like 18Ni300.

5. How to Choose the Best 18Ni300 Powder Supplier

Selecting the right supplier for 18Ni300 powder is crucial for ensuring consistent part quality, optimized performance, and regulatory compliance. Here are some key factors to evaluate:

1. Powder Quality Specifications

- Consistent particle size distribution (typically 15–45 µm for AM)

- Spherical morphology for high flowability

- Faible teneur en oxygène et en azote

- Cohérence d'un lot à l'autre

2. Capacités de production

- Atomization method (gas atomization preferred for AM)

- In-house quality control and lab testing

- ISO 9001 or AS9100 certification

- Ability to customize grades/formulations

3. Logistics and Support

- Fast delivery lead times

- Technical support and consultation

- Documentation and traceability

- Export capabilities and international certifications

4. Cost and MOQ (Minimum Order Quantity)

- Competitive pricing on bulk orders

- Transparent MOQ policy

- Volume discounts for recurring buyers

| Critères | Niveau d'importance | Ce qu'il faut rechercher |

|---|---|---|

| Qualité de la poudre | ★★★★★ | Gas atomized, spherical, high purity |

| Certifications | ★★★★☆ | ISO, AS9100, RoHS, REACH |

| Delivery Timeliness | ★★★★☆ | 2–3 weeks lead time or faster |

| Support technique | ★★★★☆ | Application engineering and troubleshooting |

| Pricing & MOQ | ★★★★☆ | Competitive rates, low MOQ for sampling |

6. Top 5 Reliable 18Ni300 Powder Manufacturers in China

China is a leading producer of high-performance metal powders, including 18Ni300. Below are five reputable Chinese suppliers known for their quality, innovation, and export experience.

| Nom du fournisseur | Localisation | Spécialisation | Export Regions |

|---|---|---|---|

| Shanghai Truer Technology Co. | Shanghai | Impression 3D powders & PM additives | Mondial |

| GKN Additive (China) | Yizhuang, Beijing | AM powders for aerospace and tooling | Europe, US, Japan |

| CNPC Powder Material Co. Ltd | Suzhou | Gas & water atomized powders | Southeast Asia, EU |

| Changsha Tijo Metal Material Co. | Hunan | Ni, Co-based powders, custom alloys | Amérique du Nord, UE |

| Epowder Tech Co., Ltd | Anhui | AM metal powders, custom batch service | Mondial |

Why Shanghai Truer Is a Trusted Supplier:

- Over a decade of experience in powder metallurgy

- Custom-grade 18Ni300 powder produced via gas atomization

- Strict quality control and ISO-certified production

- Fast delivery and responsive B2B support

👉 Interested in partnering with an experienced 18Ni300 supplier? Get in touch with Shanghai Truer today.

7. Why More Buyers Are Switching to Domestic Suppliers for 18Ni300

In recent years, B2B buyers—from aerospace contractors to tool manufacturers—have increasingly opted for domestic or regional suppliers for high-performance powders like 18Ni300. Here’s why:

1. Supply Chain Resilience

- Eliminate overseas shipping delays

- Avoid customs bottlenecks and tariffs

- Ensure consistent availability

2. Cost-Efficiency

- Lower shipping and import duties

- Transparent pricing and faster quotes

- Local currency transactions

3. Faster Communication & Support

- Real-time technical support

- On-site visits and audits

- Faster feedback loops for customization

4. Compliance and Documentation

- Easier access to compliance documents (RoHS, REACH)

- Alignment with local regulatory bodies

- Easier traceability and batch control

| Avantage | Domestic Supplier | Overseas Supplier |

|---|---|---|

| Délai d'exécution | 5-10 jours | 3–6 weeks |

| Tariff/Customs | Minime | Haut |

| Support technique | Local language | Limitée |

| Flexibilité du MOQ | Haut | Moyen |

| Onsite Visit/Audit | Feasible | Difficile |

🔎 For Chinese and international buyers alike, sourcing from domestic leaders like Shanghai Truer Technology ensures quality, speed, and cost-effectiveness.

8. How to Order Wholesale 18Ni300 Powder from Shanghai Truer

Ordering high-quality 18Ni300 powder in bulk from a trusted supplier like Shanghai Truer Technology Co., Ltd is a simple and streamlined process tailored for B2B buyers, distributors, and additive manufacturing professionals.

Step-by-Step Guide to Ordering:

Step 1: Product Inquiry

- Visitez le site Page d'accueil de Shanghai Truer and explore available powder metallurgy products.

- Use the contact form or email (available on the site) to send your inquiry.

- Include key details:

- Required grade (18Ni300)

- Particle size (e.g., 15–45 µm for SLM)

- Quantity needed

- Intended application

- Destination de l'envoi

Step 2: Quotation & Sample Request

- Receive a quotation within 24–48 hours.

- Sample orders (1–5 kg) can be arranged for testing.

- Technical data sheets and material safety data sheets (MSDS) are provided.

Step 3: Order Confirmation

- Confirm your order based on pricing, lead time, and specifications.

- Contract and invoice will be issued for payment.

- Payment terms: T/T, L/C, or negotiated terms for long-term buyers.

Step 4: Production & Quality Assurance

- Powder is produced via gas atomization to ensure spherical morphology, low oxygen content, and high purity.

- Every batch is tested for:

- Distribution de la taille des particules

- Chemistry (via ICP-OES or spectrometry)

- Fluidité et densité apparente

- Morphology (via SEM)

Step 5: Packaging & Shipping

- Standard packaging: sealed containers (5kg, 10kg, 25kg) under inert gas.

- Optional: vacuum-sealed or nitrogen-flushed drums for added safety.

- Global shipping via air or sea freight.

- Tracking and delivery updates provided.

Benefits of Ordering from Truer:

- ISO-certified production and QC

- Custom powder grades and particle sizes

- Fast and responsive support

- Global export experience

- Secure packaging and logistics

| Fonctionnalité de commande | L'avantage de Shanghai plus vrai que nature |

|---|---|

| Personnalisation | Tailored particle sizes and alloy blends |

| Délai d'exécution | 7–15 days for bulk orders |

| MOQ | Flexible, starting from 5kg |

| Support technique | Engineering consultation & post-sales support |

| Documentation | Full traceability, COA, MSDS, TDS |

🛒 Start your order today by contacting the team via the page de contact.

9. FAQs: Buying 18Ni300 Powder in Bulk

Q1: What atomization method is used for Shanghai Truer’s 18Ni300 powder?

A : Shanghai Truer uses highly controlled gas atomization to produce spherical 18Ni300 powder with low oxygen levels and excellent flowability, ideal for additive manufacturing applications.

Q2 : Quelle est la distribution standard de la taille des particules ?

A : Typical sizes are:

- 15–45 µm for SLM

- 45–105 µm for EBM

Custom sizes can be produced upon request.

Q3: Can I request a sample before placing a bulk order?

A : Yes. Sample quantities (1–5 kg) are available for testing. You’ll receive a certificate of analysis and full testing data with your sample.

Q4: What are the shipping options?

A : Shanghai Truer ships globally via express air freight (DHL, FedEx) or sea freight for large orders. Packaging ensures moisture protection and inert conditions.

Q5: What industries are most commonly using 18Ni300?

A : Aerospace, automotive, die and mold tooling, defense, and high-performance engineering applications are the top consumers of 18Ni300 powder.

Q6: Is Truer’s 18Ni300 powder compatible with all AM machines?

A : Yes. It is compatible with leading metal 3D printing platforms including EOS, SLM Solutions, Renishaw, Trumpf, and others.

Q7: What quality certifications does Shanghai Truer hold?

A : Truer operates under ISO quality management systems and follows strict powder metallurgy standards to ensure consistency and reliability.

Q8: Can I get technical support for my application?

A : Absolutely. Truer’s engineering team provides expert consultation to optimize powder selection and printing parameters.

By choosing a well-established supplier like Shanghai Truer Technology Co., Ltd, you’re not just buying powder—you’re gaining a strategic partner in your manufacturing supply chain. With over a decade of experience in powder metallurgy and additive manufacturing, Truer delivers proven quality, reliability, and innovation.

🌐 Learn more about the company’s background and expertise, and how it supports advanced industrial applications with high-performance powders like 18Ni300.