Poudre de brasage

Shanghai Truer Technology Co,.LTD

Poudre de brasage

Poudres de brasage, y compris à base de nickel, à base de cuivre et à base d'aluminium poudres d'alliage.

Comparable à Poudres de brasage à base de Cu et d'Al, Poudres de brasage à base de Ni a de meilleures performances à haute température, une conductivité thermique élevée et une résistance à la corrosion qui conviennent à l'électronique marine ou à l'industrie chimique, mais des points de fusion plus élevés nécessitent des températures de soudure plus élevées.

Poudres de brasage à base de nickel sont utilisés pour le brasage sous vide et le brasage sous protection gazeuse de divers aciers au carbone, aciers inoxydables, superalliages et carbures de tungstène.

Poudre à braser à base de cuivre est applicable à tous les types de brasage à la flamme, de brasage par résistance, de brasage à haute fréquence et de brasage au four entre différents cuivres et alliages de cuivre.

Poudre de brasage à base d'aluminium convient au soudage de l'aluminium et de l'acier inoxydable, de l'aluminium et de l'aluminium.

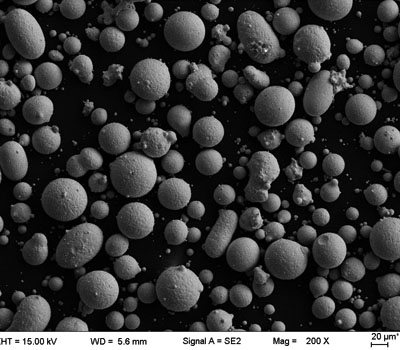

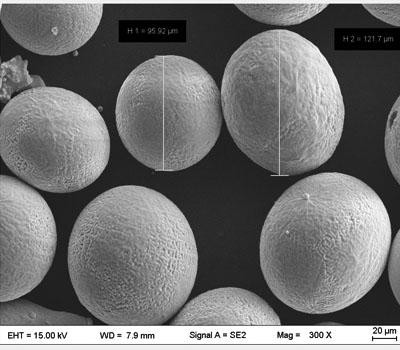

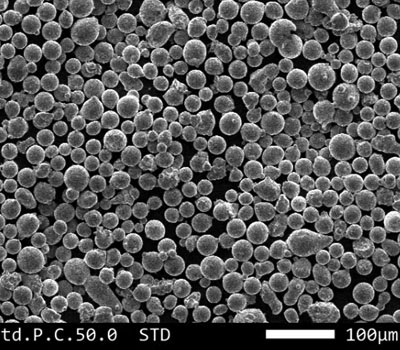

Nos poudres à braser sont produites par Processus d'atomisation des gaz avec morphologie sphérique. La taille des particules peut être personnalisée en fonction des exigences du client.

Morphologie de la poudre de CuNi5Sn7

Morphologie de la poudre d'AlSi10Mg

Morphologie de la poudre de BNi-5

Composition chimique (% en poids) - base Ni

| Objet | Ni | Cr | B | Si | Fe | C | P | Mn | Cu |

|---|---|---|---|---|---|---|---|---|---|

| BNi-1 | Bal | 14 | 3.1 | 4.5 | 4.5 | 0.7 | / | / | / |

| BNi-2 | Bal | 7 | 3.1 | 4.5 | 3 | / | / | / | / |

| BNi-3 | Bal | / | 2.9 | 4.5 | 0.5 | / | / | / | / |

| BNi-4 | Bal | / | 2.0 | 3.5 | 1.5 | / | / | / | / |

| BNi-5 | Bal | 19 | / | 10 | / | / | / | / | / |

| BNi-6 | Bal | / | / | / | / | / | 11 | / | / |

| BNi-7 | Bal | 14 | / | / | / | / | 10 | / | / |

| BNi-8 | Bal | / | / | 7 | / | / | / | 23 | 4.5 |

Composition chimique (% en poids) - à base de Cu

| Objet | Cu | P | Sn | Ni | Taille des particules (um) | Température de brasage (℃) |

|---|---|---|---|---|---|---|

| Cu93P7 | 93 | 7 | / | / | 0-75um, 0-45um | 743-840 |

| Cu86P7Sn7 | 86 | 7 | 7 | / | 0-75um, 0-45um | 700-750 |

| Cu88Ni5Sn7 | 88 | / | 7 | 5 | 0-75um, 0-45um | 890-900 |

Composition chimique (% en poids) - base Al

| Objet | Al | Si | Mg | Cu | Zn | Taille des particules (um) | Température de brasage (℃) |

|---|---|---|---|---|---|---|---|

| AlSi5 | Bal | 5 | / | / | / | 0-150um, 0-45um | 575-630 |

| AlSi8 | Bal | 8 | / | / | / | 0-150um, 0-45um | 575-615 |

| AlSi10 | Bal | 10 | / | / | / | 0-150um, 0-45um | 575-590 |

| AlSi12 | Bal | 12 | / | / | / | 0-150um, 0-45um | 575-585 |

| AlSi12Cu4 | Bal | 12 | / | 4 | / | 0-150um, 0-45um | 520-585 |

| AlSi10Mg | Bal | 10 | 1 | / | / | 0-150um, 0-45um | 555-590 |

| AlSi12Mg | Bal | 12 | 1 | / | / | 0-150um, 0-45um | 559-579 |

| AlSi10Zn3 | Bal | 10 | / | / | 3 | 0-150um, 0-45um | 576-588 |

| AlSi12Zn3 | Bal | 12 | / | / | 3 | 0-150um, 0-45um | 576-609 |

Les données détaillées des tests sont indiquées dans le certificat d'analyse de chaque commande.

Emballage :

Les poudres TRUER sont disponibles en paquets de 1, 2, 5, 10 et 25 kg, ou à la demande, emballés dans des bouteilles en plastique remplies de gaz inerte ou sous vide.