1. Introduction to CuP7 Powder in Powder Metallurgy

In the evolving world of powder metallurgy (PM), CuP7 powder plays a critical role due to its unique composition and versatility across multiple industrial applications. CuP7 is a copper-phosphorus alloy powder with approximately 7% phosphorus content. It is primarily used in brazing, sintering, and other metallurgical processes where high thermal conductivity and capillary action are required.

With the global demand for high-performance copper-based powders rising, CuP7 has emerged as a top choice among OEMs, e-commerce sellers, and industrial distributors. Its ability to deliver consistent results in automated and manual brazing applications makes it indispensable in industries such as HVAC, electronics, automotive, and aerospace.

Why CuP7 Is Important for B2B Buyers

- Rentabilité solution for mass production

- Reliable bonding in metal-joining processes

- Excellente fluidité for consistent manufacturing

- Preferred in automated assembly lines et high-precision components

2. Industrial Applications of CuP7 Powder

CuP7 powder is widely used in various industries, where its unique metallurgical and mechanical properties offer superior performance. Below is a breakdown of its most common applications:

1. Brazing and Soldering

- CuP7 is a standard brazing alloy for joining copper and copper alloys.

- Ideal for HVAC, refrigeration, and plumbing systems.

- Works in both manual torch brazing et automated furnace brazing.

2. Electrical and Thermal Conductors

- High conductivity makes it suitable for electrical components.

- Used in manufacturing of conductors, terminals, and heat sinks.

3. Automotive and Aerospace Components

- Applied in exhaust systems, fuel rails, and heat exchangers.

- Ensures robust mechanical bonding under high temperatures.

4. Diamond Tool Manufacturing

- Acts as a binder phase in diamond-impregnated tools.

- Enhances tool life and cutting efficiency.

5. Oil-impregnated Bearings and Bushings

- The phosphorus in CuP7 improves résistance à l'usure et lubricity.

- Commonly used in self-lubricating bearings.

| L'industrie | Domaine d'application | Advantages of CuP7 |

|---|---|---|

| HVAC | Brazing copper pipes | Clean flow, strong joints |

| Électronique | Soldering terminals | Conductivité élevée |

| Automobile | Fuel rails, exhaust systems | High-temp resistance |

| Outillage | Diamond cutting tools | Enhanced cutting performance |

| Paliers | Oil-impregnated sintered bearings | Reduced friction, longer life |

3. Key Properties and Performance Benefits of CuP7

CuP7 powder delivers an optimal balance of thermal, mechanical, and chemical characteristics that make it a preferred choice for wholesale buyers and industrial manufacturers.

composition chimique

| Élément | Contenu typique (%) |

|---|---|

| Cuivre (Cu) | Balance |

| Phosphore (P) | 6.8 – 7.2 |

Propriétés physiques

- Point de fusion: Approx. 710–890°C

- Densité: 8.2–8.9 g/cm³

- Débit: Consistent under controlled sintering conditions

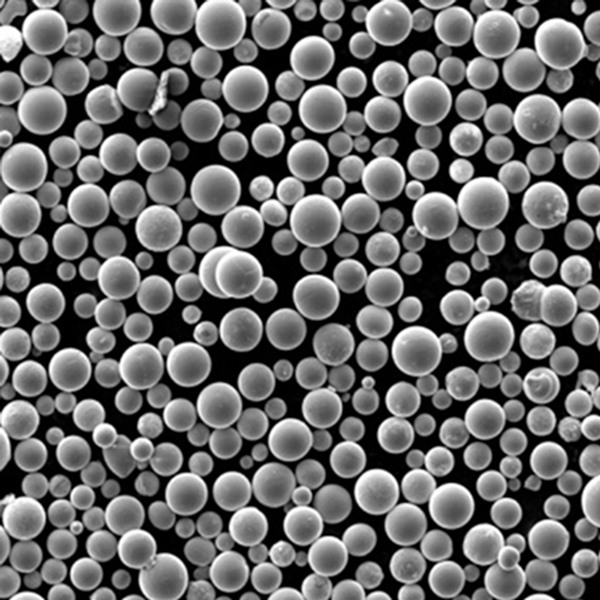

- Taille des grains: Optimized for sintering and brazing applications

Key Performance Benefits

- ✅ Excellent wetting ability on copper substrates

- ✅ Strong capillary action for tight joint filling

- ✅ Forms leak-proof, corrosion-resistant joints

- ✅ Suitable for robotic and manual processes

- ✅ Low fume generation during brazing

Compatibility and Processing

- Compatible Materials: Copper, brass, bronze

- Processing Methods: Induction brazing, furnace brazing, flame brazing

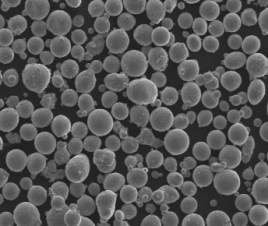

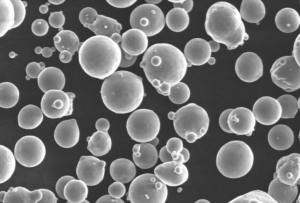

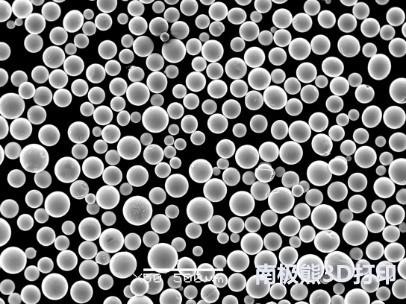

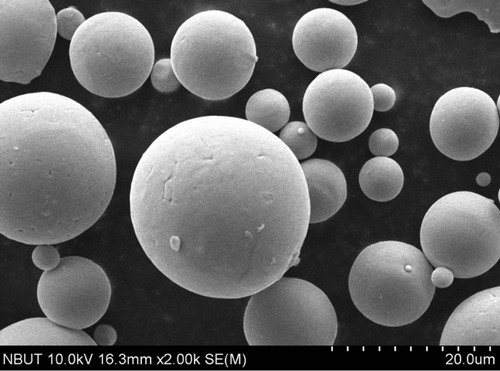

Truer’s CuP7 powder is manufactured using high-precision water atomization, ensuring uniform particle size distribution and minimal oxydation. This guarantees high repeatability in industrial production settings.

To understand more about Truer’s manufacturing expertise and powder solutions, visit their company profile and capabilities page.

4. Choosing the Right CuP7 Powder Supplier

For B2B buyers, OEMs, and procurement managers, sourcing a reliable CuP7 powder supplier is not just about price—it’s about consistency, certification, logistics, and technical support.

Here are the key factors to evaluate when selecting a CuP7 supplier:

✅ 1. Technical Specifications & Quality Standards

- Ensure the CuP7 powder meets:

- ISO 9001 ou IATF 16949 certifications

- Consistency in phosphorus content (6.8–7.2%)

- Controlled Distribution de la taille des particules for your application (e.g., 100–300 mesh)

✅ 2. Manufacturing Technology

- Look for suppliers using:

- Vaporisation de l'eau for clean, cost-effective production

- Controlled atmosphere processing to reduce oxidation

- In-house testing labs for quality control

✅ 3. MOQ and Delivery Capabilities

- Global buyers often require:

- Flexible minimum order quantities (MOQs)

- Options d'emballage en vrac (25kg drums, 1-ton pallets)

- Fast delivery with customs clearance support

✅ 4. Technical Support and Documentation

- Essential documents include:

- Fiches de données de sécurité (FDS)

- Certificat d'analyse (COA)

- RoHS & REACH compliance

✅ 5. Pricing Transparency

- Prefer suppliers offering:

- Stable pricing contracts

- Volume discounts

- Clear incoterms (FOB, CIF, DDP)

5. Top CuP7 Powder Suppliers in Asia

Asia is a stronghold of high-quality powder metallurgy production, especially in China, South Korea, and Japan. Here’s a comparison of leading CuP7 powder suppliers:

| Nom du fournisseur | Pays | Méthode de production | Certifications | MOQ | Délai d'exécution |

|---|---|---|---|---|---|

| Shanghai Truer | Chine | Eau pulvérisée | ISO 9001, RoHS | 25 kg | 7-14 jours |

| Kymera International | Korea | Gaz Atomisé | ISO 14001, ISO 9001 | 100 kg | 3-4 semaines |

| Fukuda Metal Foil | Japon | Électrolytique | JIS, ISO | 50 kg | 4-6 semaines |

| GGP Poudre métallique | Inde | Eau pulvérisée | ISO, REACH | 100 kg | 2-3 semaines |

| Ningbo Heli Metal Powder | Chine | Eau pulvérisée | ISO 9001 | 25 kg | 10–15 days |

Parmi ces derniers, Shanghai Truer Technology Co. stands out for its in-house manufacturing, global logistics support, and full-spectrum powder metallurgy solutions.

6. Why More Buyers Are Switching to Shanghai Truer

Shanghai Truer isn’t just another metal powder supplier. Since launching its additive manufacturing division in 2019, the company has emerged as a leading supplier of CuP7 powder and other PM metal powders in China and beyond.

Why Choose Truer as Your CuP7 Supplier?

| Fonctionnalité | Avantages pour les acheteurs B2B |

|---|---|

| In-house CuP7 powder production | Full control over quality and batch consistency |

| Méthodes d'atomisation multiples | Tailored powder for different applications |

| Extensive PM powder catalog | One-stop shop for Cu, Fe, Ni, Sn-based alloys |

| Processus certifiés ISO | Meets global quality and safety standards |

| Proven export experience | Fast customs clearance and global shipping |

| Technical support team | Application guidance and process matching |

CuP7 Powder Grades Available at Truer

Truer offers CuP7 powder suitable for:

- Capillary brazing

- Diamond tool manufacturing

- Sintered bearing production

Their CuP7 powder is manufactured using atomisation contrôlée de l'eau, with particle sizes tailored to customer needs (e.g., 100–200 mesh, 200–300 mesh). You can explore Truer’s full catalog of PM powders ici.

Truer’s Expanded Product Line

Besides CuP7, Truer also supplies:

- PM bronze, nickel silver, brass, copper steel, and stainless-steel powders

- Additives like lubricants (Lube-W, SUW-5000B), cutting agents (TD-8), and graphite (TBC-1000)

- Soft magnetic materials (QH-150, QHP-330)

These enable B2B buyers to consolidate orders and reduce sourcing complexity.

7. How to Order Wholesale CuP7 Powder from China

For B2B buyers, especially those sourcing from overseas, understanding the ordering process is crucial to ensure reliable delivery, quality assurance, and full compliance with import/export regulations. Below is a step-by-step guide on how to order wholesale CuP7 powder from a trusted Chinese supplier like Shanghai Truer Technology Co.

Processus de commande en gros, étape par étape

| Étape | Action | Description |

|---|---|---|

| 1 | Soumettre une demande | Contact Truer via site officiel or email with your specifications: quantity, particle size, packaging, usage. |

| 2 | Receive Technical Datasheet & Quotation | Truer will provide TDS, MSDS, and a detailed quotation including lead time and incoterms (FOB, CIF, DDP). |

| 3 | Sample Order (Optional) | For first-time buyers, Truer offers small sample batches for testing. |

| 4 | Confirm Order and Sign Contract | Upon approval, a commercial invoice and purchase agreement are issued. |

| 5 | Production and Quality Control | CuP7 powder is produced under ISO-certified protocols and batch-tested. |

| 6 | Packaging and Shipping | Packed in sealed 25kg drums or bulk bags, with options for palletization. |

| 7 | Customs Documents Provided | Includes COA, MSDS, HS code, packing list, and bill of lading. |

| 8 | Livraison et assistance | Truer offers global logistics support via air, sea, or express courier. |

Key Ordering Features with Truer

- ✅ Flexible MOQ starting at 25 kg

- ✅ Délais rapides (7–14 days for most orders)

- ✅ Customizable powder specs (mesh size, alloy ratio)

- ✅ Global export experience (Europe, North America, Southeast Asia)

- ✅ Multilingual support team

Truer ensures that all exported CuP7 powder complies with REACH, RoHS, and country-specific import regulations. This makes them a reliable partner for long-term supply contracts.

8. FAQs: Buying CuP7 Powder in Bulk

Q1: What’s the minimum order quantity (MOQ) for CuP7 powder at Truer?

A1: The standard MOQ is 25 kg, making it accessible for testing and small-batch production. Volume discounts apply for orders over 500 kg.

Q2: Can I request a specific particle size range for CuP7 powder?

A2: Yes. Truer offers customizable mesh sizes such as 100–200 mesh, 200–300 mesh, and finer grades based on application.

Q3: Does CuP7 powder require special storage conditions?

A3: It should be stored in a dry, sealed container away from moisture and oxidizing agents. Truer supplies vacuum-sealed packaging for added shelf-life.

Q4: What is the shelf life of CuP7 powder?

A4: If stored properly, CuP7 powder from Truer maintains optimal performance for up to 2 years.

Q5: How is Truer’s CuP7 powder different from other suppliers?

A5: Truer offers:

- In-house production for better quality control

- Water atomized process for clean, consistent flow

- ISO-certified quality systems

- Full export documentation and logistics support

Q6: Can Truer assist with brazing process optimization?

A6: Absolutely. Truer’s technical team can advise on optimal temperature ranges, flux compatibility, and joint design for your CuP7 application.

Q7: Where can I see more powder options or request a quote?

A7: You can explore Truer’s full product range and request a quote via their Poudre PM page produit.

By partnering with Shanghai Truer Technology Co., Ltd., B2B buyers gain access to high-purity CuP7 powder, consistent quality, and end-to-end support—from specification matching to global logistics. Whether you’re in automotive brazing, electronic welding, or diamond tooling, Truer ensures your production runs efficiently and cost-effectively.

Prêt à commencer ? Contact Truer’s sales team today for a free consultation or technical datasheet.