1. Introduction: Why Vanadium Powder Matters in Modern Manufacturing

Vanadium powder is gaining increasing attention in industrial sectors thanks to its superior strength, corrosion resistance, and versatility in alloy production. As a strategic metal, its fine powder form is especially vital in aerospace, automotive, energy storage, and additive manufacturing applications.

Principaux avantages pour les acheteurs B2B :

- Rapport résistance/poids élevé

- Excellent thermal and corrosion resistance

- Critical in steel and titanium alloy production

- Demand driven by battery and Impression 3D sectors

With the rise of additive manufacturing and sustainable energy solutions, vanadium powder has become a key ingredient for suppliers and manufacturers aiming to enhance performance and efficiency across various applications.

For detailed insights into powder metallurgy solutions, visit our Poudre PM page.

2. Industrial Applications of Vanadium Powder

Vanadium powder is used across several high-performance industries. Below is a breakdown of common applications, along with their corresponding benefits for wholesale users and manufacturers.

Table 1: Major Industrial Applications of Vanadium Powder

| L'industrie | application | Benefits for Manufacturers |

|---|---|---|

| Aérospatiale | Titanium-vanadium alloys for airframes | Lightweight, high heat resistance |

| Automobile | High-strength steels for structural parts | Improved fuel efficiency, crash resistance |

| Fabrication additive | 3D printed vanadium alloy components | Precision, strength, and corrosion resistance |

| Stockage de l'énergie | Vanadium Redox Flow Batteries (VRFB) | Long cycle life, scalable energy storage |

| Tooling & Cutting | High-speed tool steels with vanadium | Enhanced hardness and wear resistance |

B2B Buyer Tip:

Vanadium-enhanced materials offer longer lifecycle and lower maintenance, making them ideal for cost-sensitive bulk buyers in competitive sectors.

3. Grades and Types of Vanadium Powder for B2B Buyers

Vanadium powder is available in various grades and particle sizes designed for specific industrial uses. Selecting the right type is crucial for performance and cost optimization.

Table 2: Common Vanadium Powder Grades

| Type de poudre | Méthode de production | Target Application |

|---|---|---|

| V-Pure 99.5% | Réduction de l'hydrogène | High-end alloying, 3D printing |

| V-Micro 325 Mesh | Fraisage mécanique | Battery cathodes, fine additive applications |

| Vanadium Nitride Powder | Nitridation process | Steel hardening, wear-resistant tools |

| Vanadium Carbide Powder | Carbothermal reduction | Cutting tools, ceramic applications |

| Vanadium Pentoxide (V2O5) | Oxydation | Catalysis, VRFB battery manufacturing |

Important for Distributors:

- Ensure certification (ISO, ASTM) for international trade.

- Choose powders with consistent particle size distribution (PSD).

- Look for suppliers with in-house testing labs and quality assurance.

Companies like Shanghai Truer Technology Co. offer a wide portfolio of metal powders including high-quality vanadium powders produced by advanced atomization methods. Their wide range of PM and AM-ready powders are ideal for B2B clients across industries like automotive and aerospace.

4. Global Market Trends and Forecast for Vanadium Powder

The demand for vanadium powder is rising globally, driven by its strategic role in high-performance alloys, energy storage, and 3D printing. Wholesale buyers, distributors, and manufacturers must understand these trends to make informed sourcing decisions.

Principaux moteurs du marché :

- Energy Storage Revolution: Growing adoption of Vanadium Redox Flow Batteries (VRFBs) in renewable energy grids.

- Additive Manufacturing Growth: Increased use of vanadium alloys in powder bed fusion and directed energy deposition (DED).

- Construction Boom in Asia-Pacific: Vanadium microalloys in high-strength low-alloy (HSLA) steels for infrastructure projects.

- Allègement automobile: Automakers are using vanadium-enhanced alloys to meet fuel efficiency targets.

Market Forecast Table: Global Vanadium Powder Market (2023–2030)

| Année | Estimated Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2023 | 2.1 | - |

| 2025 | 2.8 | 7.2% |

| 2027 | 3.6 | 8.1% |

| 2030 | 5.1 | 9.3% |

Regional Growth Hotspots:

- Asie-Pacifique: Largest producer and consumer, led by China.

- Amérique du Nord: Growth in aerospace and battery sectors.

- L'Europe: Demand from high-strength steel and automotive industries.

B2B buyers looking to capitalize on these trends should explore suppliers offering advanced PM solutions. Learn more about Shanghai Truer’s powder offerings.

5. Key Factors to Consider When Choosing a Vanadium Powder Supplier

Choosing the right vanadium powder supplier is critical for maintaining consistency, quality, and competitiveness in your production processes. Here’s what wholesale buyers and distributors should evaluate:

Checklist for Evaluating Vanadium Powder Suppliers:

✅ Product Quality & Certification

- ISO 9001, ASTM, RoHS compliance

- Consistent PSD (Particle Size Distribution)

- Purity above 99.5% for high-end applications

✅ Manufacturing Technology

- Gas atomization, hydrogen reduction, mechanical milling

- In-house R&D and testing capabilities

✅ Stabilité de la chaîne d'approvisionnement

- Secure and scalable raw material sourcing

- Low lead times and flexible MOQs (Minimum Order Quantities)

✅ Support technique et personnalisation

- Custom particle size, alloy composition

- Technical documentation and application guidance

✅ Logistique mondiale et conformité

- Export certifications and REACH compliance

- Competitive international freight options

Tip for OEMs and Manufacturers:

Suppliers like Shanghai Truer Technology offer end-to-end powder metallurgy services, including custom formulations and metallurgical consulting—ideal for businesses scaling additive manufacturing operations.

6. Top 5 Vanadium Powder Suppliers in Asia-Pacific

Asia-Pacific is the largest regional market for vanadium powder, with China leading production. Here are the top suppliers known for consistency, innovation, and B2B service excellence.

Table: Leading Vanadium Powder Suppliers in Asia-Pacific

| Nom de l'entreprise | Pays | Points forts |

|---|---|---|

| Shanghai Truer Technology Co. | Chine | Advanced atomization, wide PM portfolio, B2B expertise |

| Pangang Group Vanadium & Titanium | Chine | Vertical integration, large-scale production |

| HBIS Group Co., Ltd. | Chine | Steel-focused vanadium applications |

| Toho Titanium Co., Ltd. | Japon | Aerospace-grade titanium-vanadium alloys |

| Largo Inc. | Singapour | Global logistics, battery-grade vanadium |

Pourquoi Shanghai Truer se démarque :

- Offers water atomized, gas atomized, and hybrid powders

- 15+ years of experience in PM and additive manufacturing

- Full-spectrum additive solutions including lubricants and cutting agents

Discover more about our company’s capabilities and mission on our À propos de nous page.

7. Why More Buyers Are Switching to Chinese Vanadium Sources

In recent years, global buyers and distributors have increasingly turned to Chinese manufacturers for vanadium powder. Here’s why:

Compétitivité des prix

- Chinese suppliers offer vanadium powder at significantly lower prices due to domestic resource availability and large-scale production.

- Competitive pricing enables better margins for OEMs and tier-1 suppliers.

Progrès technologiques

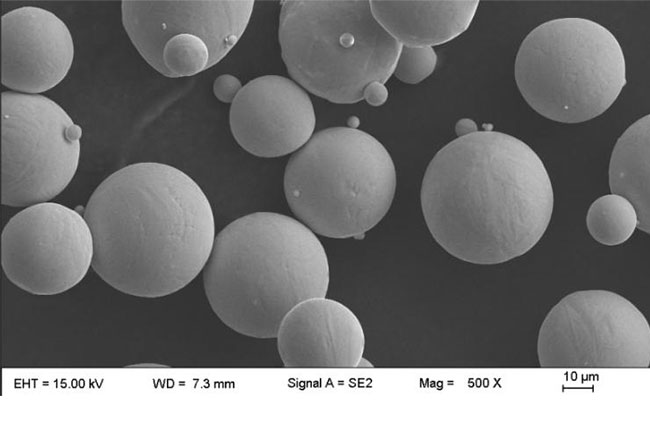

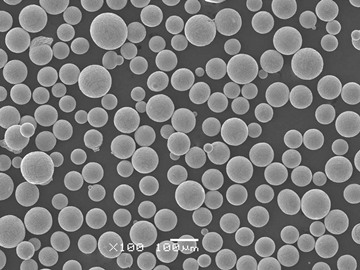

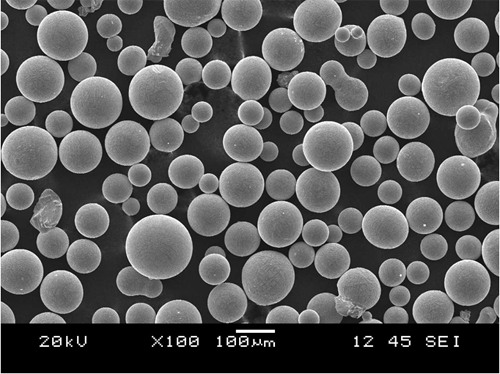

- Use of water and gas atomization for high-purity, spherical powders

- Integration of AI and automation in particle sizing and quality control

Supply Chain Advantages

- Shorter lead times for Asia-Pacific and European markets

- Government-supported logistics infrastructure

Personnalisation et flexibilité

- Custom formulations for different alloying or additive needs

- MOQs tailored to small and large-scale operations

Ready to explore Chinese vanadium solutions? Contact our team through the Nous contacter page to discuss your bulk sourcing needs.

8. Why Choose Shanghai Truer Technology for Vanadium Powder

When it comes to sourcing high-quality vanadium powder for industrial and additive manufacturing applications, Shanghai Truer Technology Co., Ltd emerges as a trusted partner for B2B buyers. With over 15 years of expertise in powder metallurgy and a dedicated additive manufacturing division launched in 2019, Truer delivers exceptional value, consistency, and technical support to global wholesalers, OEMs, and distributors.

Why B2B Buyers Prefer Shanghai Truer:

1. Un portefeuille de produits complet

Truer offers a wide range of vanadium and other PM powders including:

- PM Bronze, PM Nickel Silver, PM Brass, PM Iron, PM Steel

- PM Stainless Steel, PM Copper Steel, PM Nickel Steel

- Prealloyed Steels (FL-4605, FD-0208, FN-0205)

- Custom vanadium blends for additive manufacturing

2. Advanced Production Technologies

Truer utilizes multiple powder production techniques for tailored quality:

- Vaporisation de l'eau

- atomisation du gaz

- Combination Atomization

- Réduction de l'hydrogène

3. End-to-End Additive Manufacturing Solutions

In addition to powders, Truer provides specialized PM additives, such as:

- Lubricants (Lube-W, SUW-5000B, SUW-8000)

- Cutting Agents (Manganese Sulfide, SME-100, TD-8)

- Graphite Additives (TBC-400, TBC-1000)

- Soft Magnetic Additives (QH-150, QHP-330)

4. Technical Support & Customization

- Custom particle sizing and chemical composition

- Application-specific engineering consultation

- In-house R&D for powder innovation

5. Global Logistics & Reliability

- Stable inventory and streamlined export protocols

- Prix compétitifs pour les commandes en gros

- Fast delivery across Asia, North America, and Europe

Learn more about Truer’s advanced powder offerings on our Poudre PM page.

9. How to Order Wholesale Vanadium Powder from Shanghai Truer

Ordering vanadium powder in bulk from Shanghai Truer Technology is a simple, streamlined process designed for industrial buyers, OEMs, and distributors.

Processus de commande étape par étape

| Étape | Description |

|---|---|

| 1. Demande de renseignements | Visitez le site Nous contacter page and submit your requirements (grade, quantity, application). |

| 2. Consultation technique | Our engineering team will assess your needs and recommend the optimal vanadium powder or blend. |

| 3. Sample Delivery | Optional sample provided for testing and validation. |

| 4. Quotation & Agreement | Transparent pricing, MOQ, and delivery timelines provided. |

| 5. Bulk Production | Once confirmed, production begins with quality checks and packaging. |

| 6. Delivery & Support | Global shipping with full documentation and post-sale support. |

Bulk Order Options

| Quantité (kg) | Type d'application | Shipping Option |

|---|---|---|

| 10–100 | R&D, prototyping, sampling | Air freight |

| 100–500 | Small-scale production | Air or sea freight |

| 500–5000+ | Industrial manufacturing | Sea freight (FCL/LCL) |

Conseil aux distributeurs :

Ask about Truer’s OEM partnership program for exclusive pricing, priority production slots, and co-branding opportunities.

10. FAQs: Common Questions About Buying Vanadium Powder in Bulk

Q1: What purity levels are available for vanadium powder?

A: Truer offers vanadium powder with purities ranging from 99.0% to 99.9%, including custom grades for additive manufacturing and alloying.

Q2: Can Truer customize vanadium powder for specific applications like VRFB or AM?

A: Yes, Truer’s R&D team provides application-specific formulations, including custom particle sizes and blends with other elements like nitrogen or carbon.

Q3 : Quelle est la quantité minimale de commande (MOQ) ?

A: MOQs vary by product but typically start at 10 kg for standard powders and 25 kg for custom blends.

Q4: How do I ensure the powder meets my technical requirements?

A: Truer provides full technical data sheets, material safety data sheets (MSDS), and optional samples for pre-purchase testing.

Q5: Does Truer ship internationally?

A: Yes, Truer ships worldwide and provides necessary export documentation, REACH compliance, and logistics support.

Q6: Can I visit the factory or request third-party inspection?

A: Absolutely. Truer welcomes factory visits and supports third-party quality inspections upon request.

For more answers or to start sourcing vanadium powder, reach out to us via our Page de contact.