1. Introduction: The Importance of SiC Powder in Modern Industry

Silicon carbide (SiC) powder has become a critical material across multiple sectors, including automotive, aerospace, electronics, and metallurgy. Known for its extreme hardness, thermal resistance, and chemical stability, SiC powder is widely used in structural ceramics, cutting tools, abrasive materials, and even electronic components like semiconductors and heat sinks.

For B2B buyers, especially in the wholesale and manufacturing sectors, the quality and consistency of SiC powder can directly impact product performance and cost efficiency. As industries evolve toward higher precision and sustainability, the demand for high-purity and application-specific SiC powders continues to grow.

Key Benefits of SiC Powder:

- High hardness (Mohs scale 9.5)

- Excellente conductivité thermique

- Faible dilatation thermique

- Résistance exceptionnelle à la corrosion et à l'oxydation

- Compatible with additive manufacturing and powder metallurgy processes

This makes SiC powder not just a raw material but a strategic component in next-generation technologies and high-performance industrial systems.

2. Industrial Applications of Silicon Carbide Powder

SiC powder has diversified applications across several heavy and high-tech industries. Below is a breakdown of how different sectors utilize SiC powder for specific functionalities.

| L'industrie | application | SiC Benefit |

|---|---|---|

| Automobile | Brake discs, clutches, engine components | High thermal conductivity and abrasion resistance |

| Électronique | Semiconductors, substrates | Stable at high voltages and temperatures |

| Aérospatiale | Aubes de turbines, composants structurels | Lightweight and heat-resistant |

| Métallurgie | Refractory linings, kiln furniture | High temp endurance and chemical inertness |

| Céramique | Wear parts, seals, bearings | Exceptional hardness and dimensional stability |

| Solar Industry | Photovoltaic wafer slicing | Sharp grains, minimal kerf loss |

| Fabrication additive | Functional parts and tooling | High-performance mechanical properties |

For manufacturers and distributors, identifying the right SiC grade tailored to the end-use application is essential in maintaining product quality and reducing process inefficiencies.

3. Types and Grades of SiC Powder for Different Use Cases

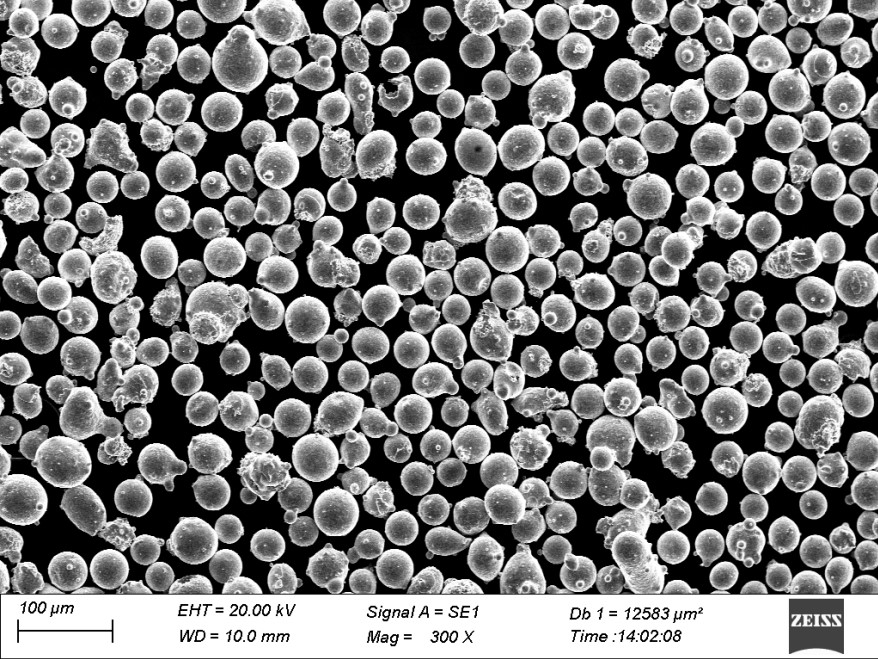

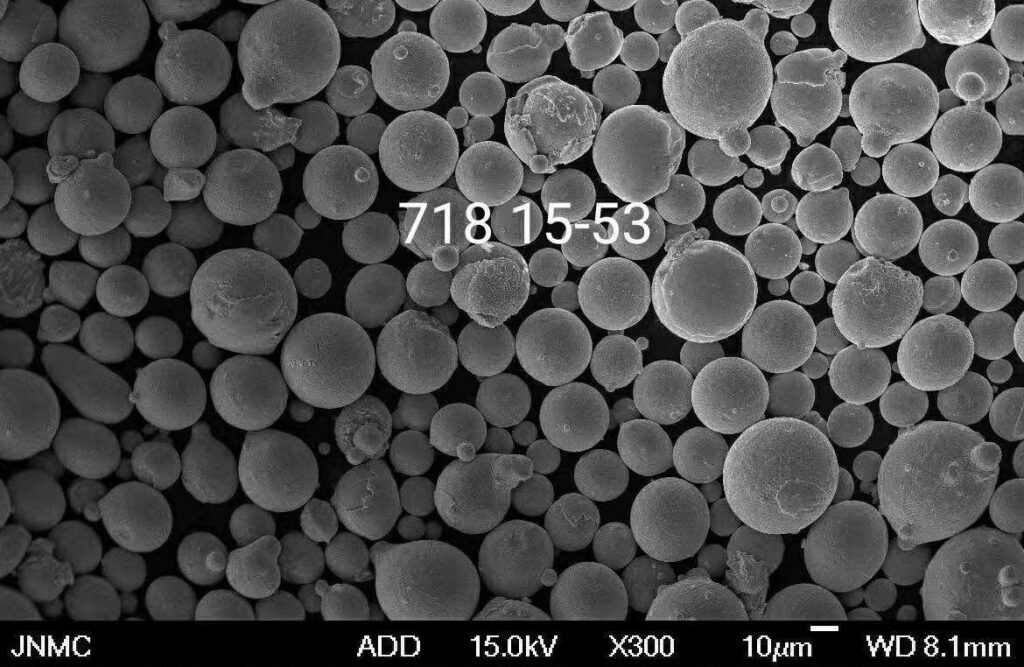

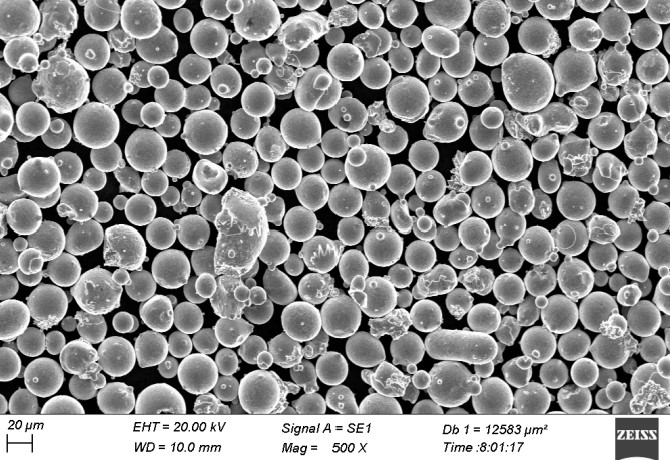

SiC powders are available in several forms, differentiated by purity, grain size, and manufacturing process (reaction bonded, sintered, or recrystallized). Understanding these types helps wholesalers and industrial buyers select the most suitable variant for their specific application.

Common Types of SiC Powder:

- Black SiC Powder

- Harder but more brittle

- Typically 98–99% purity

- Used in abrasives, grinding wheels, and refractory materials

- Green SiC Powder

- Higher purity (≥99%)

- More friable and better suited for precision grinding and electronics

- Ultrafine/Nano SiC Powder

- For high-performance ceramics and electronic components

| Grade | La pureté | Taille des particules | Utilisation courante |

|---|---|---|---|

| F240 – F1200 | 98–99% | 5–50 μm | Abrasives, lapping |

| D50 | ≥99.5% | 0.5–5 μm | Semiconductor, AM |

| Submicron | ≥99.9% | <1 μm | Thin films, coating |

| Nano SiC | ≥99.99% | <100 nm | High-tech ceramics, composite materials |

Shanghai Truer Technology Co., Ltd offers high-purity SiC powders compatible with additive manufacturing and powder metallurgy applications. Their SiC materials are engineered for consistent particle size distribution, excellent flowability, and optimized sintering behavior.

📌 Learn more about Truer’s full range of PM powders and material solutions.

4. Global Market Trends and Demand Forecast for SiC Powder

Over the last decade, the global silicon carbide (SiC) powder market has experienced exponential growth, driven by increased demand in high-performance applications such as electric vehicles, power electronics, and additive manufacturing. As of 2024, the global SiC market is valued at over $3.5 billion and is expected to exceed $7 billion by 2030, growing at a CAGR of 12.5%.

Principaux moteurs du marché :

- 🌱 EV and Renewable Energy Boom: SiC semiconductors are essential in electric vehicle inverters, solar inverters, and energy storage systems due to their high thermal conductivity and voltage tolerance.

- 🏭 Automatisation industrielle: Demand for high-wear-resistant components in robotics and machinery fuels the need for durable SiC-based ceramics.

- 🛠 Fabrication additive (AM): As AM scales for industrial use, high-performance powders like SiC are becoming essential for sintering and composite reinforcement.

Regional Demand Breakdown:

| Région | Market Share (2024) | Main Industries |

|---|---|---|

| Asie-Pacifique | 45% | Electronics, automotive, ceramics |

| Amérique du Nord | 25% | Aerospace, defense, semiconductors |

| L'Europe | 20% | Automotive, additive manufacturing |

| Moyen-Orient et Afrique | 5% | Refractories and energy sectors |

| Amérique latine | 5% | Mining and metallurgy |

Global supply chain diversification and energy-efficient manufacturing are pushing both distributors and OEMs to explore more cost-effective and scalable sources of SiC powder.

5. Key Criteria for Selecting a Reliable SiC Powder Supplier

Choosing the right SiC powder supplier is critical for B2B buyers, especially when dealing with high-volume orders intended for industrial or technological applications. Below are vital selection criteria to consider when sourcing wholesale SiC powder:

✔️ Quality and Purity Standards

- Installations de production certifiées ISO

- Consistent quality control with full traceability

- Particle size distribution reports and COA availability

✔️ Customization Capabilities

- Custom mesh sizes and particle shapes

- Specific surface area adjustments

- Compatibility with AM or PM process requirements

✔️ Logistics and Scalability

- Reliable supply chain with export capabilities

- Capacity for bulk orders and long-term contracts

- On-time delivery and responsive communication

✔️ Technical Support and Innovation

- R&D support for application-specific needs

- Technical data sheets and sintering profiles

- Experience in working with OEMs and Tier-1 manufacturers

✔️ Pricing Stability

- Des modèles de tarification transparents

- Competitive for wholesale and distributor-level buyers

- Volume-based discounts and contract terms

When evaluating a supplier, it’s essential to request samples, validate certifications, and assess their ability to scale with your business growth.

6. Top 5 Trusted SiC Powder Suppliers in Asia

Asia is a major hub for SiC powder production, owing to its advanced ceramics industry, growing semiconductor sector, and cost-effective manufacturing. Below are five trusted suppliers known for their reliability, quality, and B2B capabilities.

| Fournisseur | Pays | Principaux points forts | Site web |

|---|---|---|---|

| Shanghai Truer Technology Co. | Chine | Broad PM and AM powder portfolio, custom SiC grades, R&D support | am-material.com |

| Pacific Rundong Materials | Chine | High-purity green SiC powders for semiconductors | N/A |

| Saint-Gobain Ceramic Materials | Japon | Premium SiC ceramics and abrasives | N/A |

| Washington Mills | USA (with Asia ops) | Large-scale production, consistent mesh sizes | N/A |

| Fiven | Norway/China | High-end microgrit SiC for electronics and composites | N/A |

📌 For a comprehensive overview of Shanghai Truer’s capabilities and contexte de l'entreprise, visit their corporate profile.

7. Why More Distributors Are Sourcing SiC Powder from China

China has emerged as a dominant player in the global SiC powder supply chain. Its combination of low production costs, scalable infrastructure, and technical innovation makes it a preferred sourcing hub for international distributors and B2B buyers.

Advantages of China-Based SiC Powder Suppliers:

- 🏭 High Production Volume: Economies of scale reduce per-unit costs, ideal for wholesale orders.

- 🧪 Une gamme de produits diversifiée: From basic abrasive-grade to nano-scale SiC powders for electronics.

- 🚢 Canaux d'exportation établis: Efficient logistics and customs expertise for international orders.

- 💡 R&D Innovation: Suppliers like Shanghai Truer invest heavily in material innovation and custom powder development.

Distributors and e-commerce sellers working with Chinese suppliers often benefit from direct factory pricing, private label options, and flexible MOQ terms—giving them a competitive edge in the global market.

🧾 To get in touch or receive a quote from Shanghai Truer, visit their Page de contact.

8. Pourquoi choisir Shanghai Truer Technology Co. comme fournisseur ?

Shanghai Truer Technology Co., Ltd is one of China’s most respected suppliers of advanced powder materials, with a reputation for quality, consistency, and innovation in the powder metallurgy and additive manufacturing sectors. Since launching its additive manufacturing division in 2019, Truer has become a leading name in high-performance powder solutions, including Silicon Carbide (SiC) powder.

🔍 What Sets Truer Apart?

| Fonctionnalité | Détails |

|---|---|

| ✅ Experience | Over 15 years in powder metallurgy, including 5+ years in AM powders |

| 🧪 R&D Capabilities | In-house material scientists and custom formulation services |

| 🚀 Product Range | SiC, PM bronze, PM stainless steel, PM iron, nickel-copper alloys, and more |

| 🏭 Manufacturing | Water atomization, gas atomization, and reduction processes |

| 🌐 Global Reach | Export-ready with English-speaking sales and technical support |

| 📦 Packaging & Delivery | Customized packaging for bulk orders, fast lead times |

Whether you’re a distributor, OEM, or e-commerce seller sourcing high-purity SiC powder or tailored PM solutions, Truer provides:

- Distribution homogène de la taille des particules

- High thermal resistance SiC powders

- Custom mesh sizes and packaging

- Application-specific formulations

Truer’s SiC powders are widely used in the production of semiconductors, high-temperature ceramics, wear-resistant parts, and AM components, making it a one-stop supplier for multiple B2B industries.

📌 Explore Truer’s full product lineup to discover more SiC and PM powder solutions tailored for your industry needs.

9. How to Order Wholesale SiC Powder from Truer

Ordering silicon carbide powder in bulk from Shanghai Truer is straightforward and tailored to meet the needs of industrial buyers, OEMs, and international distributors. Here’s a step-by-step guide to streamline your procurement process:

🛒 Step-by-Step Ordering Process:

- Demande de renseignements sur le produit

- Visitez le site page de contact or email the Truer sales team directly.

- Specify the required SiC grade, mesh size, purity, and order volume.

- Consultation technique

- Optional R&D support for application-specific requirements.

- Receive technical data sheets and sample specs.

- Devis et délais

- Get a detailed quotation including FOB/CIF pricing, lead time, and logistics options.

- Approbation de l'échantillon (facultatif)

- Request small sample batches for compatibility testing before bulk order.

- Confirmation de commande

- Finalize PO, payment terms (typically T/T or L/C), and delivery timeline.

- Production & ; Emballage

- Powders are produced, quality-checked, and securely packaged.

- Expédition et livraison

- Truer arranges international shipping with tracking and customs documentation.

- Support après-vente

- Access to technical support and reordering services for future procurement.

📦 Options d'emballage :

- 25kg sealed bags (vacuum-packed or nitrogen-filled)

- 500kg drums for bulk orders

- Custom labeling and palletizing for distributors

Truer also supports long-term supply agreements and distributor partnerships, ensuring stable pricing and guaranteed inventory for repeat orders.

10. FAQs: Everything You Need to Know About Buying Wholesale SiC Powder

Q1: What is the minimum order quantity (MOQ) for SiC powder?

A: For standard SiC grades, the MOQ is typically 25kg. For custom grades or nano-sized SiC, MOQ may vary.

Q2: Can I request custom particle sizes or purities?

A: Yes, Truer specializes in custom formulations. You can specify particle size distribution, purity level, and even sintering behavior.

Q3: Do you offer samples before bulk ordering?

A: Yes. Samples (typically 500g–1kg) can be provided for validation and testing purposes.

Q4: What industries are Truer’s SiC powders best suited for?

A: Suitable industries include:

- Automotive (brake systems, engine components)

- Electronics (semiconductors, heat sinks)

- Aerospace (thermal shields, structural parts)

- Ceramics and Metallurgy

- Additive Manufacturing (Impression 3D functional parts)

Q5: How are SiC powders packaged for international shipping?

A: Powders are vacuum-sealed or nitrogen-filled in 25kg PE/PP bags, then packed in drums or cartons and secured on export pallets.

Q6: How fast can I receive my order?

A: Standard lead time is 7–15 business days depending on order size and customization. Express air shipping and sea freight options are available.

Q7: Is Truer open to distributor partnerships?

A: Yes. Truer offers exclusive distributor programs with regional price protection, marketing support, and dedicated account managers.

📌 For more information about Truer’s history, capabilities, and certifications, visit their A propos de nous.

By partnering with Shanghai Truer Technology Co., Ltd, you gain access to one of China’s most advanced powder material suppliers—backed by robust R&D, scalable production, and a strong commitment to quality. Whether you’re sourcing for industrial manufacturing, distribution, or product development, Truer offers a reliable and cost-effective solution for your SiC powder needs.

🧾 Ready to get started? Contact Truer’s sales team through their official inquiry form pour un devis personnalisé et une consultation technique.