1. Introduction: What is Chromium Carbide Powder and Why It Matters

Chromium carbide powder (Cr₃C₂) is a critical industrial material known for its exceptional hardness, corrosion resistance, and high-temperature stability. It is widely used in wear-resistant coatings, cutting tools, and thermal spray applications. Chromium carbide is especially valued in the metallurgical and manufacturing sectors due to its ability to extend the service life of components exposed to extreme conditions.

In the B2B sector, wholesale buyers, distributors, and manufacturing professionals rely on high-purity chromium carbide powder for:

- Surface engineering

- Hardfacing applications

- Composite material reinforcement

- Production of corrosion-resistant parts

As global demand for wear-resistant and high-performance materials continues to rise, chromium carbide powder is emerging as a must-have material in multiple industries.

2. Industrial Applications of Chromium Carbide Powder

Chromium carbide powder has diverse industrial applications where durability, wear resistance, and high performance are essential. Below are the major industries and use cases:

A. Thermal Spray Coatings

- Used in HVOF (High-Velocity Oxy-Fuel) and plasma spraying

- Protects turbine blades, compressor parts, and pump shafts

- Common in aerospace, power generation, and oil & gas sectors

B. Metal Matrix Composites (MMCs)

- Enhances mechanical properties of aluminum and steel composites

- Used in automotive parts for improved wear resistance

C. Cutting Tools Manufacturing

- Added to hard alloys for increased cutting efficiency

- Maintains hardness at high temperatures

D. Welding and Hardfacing Alloys

- Chromium carbide welding rods and wires

- Increases abrasion resistance in mining and construction equipment

E. Corrosion-Resistant Components

- Ideal for chemical processing industries

- Prevents degradation in acidic or high-temperature environments

Table: Chromium Carbide Applications by Industry

| L'industrie | Type d'application | Bénéfice |

|---|---|---|

| Aérospatiale | Revêtements par pulvérisation thermique | High wear and oxidation resistance |

| Pétrole et gaz | Pump and valve linings | Corrosion and erosion protection |

| Exploitation minière | Hardfacing of excavators | Abrasion resistance |

| Automobile | Brake systems, pistons | Heat resistance and wear protection |

| Traitement des métaux | Outils de coupe, matrices | Extended tool life |

3. Key Properties and Use Cases in Manufacturing

Chromium carbide powder is chosen for its superior physical and chemical properties. These make it an ideal additive or base material in high-performance components.

Propriétés principales

- Dureté: 1200–1800 HV

- Point de fusion: ~1895°C

- Densité: 6.68 g/cm³

- Conductivité thermique: 19 W/m.K

- Résistance élevée à l'oxydation: Up to 1000°C in air

Scénarios de cas d'utilisation

| Cas d'utilisation | Description |

|---|---|

| Coating for Jet Turbine Blades | Extends service life in high-temp environments |

| Lining for Chemical Reactors | Resists corrosion from acids and alkalis |

| Enhancement of Brake Pads | Increases durability and thermal performance in vehicles |

| Tooling for Metal Cutting | Retains sharpness and strength at elevated temperatures |

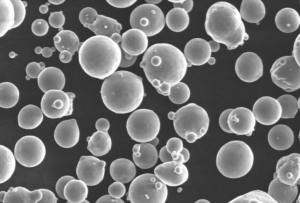

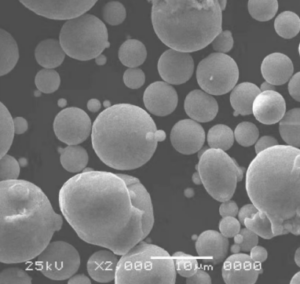

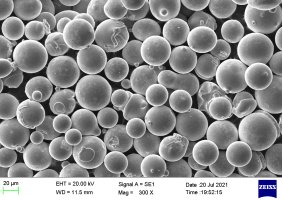

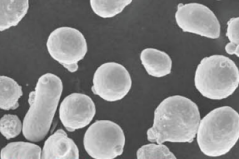

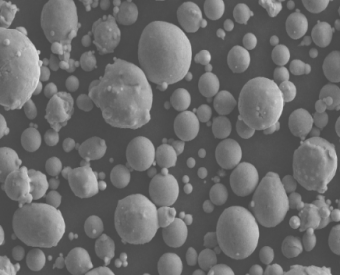

Shanghai Truer Technology Co., Ltd, a leading supplier of advanced Impression 3D and powder metallurgy materials, offers high-quality chromium carbide powder tailored for these applications. Their precision manufacturing using water atomization and gas atomization ensures consistent particle size and high purity, meeting the needs of demanding industrial applications. Learn more about their powder metallurgy offerings.

4. Top Global Suppliers of Chromium Carbide Powder

For B2B buyers, selecting a reliable supplier of chromium carbide powder ensures consistency in product quality, delivery timelines, and technical support. Below are five top global suppliers recognized in the powder metallurgy and surface coating industries.

A. H.C. Starck (Germany)

- Points forts: High-purity chromium carbide powders, consistent batch quality

- Industries Served: Aerospace, defense, and thermal spray coatings

- Certifications: ISO 9001, REACH, RoHS

B. Treibacher Industrie AG (Austria)

- Points forts: Custom powder blends, advanced R&D, global logistics

- Industries Served: Cutting tools, wear-resistant parts, MMCs

- Markets: Europe, North America, Asia

C. Shanghai Truer Technology Co., Ltd (China)

- Points forts: Full powder metallurgy solutions, high production capacity, R&D innovation

- Industries Served: Additive manufacturing, automotive, oil & gas, metallurgy

- Méthodes: Water atomization, gas atomization, hybrid techniques

- Note: Offers full-service solutions including 3D printing metal powders and production equipment.

D. Inframat Advanced Materials (USA)

- Points forts: Nanostructured coatings, thermal spray powders

- Industries Served: Defense, power generation, marine

- Spécialité: High-performance wear-resistant coatings

E. Kennametal (USA)

- Points forts: Vertical integration from raw materials to finished tooling

- Industries Served: Mining, construction, transportation

- Additional Offering: Cutting tools incorporating chromium carbide

Comparison Table: Top Global Suppliers

| Nom du fournisseur | Pays | Principaux points forts | Industries cibles |

|---|---|---|---|

| H.C. Starck | Allemagne | High-purity, batch consistency | Aérospatiale, défense |

| Treibacher Industrie AG | Autriche | Custom blends, R&D support | Tools, wear-parts |

| Shanghai Truer Technology | Chine | Full PM solutions, advanced equipment | Additive manufacturing, automotive |

| Inframat Materials | ÉTATS-UNIS | Nanostructured coatings | Power, defense, marine |

| Kennametal | ÉTATS-UNIS | End-to-end tooling solutions | Mining, construction |

5. Why More Buyers Are Turning to China-Based Suppliers

Over the last decade, China has emerged as a global hub for powder metallurgy materials, including chromium carbide powder. Here’s why more B2B buyers, e-commerce sellers, and distributors are sourcing from Chinese suppliers:

A. Competitive Pricing

- Lower production and labor costs

- Economies of scale due to high-volume manufacturing

B. Improved Quality Standards

- Many suppliers now meet ISO, RoHS, and REACH certifications

- Advanced production techniques like gas and water atomization

C. Faster Lead Times

- Domestic availability of raw materials

- Streamlined logistics networks across Asia and Europe

D. Customization Capabilities

- Tailored particle size distribution and purity levels

- OEM/ODM services for specialized applications

E. Integrated Solutions

- Suppliers like Shanghai Truer provide not just powder but also additive manufacturing equipment, lubricants, and technical support

- Truer also offers advanced additives for PM, such as:

- Lubrifiants : Lube-W, SUW-5000B

- Agents de coupe : SME-100, TD-8

- Magnetic additives: QH-150, QHP-330

Bullet List: Key Reasons for Choosing Chinese Suppliers

- ✅ Lower cost-per-kilogram

- ✅ High availability of stock

- ✅ Growing trust in quality inspection systems

- ✅ Flexible MOQs for trial orders

- ✅ Strong support for OEM formulations

Learn more about how buyers are benefiting from China-based sourcing by visiting Shanghai Truer’s page d'accueil.

6. Why Choose Shanghai Truer Technology Co., Ltd as Your Supplier

Shanghai Truer Technology Co., Ltd is one of China’s most trusted suppliers of chromium carbide powder and complete powder metallurgy solutions. Here’s why B2B buyers are making Truer their preferred supplier:

A. One-Stop PM Solution Provider

- Offers a complete ecosystem: powder production, equipment, additives, and application services

- Capable of serving industries like aerospace, automotive, energy, and tooling

B. Advanced Production Capabilities

- Atomization methods: water atomized, gas atomized, hybrid atomization

- Grades and particle sizes tailored to meet industrial standards

- Can produce chromium carbide powder with high purity and controlled morphology

C. Wide Portfolio of PM Powders

- Chromium carbide powder

- Nickel steel, copper steel, brass, bronze

- Pre-alloyed steels (FD-0208, FL-4605, etc.)

- Diffusion alloyed and hybrid low-alloy powders

D. Proven Track Record

- Established in 2009 with over a decade of PM industry experience

- Entered additive manufacturing in 2019 with rapid growth

- Recognized by clients across China, Europe, and the U.S.

E. Technical Support and R&D

- Dedicated engineering team to assist in product development and application

- Experienced in material formulation, powder customization, and process optimization

Table: Why Truer Stands Out

| Fonctionnalité | Avantages pour l'acheteur |

|---|---|

| Full PM ecosystem | Simplifies sourcing and production planning |

| Custom powder solutions | Meets unique application requirements |

| Capacités d'expédition à l'échelle mondiale | Fast delivery across continents |

| Technical R&D support | Increases efficiency and innovation |

| ISO-compliant manufacturing | Assurance of quality and traceability |

To explore Truer’s full range of powder metallurgy products and services, check out their company overview page.

7. How to Order Wholesale Chromium Carbide Powder from Trusted Sources

For procurement professionals, supply chain managers, and industrial buyers, streamlining the ordering process is critical. Working with an experienced supplier like Shanghai Truer Technology Co., Ltd ensures not only product quality but also a seamless B2B purchasing experience.

Step-by-Step Wholesale Ordering Process with Shanghai Truer

| Étape | Description |

|---|---|

| 1. | Demande de renseignements sur le produit: Contact Truer with specifications (purity, size, quantity) |

| 2. | Consultation technique: Receive expert guidance on the best product grades |

| 3. | Sample Evaluation: Request samples for internal testing (MOQ may apply) |

| 4. | Devis et délais: Get a tailored quote with shipping details |

| 5. | Contract Agreement: Finalize terms, payment method, and delivery schedule |

| 6. | Production & QC: Truer produces and inspects powders based on your specs |

| 7. | Expédition et logistique: Orders are shipped globally via air, sea, or courier |

| 8. | Support après-vente: Technical support available post-purchase |

Payment & Logistics Options

- Accepted Payment Methods: T/T, L/C, Western Union (for trial orders)

- Shipping Methods: DHL, FedEx, sea freight, air cargo

- Délai d'exécution: Typically 7–15 working days depending on order size

Documents fournis

- Certificat d'analyse (COA)

- Fiche de données de sécurité (FDS)

- Packing list and commercial invoice

- Origin certificate (if required)

Need a quick quote? Reach out to Truer’s sales team via their page de contact to start your order process today.

8. FAQs: Common Questions About Chromium Carbide Powder for B2B Buyers

Below are some of the most frequently asked questions we receive from industrial buyers and procurement teams regarding chromium carbide powder.

Q1: What grade and particle size should I choose?

- Réponse: Selection depends on your application. For thermal spray coatings, -45μm or -106+45μm fractions are common. Truer provides technical support to help you choose the right grade and mesh size.

Q2: Is Truer’s chromium carbide powder REACH and RoHS compliant?

- Réponse: Yes, all powders from Shanghai Truer are manufactured under strict environmental and quality control systems and comply with international standards like REACH and RoHS.

Q3: Can I request a custom formulation?

- Réponse: Absolutely. Truer specializes in custom powder blends and particle size distributions. Contact their engineering team for development collaboration.

Q4 : Quelles sont les options d'emballage disponibles ?

- Réponse: Standard packaging includes:

- 25kg drums with inner vacuum-sealed bags

- 5kg aluminum foil bags for smaller volumes

- Custom packaging available on request

Q5: Can you provide chromium carbide powder for additive manufacturing?

- Réponse: Yes. Truer supplies high-purity, gas-atomized chromium carbide powders suitable for additive manufacturing applications, including binder jetting and laser powder bed fusion.

Q6: How do I ensure quality consistency across batches?

- Réponse: Truer uses automated atomization systems, rigorous in-house testing, and batch-tracking systems for 100% traceability and consistency.

For more technical information, explore Truer’s full solutions pour la métallurgie des poudres and request technical data sheets.

9. Conclusion & CTA: Partner with Experts for Your Chromium Carbide Needs

As industries demand higher precision, durability, and performance from their components, chromium carbide powder is becoming an essential material for B2B buyers across sectors. Whether you’re sourcing for:

- Thermal spray coatings in aerospace

- Wear-resistant tools in mining

- Additive manufacturing in automotive

- Corrosion-resistant parts in the chemical industry

…Shanghai Truer Technology Co., Ltd is your trusted partner.

Pourquoi choisir Truer ?

- ✅ Over a decade of powder metallurgy experience

- ✅ Full range of chromium carbide and PM powders

- ✅ In-house production and custom formulations

- ✅ Global shipping and technical support

- ✅ One-stop solution from powder to equipment

🔗 Explore more about Truer’s capabilities and company profile

📦 Ready to place an order or request a sample? Get in touch with Truer’s team now and start sourcing premium chromium carbide powder at competitive wholesale prices.