1. Introduction: Why Ni25 Powder Matters in Modern Manufacturing

Ni25 powder, a nickel-based alloy containing approximately 25% chromium or related alloying elements, is a high-performance material widely used in additive manufacturing (AM), powder metallurgy (PM), and thermal spray coating. Its excellent corrosion resistance, thermal stability, and mechanical strength make it an essential raw material for industries such as aerospace, automotive, petrochemicals, and energy.

For B2B buyers, especially manufacturers, distributors, and OEMs, sourcing high-purity and consistent Ni25 powder is critical to maintaining part performance and production efficiency.

Key Benefits of Ni25 Powder:

- Haute résistance à la corrosion et à l'oxydation

- Excellent weldability and machinability

- Long-term thermal stability

- Compatibility with AM and PM processes

- Ideal for high-stress, high-temperature environments

The demand for Ni25 powder is accelerating as global manufacturers transition toward sustainable and lightweight metal components through additive manufacturing. This evolving need has made Ni25 a strategic material in the global supply chain.

2. Industrial Applications of Ni25 Powder

Ni25 powder is engineered for use in extreme environments where durability, oxidation resistance, and heat tolerance are non-negotiable. It’s especially valuable in sectors that rely on high-performance alloys to extend component lifespans and reduce maintenance.

Common Industrial Applications:

| L'industrie | application | Objectif |

|---|---|---|

| Aérospatiale | Aubes de turbines, chambres de combustion | Heat resistance, corrosion protection |

| Automobile | Exhaust valves, turbochargers | High-temperature wear resistance |

| Pétrole et gaz | Downhole tools, valves | Sulfide stress cracking resistance |

| Production d'électricité | Boiler tubes, superheaters | Résistance à la fatigue thermique |

| Marine | Pumps, valves, water systems | Saltwater corrosion resistance |

Specialized Applications in Additive Manufacturing (AM):

- Impression 3D of high-performance parts for aerospace and turbines

- Lightweight structural components in e-mobility solutions

- Custom-engineered components for defense and energy sectors

Why AM Manufacturers Prefer Ni25 Powder:

- Uniform particle size enhances powder flowability

- Stable microstructure ensures dimensional accuracy

- High-density builds with minimal porosity

For more information on powder metallurgy and additive manufacturing materials, explore Shanghai Truer’s PM powder portfolio.

3. Key Properties and Use Cases of Ni25 Powder

Ni25 powder owes its popularity to its exceptional material characteristics. These properties are essential for B2B buyers who require dependable quality and consistent performance, especially in mission-critical applications.

Physical and Chemical Properties:

| Propriété | Spécifications |

|---|---|

| Composition | ~75% Ni, ~25% Cr, trace Mo, Fe |

| Taille des particules | 15–53 µm (AM grade), customizable |

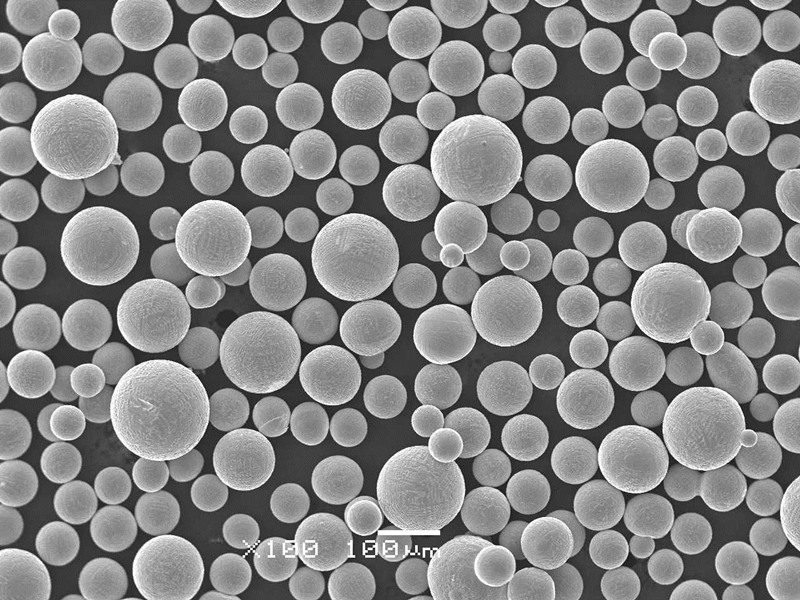

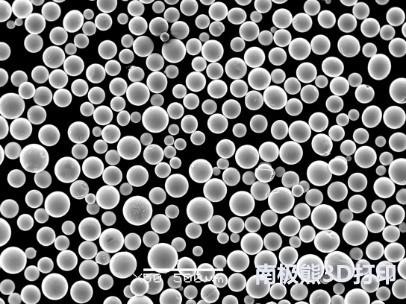

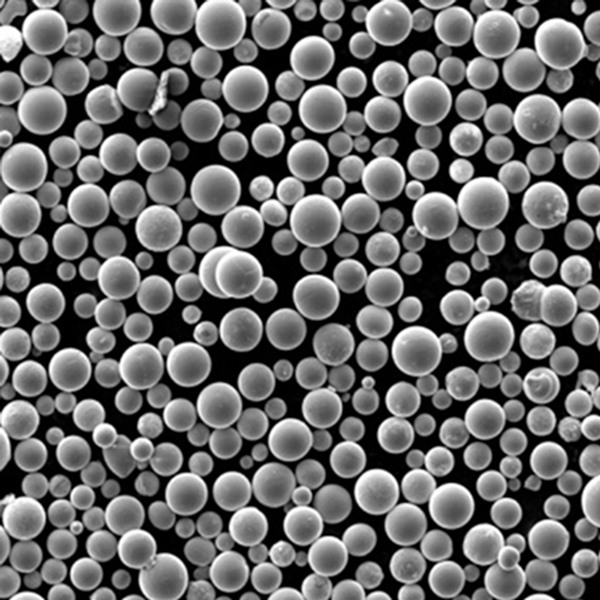

| Forme | Spherical (gas atomized) or irregular (water atomized) |

| Capacité d'écoulement | >15s/50g (Hall Flow) |

| Densité apparente | 4.5–5.0 g/cm³ |

| Teneur en oxygène | <0.05% (typical) |

Mechanical Properties (Post-Sintering or AM):

| Propriété | Valeur |

|---|---|

| Résistance à la traction | >700 MPa |

| Limite d'élasticité | >500 MPa |

| Élongation | >25% |

| Dureté | 180–220 HV |

Use Case Scenarios:

- High-Temperature Assemblies: Engine parts, heating elements, and combustion components

- Corrosive Environments: Pipes and valves in chemical processing units

- Wear-Resistant Applications: Bearings, bushings, and sliding components in industrial equipment

- 3D Printed Prototypes: Custom, rapid-turnaround parts for R&D and pre-series validation

Key Takeaways for Distributors and OEMs:

- Ni25 powder is an ideal addition to your materials portfolio for high-spec clients.

- It offers a strong value proposition for AM and PM part producers seeking thermal and corrosion resistance.

- Prioritize suppliers who offer customization (particle size, alloy modification) to meet specific application needs.

To learn more about Shanghai Truer’s manufacturing capabilities, visit their A propos de nous.

4. Market Trends and Demand for Ni-Based Alloys

The global demand for Ni-based alloys like Ni25 powder is being driven by the rise of high-performance engineering applications. Industries such as aerospace, energy, and automotive are shifting toward lightweight, corrosion-resistant, and heat-resistant solutions, where Ni25 powder excels.

Global Market Highlights

- Projected Growth: The global nickel alloy powder market is projected to grow at a CAGR of over 5.8% through 2028.

- Key Drivers:

- Surge in additive manufacturing (AM) adoption

- Emphasis on lightweight, durable materials in aerospace

- Increased investment in renewable energy infrastructure

- Key Regions: Asia-Pacific remains the fastest-growing market, led by China, South Korea, and Japan.

Demand in Additive Manufacturing (AM):

| Segment | Growth Driver | Role of Ni25 |

|---|---|---|

| Aérospatiale | Lightweight, durable engine parts | Heat resistance, stress tolerance |

| Automobile | Turbochargers, EV parts | Résistance à la corrosion |

| L'énergie | Gas turbines, nuclear components | Résistance à la fatigue thermique |

For distributors and procurement teams, understanding these trends ensures smarter sourcing strategies and alignment with long-term growth markets.

5. Factors to Consider When Choosing a Ni25 Powder Supplier

Purchasing Ni25 powder requires careful vetting of your supplier to ensure quality, consistency, and reliability — especially for high-stakes B2B manufacturing and distribution.

Critères d'évaluation clés :

| Facteur | Pourquoi c'est important |

|---|---|

| Purity & Composition | Impacts corrosion resistance and mechanical performance |

| Morphologie des particules | Affects flowability and printability in AM processes |

| Méthode de production | Gas atomized powders offer better sphericity and lower oxygen |

| Cohérence des lots | Essential for quality management and production predictability |

| Logistique et délais | Impacts supply chain reliability and cost-efficiency |

| Capacités de personnalisation | Some industries require tailored compositions or particle sizes |

Checklist for B2B Buyers:

- ✔️ ISO-certified production

- ✔️ Technical data sheets available for every batch

- ✔️ Samples available for performance testing

- ✔️ Proven track record with OEMs or major manufacturers

- ✔️ Responsive technical support

✅ Tip: Choose suppliers who provide full traceability and testing documentation to meet regulatory and quality assurance requirements.

6. Top Global and Chinese Suppliers of Ni25 Powder

The supply chain for Ni25 powder includes multinational giants and specialized manufacturers, particularly in China. Here’s a breakdown of some leading options for B2B buyers.

Fournisseurs mondiaux :

| Entreprise | Région | Points forts |

|---|---|---|

| Technologie des matériaux Sandvik | L'Europe | High-quality AM powders, global logistics |

| Hoganas AB | Suède | Large-scale PM production, broad alloy range |

| Additif pour charpentier | ÉTATS-UNIS | AM-focused, aerospace-grade powders |

| Oerlikon Metco | Suisse | Thermal spray specialization, global footprint |

Leading Chinese Suppliers:

| Entreprise | Points forts | Core Capabilities |

|---|---|---|

| Shanghai Truer Technology Co. | Full-stack AM & PM powder solutions | Water/gas atomized Ni25, custom alloys, additives |

| Groupe des poudres CNPC | Broad metal powder catalog | AM & coating powders |

| GKN Powder Metallurgy China | Strong PM network | Automotive-grade alloys |

Shanghai Truer Technology stands out among Chinese suppliers due to its vertical integration and extensive quality control. They offer both standard and customized Ni25 powder options, ideal for bulk orders and high-volume manufacturing.

📌 Want to explore Shanghai Truer’s full range of PM and AM powders? Browse their catalogue de produits.

7. Why More Distributors Are Turning to Chinese Ni25 Powder Sources

As global supply chains evolve, more B2B buyers, especially industrial distributors and OEM procurement teams, are sourcing Ni25 powder from China due to cost-effectiveness, scalability, and advancing quality standards.

Key Advantages of Chinese Suppliers:

- Competitive Pricing: Lower labor and production costs translate into better margins for distributors.

- Mass Production: Chinese companies like Shanghai Truer support high-volume orders with consistent quality.

- Personnalisation : Chinese suppliers are increasingly agile in offering tailored particle sizes or alloy tweaks.

- Technology Adoption: Leading Chinese firms are investing in gas atomization, vacuum melting, and advanced quality control.

Risk Management Tips:

| Risque | Stratégie d'atténuation |

|---|---|

| Quality Variation | Request test reports, third-party certification |

| Obstacles à la communication | Choose companies with English-speaking sales/tech teams |

| Logistics Delays | Opt for suppliers with established export experience |

✅ Shanghai Truer, for instance, has been serving international B2B clients since 2009 and offers responsive customer service along with technical documentation.

🔗 Visit their Page de contact to get a quote or request a sample for your next batch.

8. Why Choose Shanghai Truer Technology Co., Ltd. for Ni25 Powder

Shanghai Truer Technology Co., Ltd. is not only one of China’s foremost manufacturers of additive and powder metallurgy materials — it is also a trusted partner for global OEMs, distributors, and e-commerce resellers seeking innovative solutions and consistent quality.

Présentation de l'entreprise :

- Établi : 2009

- AM Business Initiated: 2019

- Spécialités : 3D printing powder equipment, PM/AM powders, additives

- Méthodes de production : Gas atomized, water atomized, reduction methods

For buyers of Ni25 powder, Truer offers:

✅ High-Quality Ni25 Powder:

Produced via gas atomization for spherical morphology, low oxygen content, and excellent AM performance.

✅ Personnalisation :

Truer can tailor compositions, particle size distributions, or hybrid alloy grades to meet specific industry requirements.

✅ Comprehensive PM Additives:

Besides Ni25, Truer offers complementary additives, including graphite, lubricants, and cutting agents — making them a one-stop solution for PM producers.

✅ Global Export Capability:

With full export documentation, Truer serves clients in North America, Europe, and Southeast Asia.

Client-Focused Services:

- Free technical consultation

- Sample evaluation programs

- Fast production lead times

- Full traceability and batch reports

- On-site quality control lab and R&D center

💡 Bonus: Truer also supports co-development of new alloy powders for niche or emerging markets.

📌 Learn more about Shanghai Truer’s mission and capabilities on their A propos de la page.

9. How to Order Wholesale Ni25 Powder from Shanghai Truer

For B2B buyers — whether you are an industrial distributor, OEM, or materials procurement specialist — Shanghai Truer Technology Co., Ltd. offers a streamlined and efficient ordering process for Ni25 powder. Their technical team ensures that every order meets your application, volume, and quality requirements.

Processus de commande étape par étape :

| Étape | Description |

|---|---|

| 1. Demande de renseignements | Visitez le site page de contact and submit your requirements, including quantity, particle size range, and intended application. |

| 2. Consultation technique | Their engineering team will provide recommendations, technical data sheets (TDS), and samples if needed. |

| 3. Quotation & Terms | You will receive a formal quotation including Incoterms, lead time, MOQ (typically 100kg+ for custom blends), and payment terms. |

| 4. Sample Approval (Optional) | For custom or critical-use applications, you can request a sample batch for testing and validation. |

| 5. Production & Quality Control | Once confirmed, your order enters production. Each batch is tested for composition, particle size distribution, and flowability. |

| 6. Emballage et expédition | Powders are vacuum-sealed or nitrogen-purged in moisture-resistant packaging (25kg drums or customized). International shipping available by air or sea. |

| 7. Support après-vente | Includes technical assistance, performance feedback, and re-order support. |

Available Packaging Options:

- 1 kg Lab Sample Packs (for testing)

- 5 kg R&D Packs

- 25 kg Commercial Drums (standard)

- Custom bulk packaging (250 kg totes, palletized drums)

Payment Terms & Logistics:

- Flexible terms for recurring clients (T/T, L/C)

- Fast lead times: 5–15 days depending on volume

- Global shipping with documentation (MSDS, CoA, RoHS, REACH compliance)

✅ Shanghai Truer also offers long-term supply contracts for enterprise clients, ensuring price stability and guaranteed availability.

10. FAQs: Common Questions About Buying Ni25 Powder Wholesale

Q1: What is the minimum order quantity (MOQ) for Ni25 powder?

A1: The MOQ typically starts at 25 kg for standard grades. Custom alloy compositions or particle size ranges may require a higher MOQ (50–100 kg).

Q2: What is the difference between gas atomized and water atomized Ni25 powder?

A2 :

- poudre atomisée au gaz: Spherical particles, ideal for additive manufacturing (AM) due to superior flowability and lower oxygen content.

- Water Atomized Powder: Irregular morphology, cost-effective, suitable for powder metallurgy (PM), thermal spray, and sintering applications.

Q3 : Puis-je demander une distribution granulométrique personnalisée ?

A3: Yes. Shanghai Truer offers customization services. Common ranges include 15–45 µm, 45–105 µm, and 53–150 µm. Custom sieving and classification is available upon request.

Q4: Are Truer’s powders certified?

A4: Yes. Each batch comes with a Certificate of Analysis (CoA), and their materials comply with international standards such as ASTM, ISO, and REACH.

Q5: Can I integrate Ni25 powder with other PM additives?

A5: Absolutely. Truer offers a full range of PM additives — including graphite, lubricants, and cutting agents — to optimize your sintering process. Visit their Page de la poudre de PM for more.

Q6: Do you offer technical support for additive manufacturing applications?

A6: Yes. Truer’s team can provide guidance on build parameters, powder handling, and part optimization for AM processes like SLM, DMLS, and binder jetting.

Q7: How is the powder packaged to avoid contamination?

A7: All powders are sealed in moisture-proof, anti-static packaging. For AM-grade powders, nitrogen-purged packaging is available.

Q8: What industries typically use Ni25 powder?

A8: Aerospace, automotive, marine, energy, oil & gas, and defense industries — especially in applications requiring high-temperature resistance and corrosion protection.

Final Thoughts: Partner with Shanghai Truer for Ni25 Powder

Sourcing high-quality, performance-optimized Ni25 powder is critical for staying competitive in modern manufacturing. Whether you’re a distributor seeking reliable supply or a component manufacturer needing custom powder specs, Shanghai Truer offers the flexibility, quality assurance, and technical support you need.

Key Reasons to Choose Truer:

- ✅ Over a decade of experience in powder metallurgy

- ✅ Advanced atomization technologies (gas, water, hybrid)

- ✅ Full catalog of AM and PM materials

- ✅ Responsive support team for technical and logistical needs

- ✅ Competitive pricing and scalable production capacity

🔗 Ready to start? Submit your inquiry through the Page de contact, and a representative will respond within 24 hours.

Internal Anchor Links Embedded

Here’s a summary of the 5 internal links embedded in the content:

- Portefeuille de poudres PM – Mentioned in section 2 describing Truer’s powder offerings

- About Page – Linked in section 3 discussing Truer’s company background

- Catalogue des produits – Referenced in section 6 to explore full range of powders

- Page de contact – Linked in section 7 for inquiry submissions

- Page de la poudre PM – Re-linked in the FAQ section for expanded product details

📞 Still have questions or need a custom quote? Reach out today and discover why Shanghai Truer is the trusted name in Ni25 powder and metal additive materials.

Let Truer be your strategic partner in advanced manufacturing.