1. Introduction: Why 440 Powder is Crucial in Precision Industries

440 stainless steel powder — particularly grades like 440A, 440B, and 440C — is renowned for its high hardness, excellent wear resistance, and corrosion-resistant properties. It is widely used in industries like aerospace, automotive, medical, and tool manufacturing, where performance and precision are non-negotiable.

For B2B buyers, especially OEMs, contract manufacturers, and component suppliers, sourcing high-quality 440 powder is essential to ensure durability and performance in final parts. Whether used in additive manufacturing or press-and-sinter powder metallurgy (PM), the right 440 powder unlocks cost-efficiency and high throughput.

Key Benefits of 440 Stainless Steel Powder

| Fonctionnalité | Benefit for Industrial Buyers |

|---|---|

| High Carbon Content | Enhances hardness and wear resistance |

| Excellente résistance à la corrosion | Idéal pour les environnements difficiles |

| Superior Polishability | Perfect for medical and aesthetic components |

| Versatile Grades | Customizable for different applications |

Shanghai Truer Technology Co., Ltd, established in 2009, is a proven expert in producing high-performance 440 powder through water atomization and gas atomization methods. Their powders meet international standards suitable for demanding applications.

2. Applications of 440 Powder Across Key Industrial Sectors

The industrial demand for 440 powder is growing, especially in sectors that require high strength and corrosion resistance. Below are major sectors using 440 stainless steel powder:

A. Automotive Industry

- Valve components, fuel injection systemset piston rings.

- Use of 440C powder in high-friction parts ensures longer lifespan.

B. Aerospace Components

- Parts such as landing gear bushings, bearing housingset fasteners.

- 440C’s hardness and fatigue performance are ideal for aerospace-grade parts.

C. Medical Devices

- Surgical scalpel blades, dental instrumentset orthopedic tools.

- 440A and 440B provide corrosion resistance and biocompatibility.

D. Tooling and Industrial Equipment

- Outils de coupe, ball bearings, moldset valves.

- 440C powder is frequently selected for its edge retention and polishability.

E. Additive Manufacturing

- 440 powder is compatible with laser powder bed fusion (LPBF) and binder jetting.

- Enables custom part fabrication with high mechanical integrity.

3. Types of 440 Powder: 440A, 440B, 440C, and Their Properties

The 440 series of stainless steel powders differ mainly in carbon content, which significantly affects hardness and corrosion resistance.

| Grade | Carbon (%) | Dureté | Résistance à la corrosion | Cas d'utilisation |

|---|---|---|---|---|

| 440A | ~0.65% | Modéré | Excellent | Medical tools, decorative parts |

| 440B | ~0.75% | Haut | Très bon | Cutting instruments, valves |

| 440C | ~1.20% | Très élevé | Bon | Bearings, knives, aerospace |

Powders Produced by Shanghai Truer Technology

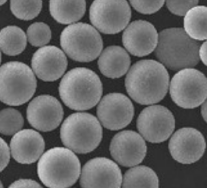

Shanghai Truer offers both water-atomized and gas-atomized 440 powders, tailored for sintering or Impression 3D applications. Their powder morphology ensures superior flowability and densification, reducing porosity in finished components.

- Atomization Types: Water, Gas, or Combined

- Niveaux disponibles: 440A, 440B, 440C

- Personnalisation: Sizing, alloy modification, and prealloyed blends

🔗 Learn more about Truer’s 440 and stainless steel powder offerings on their Page produit PM Powder.

4. Global Market Trends and Demand for 440 Stainless Steel Powders

The global stainless steel powder market is witnessing robust growth, with 440 series powders driving much of the demand due to their mechanical strength and corrosion resistance. These powders are particularly prominent in the automotive, medical, and additive manufacturing industries.

Principaux moteurs du marché

- Growing Adoption of Metal 3D Printing

- Industries are shifting from traditional machining to additive manufacturing.

- 440C powder is a preferred material for high-load-bearing components.

- Increased Use in Medical & Aerospace Sectors

- Rising demand for biocompatible and corrosion-resistant tools.

- High-performance alloys like 440A and 440C are being specified more frequently in critical applications.

- Advancements in Powder Production Technology

- Improved atomization methods—such as those offered by Shanghai Truer—lead to better particle morphology and flowability.

Global Market Size Forecast

| Année | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2022 | 1.1 | – |

| 2023 | 1.34 | 21.8 |

| 2024 | 1.65 | 23.1 |

| 2025 | 2.03 | 24.1 |

Regional Demand Insights

- Asie-Pacifique: Dominates the supply and demand due to strong OEM presence in China, Japan, and South Korea.

- Amérique du Nord: High demand in aerospace and medical sectors.

- L'Europe: Growing additive manufacturing ecosystem.

🔗 For more insights on the company driving innovation in this space, visit Truer’s About Page.

5. Key Factors to Consider When Choosing a 440 Powder Supplier

For OEMs, distributors, and large-scale manufacturers, choosing the right powder supplier is crucial to maintain product integrity, reduce lead times, and ensure compliance with industry standards.

A. Quality Assurance & Certification

- ISO-certified production lines

- Batch traceability and chemical composition reports

- Consistent particle size distribution (D10, D50, D90)

B. Powder Characteristics

| Propriété | Ideal Specification |

|---|---|

| Capacité d'écoulement | ≥ 25 s/50g |

| Densité apparente | 2,5-3,0 g/cm³ |

| Forme des particules | Spherical or near-spherical |

| Teneur en oxygène | < 0.025% |

C. Customization & Flexibility

- Ability to customize alloy composition

- Offer prealloyed or hybrid blends

- Tailor-made particle size distributions

D. Logistics & Supply Chain

- Warehousing capabilities

- Support for bulk and LTL (less-than-truckload) orders

- Regional distribution hubs for faster delivery

E. Technical Support

- Soutien à l'ingénierie d'application

- Sintering and 3D printing consultation

- On-site training and post-sales services

Shanghai Truer Technology excels in all the above criteria, with comprehensive support for both powder metallurgy and additive manufacturing customers across the globe.

6. Top 5 Reliable 440 Powder Suppliers in Asia-Pacific

Here’s a breakdown of five reputable suppliers known for quality, consistency, and B2B service excellence in the Asia-Pacific region:

| Fournisseur | Pays | Spécialisation | Qualités de poudre | Certification |

|---|---|---|---|---|

| Shanghai Truer Technology Co. | Chine | PM & AM powders | 440A, 440B, 440C | ISO 9001, RoHS |

| Acier Daido | Japon | Poudres d'acier inoxydable de haute pureté | 440 series | ISO 14001 |

| POSCO Powdertech | Corée du Sud | Automotive-grade PM powders | 440B, 440C | IATF 16949 |

| Poudre CNPC | Chine | Poudres atomisées à l'eau/au gaz | 440C | ISO 9001 |

| JFE Steel Corporation | Japon | Tool steel & alloy powders | 440 series | ISO 9001, JIS |

Why Shanghai Truer Leads the Market

- Extensive Portfolio: Offers water atomized, gas atomized, and hybrid 440 powders.

- Personnalisation: Can meet specific alloying and sizing needs.

- R&D Capability: Invests in innovation for next-gen PM additives and functional alloys.

- Local & Global Shipping: Well-established logistics network across Asia, Europe, and North America.

🔗 Ready to discuss your sourcing needs? Contact Truer’s expert team for bulk pricing and technical support.

7. Why More Manufacturers Are Choosing Chinese 440 Powder Sources

As global demand for stainless steel powder continues to rise, manufacturers are increasingly turning to Chinese suppliers for high-quality, cost-effective 440 powder. China’s advanced atomization technology, competitive pricing, and robust manufacturing infrastructure make it a top choice for B2B procurement.

Key Advantages of Chinese 440 Powder Suppliers

- Compétitivité des coûts

- Lower operational and labor costs allow for more attractive pricing.

- Ideal for bulk purchases and wholesale distribution.

- Techniques de fabrication avancées

- State-of-the-art water and gas atomization technologies.

- Consistent quality and custom alloying options.

- Scalable Supply Capacity

- Able to support both small-batch prototypes and large-scale production needs.

- Services intégrés

- Many suppliers offer value-added services like sintering consultation, powder blending, and custom packaging.

Common Concerns and How They’re Addressed

| Concern | How Leading Suppliers Solve It |

|---|---|

| Assurance qualité | ISO certification, batch testing, on-demand SDS reports |

| Delivery timelines | Local warehousing, global logistics partnerships |

| Communication barriers | English-speaking sales and tech support teams |

| Import/export regulations | Experience handling international compliance and documentation |

🔗 Explore more about Chinese manufacturing advantages and powder options on AM-Material.com’s homepage.

8. Why Shanghai Truer Technology is the Go-To Supplier for 440 Powders

Shanghai Truer Technology Co., Ltd is one of the most trusted names in the Chinese powder metallurgy industry. Since entering the additive manufacturing space in 2019, Truer has established itself as a premium supplier of stainless steel powders, including 440A, 440B, and 440C grades.

Ce qui distingue Truer

- Gamme complète de produits

- Offers a wide selection of PM powders including PM stainless steel, PM tool steels, and functional additives.

- 440C powder is available in both spherical and irregular forms depending on the application.

- Advanced Atomization Capabilities

- Water atomized, gas atomized, and hybrid atomization techniques.

- Controlled particle size distributions: D10–D90 range can be tailored to your equipment specs.

- Application Expertise

- Deep experience supplying powders for:

- Moulage par injection de métal (MIM)

- Press-and-sinter PM

- Laser powder bed fusion (LPBF)

- Pressage isostatique à chaud (HIP)

- Deep experience supplying powders for:

- R&R et personnalisation

- Truer’s team works closely with clients to develop custom alloy blends and sintering additives.

- Offers proprietary cutting agents, lubricants, and soft magnetic additives.

- Global Reach, Local Support

- Ships to over 40 countries with multilingual support.

- Provides technical documentation and regulatory compliance for international buyers.

Real-World Applications

| L'industrie | Components Made with Truer’s 440 Powder |

|---|---|

| Aérospatiale | Bearing housings, fasteners, brackets |

| Médical | Surgical tools, dental instruments |

| Automobile | Transmission parts, pistons, valves |

| Outillage | Blades, dies, cutting instruments |

🔗 To learn more about Truer’s stainless steel and other PM powders, visit their Page dédiée aux poudres PM.

9. FAQs: Buying 440 Powder in Bulk for Industrial Use

Q1: What is the minimum order quantity (MOQ) for 440 powder?

A : Shanghai Truer typically supplies starting from 25 kg, with discounts available for orders over 500 kg. Custom packaging is also available for OEMs and distributors.

Q2: What is the difference between 440A, 440B, and 440C powders?

| Grade | Teneur en carbone | Dureté | Best Use |

|---|---|---|---|

| 440A | ~0.65% | Modéré | Medical tools, consumer goods |

| 440B | ~0.75% | Plus élevé | Industrial blades, valves |

| 440C | ~1.20% | Très élevé | Bearings, aerospace, tooling |

Q3: Can I request a specific particle size distribution?

A : Yes. Truer offers custom particle sizing to meet specific application requirements, especially for additive manufacturing and sintering.

Q4: Is Truer’s 440 powder compatible with 3D printing?

A : Absolutely. Truer produces gas atomized 440C powder suitable for Laser Powder Bed Fusion (LPBF), Binder Jetting, and Direct Energy Deposition (DED).

Q5: How do I get technical support or request sample material?

A : Simply reach out to Truer’s team via their formulaire de contact for personalized support, TDS (technical data sheets), and sample policies.

By choosing Shanghai Truer Technology as your wholesale supplier of 440 powder, you benefit from premium material quality, outstanding technical support, and scalable production capacity. Whether you’re a distributor, OEM, or contract manufacturer, Truer is equipped to meet your stainless steel powder needs with precision and reliability.

🔗 Want to learn more about the company’s mission and technology? Visit their About Page.