1. Introduction: Why Tool Steel Powder Is Essential for Modern Manufacturing

Tool steel powder is a critical raw material in various high-precision and high-strength manufacturing processes. It is especially vital in industries such as automotive, aerospace, defense, mold-making, and heavy machinery where components must endure high friction, temperature, and wear.

What Makes Tool Steel Powder a Preferred Material?

- Dureté élevée: Maintains cutting edges and precise shapes under pressure.

- Résistance à l'usure: Ideal for high-cycle operations.

- Solidité: Withstands impact and stress without cracking.

- Usinabilité: Allows for easier post-processing like grinding or polishing.

Tool steel powders are widely used in:

- Moulage par injection de métal (MIM)

- Additive Manufacturing / Impression 3D

- Powder Metallurgy Sintering

- Cold and Hot Work Tooling

- Die Casting and Forging Dies

As demand for complex, custom-fabricated metal parts increases, so does the need for advanced tool steel powders.

2. Key Industrial Applications of Tool Steel Powder

Tool steel powders enable manufacturers to produce parts that are difficult or impossible to make with traditional methods. Their adaptability in sintering, additive manufacturing, and MIM makes them indispensable.

Industries That Rely on Tool Steel Powder

| L'industrie | Exemple d'application | Tool Steel Grade Used |

|---|---|---|

| Automobile | Engine valves, gears, transmission parts | AISI D2, M2, H13 |

| Aérospatiale | Turbine blades, structural brackets | M4, T15, PM-grade steels |

| Dispositifs médicaux | Surgical tools, orthopedic implants | MIM-grade tool steels |

| Outillage | Cutting dies, injection molds, stamping tools | H13, A2, O1 |

| Pétrole et gaz | Drill bits, valves, custom fittings | PM H13, M42 |

Benefits in Industrial Use

- Personnalisation: Tailored alloy compositions to meet specific mechanical and thermal requirements.

- Efficacité de la production: Reduces material waste in subtractive manufacturing.

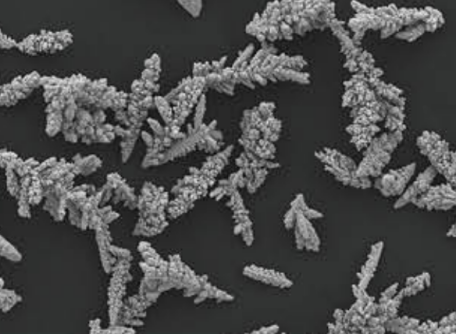

- Superior Microstructure: Uniform distribution of carbides and fine grain size improves performance.

3. Types of Tool Steel Powders and Their Properties

Tool steel powders are classified based on alloy composition and application suitability. Each type offers distinct characteristics in terms of hardness, toughness, and wear resistance.

Major Types of Tool Steel Powders

| Type | Notes communes | Caractéristiques | application |

|---|---|---|---|

| Cold Work | D2, A2, O1 | High wear resistance, moderate toughness | Stamping dies, cutting tools |

| Hot Work | H13, H11 | Résistance à la fatigue thermique | Die casting, extrusion dies |

| High-Speed | M2, M4, T15 | Maintains hardness at high temperatures | Drills, end mills, cutters |

| PM Tool Steels | PM M4, PM 60 | Uniform microstructure, high performance | Aerospace, medical, 3D printing |

Shanghai Truer’s PM Tool Steel Powder Offering

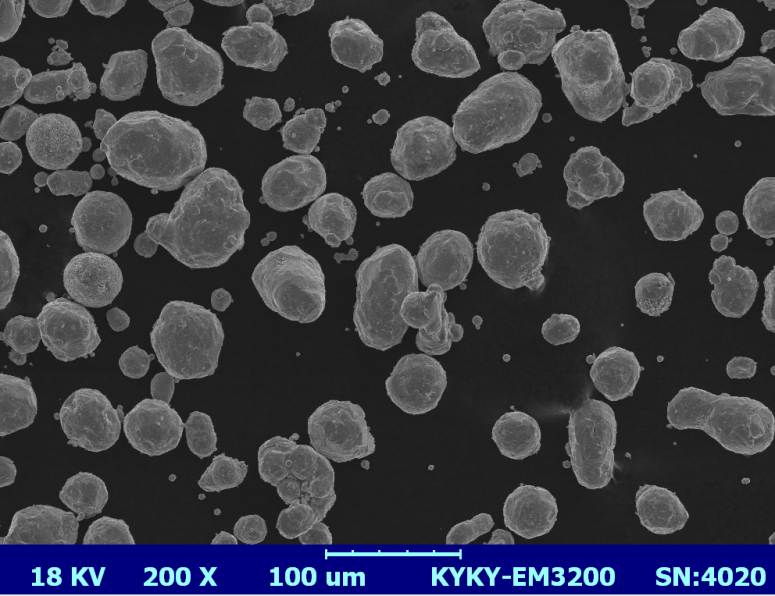

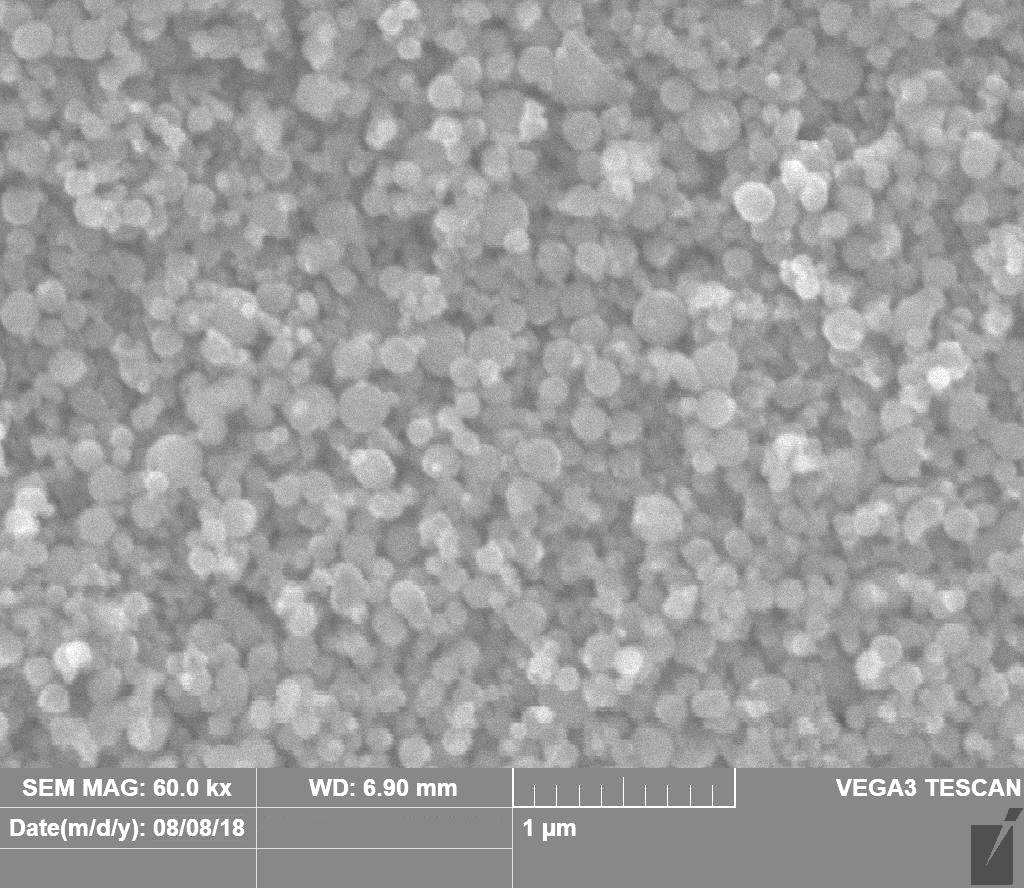

Shanghai Truer Technology Co., Ltd, a trusted name since 2009, offers a comprehensive range of Powder Metallurgy (PM) tool steel powders. Their production uses advanced atomization techniques including:

- Vaporisation de l'eau

- atomisation du gaz

- Hybrid Water-Gas Atomization

Their PM steels such as FD-0200, FD-0208 (diffusion alloyed steel), and FL-4605 are well-suited for tooling applications requiring precision and durability.

Their additive solutions also include cutting-edge lubricants (e.g., Lube-W, SUW-8000), cutting agents (SME-100), and soft magnetic additives (QH-150), providing a complete material ecosystem for tool steel part production.

📌 Learn more about Truer’s full Ligne de produits de poudres PM

4. Global Market Trends and Growth Potential in Tool Steel Powder

The global tool steel powder market is experiencing robust growth, driven by the rising demand for precision-engineered components, sustainable manufacturing, and high-performance metal parts. This trend is particularly strong in the automotive, aerospace, and additive manufacturing sectors.

Market Overview and Forecast

| Métrique | Value (2023) | Projected (2028) | CAGR |

|---|---|---|---|

| Global Market Size | 2,1 milliards de dollars | USD 3.8 Billion | 11.2% |

| Largest Market Share | Asie-Pacifique | Asie-Pacifique | – |

| Fastest Growing Segment | Fabrication additive | Fabrication additive | 14.5% |

| Key End-Use Sectors | Automobile, aérospatiale, outillage | – | – |

Principaux facteurs de croissance

- Increase in Additive Manufacturing: Surge in metal 3D printing for complex geometries and custom parts.

- Precision Tooling Demand: High-speed and hot-work steels needed for modern die and mold applications.

- Objectifs de développement durable: Manufacturers switching to PM processes to reduce material waste and energy consumption.

- Advanced Alloys: Rising demand for tailored PM steels with superior microstructures and performance.

Défis

- Volatilité des prix: Tool steel alloy ingredients like tungsten and molybdenum are subject to global fluctuations.

- Supply Chain Disruptions: Political tensions and trade restrictions can affect raw material flow.

For buyers and distributors, staying ahead of these trends means forging relationships with reliable and agile suppliers.

5. How to Choose the Right Tool Steel Powder Supplier

Selecting the right supplier is crucial to ensuring consistent quality, timely delivery, and technical support. For B2B buyers, the stakes are high — a single deviation in powder quality can result in costly production failures or rejected parts.

Key Evaluation Criteria for Tool Steel Powder Suppliers

| Facteur d'évaluation | Pourquoi c'est important | Ce qu'il faut rechercher |

|---|---|---|

| Certifications de qualité | Ensures product consistency and traceability | ISO 9001, ASTM, RoHS, REACH compliance |

| Powder Granulometry | Impacts flowability and sintering behavior | Particle size distribution (D10, D50, D90) |

| Alloy Purity | Affects performance and mechanical strength | Controlled levels of C, Cr, Mo, W, V |

| Méthode de production | Determines surface texture and porosity | Gas Atomized preferred for AM & MIM |

| Support technique | Reduces downtime and enhances productivity | On-site consultants, lab analysis, application support |

| MOQ et délai d'exécution | Affects inventory and cash flow | Low MOQ, short lead times, flexible logistics |

Drapeaux rouges à éviter

- No material traceability or batch records

- Non-responsive customer service

- Unwillingness to provide samples or technical data

- Lack of experience in your application area

By partnering with a supplier that aligns with your production needs and quality expectations, you ensure a stable supply chain and long-term cost efficiency.

6. Top Tool Steel Powder Suppliers in Asia and Europe

In recent years, both established and emerging suppliers in Asia and Europe have played pivotal roles in advancing the tool steel powder market. Below is a curated list of reliable B2B suppliers serving various global markets.

Top Suppliers and Their Strengths

| Nom de l'entreprise | Région | Spécialités | Website/Contact |

|---|---|---|---|

| Shanghai Truer Technology Co. | Chine | Full-range PM powders, additives, 3D printing | Contacter Truer |

| Hoganas AB | Suède | Gas-atomized powders, tool steel blends | www.hoganas.com |

| Technologie des charpentiers | ÉTATS-UNIS | High-speed steels, AM powders | www.carpentertechnology.com |

| GKN Hoeganaes | Allemagne | MIM-grade tool steels, ferrous powders | www.hoeganaes.com |

| Sandvik Osprey | ROYAUME-UNI | Fine gas-atomized AM powders | www.materials.sandvik |

Pourquoi Shanghai Truer se démarque

Shanghai Truer is not just a material supplier but a full-spectrum solution provider. Since launching its additive manufacturing division in 2019, the company has quickly built a reputation for:

- Customized Alloy Development: Tailored PM and hybrid tool steel powders.

- Advanced Atomization Technologies: Water, gas, or combined atomization for optimal morphology.

- High-Grade PM Steels: Including FL-4605, FD-0200, FX-2008, and FD-0208.

- Additive Enhancers: Lubricants, graphite, cutting agents, and soft magnetic additives.

- Expertise technique: Application specialists who support customers from testing to mass production.

🧪 Visit their A propos de nous to learn more about their manufacturing capabilities and R&D focus.

7. Why More Distributors Are Switching to Chinese Tool Steel Powder

Global buyers and distributors are increasingly sourcing tool steel powder from Chinese suppliers due to a combination of cost-effectiveness, quality advancement, and improved logistics infrastructure.

Principales raisons de ce changement

- Prix compétitifs: Lower material and labor costs lead to better margins.

- Progrès technologiques: Chinese manufacturers like Truer are investing in world-class atomization and QA equipment.

- Shorter Supply Chains: Faster lead times and centralized logistics reduce uncertainty.

- Commandes personnalisées: More flexibility in MOQ and grade customization.

- Growing Reputation: Chinese PM suppliers now meet or exceed ASTM and ISO standards.

Case Study: Shanghai Truer’s Global Reach

Truer’s tool steel powders are now exported to:

- Southeast Asia (Vietnam, Thailand)

- Europe (Germany, Italy)

- Middle East (UAE, Turkey)

- Amérique du Nord (États-Unis, Mexique)

Buyers trust Truer not just for pricing, but for consistent supply, grade versatility, and technical after-sales support.

🌐 Explore Truer’s full range of Produits en poudre PM for tool steel, soft magnetic alloys, and more.

8. Why Choose Shanghai Truer Technology for Tool Steel Powder

Shanghai Truer Technology Co., Ltd is one of the most professional and reliable tool steel powder suppliers in China. Since its establishment in 2009, and especially after launching its additive manufacturing division in 2019, Truer has become a go-to partner for global buyers seeking high-performance PM materials and technical expertise.

What Makes Shanghai Truer Stand Out?

✅ Full-Spectrum PM Solutions

- Water, gas, and combined atomization processes.

- PM steel grades like FD-0200, FD-0208, FL-4605, FX-1005, FN-5000.

- Specialized diffusion-alloyed tool steels for MIM and PM sintering.

- Integrated additive materials including lubricants, graphite, cutting agents.

✅ Customization & R&D Strength

- Tailored alloy development based on application (e.g., hot work, cold work, MIM).

- Dedicated R&D support for creating new formulations.

- Application testing and on-site technical guidance.

✅ Global Supply Chain & Logistics

- Export-ready packaging and documentation.

- Fast lead time and flexible order quantities.

- Responsive B2B support team.

✅ Industry Certifications

- ISO 9001 certified quality management.

- Full batch traceability and test reports.

- Compliance with international standards like ASTM, MPIF.

📊 Here’s a quick comparison of why buyers choose Shanghai Truer over competitors:

| Fonctionnalité | Shanghai Truer | Autres fournisseurs |

|---|---|---|

| Atomization Methods | Eau, gaz, hybride | Mostly single-method |

| Développement d'alliages sur mesure | Oui | Limitée |

| Additive Product Integration | Full suite of solutions | Rare |

| Flexibilité du MOQ | Low MOQ available | Often high MOQ |

| Technical Consultation Services | Included | Additional cost |

📍 Learn more about Truer’s company background and mission on their A propos de nous

9. How to Order Wholesale Tool Steel Powder from Shanghai Truer

Ordering from Shanghai Truer is designed to be efficient and transparent, ensuring that you receive the exact material you need — on time and within budget.

Processus de commande étape par étape

1. Demande de renseignements sur le produit

- Visitez le site Tool Steel Powder Products page on the Truer website.

- Identify the grade(s) you’re interested in (e.g., FD-0208, FL-4605, FX-1005).

- Submit an inquiry with desired specifications, quantity, and delivery location.

2. Consultation technique

Truer’s application engineers assist with:

- Material grade selection

- Compatibility with your MIM, PM, or AM processes

- Additive recommendations (e.g., lubricants or graphite)

3. Quotation

- Recevez un devis détaillé comprenant :

- Price per kg or ton

- Délai d'exécution

- Shipping terms (FOB, CIF, DDP)

- Certificate of Analysis (COA) and SDS

4. Sample Request (Optional)

- Small sample batches (1–5 kg) available for testing.

- Includes full tech data and MSDS.

5. Contract & Payment

- Sign purchase agreement (can align with your ERP system).

- Flexible payment terms for repeat customers (T/T, L/C, etc.).

6. Production & QA

- Powder is produced and tested per your specification.

- Quality control ensures consistent particle size, morphology, and chemical composition.

7. Expédition et livraison

- Export documentation (COO, COA, SDS, packing list).

- Ocean, air, or express shipping options available.

- Delivery tracking support.

🚚 Ready to place your order or request a technical consultation? Contact Truer here

10. FAQs: Buying Wholesale Tool Steel Powder

Here are some of the most common questions industrial buyers ask when sourcing tool steel powder for MIM, PM, or AM applications.

Quelle est la quantité minimale de commande (QMC) ?

Truer offers flexible MOQs depending on the powder type. For standard grades like FD-0200 or FL-4605, MOQs can start at 100 kg. Custom formulations may require higher quantities.

Can I get a sample before placing a bulk order?

Yes. Samples between 1–5 kg are available for testing. These come with a full technical datasheet and SDS.

What is the typical lead time?

- Standard grades: 7–15 working days

- Custom grades: 20–30 working days

- Shipping time varies by location (express, air, or sea freight)

Do you offer technical support for material selection?

Absolutely. Truer’s technical team offers full support from grade selection to sintering recommendations and additive compatibility.

Are Truer’s tool steel powders suitable for MIM and AM?

Yes. Truer produces metal powders specifically engineered for MIM and additive manufacturing, with controlled particle size distribution and spherical morphology (when gas-atomized).

Do you provide Certificates of Analysis (COA)?

Yes. Every shipment includes a COA detailing chemical composition, particle size, and other critical parameters.

Does Truer support international shipping?

Yes. Truer exports globally, including to North America, Europe, Southeast Asia, and the Middle East. All necessary export documents are provided.

🔗 Internal Link Recap for Seamless Navigation:

- Tool Steel Powder Products

- Contacter Shanghai Truer

- À propos de Shanghai Truer Technology

- Main Website Homepage

- PM Powder Grades & Applications

This in-depth blog is designed to guide B2B buyers, distributors, and engineers through the complete landscape of sourcing tool steel powders, from understanding applications to selecting suppliers and placing orders. Shanghai Truer remains a top choice for businesses looking to scale with high-performance PM materials and expert support.

Ready to discuss your tool steel powder needs?

📧 Get in touch with Shanghai Truer Technology today and streamline your procurement process.