Introduction: The Growing Role of Stainless Steel Powder in Manufacturing

Stainless steel powder is becoming a cornerstone of advanced industrial manufacturing due to its versatility, durability, and compatibility with additive manufacturing and powder metallurgy (PM) processes. As global industries shift toward precision-engineered components and sustainable production methods, stainless steel powder plays a critical role in enabling cost-effective, high-performance solutions for sectors such as:

- Automobile

- Aérospatiale

- Dispositifs médicaux

- Electronique grand public

- Energy and heavy machinery

For B2B buyers, distributors, and e-commerce sellers, stainless steel powder offers scalable opportunities in metal additive manufacturing, metal injection molding (MIM), and sintered parts production. The demand for bulk and custom stainless steel powder is growing, and companies are looking for reliable suppliers who can offer quality, consistency, and technical expertise.

What Makes Stainless Steel Powder So Valuable?

| Fonctionnalité | Benefit for Industrial Buyers |

|---|---|

| Résistance à la corrosion | Ideal for harsh environments (marine, chemical, etc.) |

| Résistance mécanique | Supports load-bearing and critical applications |

| Stabilité thermique | Performs under high temperatures |

| Compatibility with AM/PM | Enables complex part geometries with minimal waste |

| Recyclabilité | Sustainable and cost-efficient |

With these advantages, stainless steel powder opens new doors for innovation in product design and manufacturing scalability.

Applications of Stainless Steel Powder in B2B Industries

Stainless steel powder finds widespread applications across various industrial verticals. For B2B customers, understanding these use cases can help identify where the material fits into their supply chain and production models.

1. L'industrie automobile

Stainless steel powder is used to manufacture:

- Sintered gears and bushings

- Exhaust system components

- Fuel injector parts

- Pièces de transmission

These parts require strength, corrosion resistance, and dimensional accuracy—all achievable with stainless steel PM parts.

2. Aérospatiale et défense

In aerospace, where high performance and light weight are essential, stainless steel powder is used for:

- Composants de la turbine

- Fuel nozzles

- Supports structurels

- Additive manufactured prototypes and end-use parts

The powder supports both direct metal laser sintering (DMLS) and binder jetting processes, enabling rapid prototyping and low-volume production of complex parts.

3. Medical and Dental Devices

Because of its biocompatibility and resistance to sterilization processes, stainless steel powder is used in:

- Instruments chirurgicaux

- Implants orthopédiques

- Dental prosthetics

- Custom implants via Impression 3D

4. Consumer Electronics

Miniaturization and high precision are critical in electronics. Stainless steel powder is used in:

- Housings for mobile devices

- Wearable tech components

- EMI shielding parts

5. Oil & Gas Equipment

For downhole and high-pressure applications:

- Filters and valve components

- Connecteurs

- Pièces résistantes à l'usure

These applications demonstrate how stainless steel powder helps manufacturers meet rigorous performance standards in demanding environments.

Types of Stainless Steel Powders & Their Properties

Different grades and processing methods of stainless steel powders cater to varied industrial needs. At Shanghai Truer Technology Co., Ltd, we supply a wide range of stainless steel powders tailored for powder metallurgy and additive manufacturing.

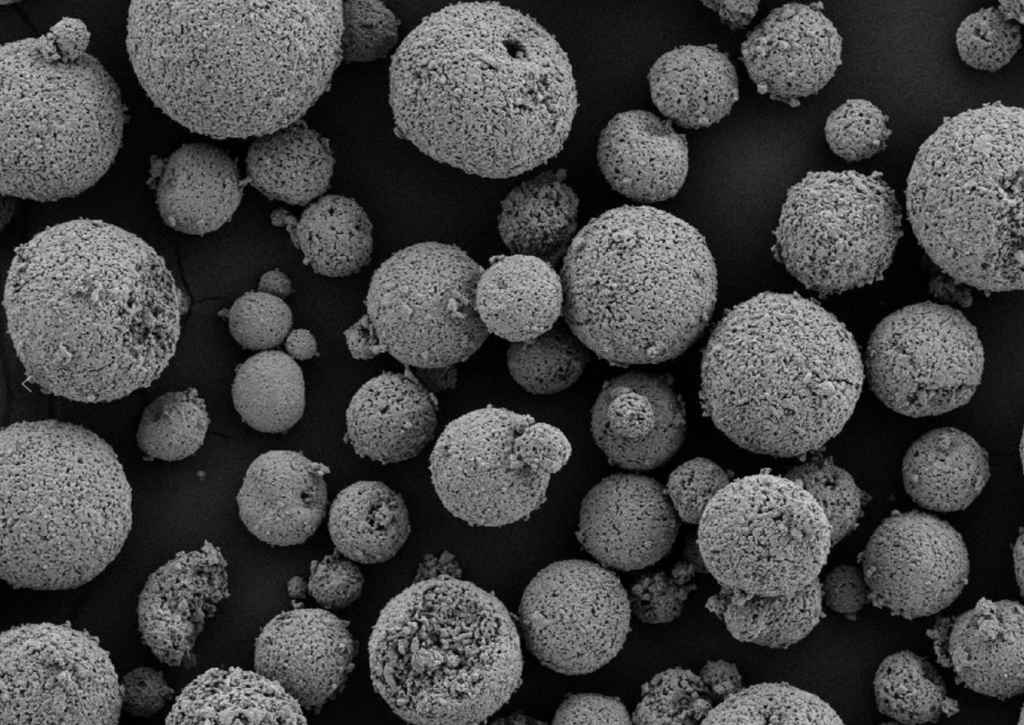

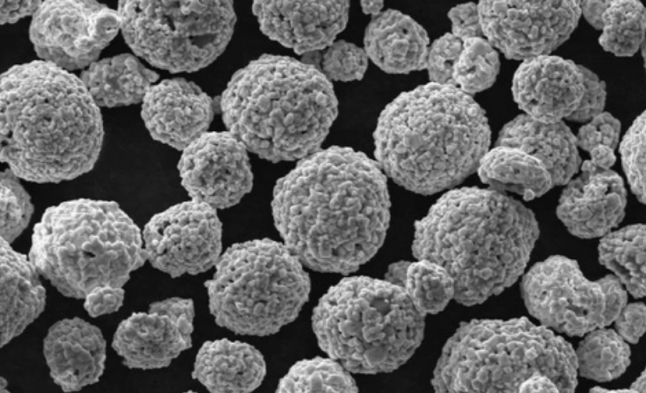

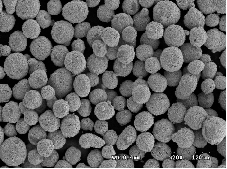

1. Manufacturing Methods

| Méthode | Description |

|---|---|

| Vaporisation de l'eau | Cost-effective; good for PM parts with moderate density and strength |

| atomisation du gaz | Produces spherical particles; ideal for additive manufacturing |

| Atomisation combinée | Hybrid method for tailored particle morphology and flow performance |

2. Common Stainless Steel Grades

| Grade | Composition | Domaines d'application |

|---|---|---|

| 316L | Low carbon, molybdenum | Medical, marine, food processing |

| 304L | Low carbon, chromium-nickel | Automotive, appliances, architectural |

| 410 | Martensitic, high strength | Tools, cutlery, wear-resistant parts |

| 17-4PH | Precipitation-hardening | Aerospace, structural components |

3. Specifications Available from Shanghai Truer

Shanghai Truer provides stainless steel powders with customizable properties such as:

- Particle size distribution (10–100 microns)

- Fluidité et densité apparente

- Low oxygen and impurity levels

- High sphericity for AM-grade powders

Our stainless steel powders are used by clients in metal injection molding, laser sintering, binder jetting, and conventional PM.

🔗 Learn more about our stainless steel powder offerings on our Page produit PM Powder.

Global Market Trends & Growth Opportunities in Stainless Steel Powder

The global stainless steel powder market is experiencing rapid growth, driven by the rising demand in additive manufacturing, automotive lightweighting, and sustainable production practices. For B2B buyers, this presents a lucrative opportunity to capitalize on emerging trends and secure long-term supply chain advantages.

Market Overview

Selon une étude de marché récente :

- The global stainless steel powder market is projected to reach USD 6.9 billion by 2030, growing at a CAGR of 5.8% from 2023 to 2030.

- Asia-Pacific holds the largest market share, with China, Japan, and South Korea leading in powder metallurgy and additive manufacturing adoption.

- Les automobile, aérospatialeet médical sectors are the biggest consumers of stainless steel powder.

Principaux facteurs de croissance

| Facteur | Impact on Wholesale Buyers & Distributors |

|---|---|

| Adoption of Additive Manufacturing | Drives demand for high-purity, spherical powders |

| Passer à la fabrication durable | Boosts use of recyclable, lower-waste materials like metal powders |

| Lightweighting in Automotive | Increases use of sintered stainless components |

| Rise in Custom Metal Parts | Fuels demand for small-batch, high-precision applications |

| Government Support & Incentives | Promotes domestic PM and AM capabilities in key markets |

For B2B distributors and e-commerce sellers, these trends point toward increasing demand for bulk stainless steel powder, reliable supply chains, and value-added sourcing.

Opportunities for Wholesale Buyers

- Expand product catalogs to include custom-grade stainless powders.

- Offer private-label packaging for niche industrial markets.

- Partner with Chinese manufacturers to achieve cost competitiveness and volume scalability.

Key Considerations When Sourcing Stainless Steel Powder from Suppliers

Choosing the right stainless steel powder supplier is critical to ensuring consistent product quality, meeting compliance standards, and maintaining production efficiency. Here are the most important factors B2B buyers should evaluate:

1. Powder Quality & Purity

Ensure the supplier offers:

- Distribution homogène de la taille des particules

- Low oxygen and impurity levels

- Customized compositions (e.g., 316L, 304, 17-4PH)

- Morphologie sphérique for AM applications

2. Capacités de production

Assess the powder production methods:

| Méthode | Ideal Use Case |

|---|---|

| atomisation du gaz | Additive manufacturing & binder jetting |

| Vaporisation de l'eau | Conventional PM and press-sinter applications |

| Atomisation combinée | Tailored physical properties |

Shanghai Truer Technology Co., Ltd offers all three methods, providing flexibility in sourcing based on your application needs.

3. Certifications & Standards

Look for ISO and industry-specific compliance, such as:

- ISO 9001:2015

- RoHS/REACH compliance

- Material test reports (MTRs)

- Custom compliance for aerospace or medical sectors

4. Customization & Logistics

A reliable supplier should offer:

- Custom blending and sieving

- Bulk packaging options (25kg, 500kg, 1 ton)

- Global logistics support

- Technical consultation and sample trials

🔗 Learn more about our services and capabilities on the À propos de Truer Technology page.

Top 5 Stainless Steel Powder Suppliers in Asia

Asia is home to some of the world’s most advanced stainless steel powder manufacturers. Here are five of the most trusted suppliers for B2B buyers:

| Nom de l'entreprise | Pays | Spécialité | Points forts |

|---|---|---|---|

| Shanghai Truer Technology Co. | Chine | PM & AM stainless steel powder | Custom grades, atomization tech, industry R&D |

| Pometon S.p.A | Inde/Italie | Water and gas atomized powders | Decades of metallurgy experience |

| Hoganas AB | Japan/Sweden | Poudres métalliques à haute performance | Global reach, advanced R&D |

| CNPC Powder Material Co. Ltd | Chine | Poudres pour la fabrication additive | Large-scale production, AM certified powders |

| Kymera International | Corée du Sud | Poudres d'alliages spéciaux | Diverse alloy range, strong export network |

Why Shanghai Truer Leads in Stainless Steel Powder

- Over 14 years of industry experience

- Dedicated PM and AM powder division

- Full range of stainless steel grades and blends

- Custom particle sizes and bulk packaging

- Fast lead times for international orders

🔗 Discover more about our stainless steel powder portfolio on the Page de la poudre PM.

Why More Buyers Are Turning to Chinese Stainless Steel Powder Manufacturers

China has rapidly become a global hub for stainless steel powder production, thanks to competitive pricing, technological advancement, and large-scale manufacturing capacity. Here’s why more B2B buyers, e-commerce sellers, and OEMs are sourcing stainless steel powder from China:

1. Rapport coût-efficacité

- Réduction des coûts de main-d'œuvre et des coûts opérationnels

- Competitive raw material sourcing

- High-volume production capabilities

2. Advanced Manufacturing Technology

- State-of-the-art atomization equipment

- Integration of AI and automation in quality control

- Ability to produce poudres sphériques for additive manufacturing

3. Export-Friendly Supply Chains

- Well-established global logistics networks

- Support multilingue and export compliance

- Customization for regional standards (e.g., EU, US)

4. Broad Application Expertise

Chinese suppliers like Shanghai Truer support a wide range of industries:

- Automotive sintered parts

- Aerospace-grade 3D printing

- Medical implant prototyping

- Electronics shielding and enclosures

🔗 Interested in sourcing from China? Contact us through our Page de contact for a free consultation and sample support.

Why Choose Shanghai Truer Technology as Your Trusted Supplier

When it comes to sourcing stainless steel powder for powder metallurgy (PM) and additive manufacturing (AM), Shanghai Truer Technology Co., Ltd stands out as one of the most trusted and capable suppliers in the Chinese metallurgy landscape. With over a decade of experience and a dedicated powder division, Truer offers unmatched product quality, technical expertise, and B2B service capabilities.

Company Profile: Shanghai Truer Technology Co., Ltd

- Founded: 2009

- AM Division Established: 2019

- Core Competency: Manufacturing and supplying high-quality 3D printing powders and PM-grade metal powders

- Localisation : Shanghai, Chine

- Site web : am-material.com

What Makes Truer a Preferred Choice for Wholesale Buyers?

| Fonctionnalité | Value to B2B Buyers |

|---|---|

| Gamme complète de produits | From stainless steel to bronze, brass, nickel steel, and custom alloys |

| Personnalisation des poudres | Particle size, flowability, composition, and blending tailored to customer needs |

| Multiple Atomization Methods | Water, gas, and combined atomization for optimal particle morphology |

| Solutions additives | Lubricants, cutting agents, soft magnetic additives, and diffusion alloys |

| Support technique | Expert consultations, application guidance, and sample testing services |

| Portée mondiale | Export-ready logistics and multilingual customer service |

Product Range Highlights

Shanghai Truer supplies a rich variety of stainless steel powders suitable for:

- Moulage par injection de métal (MIM)

- Jetting de liant

- Laser sintering (SLS, DMLS)

- Conventional PM parts

Available grades include:

- 316L, 304L, 410, 17-4PH, and other stainless steel variants

- Specialty grades tailored for corrosion resistance, strength, or sinterability

In addition, Truer also offers PM4200, PM4600, SBF2218et FX series powders for advanced sintering applications.

Additive Materials Division

Truer’s Additive Materials Division is known for:

- High-performance lubricants: Lube-W, SUW-5000B, SUW-8000

- Cutting agents: Manganese sulfide, SME-100 (sulfur-free), TD-8 (composite cutting agent)

- Magnetic additives: QH-150, QHP-330

- Graphite additives: TBC-400, TBC-1000

🔗 Visit the About Truer Technology page to learn more about the company’s history, mission, and capabilities.

How to Order Wholesale Stainless Steel Powder from China

Ordering stainless steel powder in bulk from a reputable Chinese manufacturer like Shanghai Truer is a streamlined process. Here’s a detailed step-by-step guide for distributors, OEMs, and industrial buyers.

Étape 1 : Définir vos besoins

Before contacting the supplier, determine:

- Powder grade or material composition (e.g., 316L stainless steel)

- Application method (AM, PM, MIM)

- Gamme de taille des particules (e.g., 15–45 μm for AM, 45–150 μm for PM)

- Quantité requise (e.g., 500 kg, 1 ton, 5 tons monthly, etc.)

- Packaging preferences (sealed drums, vacuum-packed bags, etc.)

Step 2: Submit an Inquiry

You can initiate a quote request via:

- Online contact form

- Email or WhatsApp

- Direct phone call with a sales representative

🔗 Use Truer’s Page de contact to submit your inquiry directly.

Étape 3 : Recevoir une consultation technique

Truer assigns a dedicated technical consultant to:

- Review your application and volume needs

- Recommend suitable powder grades and specifications

- Provide a technical data sheet (TDS) and Material Safety Data Sheet (MSDS)

- Suggest trial samples if needed

Step 4: Receive Quotation and Confirm Order

After technical alignment, you will receive:

- Quotation including FOB/CIF price

- Lead time estimates

- Shipping options

- Conditions de paiement (T/T, LC, etc.)

Once confirmed, a proforma invoice (PI) is issued.

Step 5: Production and Dispatch

- Truer begins production or prepares inventory

- Powder is packed in moisture-resistant, export-grade containers

- Courier or freight partner arranges delivery to your location

- Tracking and shipment documents are provided

Étape 6 : Assistance après-vente

- Receive technical support on powder performance

- Custom re-ordering and recurring supply options

- Product certifications and compliance documentation

| Ordering Milestone | Timeframe (Est.) |

|---|---|

| Inquiry Response | Within 24 hours |

| Sample Dispatch | 3–7 business days |

| Bulk Order Production | 10–25 business days |

| International Shipping | 7–20 business days |

FAQs: Common Questions About Buying Wholesale Stainless Steel Powder

1. What is the minimum order quantity (MOQ) for stainless steel powder?

Most grades have an MOQ of 25 kg, but bulk discounts begin at 500 kg and above.

2. Can I request custom blends or particle sizes?

Yes. Truer specializes in custom formulations, including blends of stainless steel with copper, nickel, or other metals, as well as tailored particle size distributions for AM and PM needs.

3. What certifications do your powders comply with?

Truer’s powders comply with ISO 9001, RoHSet REACH regulations, and certifications can be provided upon request.

4. Do you offer samples for testing?

Yes. Small quantity samples (500g–5kg) can be shipped for testing, depending on the powder type and application.

5. How do you ensure quality consistency for recurring orders?

- Batch-to-batch quality control

- In-house lab testing

- Customer-specific documentation and spec sheets

6. Can I use your powders for 3D printing applications?

Absolutely. Truer’s gas-atomized stainless steel powders are suitable for DMLS, SLM, and binder jetting with high flowability and spherical morphology.

7. Do you export globally?

Yes, Truer exports to Europe, North America, Southeast Asia, and the Middle East, with full logistics and documentation support.

8. What are your payment terms?

Standard terms include T/T (Telegraphic Transfer) et L/C (Letter of Credit) for larger orders.

9. How do I reach you for technical support?

You can contact Truer’s technical and sales team via the Page de contact or email for immediate assistance.

By sourcing stainless steel powder from a specialized supplier like Shanghai Truer Technology, B2B buyers gain access to a reliable, scalable, and quality-assured supply chain for advanced manufacturing applications.

🔗 Explore our full range of metal powders and additive materials on the official Product Page.