1. Introduction: Importance of Ferro Silicon Powder in Modern Industry

Ferro silicon powder (FeSi powder) is a critical alloying material widely used in the steel, metallurgical, and casting industries. A compound of iron and silicon, typically containing 15–90% silicon, ferro silicon serves as a deoxidizer, alloying agent, and inoculant in various industrial processes.

In powder form, ferro silicon offers greater flexibility for advanced applications. It is especially valuable in powder metallurgy (PM), additive manufacturing, and specialized steelmaking where particle size distribution, purity, and chemical consistency directly influence performance.

Why B2B Buyers Choose Ferro Silicon Powder:

- Versatility across steelmaking, casting, and metallurgical sectors

- Enhances strength, hardness, and corrosion resistance of alloys

- Available in multiple mesh sizes for tailored industrial use

- Cost-effective for bulk and wholesale applications

- Compatible with powder metallurgy processes

2. Industrial Applications of Ferro Silicon Powder

Ferro silicon powder is indispensable in several high-demand sectors. Here’s a breakdown of its major industrial uses and the benefits it brings:

| L'industrie | application | Role of Ferro Silicon Powder |

|---|---|---|

| Fabrication d'acier | Deoxidizer, Alloying Agent | Improves strength, reduces oxygen content |

| Foundries | Inoculant in Cast Iron | Enhances graphite formation, improves structure |

| Métallurgie des poudres (PM) | Precise Alloying | Used in sintered parts for automotive, tools |

| Soudage | Flux Coating | Enhances arc stability, slag formation |

| Fabrication additive | Specialized Binder | Used in metal Impression 3D feedstock |

| Refractory Materials | Component in High-Temp Alloys | Improves thermal resistance |

Benefits for B2B and Wholesale Buyers:

- Enables bulk production of consistent steel grades

- Reduces material waste with precision particle sizing

- Compatible with both ferrous and non-ferrous alloy systems

- Scalable for large-volume manufacturing processes

3. Key Properties and Use Cases in Steel and Foundries

Ferro silicon powder is engineered for high-performance output in steel and casting operations. Below are its key chemical and physical properties that make it ideal for B2B industrial applications:

Chemical Composition (Typical for 75% FeSi Powder):

| Élément | Contenu (%) |

|---|---|

| Silicium (Si) | 72–75 |

| Fer (Fe) | Balance |

| Aluminium (Al) | ≤ 2.0 |

| Carbone (C) | ≤ 0.2 |

| Phosphore (P) | ≤ 0.04 |

| Soufre (S) | ≤ 0.02 |

Physical Characteristics:

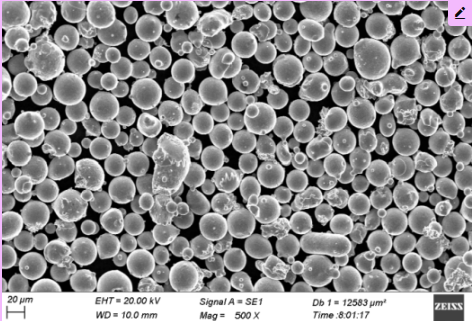

- Particle Size: 0–100 mesh (customizable)

- Density: ~2.5–2.8 g/cm³

- Melting Point: ~1200°C

- Color: Grey to dark grey

Use Cases in Steel Manufacturing:

- Deoxidation: Removes oxygen from molten steel, preventing porosity.

- Alliage: Adds silicon to improve hardness, magnetic properties, and corrosion resistance.

- Grain Refinement: Enhances microstructure for high-performance applications.

Use Cases in Foundries:

- Inoculation: Promotes graphite formation in cast iron, improving casting quality.

- Nodular Cast Iron: Helps in the formation of nodules during ductile iron production.

If you’re looking to optimize your industrial processes with high-performance ferro silicon powder, be sure to explore our full PM powder product line here.

4. Market Demand and Growth Opportunities for Ferro Silicon Powder

The global ferro silicon powder market has shown steady growth over the past decade, driven by increasing steel production, advancements in powder metallurgy, and rising demand in automotive, aerospace, and construction industries.

Aperçu du marché mondial

| Région | Part de marché (%) | Key Growth Driver |

|---|---|---|

| Asie-Pacifique | 55% | Rapid urbanization and industrialization |

| L'Europe | 20% | Automotive and aerospace manufacturing |

| Amérique du Nord | 15% | Advanced metallurgy and R&D |

| Amérique latine | 5% | Infrastructure development |

| Moyen-Orient et Afrique | 5% | Energy and construction projects |

Key Trends:

- Shift Toward Additive Manufacturing: 3D printing and metal injection molding (MIM) are driving demand for fine-grade ferro silicon powders.

- Sustainable Metallurgy: Environmentally conscious buyers are seeking low-emission, high-efficiency alloying materials.

- Increased Use in Automotive Lightweighting: Ferro silicon alloys are being used to enhance hardenability in lightweight automotive components.

- Localized Sourcing: Manufacturers are diversifying suppliers to reduce dependency on a single region, especially due to global supply chain challenges.

For businesses looking to capitalize on this growth, partnering with a supplier that offers both scale and customization is critical.

5. Choosing the Right Ferro Silicon Powder Supplier: Key Considerations

When sourcing ferro silicon powder in bulk, choosing the right supplier directly impacts product quality, cost efficiency, and production timelines. Here are key criteria B2B buyers should evaluate:

1. Consistent Quality and Certification

- Ensure powders meet international standards such as ISO 9001 or ASTM.

- Ask for batch-wise test reports and material traceability.

2. Capacités de personnalisation

- Can the supplier provide tailored mesh sizes?

- Are chemical compositions adjustable for specific applications?

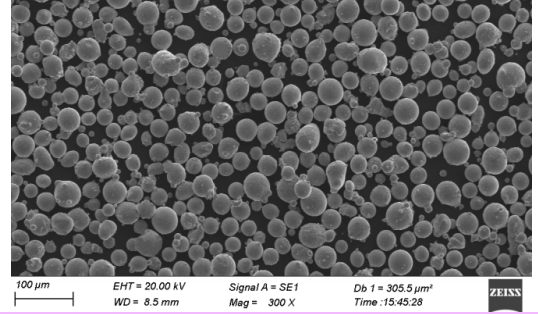

3. Production Methods

- Suppliers using advanced atomization (water or gas) offer superior powder morphology.

- Reduction and milling methods for cost-effective bulk production.

4. Logistique et livraison

- Global shipping capabilities with just-in-time delivery

- Inventory management and MOQ flexibility

5. Support technique

- On-site application consultation

- Metallurgical testing and R&D collaboration

Choosing a supplier that can meet technical specifications and provide continuous support ensures smoother production and higher ROI.

6. Top Global and China-Based Ferro Silicon Powder Suppliers

Here’s a curated list of top ferro silicon powder suppliers known for reliability, quality, and innovation, especially in the B2B and wholesale sectors:

Principaux fournisseurs mondiaux

| Nom de l'entreprise | Pays | Points forts |

|---|---|---|

| Elkem ASA | Norway | One of the largest global silicon suppliers |

| Ferroglobe PLC | UK/Spain | Global production network, high-purity grades |

| RFA International | ÉTATS-UNIS | Specialized in ferroalloys and silicon-based products |

Principaux fournisseurs chinois

| Nom de l'entreprise | Région | Caractéristiques |

|---|---|---|

| Shanghai Truer Technology Co. | Shanghai | Offers complete PM additives, custom FeSi powders |

| Anyang Huatuo Metallurgy | Henan | Bulk ferroalloy production, fast delivery |

| Henan Star Metallurgy Material Co., Ltd | Henan | Competitive pricing, wide product range |

Parmi ces derniers, Shanghai Truer Technology Co. stands out by offering both powder metallurgy integration and additive manufacturing services. Truer not only supplies high-quality ferro silicon powder but also provides customized alloy development, technical support, and flexible order quantities for OEMs, foundries, and distributors.

7. Why More Buyers Are Turning to Integrated Powder Manufacturing Solutions

In recent years, B2B buyers—especially in automotive, aerospace, and tooling—have shifted toward integrated powder solutions instead of purchasing powders from generic traders. Why?

Benefits of Integrated Suppliers Like Shanghai Truer:

- Vertical Manufacturing: From raw material processing to final powder production, ensuring consistency.

- R&D Collaboration: Partners can co-develop powders tailored to unique applications.

- Application Expertise: Advises on best practices for sintering, compaction, and additive manufacturing.

- One-Stop Sourcing: Access to complementary powders like PM bronze, PM steel, and PM copper.

Shanghai Truer Technology Co., Ltd is a pioneer in this space. Since expanding its additive manufacturing division in 2019, it has become one of China’s most professional PM additive solution providers. Truer’s full-service approach includes:

- Water and gas atomized ferro silicon powder

- Grades such as F-0000, F0008, FC-0208, and diffusion alloyed steel options

- Advanced lubricants and cutting agents for optimized processing

- Custom blends for diamond tools, bearings, and magnetic components

If you’re looking for a reliable partner to streamline your powder sourcing, Truer provides unmatched value. Learn more about their capabilities and products on their page d'accueil

8. How to Order Wholesale Ferro Silicon Powder from Truer

Ordering wholesale ferro silicon powder involves more than just requesting a quote—it requires a streamlined procurement process to ensure quality, delivery, and performance meet strict industrial requirements. Shanghai Truer Technology Co., Ltd has designed its ordering and support system to cater specifically to the needs of B2B buyers, OEMs, and distributors.

Processus de commande étape par étape :

| Étape | Description | Détails |

|---|---|---|

| 1 | Enquête initiale | Contactez Truer via le site page de contact or email with product specs and volume. |

| 2 | Consultation technique | Truer’s R&D engineers work with you to confirm grade, mesh size, and composition. |

| 3 | Devis | Receive a detailed quote including lead time, shipping, and payment terms. |

| 4 | Approbation de l'échantillon | Optional samples sent for testing and approval before bulk production. |

| 5 | Bulk Production | Upon confirmation, Truer schedules production and initiates QA processes. |

| 6 | Logistics & Delivery | Global shipping available with tracking and documentation included. |

| 7 | Post-Sale Support | Ongoing technical assistance and reorder support from Truer’s customer service team. |

Available Packaging Options:

- 25kg plastic-lined woven bags

- 1-ton jumbo bags for industrial use

- Emballage personnalisé disponible sur demande

Payment Terms & Lead Time:

- Flexible payment options: T/T, L/C, bulk order credit terms for long-term partners

- Typical lead time: 7–15 working days depending on quantity and specifications

Wholesale MOQ:

- Minimum order quantity: 500 kg

- Volume discounts available for orders above 5 tons

If you’re ready to place an order or request a quote, visit the page de contact to get started with Truer’s procurement team.

9. FAQ: Common Questions About Buying Wholesale Ferro Silicon Powder

Below are some of the most frequently asked questions from B2B buyers and procurement officers interested in ferro silicon powder:

Q1: What mesh sizes are available for ferro silicon powder?

A : Truer offers a range from 0–100 mesh, with custom sizes available upon request. Common mesh sizes include -40 mesh, -60 mesh, and -100 mesh based on application needs.

Q2: Can I request customized chemical compositions?

A : Yes. Truer can adjust silicon content (e.g., 65%, 72%, 75%) and control trace elements like Al, C, or S to meet specific metallurgical requirements.

Q3: Is the powder suitable for additive manufacturing or MIM?

A : Absolutely. Truer’s gas atomized powders are optimized for use in AM and MIM applications where uniform particle size and flowability are crucial.

Q4: Does Truer provide technical documentation and MSDS?

A : Yes. Each shipment includes a full material test report (MTR), certificate of analysis (COA), and MSDS for safe handling and compliance.

Q5: Can I order other PM products together with ferro silicon powder?

A : Yes. Truer provides bundled solutions, including PM bronze, PM copper steel, PM stainless steel, and additives like graphite and lubricants. Explore the full Gamme de poudres PM for more.

Q6: Where is Truer’s manufacturing facility located?

A : Shanghai Truer Technology Co., Ltd is headquartered in Shanghai, China, with production facilities equipped for water atomization, gas atomization, and reduction methods.

Final Thoughts: Partner with a Trusted Ferro Silicon Powder Supplier

Ferro silicon powder is a strategic material that plays a vital role in steelmaking, foundries, powder metallurgy, and additive manufacturing. As global supply chains become more complex, the need for reliable, high-quality, and customizable powder solutions continues to grow.

Shanghai Truer Technology Co., Ltd is uniquely positioned to meet these demands. With over a decade of experience, Truer combines technical expertise, flexible manufacturing, and a customer-first approach to serve OEMs, industrial manufacturers, and distributors worldwide.

Pourquoi plus vrai ?

✅ One-stop supplier for PM and additive powders

✅ Customizable ferro silicon powder grades and particle sizes

✅ Integrated R&D support for application optimization

✅ Competitive pricing for wholesale buyers

✅ Global delivery with responsive service

Whether you’re looking to secure a dependable ferro silicon powder supplier or expand your PM product line, Shanghai Truer Technology Co. offers the quality, service, and innovation your business deserves. Visit the site officiel to learn more or contact the team to request a quote today.