Lorsqu'il s'agit d'alliages à haute performance utilisés dans des environnements extrêmes, Haynes 188 Poudre s'impose comme un choix de premier plan. Que vous travailliez dans l'aérospatiale, la production d'énergie ou toute autre industrie nécessitant des matériaux capables de résister à une chaleur extrême, la poudre Haynes 188 est réputée pour sa résistance à la chaleur, à l'oxydation et au fluage. Mais qu'est-ce qui rend cette poudre vraiment unique et pourquoi devriez-vous l'envisager pour votre prochain projet à haute température ?

Ce guide complet vous présentera tout ce que vous devez savoir sur la poudre Haynes 188. Nous explorerons sa composition, ses propriétés, ses applications et nous la comparerons même à d'autres poudres métalliques populaires. Alors, attachez votre ceinture et plongeons dans le monde des superalliages à base de cobalt.

Aperçu de la poudre Haynes 188

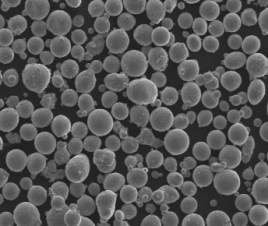

La poudre Haynes 188 est un superalliage à base de cobalt connu pour ses performances exceptionnelles à haute température. Il est largement utilisé dans les environnements où la résistance à l'oxydation et la stabilité thermique sont cruciales. La forme de poudre de Haynes 188 le rend idéal pour la fabrication additive, ce qui permet de créer facilement des formes et des composants complexes.

Attributs clés :

- Excellente résistance à l'oxydation jusqu'à 1095°C (2000°F)

- Bonne résistance à haute température

- Résistance supérieure à la fatigue thermique

- Résistance exceptionnelle au fluage et à l'oxydation

- Idéal pour l'aérospatiale, les turbines à gaz et les revêtements de chambres de combustion

Utilisations courantes :

- Composants aérospatiaux comme les chambres de combustion et les postcombustions

- Production d'électricité applications

- Fours industriels et revêtements à barrière thermique

Composition de la poudre Haynes 188

La clé pour comprendre pourquoi la poudre Haynes 188 est si performante réside dans sa composition. Cet alliage à base de cobalt est spécialement conçu pour résister à des conditions environnementales extrêmes.

| Élément | Composition (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chrome (Cr) | 22.0 |

| Nickel (Ni) | 22.0 |

| Tungstène (W) | 14.0 |

| Lanthane (La) | 0.03 |

| Carbone (C) | 0.10 |

| Silicium (Si) | 0.35 |

| Manganèse (Mn) | 1.25 |

Qu'est-ce qui fait la particularité de cette composition ?

- Chrome améliore la résistance du matériau à l'oxydation et à la corrosion.

- Nickel améliore la stabilité générale de l'alliage à haute température.

- Tungstène ajoute de la résistance, en particulier dans les applications à haute température.

- Lanthane renforce la résistance à l'oxydation et contribue à la longévité de l'alliage.

Chaque élément est stratégiquement inclus pour donner à Haynes 188 Powder ses capacités de haute performance, en particulier dans les environnements extrêmes.

Caractéristiques de la poudre Haynes 188

Maintenant que nous savons ce que contient la poudre Haynes 188, voyons ce qu'il en est caractéristiques physiques et mécaniques.

| Propriété | Valeur |

|---|---|

| Plage de fusion | 1330°C – ; 1410°C |

| Densité | 8.90 g/cm³ |

| Résistance à la traction à température ambiante | 895 MPa (130 ksi) |

| Limite d'élasticité à température ambiante | 430 MPa (62 ksi) |

| Élongation | 45% |

| Dureté (Rockwell C) | 24 |

| Coefficient de dilatation thermique | 12.8 μm/m°C (jusqu'à 800°C) |

| Conductivité thermique | 10.7 W/m-K |

| Résistance à l'oxydation | Jusqu'à 1095°C |

Caractéristiques notables :

- Haute résistance et ductilité: Offre une résistance mécanique supérieure combinée à une excellente ductilité, ce qui le rend idéal pour les pièces soumises à de fortes contraintes.

- Stabilité thermique: Résiste à des températures extrêmes sans perdre son intégrité mécanique.

- Résistance au fluage: L'excellente résistance au fluage permet à l'alliage de conserver sa forme en cas d'exposition prolongée à la chaleur.

Applications de la Haynes 188 Poudre

Grâce à ses propriétés remarquables, la poudre Haynes 188 est un choix de premier ordre dans les industries où la résistance à la chaleur et la protection contre l'oxydation sont primordiales. Examinons les industries et les applications spécifiques où ce superalliage se distingue vraiment.

| application | Détails |

|---|---|

| Aérospatiale | Chambres de combustion, post-brûleurs, tuyères d'échappement, turbines à gaz |

| Production d'électricité | Aubes de turbines à gaz, parcours de gaz chauds, chemises de combustion |

| Fours industriels | Composants exposés à des températures élevées et à des environnements oxydants |

| Fabrication additive (impression 3D) | Production de formes complexes pour des applications aérospatiales et de production d'énergie |

| Traitement chimique | Échangeurs de chaleur, réacteurs et autres équipements dans des environnements corrosifs |

Dans l'industrie aérospatiale, la poudre Haynes 188 est couramment utilisée dans la fabrication des chambres de combustion et des sections de turbine des moteurs d'avion. Les centrales électriques font également largement appel à ce superalliage en raison de ses excellentes propriétés de résistance à la chaleur.

Fabrication additive :

L'un des principaux avantages de la poudre Haynes 188 est son adaptabilité à la fabrication additive ou à l'impression 3D. Cela permet de produire des pièces complexes et performantes avec un minimum de déchets, ce qui est à la fois rentable et respectueux de l'environnement.

Modèles populaires de poudres métalliques : Haynes 188 Poudre et alternatives

Comparons Haynes 188 avec d'autres modèles de poudres métalliques couramment utilisés dans les applications à haute température.

| Poudre métallique | Composition | Propriétés notables | Applications |

|---|---|---|---|

| Haynes 188 | Co, Cr, Ni, W, La | Résistance élevée à la chaleur et à l'oxydation | Aérospatiale, production d'énergie, fours |

| Inconel 625 | Ni, Cr, Mo, Nb | Excellente résistance à la corrosion et à l'oxydation | Marine, traitement chimique, réacteurs nucléaires |

| Inconel 718 | Ni, Cr, Mo, Fe | Résistance élevée, résistance à la fatigue et au fluage à des températures élevées | Moteurs à réaction, engins spatiaux, turbines |

| Haynes 230 | Co, Cr, W, Mo | Bonne stabilité thermique, résistance à l'oxydation jusqu'à 1200°C | Aérospatiale, traitement chimique, centrales électriques |

| Haynes 282 | Ni, Cr, Mo, Ti | Excellente soudabilité et stabilité thermique | Turbines à gaz, chemises de combustion |

| Hastelloy X | Ni, Cr, Fe, Mo, Co | Haute résistance à l'oxydation et bonne aptitude à la mise en forme | Composants de moteurs à réaction, applications de fours |

| Carbure de tungstène (WC) | W, C | Dureté extrême, point de fusion élevé | Outils de coupe, applications résistantes à l'usure |

| Poudre de nickel 625 | Ni, Cr, Mo, Nb | Résistance élevée à la corrosion, soudabilité | Traitement chimique, industries marines |

| Stellite 6B | Co, Cr, W, Mo | Excellente résistance à l'usure, ténacité | Outils de coupe, lames de scie, pièces d'usure |

| Chrome cobalt | Co, Cr | Résistance élevée à l'usure, biocompatibilité | Implants médicaux, applications dentaires |

Avantages de la poudre Haynes 188

La poudre Haynes 188 présente de nombreux avantages par rapport aux autres poudres métalliques hautes performances. Examinons de plus près ce qui en fait le meilleur choix dans les conditions extrêmes.

1. Résistance à haute température

Comparé à d'autres alliages, Haynes 188 excelle à maintenir sa résistance dans des conditions de chaleur extrême. Alors que certains matériaux se ramollissent à haute température, Haynes 188 peut supporter un fonctionnement continu jusqu'à 1095°C.

2. Résistance à l'oxydation

La teneur élevée en chrome et en nickel de l'alliage lui confère une excellente résistance à l'oxydation, même dans des environnements extrêmes. Cette caractéristique est cruciale dans les industries telles que l'aérospatiale et la production d'énergie, où les composants sont exposés à des atmosphères riches en oxygène et à des températures élevées.

3. Résistance au fluage

Par rapport à d'autres superalliages tels que Inconel 625 ou Hastelloy X, Haynes 188 montre mieux résistance au fluage. Cela signifie que l'alliage conserve son intégrité structurelle même en cas de contraintes à long terme à des températures élevées.

4. La polyvalence dans la fabrication additive

En tant que poudre, Haynes 188 convient particulièrement pour Impression 3Dle système d'information sur la qualité de l'air permet de produire des pièces complexes et de haute précision avec un minimum de déchets.

Limites de la Haynes 188 Poudre

Bien entendu, aucun matériau n'est parfait. Examinons quelques-unes des limites potentielles de la poudre Haynes 188.

1. Coût

L'un des principaux inconvénients de la poudre Haynes 188 est son coût. La présence de cobalt et de tungstène le rend relativement plus cher que d'autres superalliages comme l'Inconel 718. Cependant, les avantages en termes de longévité et de performances justifient souvent ce prix plus élevé.

2. Soudabilité

Bien que l'alliage Haynes 188 puisse être soudé, il n'offre pas le même niveau de soudabilité que d'autres alliages à base de nickel

comme l'Inconel 625. Cela peut constituer un défi pour les applications nécessitant de nombreux travaux de soudage.

3. Résistance limitée à la corrosion

Bien qu'il soit exceptionnellement performant à haute température, le Haynes 188 n'est pas aussi résistant à la corrosion que d'autres alliages tels que l'Hastelloy X, en particulier dans les environnements marins ou très acides.

Spécifications, tailles, qualités et normes de la poudre Haynes 188

Voici quelques-unes des principales spécifications et normes associées à l'utilisation de l'énergie solaire Haynes 188 Poudre.

| Spécifications | Détails |

|---|---|

| Densité | 8.90 g/cm³ |

| Plage de fusion | 1330°C – ; 1410°C |

| Tailles standard | Disponible dans une variété de maillages pour l'impression 3D |

| Normes ASTM | ASTM F75, ASTM B637 |

| Grades typiques | AMS 5608, AMS 5801, AMS 5943 |

| Normes applicables | ISO 9001:2015, AS 9100D, NADCAP |

Fournisseurs et prix de la poudre Haynes 188

Lors de l'approvisionnement en poudre Haynes 188, il est important de rechercher les éléments suivants des fournisseurs réputés pour vous assurer que vous obtenez un produit de haute qualité. Vous trouverez ci-dessous quelques fournisseurs réputés ainsi qu'une fourchette de prix estimée.

| Fournisseur | Fourchette de prix (USD/kg) | Région | Certification |

|---|---|---|---|

| Technologie des charpentiers | $150 – $300 | ÉTATS-UNIS | ISO 9001, AS 9100, NADCAP |

| Höganäs | $180 – $320 | Europe, Monde | ISO 9001, AS 9100 |

| Praxair | $170 – $280 | États-Unis, Monde | ISO 9001, NADCAP |

| EOS | $200 – $350 | Allemagne, Monde | ISO 9001 |

| Kennametal | $160 – $310 | ÉTATS-UNIS | AS 9100, ISO 14001 |

Les prix varient en fonction de facteurs tels que pureté, taille des particuleset certifications des fournisseurs. Les commandes plus importantes font généralement l'objet de remises, et les services supplémentaires tels que les mélanges sur mesure ou la taille des mailles peuvent augmenter le prix.

Avantages et inconvénients de la poudre Haynes 188

Lorsqu'il s'agit de décider si Haynes 188 Poudre est le bon matériau pour votre projet, il est important d'en peser les avantages et les inconvénients.

| Pour | Cons |

|---|---|

| Résistance exceptionnelle à la chaleur et à l'oxydation | Relativement cher par rapport à d'autres |

| Résistant aux températures élevées | Résistance limitée à la corrosion |

| Résistant au fluage | La soudabilité n'est pas aussi facile que pour d'autres alliages |

| Idéal pour la fabrication additive | Nécessite une manipulation et un traitement spécialisés en raison de son coût |

FAQ

Voici une brève section FAQ pour répondre aux questions les plus fréquentes sur les poudres Haynes 188.

| Question | Réponse |

|---|---|

| À quoi sert la poudre Haynes 188 ? | Il est utilisé dans l'aérospatiale, la production d'énergie et les fours industriels, principalement pour les composants à haute température. |

| Comment se compare-t-il à l'Inconel 625 ? | Haynes 188 offre une meilleure résistance au fluage à haute température, tandis que l'Inconel 625 présente une meilleure résistance à la corrosion. |

| La poudre Haynes 188 peut-elle être imprimée en 3D ? | Oui, la poudre Haynes 188 est couramment utilisée dans la fabrication additive de pièces complexes et résistantes à la chaleur. |

| La poudre Haynes 188 est-elle chère ? | Oui, en raison de sa composition (forte teneur en cobalt et en tungstène), il est généralement plus cher que les autres superalliages. |

| Quelle température peut supporter Haynes 188 ? | Il peut résister à des températures allant jusqu'à 1095°C (2000°F), ce qui le rend adapté aux environnements extrêmes. |

| Haynes 188 est-il facile à souder ? | Bien qu'il puisse être soudé, il n'est pas aussi facile à souder que d'autres alliages à base de nickel comme l'Inconel 625. |

| Où puis-je acheter la poudre Haynes 188 ? | Vous pouvez l'acheter auprès de fournisseurs tels que Carpenter Technology, Höganäs et EOS. Les prix varient en fonction du fournisseur et de la taille de la commande. |