Vue d'ensemble Plasma inductif (PIC)

Le plasma inductif (ICP) est une technologie devenue fondamentale dans le domaine de la chimie analytique, de la science des matériaux et de la métallurgie. Mais qu'est-ce que l'ICP exactement et pourquoi a-t-il acquis une telle importance ? En termes simples, l'ICP est une technique utilisée pour générer un plasma à haute température, qui peut être utilisé pour la détection et l'analyse de divers éléments, en particulier les métaux. Ce puissant outil analytique est couramment utilisé en spectrométrie, ce qui permet de mesurer avec une précision exceptionnelle les concentrations de métaux dans les échantillons.

Imaginez que vous essayez de trouver une aiguille dans une botte de foin - et si vous pouviez brûler tout le foin pour ne garder que l'aiguille ? C'est un peu ce que fait l'ICP lorsqu'il analyse la composition élémentaire d'échantillons. Il brûle toutes les matières indésirables, ne laissant que les éléments qui vous intéressent, ce qui en fait une méthode très efficace pour l'analyse des matériaux.

Dans ce guide complet, nous entrerons dans les détails de l'ICP, en explorant ses principes, ses types, ses applications et les modèles spécifiques de poudres métalliques utilisés en conjonction avec l'ICP. À la fin de cet article, vous aurez une compréhension approfondie du fonctionnement de l'ICP, des raisons de son utilisation et de sa comparaison avec d'autres techniques d'analyse.

Qu'est-ce que le plasma inductif (ICP) ?

Le plasma à couplage inductif est un type de source de plasma dans lequel l'énergie est fournie par des courants électriques produits par induction électromagnétique. Cette technologie a été développée pour la première fois dans les années 1960 et est devenue depuis la pierre angulaire de l'analyse élémentaire. Mais décomposons-la.

À la base, l'ICP implique l'utilisation d'un champ électromagnétique à haute fréquence, généré par une bobine de radiofréquence (RF), pour ioniser un gaz (généralement de l'argon) et créer un plasma. Ce plasma atteint des températures allant jusqu'à 10 000 K (c'est plus chaud que la surface du soleil !), ce qui est suffisant pour atomiser et ioniser les éléments d'un échantillon. Ces éléments ionisés peuvent ensuite être détectés à l'aide de différents types de spectrométrie, le plus souvent ICP-OES (spectrométrie d'émission optique) ou ICP-MS (spectrométrie de masse).

Composants clés d'un système de PCI :

- Générateur RF : Produit le champ électromagnétique.

- Torche : Généralement en quartz, c'est là que le plasma est généré.

- Exemple de système d'introduction : Introduit l'échantillon dans le plasma.

- Alimentation en gaz plasmatique : Le gaz argon est le plus couramment utilisé.

- Spectromètre : Analyse les ions émis ou détectés.

L'énergie élevée du plasma ne se contente pas d'atomiser l'échantillon, elle excite également les atomes et les ions, qui émettent alors de la lumière à des longueurs d'onde spécifiques. Cette lumière est caractéristique des éléments présents dans l'échantillon, ce qui permet de les identifier et de les quantifier.

Types de systèmes à plasma inductif

Différents types de systèmes ICP sont adaptés à des applications spécifiques, en fonction de la nature de l'échantillon, de la sensibilité requise et de la précision souhaitée. Les principaux types sont les suivants :

1. Spectrométrie d'émission optique ICP (ICP-OES)

Également appelée ICP-AES (spectrométrie d'émission atomique), cette méthode consiste à mesurer la lumière émise par les atomes et les ions lorsqu'ils retournent à un état d'énergie inférieur. L'ICP-OES est particulièrement bien adaptée à l'analyse de plusieurs éléments, car elle offre un bon équilibre entre la sensibilité et la gamme dynamique.

Applications :

- Analyse environnementale (eau, sol, air)

- Analyse métallurgique

- Essais de produits alimentaires et de boissons

- Analyse pharmaceutique

Avantages :

- Détection simultanée de plusieurs éléments

- Haut débit

- Coûts opérationnels inférieurs à ceux de l'ICP-MS

2. Spectrométrie de masse ICP (ICP-MS)

L'ICP-MS pousse l'analyse plus loin en détectant les ions sur la base de leur rapport masse/charge. Cette technique offre une sensibilité inégalée et la possibilité de détecter des éléments traces à des concentrations extrêmement faibles.

Applications :

- Analyse des traces de métaux dans les échantillons biologiques

- Analyse géochimique et isotopique

- Industrie des semi-conducteurs

- Science nucléaire

Avantages :

- Sensibilité extrêmement élevée

- Capacité à détecter les isotopes

- Gamme dynamique étendue

3. Spectrométrie de masse à temps de vol ICP (ICP-TOFMS)

L'ICP-TOFMS est une variante de l'ICP-MS, dans laquelle les ions sont séparés en fonction du temps qu'ils mettent à traverser un tube de vol. Cette méthode permet la détection rapide et simultanée de plusieurs éléments et isotopes, ce qui la rend idéale pour les applications à haut débit.

Applications :

- Science des matériaux avancés

- Analyse des nanoparticules

- Analyse multiélémentaire d'échantillons environnementaux

Avantages :

- Analyse rapide

- Haute résolution

- Détection simultanée

Composition des Plasma inductif

La composition du plasma dans l'ICP est principalement constituée d'argon, un gaz noble chimiquement inerte qui aide à stabiliser le plasma tout en empêchant la contamination de l'échantillon. L'utilisation de l'argon est cruciale car il ne réagit pas avec l'échantillon ou la torche, ce qui garantit un environnement propre et contrôlé pour l'ionisation.

Toutefois, en fonction de l'application, d'autres gaz ou additifs peuvent être introduits dans le plasma pour améliorer ses propriétés ou l'adapter à des besoins analytiques spécifiques.

Composition du gaz plasmatique et additifs :

| Composant | Fonction | Avantages |

|---|---|---|

| Argon | Gaz plasmagène principal | Stable, inerte, évite la contamination |

| Hélium | Gaz vecteur ou additif | Augmentation de la sensibilité pour certains éléments |

| Azote | Additif | Renforce l'intensité du signal pour des analyses spécifiques |

| Oxygène | Combustion d'échantillons | Utile pour l'analyse d'échantillons organiques |

L'argon est choisi principalement en raison de son potentiel d'ionisation élevé et de sa capacité à maintenir un plasma stable. D'autres gaz comme l'hélium peuvent être utilisés pour améliorer le transport de l'échantillon dans le plasma ou pour améliorer la détection de certains éléments en modifiant les caractéristiques du plasma.

Pourquoi l'argon ?

Le choix de l'argon comme gaz plasmagène primaire s'explique par plusieurs raisons. Tout d'abord, sa nature inerte garantit qu'il n'interfère pas avec l'analyse en réagissant avec l'échantillon. Deuxièmement, son énergie d'ionisation élevée est idéale pour créer un plasma robuste capable d'ioniser efficacement les éléments de l'échantillon.

Caractéristiques du plasma inductif

Les caractéristiques uniques de l'ICP en font un choix privilégié pour l'analyse élémentaire. Nous examinerons ici les propriétés les plus importantes qui contribuent à son efficacité.

Haute température

La température élevée de l'ICP (jusqu'à 10 000 K) garantit que même les éléments les plus réfractaires sont entièrement atomisés et ionisés. Ceci est crucial pour une analyse élémentaire précise et complète, en particulier pour les échantillons avec des matrices complexes.

Atmosphère inerte

L'utilisation de l'argon permet d'obtenir une atmosphère inerte, ce qui minimise le risque de contamination ou de réactions indésirables. Ceci est particulièrement important dans les applications où la précision est critique, comme dans l'analyse des traces de métaux ou la fabrication de semi-conducteurs.

Ionisation efficace

La capacité de l'ICP à ioniser efficacement les éléments, y compris ceux dont le potentiel d'ionisation est élevé, est l'une de ses principales caractéristiques. Cela permet de détecter une large gamme d'éléments, des métaux légers comme le lithium aux métaux lourds comme l'uranium.

Conditions stables et reproductibles

La stabilité du plasma et la reproductibilité des conditions de l'ICP garantissent la cohérence et la fiabilité des résultats. Ceci est essentiel pour les applications où la répétabilité est primordiale, telles que le contrôle de la qualité ou les tests de conformité réglementaire.

Capacité multi-éléments

L'un des principaux avantages de l'ICP est sa capacité à analyser simultanément plusieurs éléments. Ceci est particulièrement utile dans les industries où une analyse complète d'échantillons complexes est nécessaire, comme les tests environnementaux ou l'analyse métallurgique.

Applications du plasma inductif

Le plasma inductif est utilisé dans une grande variété d'applications, grâce à sa polyvalence et à sa précision. Ci-dessous, nous explorons quelques-uns des principaux secteurs et industries où le plasma inductif est utilisé.

Analyse environnementale

Le PCI est largement utilisé dans les essais environnementaux pour contrôler et évaluer les niveaux de divers éléments dans l'eau, le sol et l'air. Cela inclut la détection de métaux lourds tels que le plomb, le mercure et l'arsenic, qui sont particulièrement préoccupants en raison de leur toxicité.

Exemples d'utilisation :

- Recherche de contaminants dans l'eau potable

- Surveillance des sols à des fins agricoles

- Évaluation de la qualité de l'air dans les zones industrielles

Industrie pharmaceutique

Dans l'industrie pharmaceutique, l'ICP est utilisé pour garantir la pureté des matières premières et la sécurité des produits finis. L'analyse des métaux à l'état de traces est essentielle dans ce secteur pour éviter toute contamination susceptible d'affecter l'efficacité et la sécurité des médicaments.

Exemples d'utilisation :

- Analyse des ingrédients pharmaceutiques actifs (API)

- Recherche de contaminants métalliques dans les médicaments

- Garantir le respect des normes réglementaires

Tests de produits alimentaires et de boissons

Il est essentiel pour la santé publique de veiller à ce que les aliments et les boissons ne contiennent pas de métaux nocifs. Le PCI est largement utilisé pour rechercher des contaminants tels que le plomb, le cadmium et le mercure dans une large gamme de produits alimentaires.

Exemples d'utilisation :

- Analyse de la teneur en métaux des aliments en conserve

- Recherche de contaminants dans l'eau en bouteille

- Surveillance des niveaux de métaux dans les produits agricoles

Métallurgie et science des matériaux

Le PIC joue un rôle crucial dans la métallurgie, où il est utilisé pour analyser la composition des métaux et des alliages. Elle est importante pour le contrôle de la qualité, le développement des matériaux et la garantie que les produits répondent aux spécifications requises.

Exemples d'utilisation :

- Analyse des alliages métalliques pour les applications aérospatiales

- Contrôle de la pureté des métaux précieux

- Contrôle de la composition de l'acier et d'autres matériaux industriels

Analyse géochimique et isotopique

Le PIC est

est également utilisé dans le domaine de la géologie pour analyser des échantillons de roches, de minéraux et de sol afin d'en déterminer la composition élémentaire et isotopique. Cette analyse est importante pour comprendre l'histoire de la Terre, ainsi que pour les activités d'exploration et d'exploitation minière.

Exemples d'utilisation :

- Détermination de la composition des gisements minéraux

- Analyse d'échantillons de roches pour des études isotopiques

- L'étude de la composition du sol dans la recherche agricole

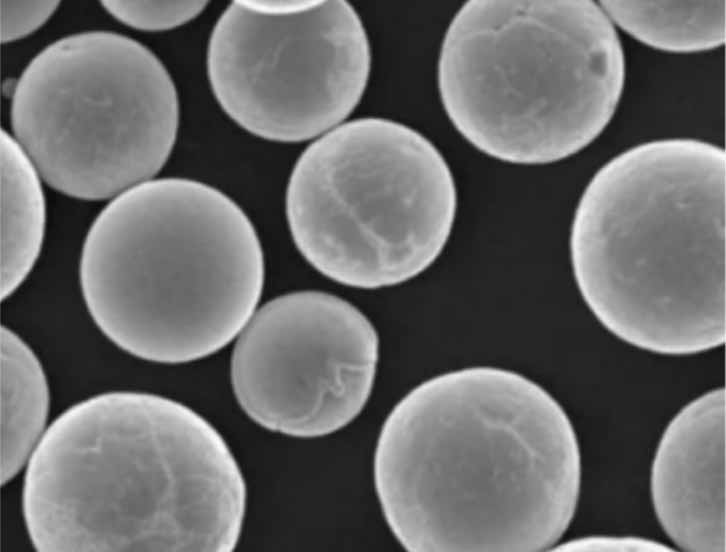

Modèles de poudres métalliques spécifiques utilisées dans l'ICP

Les poudres métalliques sont souvent analysées par ICP pour déterminer leur composition, leur pureté et d'autres caractéristiques. Vous trouverez ci-dessous dix modèles de poudres métalliques spécifiques couramment utilisés dans le cadre de l'analyse ICP, ainsi que leur description.

1. Poudre de nickel (Ni)

La poudre de nickel est utilisée dans une variété d'applications industrielles, y compris la production d'alliages, de revêtements et de batteries. Dans l'analyse ICP, la poudre de nickel est évaluée pour sa pureté et la présence d'éléments traces.

2. Poudre de titane (Ti)

La poudre de titane est largement utilisée dans l'aérospatiale, les implants médicaux et la fabrication additive. L'ICP est utilisé pour s'assurer que la poudre de titane répond aux exigences strictes de pureté pour ces applications.

3. Poudre d'aluminium (Al)

La poudre d'aluminium est utilisée dans la production de matériaux légers, d'explosifs et de revêtements. L'analyse ICP est essentielle pour vérifier la composition élémentaire et détecter d'éventuelles impuretés.

4. Poudre de cuivre (Cu)

La poudre de cuivre est un matériau clé dans l'électronique, les encres conductrices et la métallurgie. L'analyse ICP permet de déterminer la pureté et la composition de la poudre de cuivre, ce qui est crucial pour ses performances dans ces applications.

5. Poudre de fer (Fe)

La poudre de fer est utilisée dans un large éventail d'applications, notamment les pièces automobiles, les matériaux magnétiques et la métallurgie. L'analyse ICP permet de s'assurer que la poudre de fer répond aux spécifications requises pour ces utilisations.

6. Poudre d'argent (Ag)

La poudre d'argent est couramment utilisée dans l'électronique, la bijouterie et les applications médicales. L'analyse ICP est utilisée pour confirmer la pureté de la poudre d'argent et pour détecter tout contaminant susceptible d'affecter ses performances.

7. Poudre de tungstène (W)

La poudre de tungstène est utilisée dans la production d'alliages lourds, de contacts électriques et d'outils de coupe. L'analyse ICP est essentielle pour garantir la grande pureté de la poudre de tungstène, qui est nécessaire pour ses applications exigeantes.

8. Poudre de cobalt (Co)

La poudre de cobalt est utilisée dans la production de superalliages, de batteries et de matériaux magnétiques. L'analyse ICP permet de déterminer la composition élémentaire et la pureté de la poudre de cobalt, ce qui est essentiel pour ses performances dans ces applications.

9. Poudre de zinc (Zn)

La poudre de zinc est utilisée dans la galvanisation, les batteries et la synthèse chimique. L'analyse ICP est importante pour évaluer la pureté et la composition de la poudre de zinc, afin de s'assurer qu'elle convient aux applications industrielles.

10. Poudre de platine (Pt)

La poudre de platine est utilisée dans les convertisseurs catalytiques, la bijouterie et l'électronique. L'analyse ICP garantit que la poudre de platine répond aux normes de pureté élevées requises pour ces applications de grande valeur.

Spécifications et normes pour les poudres métalliques dans les analyses ICP

Lorsqu'il s'agit d'analyser des poudres métalliques à l'aide de l'ICP, il existe des normes et des spécifications spécifiques qui doivent être respectées. Ces normes garantissent la précision, la cohérence et la fiabilité de l'analyse dans différents laboratoires et applications.

Normes communes pour les poudres métalliques

| Poudre métallique | Standard | Description |

|---|---|---|

| poudre de nickel | ASTM B330 | Norme pour la distribution de la taille des particules |

| Poudre de titane | ASTM F1580 | Spécification pour la poudre utilisée dans les implants médicaux |

| Poudre d'aluminium | ASTM B212 | Norme pour les matériaux de la métallurgie des poudres |

| Poudre de cuivre | ASTM B216 | Norme pour la poudre de cuivre électrodéposée |

| poudre de fer | ISO 4497 | Mesure de la taille des particules par diffraction laser |

| Poudre d'argent | ISO 17832 | Norme pour les poudres d'argent destinées aux applications électroniques |

| poudre de tungstène | ASTM B777 | Spécification pour les poudres d'alliage lourd de tungstène |

| Poudre de cobalt | ASTM B814 | Norme pour la distribution granulométrique des poudres de cobalt |

| Poudre de zinc | ASTM B211 | Norme pour les poudres de zinc pour la galvanisation |

| Poudre de platine | ASTM E761 | Norme pour l'analyse des poudres de platine |

Ces normes décrivent les méthodes et les procédures d'analyse des propriétés physiques et chimiques des poudres métalliques. Le respect de ces normes garantit que les résultats de l'analyse ICP sont cohérents et fiables, quelle que soit l'application ou l'industrie concernée.

Comparaison entre l'ICP et d'autres techniques d'analyse

L'ICP n'est pas la seule méthode disponible pour l'analyse élémentaire. Il est important de comprendre comment l'ICP se compare à d'autres techniques telles que la spectrométrie d'absorption atomique (AAS), la fluorescence X (XRF) et la spectroscopie de rupture induite par laser (LIBS).

ICP vs. Spectrométrie d'absorption atomique (SAA)

| Paramètres | PIC | AAS |

|---|---|---|

| Sensibilité | Plus élevé | Plus bas |

| Multi-éléments | Oui, détection simultanée | Non, un élément à la fois |

| Gamme dynamique | Large | Étroite |

| Coût | Coûts opérationnels plus élevés | Réduction des coûts opérationnels |

| Applications | Analyse des traces de métaux, isotopes | Métaux en solution |

ICP vs. Fluorescence X (XRF)

| Paramètres | PIC | XRF |

|---|---|---|

| Sensibilité | Plus élevé, surtout pour les éléments légers | Plus bas, meilleur pour les éléments lourds |

| Type d'échantillon | Liquide, solide, gaz | Solides, couches minces |

| Non-destructif | Non | Oui |

| Coût | Plus élevé | Plus bas |

| Applications | Analyse environnementale, métallurgie | Exploitation minière, essais de matériaux |

ICP vs. Spectroscopie de rupture induite par laser (LIBS)

| Paramètres | PIC | LIBS |

|---|---|---|

| Sensibilité | Plus élevé | Plus bas |

| Portabilité | En laboratoire | Portable, utilisation sur le terrain |

| Vitesse | Plus lent | Plus rapide |

| Coût | Plus élevé | Modéré |

| Applications | Analyse de haute précision, recherche | Test sur site, analyse rapide |

Avantages et inconvénients de la Plasma inductif

Chaque technique analytique a ses forces et ses faiblesses, et l'ICP ne fait pas exception. Nous examinons ici les avantages et les inconvénients de l'utilisation de l'ICP pour l'analyse élémentaire.

Avantages du PCI :

- Haute sensibilité : L'ICP est capable de détecter des éléments à l'état de traces, ce qui le rend idéal pour les applications où des mesures précises sont essentielles.

- Capacité multi-éléments : La possibilité d'analyser simultanément plusieurs éléments permet de gagner du temps et d'économiser des ressources.

- Gamme dynamique étendue : L'ICP peut mesurer avec précision des éléments dans une large gamme de concentrations.

- Polyvalence : L'ICP peut être utilisé pour analyser une variété de types d'échantillons, y compris les liquides, les solides et les gaz.

- Reproductibilité : Les conditions stables de l'ICP garantissent des résultats cohérents et fiables.

Inconvénients du PCI :

- Coûts opérationnels élevés : Le coût de fonctionnement d'un système ICP, y compris la consommation de gaz argon et la maintenance du générateur RF, peut être important.

- La complexité : Les systèmes ICP nécessitent des opérateurs qualifiés et un étalonnage minutieux pour garantir des résultats précis.

- Préparation de l'échantillon : Certains échantillons peuvent nécessiter une préparation poussée avant d'être analysés par ICP, ce qui ajoute du temps et de la complexité au processus.

- Interférence : Bien que l'ICP soit très sensible, il peut être sujet à des interférences dues à certains éléments ou à des effets de matrice, ce qui peut affecter la précision de l'analyse.

FAQ

Pour conclure, abordons quelques questions courantes sur le PCI qui reviennent souvent dans les discussions sur cette technologie.

| Question | Réponse |

|---|---|

| Qu'est-ce que le plasma inductif (ICP) ? | L'ICP est une technique utilisée pour générer du plasma en vue de la détection et de l'analyse d'éléments, en particulier de métaux. |

| Comment fonctionne le PCI ? | L'ICP utilise un champ électromagnétique à haute fréquence pour ioniser le gaz et créer un plasma, qui est ensuite utilisé pour atomiser et analyser les éléments d'un échantillon. |

| Quels sont les types de systèmes ICP ? | Les principaux types sont l'ICP-OES, l'ICP-MS et l'ICP-TOFMS, chacun étant adapté à des applications spécifiques. |

| Quels sont les métaux qui peuvent être analysés par ICP ? | L'ICP peut analyser une large gamme de métaux, y compris le nickel, le titane, l'aluminium, le cuivre, le fer et bien d'autres. |

| Pourquoi l'argon est-il utilisé dans l'ICP ? | L'argon est utilisé parce qu'il est inerte, qu'il a un potentiel d'ionisation élevé et qu'il stabilise le plasma sans contaminer l'échantillon. |

| Quels sont les avantages de l'utilisation du PCI ? | L'ICP offre une grande sensibilité, une capacité multi-éléments, une large gamme dynamique et une grande polyvalence dans l'analyse des échantillons. |

| L'utilisation du PCI présente-t-elle des inconvénients ? | Oui, l'ICP peut être coûteux à utiliser, nécessite des opérateurs qualifiés et peut poser des problèmes d'interférence et de préparation des échantillons. |

| Comment l'ICP se compare-t-il à d'autres techniques telles que l'AAS ? | L'ICP offre généralement une plus grande sensibilité, la possibilité de détecter plusieurs éléments simultanément et une gamme dynamique plus large que l'AAS. |