1. Introducción: Por qué es importante el polvo de hierro SC100.26

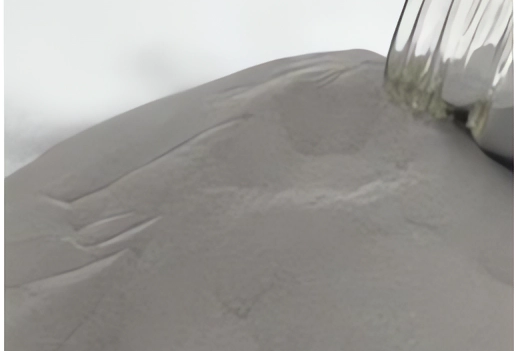

El polvo de hierro SC100.26 es una materia prima muy utilizada en pulvimetalurgia debido a su excelente compresibilidad, fluidez y rentabilidad. Es un polvo de hierro atomizado en agua de gran pureza diseñado para piezas estructurales de PM en los sectores de la automoción, la electrónica y la maquinaria industrial. Con una distribución granulométrica típica y una composición química estable, los fabricantes de todo el mundo confían en SC100.26 para la producción en serie.

Para compradores B2B, como fabricantes de componentes PM al por mayor, proveedores de automoción de primer nivel, y oEM industriales, SC100.26 ofertas:

- Escalabilidad para la producción en serie

- Rendimiento constante en aplicaciones de sinterización

- Rentabilidad por su alto rendimiento y bajo nivel de residuos

A medida que crece la demanda mundial de piezas metálicas sostenibles y ligeras, el polvo de hierro SC100.26 sigue siendo una piedra angular en la cadena de suministro de fabricación aditiva y técnicas tradicionales de PM.

2. Aplicaciones industriales del polvo de hierro SC100.26

El SC100.26 se utiliza en una amplia gama de componentes de PM en todas las industrias. Sus propiedades físicas y mecánicas lo hacen ideal tanto para prensa y sinterización y parte infiltrada fabricación.

Principales ámbitos de aplicación:

| Industria | Componentes de la aplicación | Notas |

|---|---|---|

| Automotor | Engranajes, bujes, cubos de embrague, piñones | Producción de gran volumen |

| Maquinaria industrial | Rodamientos, poleas, levas, conectores mecánicos | Piezas de precisión |

| Electrónica de consumo | Núcleos magnéticoscomponentes de blindaje | Propiedades magnéticas optimizadas |

| Electrodomésticos | Piezas de motor, soportes, elementos estructurales | Aplicaciones duraderas y sensibles a los costes |

| Herramientas y herrajes | Componentes de herramientas manuales, piezas de taladro | Resistente al desgaste, mecanizable |

Ventajas para los compradores B2B:

- Excelente resistencia en verde para manipular & mecanizado

- Alta densidad sinterizada para la integridad estructural

- Compatible con diversas técnicas de aleación

Casos de uso especiales:

- Puede alearse con cobre, níquel o molibdeno para mejorar las propiedades mecánicas.

- Adecuado para aleación por difusión y formulaciones prealeadas en piezas de precisión.

Para obtener información detallada sobre las opciones de polvo más allá de SC100.26, consulte Toda la gama de polvos PM de Truer aquí.

3. Propiedades principales y especificaciones técnicas

SC100.26 cumple las normas MPIF e ISO sobre polvos de hierro atomizados en agua. Conocer sus propiedades ayuda a los ingenieros y a los equipos de compras a tomar decisiones de abastecimiento bien fundadas.

Composición química (típica):

| Elemento | Contenido (%) |

|---|---|

| Hierro (Fe) | 99,5 |

| Carbono | < 0.01 |

| Azufre | < 0.02 |

| Fósforo | < 0.03 |

Propiedades físicas:

| Propiedad | Valor |

|---|---|

| Densidad aparente | 2.50 – 2,90 g/cm³ |

| Caudal (Hall, 50g) | < 30 seg |

| Resistencia en verde (MPa) | 35 – 50 |

| Compressibility @ 600 MPa | 6.8 – 7,1 g/cm³ |

| Distribución del tamaño de las partículas | 100 mesh (mayoría) |

Opciones de envasado para distribuidores:

- sacos de 25 kg (sellado)

- sacos jumbo de 1 tonelada

- Bidones sellados al vacío para exportación

Uso en aleación:

SC100.26 puede combinarse con grafito, polvo de cobre o lubricantes orgánicos como SUW-8000 para formulaciones PM a medida.

Compatibilidad con aditivos:

Shanghai Truer ofrece un conjunto completo de aditivos de PM para mezclar con SC100.26:

- Lubricantes: Lube-W, SUW-5000B

- Agentes de corte: SME-100, TD-8

- Aditivos magnéticos blandos: QH-150

- Grafito: QHP-330, TBC-1000

Para más información sobre productos y la empresa, visite Acerca de Shanghai Truer.

4. Demanda del mercado y tendencias de la cadena de suministro

En el cambiante panorama de la pulvimetalurgia, la demanda de polvo de hierro SC100.26 ha experimentado un crecimiento significativo debido al aumento de su uso en los sectores de la automoción, la industria y la fabricación aditiva. Las cadenas de suministro mundiales se están adaptando para satisfacer los requisitos de grandes volúmenes, manteniendo al mismo tiempo la calidad, la competitividad de los precios y la fiabilidad de las entregas.

Impulsores de la demanda mundial:

- Aligeramiento en automoción: Los fabricantes de automóviles recurren cada vez más a la pulvimetalurgia para fabricar componentes duraderos y ligeros.

- Fabricación aditiva (AM): SC100.26 se utiliza cada vez más para formulaciones base en metal AM.

- Fabricación sostenible: Los procesos PM que utilizan SC100.26 generan menos residuos y consumo de energía.

Tendencias de la cadena de suministro:

| Tendencia | Impacto en los compradores |

|---|---|

| Deslocalización y localización | Los compradores buscan proveedores regionales para reducir riesgos |

| Volatilidad de los precios del hierro en bruto | Impulsar los contratos a largo plazo con los proveedores |

| Certificaciones de calidad | El cumplimiento de las normas ISO/MPIF es ahora una norma de contratación pública |

| Contratación digital | Los compradores utilizan plataformas en línea para abastecerse |

Perspectivas de los mercados regionales:

- Asia-Pacífico lidera la producción mundial, especialmente China e India.

- Europa hace hincapié en los polvos PM certificados y ecológicos para piezas de automóviles.

- Norteamérica se centra en aplicaciones de alto rendimiento en el sector aeroespacial y de defensa.

Para racionalizar su estrategia de compras y asegurarse un abastecimiento fiable, consulte Página de contacto de Shanghai Truer para discutir MOQ, plazos de entrega y logística.

5. Cómo elegir un proveedor fiable de SC100.26

Cuando se adquiere hierro en polvo SC100.26 a granel, la garantía de calidad, la consistencia y la estabilidad del suministro son fundamentales para los compradores B2B. He aquí cómo evaluar la fiabilidad del proveedor:

Criterios clave de selección para distribuidores y fabricantes de equipos originales:

- Certificación de productos & Normas

- Cumplimiento de las normas MPIF, ISO 4499 y ASTM

- Informes de ensayos de materiales disponibles previa solicitud

- Capacidad de fabricación

- Instalaciones propias de atomización y mezcla

- Trazabilidad de los lotes y sistemas de control de calidad

- Opciones de personalización

- Posibilidad de premezcla con grafito, cobre o lubricantes

- Distribuciones granulométricas a medida

- Logística y embalaje

- Embalaje para exportación

- Opciones de entrega justo a tiempo (JIT)

- Atención al cliente y asistencia técnica

- Asistencia técnica in situ

- Descargas de especificaciones en línea, hojas SDS

Lo que deben preguntar los compradores B2B:

- ¿Cuál es el plazo de entrega habitual para más de 10 toneladas?

- ¿Es compatible el polvo con mi perfil de sinterización actual?

- ¿Puedo solicitar lotes de muestras para pruebas?

Ejemplo de lista de control:

| Factor | Importancia | Criterio de referencia recomendado |

|---|---|---|

| Tamaño uniforme de las partículas | ★★★★★ | malla 100 (o según sea necesario) |

| Pureza química | ★★★★★ | 99,5% Fe |

| Fluidez & humedad; Densidad | ★★★★☆ | 2.5-2,9 g/cm³ |

| Asistencia técnica | ★★★★☆ | Consulta de ingeniería |

| Estabilidad de precios | ★★★★☆ | Opciones de contrato a largo plazo |

6. Principales proveedores mundiales de SC100.26 Polvo de hierro

El panorama mundial de proveedores SC100.26 incluye una mezcla de empresas tradicionales y proveedores emergentes, especialmente de Asia. Estas son las principales fuentes que los equipos de compras B2B suelen tener en cuenta:

Los 5 mejores proveedores mundiales de SC100.26:

| Nombre del proveedor | País | Capacidades | Certificaciones |

|---|---|---|---|

| Höganäs AB | Suecia | Líder mundial en polvos PM | ISO 9001, IATF 16949 |

| Río Tinto / QMP | Canadá | Polvos atomizados en agua de gran pureza | ISO 14001 |

| Tecnología Truer de Shanghai | China | Soluciones completas de aditivos PM & equipos | ISO 9001, SGS |

| Pometon S.p.A | Italia | Formulaciones PM a medida | ISO 45001 |

| JFE Steel Corp. | Japón | Materiales PM de alto rendimiento | JIS, ISO 9001 |

Por qué destaca Shanghai Truer:

- Integración vertical total: De la producción de polvo a la mezcla de aditivos

- Grados personalizados: Variantes SC100.26 con premezcla de grafito/lubricante

- Plazos de entrega rápidos: Ideal para pedidos al por mayor o urgentes

- Logística mundial: Embalaje y documentación listos para la exportación

Shanghai Truer también ofrece soluciones PM avanzadas para aleado por difusión, prealeado, y aceros híbridos de baja aleación, ampliando el valor a los clientes más allá de SC100.26.

Explore La gama completa de polvos PM de Truer incluyendo FL-4605, FD-0208, FN-0205, y

7. Por qué cada vez más compradores eligen fabricantes chinos

En los últimos años, los fabricantes chinos se han convertido en proveedores mundiales clave de polvo de hierro SC100.26 y otros materiales pulvimetalúrgicos (PM). Empresas de todo el mundo, especialmente compradores mayoristas, fabricantes de equipos originales y fabricantes de piezas, están cambiando sus estrategias de abastecimiento para incluir a China por varias razones de peso.

Principales ventajas para los compradores B2B:

- Precios competitivos

- Los menores costes de producción permiten obtener mejores precios en los pedidos al por mayor

- Ideal para la fabricación de grandes volúmenes y aplicaciones sensibles a los costes

- Capacidad de producción ampliable

- Los proveedores chinos, como Shanghai Truer, pueden satisfacer pedidos de 1 a más de 100 toneladas

- MOQs flexibles adaptados a pequeños y grandes compradores

- Tecnología de fabricación avanzada

- Adopción de equipos de atomización de agua y gas

- I+D propio para mezclas en polvo personalizadas

- Plazos de entrega rápidos

- Optimización de la logística y las rutas de transporte

- Ciclos de producción más rápidos que los de los competidores occidentales

- Servicio multilingüe de atención al cliente

- Asistencia técnica y comercial en inglés

- comunicación permanente por correo electrónico, WeChat y WhatsApp

Ejemplo de caso: Shanghai Truer Technology Co., Ltd

Shanghai Truer es un proveedor chino líder que combina asequibilidad, conocimientos técnicos y personalización para compradores internacionales. Con más de una década de experiencia en pulvimetalurgia y materiales aditivos, apoyan a los socios globales con:

- Mezclas en polvo a medida (SC100.26 + grafito/lubricantes)

- Documentación técnica (SDS, COA, TDS)

- Envases listos para la exportación y gestión global de envíos

Para obtener más información sobre la trayectoria, la capacidad de I+D y las certificaciones de Shanghai Truer, visite su página web Quiénes somos.

8. Por qué elegir Shanghai Truer como proveedor

Shanghai Truer Technology Co., Ltd ofrece una solución completa para las empresas que se abastecen de polvo de hierro SC100.26 y materiales PM relacionados. No se trata sólo de un proveedor de materias primas, sino también de un proveedor de servicios socio técnico, experto en personalización, y facilitador logístico.

Qué hace de Truer el socio B2B ideal:

| Característica | Ventajas para los compradores |

|---|---|

| Tecnología de atomización propia | Calidad controlada & coherencia |

| Integración aditiva completa | Polvos premezclados adaptados a sus especificaciones |

| Capacidad de exportación internacional | Envíos eficaces a todo el mundo, incluidos Europa y EE.UU |

| Opciones de envasado a granel | sacos de 25 kg, sacos jumbo de 1 tonelada, bidones sellados |

| Asistencia técnica especializada | Ingenieros de aplicaciones disponibles para consultas |

Productos destacados:

- SC100.26 Polvo de hierro (estándar y personalizado)

- Aceros aleados por difusión: FD-0208, FD-0200, etc.

- Aceros híbridos de baja aleación: FX-2008, FX-1005

- Aditivos: SUW-8000 (lubricantes), SME-100 (agentes de corte), TBC-1000 (grafito)

Casos de uso en el mundo real:

- Proveedores de automoción de primer nivel que utilizan SC100.26 + grafito para engranajes de transmisión

- Los fabricantes de equipos electrónicos buscan mezclas de aditivos magnéticos blandos

- Fabricantes de herramientas que utilizan SC100.26 con SUW-5000B para piezas resistentes al desgaste

Los MOQ flexibles, la rapidez de entrega y el asesoramiento técnico de Shanghai Truer los convierten en la mejor opción para distribuidores, mayoristas y fabricantes de equipos originales.

Para empezar a trabajar con Truer, póngase en contacto a través de este formulario de contacto.

9. Preguntas frecuentes: Compra de hierro en polvo SC100.26 a granel

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para SC100.26?

A: Shanghai Truer ofrece opciones flexibles de MOQ a partir de 500 kg para lotes de prueba y 1 tonelada para pedidos estándar a granel.

P2: ¿Se puede personalizar SC100.26 con aditivos?

A: Sí, Truer puede premezclar SC100.26 con grafito, cobre, lubricantes (por ejemplo, SUW-8000), etc. para satisfacer las necesidades de su aplicación.

P3: ¿Qué certificaciones ofrece Truer?

A: Todos los envíos incluyen la certificación ISO 9001, SDS, COA y hojas de datos técnicos. Documentación personalizada disponible previa solicitud.

P4: ¿Cuál es el plazo de entrega de los pedidos internacionales?

A: El plazo de producción suele ser de 7 a 14 días, más gastos de envío. Hay opciones exprés disponibles para pedidos urgentes.

P5: ¿Puedo solicitar una muestra para pruebas de laboratorio?

A: Sí, Truer suministra muestras de 1-5 kg para I+D y pruebas piloto previa solicitud.

P6: ¿En qué tamaño de partícula se suministra el SC100.26?

A: El tamizado estándar SC100.26 es de 100 mallas, pero se pueden realizar tamizados personalizados de 200 mallas o más finos, en función de la aplicación.

P7: ¿Cómo se envasa el producto para la exportación?

A: Las opciones incluyen:

- sacos sellados de PE de 25 kg

- sacos jumbo de 1 tonelada

- Bidones sellados al vacío para entornos sensibles

P8: ¿Es SC100.26 adecuado para la fabricación aditiva?

A: Aunque se utiliza principalmente en prensado y sinterizado, el SC100.26 puede servir como material base en la fabricación aditiva si se procesa correctamente.

P9: ¿Dónde puedo encontrar otros polvos PM?

A: Puede consultar el catálogo completo de productos de latón, bronce, acero inoxidable y polvos aleados en Página de polvos PM de Truer.

🔗 Resumen de enlaces de texto de anclaje interno (5 en total)

| Texto de anclaje | URL |

|---|---|

| Toda la gama de polvos PM de Truer | https://am-material.com/pm-powder/ |

| Acerca de Shanghai Truer | https://am-material.com/about/ |

| Página de contacto de Shanghai Truer | https://am-material.com/contact-us/ |

| La gama completa de polvos PM de Truer | https://am-material.com/pm-powder/ |

| Página de polvos PM de Truer | https://am-material.com/pm-powder/ |

Esta completa guía proporciona todo lo que un comprador B2B necesita saber sobre el aprovisionamiento de polvo de hierro SC100.26, desde aplicaciones y especificaciones hasta los principales proveedores y procedimientos de pedido. Si está preparado para racionalizar su cadena de suministro con materiales PM de alta calidad, póngase en contacto con Shanghai Truer hoy mismo y solicite un presupuesto o una muestra.