1. Introducción: Por qué el polvo SBK2218 es importante en pulvimetalurgia

El polvo SBK2218 es un material pulvimetalúrgico (PM) de alto rendimiento conocido por su equilibrio optimizado de fuerza, resistencia al desgaste y compresibilidad. Este polvo se utiliza ampliamente en la fabricación de componentes sinterizados para automoción, maquinaria y aplicaciones industriales.

Para los compradores B2B, especialmente distribuidores, fabricantes de componentes y OEM, comprender las características de rendimiento exclusivas del polvo SBK2218 es clave para seguir siendo competitivos en el panorama actual de la ingeniería, en rápida evolución.

Por qué el polvo SBK2218 está ganando popularidad entre los compradores mayoristas:

- Alta resistencia en verde para una compactación estable

- Excelente templabilidad y estabilidad dimensional

- Adecuado para piezas mecánicas de alta carga

- Ideal para líneas de producción automatizadas de gran volumen

Compradores B2B más beneficiados:

- Fabricantes de piezas para automóviles

- OEM de maquinaria pesada

- Proveedores de componentes pulvimetalúrgicos

- Distribuidores industriales en busca de materiales PM de alta calidad

📌 ¿Busca obtener SBK2218 en polvo directamente de un proveedor certificado? Visite nuestro PM polvo página de producto para especificaciones, muestras y precios al por mayor.

2. Principales aplicaciones industriales del polvo SBK2218

SBK2218 es un polvo de acero aleado por difusión que destaca por sus propiedades mecánicas y su rendimiento de sinterización superiores. Suele utilizarse cuando se requiere una mayor resistencia mecánica y a la fatiga.

Principales aplicaciones en los sectores B2B:

| Industria | Área de aplicación | Ejemplos de componentes |

|---|---|---|

| Automotor | Sistemas de transmisión, sistemas de frenado | Engranajes, piñones, bujes |

| Maquinaria industrial | Transmisión de potencia, herramientas de alto esfuerzo | Casquillos, levas, acoplamientos |

| Equipos de ingeniería | Piezas portantes | Soportes estructurales, manguitos |

Ventajas para los grandes fabricantes:

- Calidad y rendimiento homogéneos en grandes lotes

- Compatibilidad con operaciones automatizadas de prensa y sinterización

- Reducción del mecanizado gracias a la fabricación en forma de red

- Rentable para grandes pedidos OEM

Ejemplo de caso:

Un proveedor de automoción de primer nivel del sudeste asiático adoptó el polvo SBK2218 para fabricar bujes de engranajes. El cambio mejoró la resistencia mecánica en un 12% y redujo el tiempo de mecanizado posterior a la sinterización en un 30%, mejorando la eficiencia de la producción.

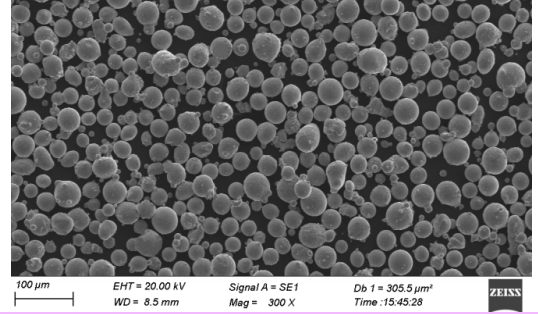

3. Propiedades técnicas y composición del polvo SBK2218

Comprender las especificaciones técnicas es esencial para los responsables de compras, ingenieros y desarrolladores de productos, que deben ajustar las propiedades de los materiales a las necesidades de las aplicaciones.

Composición técnica del polvo SBK2218:

| Elemento | Contenido típico (%) |

|---|---|

| Fe (Hierro) | Saldo |

| C (Carbono) | 0.2 - 0.4 |

| Cu (Cobre) | ~2.0 |

| Ni (Níquel) | ~1.8 |

| Mn (Manganeso) | ~0.5 |

| Mo (molibdeno) | ~0.5 |

Propiedades físicas:

| Propiedad | Valor |

|---|---|

| Densidad aparente | 2.90-3,10 g/cm³ |

| Caudal | < 30 s/50g |

| Compresibilidad | Alta |

| Densidad sinterizada | 6.6-7,2 g/cm³ |

| Dureza (HRB) | 80-90 |

| Resistencia a la tracción | 700 MPa tras la sinterización |

Actuaciones destacadas:

- Excelente resistencia mecánica sinterizada

- Alta densidad verde para una compactación superior

- Bajo cambio dimensional durante la sinterización

- Adecuado para piezas que requieren tratamiento térmico

Compatibilidad de producción:

El polvo SBK2218 es especialmente compatible con las técnicas automatizadas de prensado y sinterización, y puede someterse a operaciones secundarias como el calibrado, el mecanizado y el tratamiento térmico. Esto lo hace muy atractivo para compradores B2B de gran volumen que buscan un rendimiento constante y escalable.

🔍 ¿Quiere saber más sobre nuestras capacidades de producción? Explore Shanghai Truer’perfil de la empresa para ver qué nos convierte en un proveedor de polvo PM de confianza.

4. Tendencias del mercado mundial y oportunidades de crecimiento

La industria pulvimetalúrgica (PM) está experimentando un rápido crecimiento, impulsada por la creciente demanda de componentes ligeros y de alto rendimiento en los sectores de automoción, aeroespacial e industrial. El polvo SBK2218, como acero aleado por difusión con excelentes propiedades mecánicas, está posicionado para beneficiarse de estas tendencias.

🔍 Principales impulsores del crecimiento del mercado:

- Aligeramiento en automoción: El impulso a la eficiencia del combustible y vehículos eléctricos está aumentando la demanda de materiales resistentes pero ligeros como el SBK2218.

- Eficiencia de costes en la fabricación: PM permite la producción de formas casi netas, reduciendo el desperdicio de material y los costes de mecanizado.

- Expansión de los mercados de vehículos eléctricos e híbridos: La SBK2218 es ideal para fabricar componentes estructurales y de transmisión para vehículos eléctricos.

- Automatización industrial: Los fabricantes de robots, herramientas y equipos buscan materiales de alta resistencia y compactables para piezas complejas.

🌍 Previsión del mercado mundial:

| Región | CAGR del mercado (2024-2030) | Principales impulsores |

|---|---|---|

| Asia-Pacífico | 7.2% | Automoción, automatización industrial, fabricación rentable |

| Norteamérica | 6.5% | Aeroespacial, componentes de vehículos eléctricos, inversiones en I+D |

| Europa | 6.8% | Normativa sobre sostenibilidad, aligeramiento |

| América Latina | 5.9% | Desarrollo de infraestructuras, exportación de automóviles |

Instantánea de la oportunidad B2B:

- 📦 Los distribuidores pueden diversificar sus líneas de productos con polvos PM de alta demanda.

- 🏭 Los fabricantes de equipos originales pueden reducir los costes de producción cambiando a SBK2218 para componentes de alta resistencia.

- 📈 Los exportadores pueden acceder a los mercados emergentes con carteras de materiales de alto rendimiento.

📘 ¿Quieres mantenerte a la vanguardia de la industria PM? Consulte nuestra blog y sección de noticias para estar al día de las últimas novedades.

5. Cómo elegir el proveedor de polvo SBK2218 adecuado

Elegir al proveedor adecuado de polvo SBK2218 es fundamental para garantizar una calidad constante, una entrega fiable y asistencia técnica. Los compradores B2B deben evaluar múltiples factores antes de finalizar su estrategia de abastecimiento.

✅ Criterios clave para la evaluación de proveedores:

| Criterios | Por qué es importante |

|---|---|

| Consistencia en polvo | Garantiza la estabilidad mecánica y dimensional en la producción en serie |

| Capacidad de producción | Soporta grandes & pedidos urgentes sin retrasos |

| Asistencia técnica | Ayuda a optimizar los parámetros de sinterización y el diseño de las piezas |

| Personalización | Ofrece flexibilidad de composición y granularidad |

| Certificaciones | Garantiza el cumplimiento de las normas internacionales de calidad |

| Logística & Plazo de entrega | Reduce el tiempo de inactividad y los riesgos de inventario |

| Precios y condiciones | Repercusión en el coste total de propiedad y el ROI |

🔍 Preguntas que deben hacerse los compradores B2B:

- ¿Cuál es su capacidad de producción mensual de SBK2218?

- ¿Pueden facilitar informes de coherencia composicional lote a lote?

- ¿Ofrecen asesoramiento técnico para retos de sinterización?

- ¿Tiene la certificación ISO 9001 o IATF?

- ¿Cuál es su MOQ y plazo de entrega para envíos internacionales?

consejo: Los proveedores con capacidades internas de I+D y pruebas suelen ofrecer un mejor valor a largo plazo a través de la innovación y la asistencia.

6. Top SBK2218 Polvo Fabricantes y Distribuidores en China

China es uno de los líderes mundiales en la fabricación de pulvimetalurgia, con varias empresas que ofrecen SBK2218 y otros polvos de acero aleado. A continuación, los principales actores para los compradores B2B.

🇨🇳 Principales proveedores chinos de polvo SBK2218:

| Nombre de la empresa | Puntos fuertes | Capacidad de exportación | Ubicación |

|---|---|---|---|

| Shanghai Truer Technology Co. | Proveedor de soluciones PM completas, tecnología de atomización avanzada, excelente soporte técnico | envío internacional | Shanghai |

| ABC Powder Metallurgy Co. | Pedidos al por mayor rentables | Limitado | Guangdong |

| Grupo de materiales PMTech | Mezclas de polvos a medida, investigación y desarrollo | ✅ | Jiangsu |

| SinoAlloy Polvos | Bueno para pequeños fabricantes | ❌ (Enfoque nacional) | Hebei |

| Allied Metallurgy China | Calidades estándar de bajo coste | ✅ | Zhejiang |

más información Capacidades de Shanghai Truer y cómo ayudamos a clientes de todo el mundo con soluciones personalizadas de polvo PM.

7. Por qué cada vez más compradores compran polvo SBK2218 en China

La industria pulvimetalúrgica china ha evolucionado notablemente en la última década, ofreciendo ventajas competitivas en precios, escalabilidad e innovación. El polvo SBK2218, en particular, ha experimentado un aumento de las exportaciones a Europa, el Sudeste Asiático y América.

🚀 Ventajas de abastecerse en China:

- Eficiencia de costes: Los menores costes de producción y mano de obra permiten precios competitivos.

- Fabricación avanzada: La adopción de tecnologías de atomización (agua, gas, combinada) garantiza una alta calidad.

- Alta capacidad: Los grandes proveedores garantizan un suministro estable para pedidos B2B de gran volumen.

- Soluciones a medida: Muchos proveedores chinos, como Shanghai Truer, ofrecen composiciones y mezclas a medida.

- Políticas comerciales favorables: La sólida infraestructura logística y las zonas francas permiten un rápido transporte marítimo mundial.

🌐 Por qué los compradores B2B prefieren a los proveedores chinos:

- Capacidad para gestionar los requisitos de OEM y ODM

- Equipos técnicos y laboratorios internos sólidos

- Asistencia multilingüe y servicio de atención al cliente reactivo

- Experiencia probada con marcas mundiales de automoción y maquinaria

📩 ¿Está interesado en adquirir polvo SBK2218 de un proveedor chino fiable? Póngase en contacto con nosotros a través de nuestro página de contacto para solicitar un presupuesto o una muestra.

8. Por qué elegir Shanghai Truer Technology como su proveedor de SBK2218

Shanghai Truer Technology Co., Ltd. es un líder reconocido en la industria pulvimetalúrgica china, que ofrece una amplia gama de polvos PM y materiales de fabricación aditiva. Con una experiencia que se remonta a 2009 y una división dedicada a PM lanzada en 2019, Truer es un proveedor de confianza para clientes B2B de todo el mundo.

🏆 Por qué los compradores B2B confían en Truer:

| Característica | Ventajas para los compradores |

|---|---|

| Integración vertical completa | Desde la fabricación de polvo hasta la asistencia técnica |

| Métodos avanzados de atomización | Agua, gas y opciones combinadas para una calidad óptima |

| Normas internacionales | Los procesos con certificación ISO garantizan el cumplimiento global |

| Amplia gama de productos | SBK2218, FD-0208, FN-0205, FC-0208, etc |

| Soluciones aditivas personalizadas | Lubricantes (Lube-W, SUW-5000B), grafito (TBC-400), agentes de corte (TD-8) |

| Plazos de entrega rápidos | Procesos eficaces de logística y exportación |

| Conocimientos técnicos | Ingenieros y metalúrgicos de apoyo in situ |

🌍 Alcance mundial de Truer:

- Exportación a más de 20 países, entre ellos Alemania, Brasil, India y EE.UU.

- Apoyo a fabricantes de equipos originales, distribuidores y fabricantes de componentes

- Soporte multilingüe para una comunicación fluida

🔗 Explore toda nuestra cartera de productos, incluido el SBK2218, en nuestra Página de polvos PMdonde podrá descargar fichas técnicas y solicitar muestras.

9. Cómo pedir polvo SBK2218 al por mayor a Shanghai Truer

Para los compradores B2B, ya sean distribuidores, fabricantes de equipos originales o vendedores de comercio electrónico, el pedido de polvo SBK2218 a Shanghai Truer Technology es un proceso fluido diseñado para satisfacer tanto las necesidades de pequeño volumen como las de gran volumen. La cadena de suministro, la logística y los equipos de asistencia técnica de Truer trabajan en sincronía para garantizar una entrega puntual y una calidad constante del producto.

🛒 Proceso de pedido paso a paso

| Paso | Descripción | Notas |

|---|---|---|

| 1. Solicitud de información | Póngase en contacto con nuestro equipo de ventas a través de formulario de contacto o envíe un correo electrónico con sus requisitos | Incluya especificaciones, cantidad, destino |

| 2. Consulta técnica | Nuestros ingenieros recomiendan materiales y confirman las especificaciones del polvo | Opcional pero recomendado para mayor precisión |

| 3. Presupuesto y muestra | Proporcionamos un presupuesto detallado que incluye los gastos de envío y ofrecemos muestras a petición del cliente | MOQ depende del grado |

| 4. Realización de pedidos | Confirme su pedido con un contrato de compra o un pedido | Personalización OEM/ODM disponible |

| 5. Producción & Pruebas | Comienza la fabricación, con pruebas de control de calidad y de lotes para garantizar la coherencia | Plazo de entrega: 7-15 días según cantidad |

| 6. Embalaje y envío | Embalaje seguro y logística internacional concertada | Ex-works, CIF, FOB opciones disponibles |

| 7. Asistencia posventa | Asistencia técnica y de atención al cliente permanente | Para ayuda sobre sinterización, resolución de problemas, etc. |

📦 Opciones de embalaje para compradores B2B:

- sacos precintados de 25 kg

- bidones de 500 kg

- Envases a granel personalizados para OEM

🌍 Capacidades de envío y exportación

- Envíos a todo el mundo por vía marítima, aérea y exprés

- Socios logísticos: DHL, FedEx, Maersk

- Documentación lista para la exportación: MSDS, COA, RoHS, REACH si es necesario

📩 ¿Listo para hacer un pedido o solicitar una muestra? Envíe su solicitud a través de nuestro página de contacto y nuestro equipo le responderá en 24 horas.

10. Preguntas frecuentes: Todo lo que los compradores deben saber sobre la pólvora SBK2218

A continuación encontrará las preguntas más frecuentes de los compradores B2B que están considerando el polvo SBK2218 para sus necesidades de fabricación o distribución.

❓ ¿Para qué se utiliza mejor el polvo SBK2218?

SBK2218 es ideal para piezas estructurales que requieren alta resistencia y resistencia al desgaste, tales como:

- Engranajes y bujes de automoción

- Componentes de transmisión de potencia

- Piezas de maquinaria industrial

❓ ¿Cuál es la diferencia entre SBK2218 y FD-0208?

| Característica | SBK2218 | FD-0208 |

|---|---|---|

| Composición | Aleación por difusión con Cu, Ni, Mo | Aleación por difusión con Cu, Ni |

| Fuerza | Mayor resistencia mecánica | Resistencia moderada |

| Aplicaciones | Piezas de alta carga y rendimiento crítico | Componentes estructurales generales |

¿Cuáles son las cantidades mínimas de pedido?

- MOQ para SBK2218 estándar: 100 kg

- MOQ para mezclas o envases personalizados: 500 kg

- Cantidades de muestra (1-2 kg) disponibles para las pruebas

❓ ¿Puede Truer personalizar los grados de polvo en función de nuestra aplicación?

Sí Shanghai Truer ofrece servicios de diseño de polvo OEM. Usted puede solicitar:

- Composición química ajustada

- Distribución granulométrica modificada

- Lubricantes o aditivos mezclados a medida

❓ ¿Qué certificaciones cumple su polvo SBK2218?

- ISO 9001: Gestión de la calidad

- Conformidad RoHS/REACH bajo pedido

- Informes internos de COA y pruebas por lotes

❓ ¿Cómo puedo garantizar la homogeneidad entre lotes?

Truer realiza pruebas lote a lote que incluyen:

- Análisis granulométrico

- Pruebas de caudal

- Composición química por espectrometría

- Mediciones de densidad en verde y sinterizada

💼 Obtenga más información sobre nuestras capacidades de control de calidad e I+D en nuestro Quiénes somos.

❓ ¿Apoyan a compradores internacionales y fabricantes de equipos originales?

Sí. Enviamos SBK2218 polvo a nivel mundial y el apoyo:

- Fabricación OEM/ODM

- Documentación personalizada

- Asistencia técnica y comercial multilingüe

Conclusión: Por qué el polvo SBK2218 de Truer es su mejor elección B2B

Shanghai Truer Technology es más que un simple proveedor: somos su socio estratégico en pulvimetalurgia. Con más de una década de experiencia y capacidades de fabricación de vanguardia, ofrecemos polvo SBK2218 que cumple con los exigentes requisitos de las industrias de alto rendimiento de hoy en día.

🌟 Resumen de las principales ventajas:

- ✅ Polvo SBK2218 de alto rendimiento y calidad constante

- ✅ Producción flexible de calidades estándar y personalizadas

- ✅ Precios competitivos con entrega mundial

- ✅ Asistencia técnica completa para aplicaciones B2B

- ✅ Con la confianza de fabricantes de equipos originales, distribuidores y fabricantes de primer nivel de todo el mundo

📈 Da el siguiente paso

Si está ampliando su línea de productos, optimizando su proceso de fabricación o introduciéndose en un nuevo mercado, el polvo SBK2218 de Truer puede darle ventaja. Respaldados por una amplia experiencia técnica y sólidos sistemas de control de calidad, estamos aquí para ayudar a que su negocio tenga éxito.

🔗 Visite nuestro PM Polvo Página de producto para descargar fichas técnicas, buscar productos relacionados e iniciar su búsqueda de proveedores.

🔗 Resumen de enlaces internos incrustados (5 en total):

- PM polvo página de producto

- Perfil de la empresa Shanghai Truer

- Blog y sección de noticias

- Página de contacto

- PM Polvo Página de producto

Si usted es un comprador B2B en busca de polvo SBK2218 fiable y de alto rendimiento, Shanghai Truer Technology está preparada para satisfacer sus necesidades con precisión, profesionalidad y asistencia de primera clase.