1. Introducción: Qué es el polvo SBK1218 y por qué es importante en la industria PM

El polvo SBK1218 es un acero pulvimetalúrgico (PM) prealeado y atomizado con agua que se utiliza ampliamente en componentes estructurales que requieren alta resistencia, resistencia al desgaste y un excelente control dimensional. Este polvo es un material de alto rendimiento utilizado habitualmente en las industrias de automoción, aeroespacial y de utillaje debido a su fiable capacidad de densificación y a sus equilibradas propiedades mecánicas.

En la industria pulvimetalúrgica (PM), materiales como el SBK1218 ofrecen:

- Producción en serie rentable

- Reducción del desperdicio de material en comparación con el mecanizado

- Mayor control de la microestructura

- Resistencia verde superior y densidad sinterizada

Por qué SBK1218 es importante para los compradores y distribuidores de PM:

| Característica | Ventajas para los compradores B2B |

|---|---|

| Composición prealeada | Calidad constante y rendimiento previsible |

| Alta compresibilidad | Menor desgaste y mayor vida útil de las herramientas |

| Excelente resistencia al desgaste | Ideal para aplicaciones de alta carga y alta fricción |

| Propiedades endurecibles por sinterización | Elimina la necesidad de un tratamiento térmico secundario |

Esto hace que el SBK1218 resulte especialmente atractivo para:

- Fabricantes de piezas de automóviles

- Fabricantes de piezas pulvimetalúrgicas

- Los OEM industriales buscan soluciones duraderas de PM

2. Principales aplicaciones del polvo SBK1218 en la fabricación

El polvo SBK1218 está diseñado para ofrecer versatilidad en diversos sectores industriales. Su resistencia mecánica y al desgaste lo hacen ideal para componentes que deben soportar grandes tensiones y fricciones. Entre las aplicaciones más comunes se incluyen:

Industria del automóvil

- Cubos y engranajes sincronizadores

- Poleas del árbol de levas

- Bielas

- Piezas de amortiguador

Herramientas y maquinaria

- Bujes

- Rodamientos

- Ruedas dentadas

- Portaherramientas de corte

Otras aplicaciones industriales

- Piezas de bombas hidráulicas

- Componentes del compresor

- Piezas de motores eléctricos

Matriz de aplicación del polvo SBK1218:

| Área de aplicación | Componentes comunes | Ventajas de SBK1218 |

|---|---|---|

| Automotor | Engranajes, bujes, bielas | Alta resistencia a la fatiga y al desgaste |

| Herramientas eléctricas | Cojinetes, casquillos | Precisión dimensional, fiabilidad |

| Maquinaria | Engranajes, piezas estructurales | Capacidad de carga, durabilidad |

| Aeroespacial (no crítico) | Anillos guía, soportes | Ligero y resistente |

Para los compradores que deseen adquirir al por mayor materiales PM de alto rendimiento, SBK1218 ofrece un equilibrio ideal entre coste y funcionalidad.

3. Composición química y propiedades mecánicas de SBK1218

El SBK1218 está clasificado como un acero PM híbrido de baja aleación con una formulación avanzada que mejora su rendimiento en entornos exigentes.

Composición química típica (%)

| Elemento | Contenido (%) |

|---|---|

| Hierro (Fe) | Saldo |

| Carbono (C) | ~0.18 |

| Níquel (Ni) | ~1.5 |

| Molibdeno (Mo) | ~0.5 |

| Cobre (Cu) | ~1.5 |

| Manganeso (Mn) | ~0.5 |

| Otros | Oligoelementos |

Propiedades mecánicas tras la sinterización y el tratamiento térmico

| Propiedad | Rango de valores |

|---|---|

| Densidad sinterizada | 6.8 - 7,2 g/cm³ |

| Resistencia a la tracción | 600 - 750 MPa |

| Límite elástico | 500 - 650 MPa |

| Alargamiento | 1.5% - 3.0% |

| Dureza (HRB) | 85 - 95 |

| Resistencia al impacto | Moderado |

Estas propiedades convierten a SBK1218 en la solución ideal para piezas que deben soportar esfuerzos mecánicos repetidos y cargas dinámicas.

Ventajas para compradores mayoristas y distribuidores:

- Prealeado para un comportamiento de sinterización uniforme

- Entrega fiable para los plazos de producción de los OEM

- Compatible con los sistemas de procesamiento PM estándar

- Alto aprovechamiento del material y mecanizado mínimo

Los distribuidores y revendedores pueden incluir SBK1218 con confianza en su cartera de productos, ofreciendo soluciones de valor añadido a los fabricantes de piezas PM.

4. Demanda del mercado mundial y tendencias de crecimiento de los aceros PM

El mercado mundial de la pulvimetalurgia está experimentando un fuerte crecimiento, impulsado por la creciente demanda de materiales ligeros, rentables y de alto rendimiento. El polvo SBK1218, un acero híbrido de baja aleación, es fundamental en esta tendencia por su versatilidad en una amplia gama de aplicaciones estructurales.

Tendencias del mercado que influyen en la demanda de SBK1218:

- Iniciativas de aligeramiento en automoción: Los fabricantes de automóviles están sustituyendo las piezas forjadas o fundidas tradicionales por componentes de PM para reducir el peso de los vehículos y mejorar la eficiencia del combustible.

- Electrificación de vehículos: Mayor uso de piezas PM en motores eléctricos, sistemas de frenado y componentes de transmisión.

- Automatización industrial: Más engranajes PM y piezas estructurales utilizadas en robótica y maquinaria automatizada.

- Optimización de costes: Los fabricantes prefieren cada vez más los aceros PM como el SBK1218, ya que reducen el desperdicio de material y los costes de producción.

Panorama del mercado mundial del acero PM

| Región | Cuota de mercado (%) | Industrias clave que impulsan la demanda |

|---|---|---|

| Asia-Pacífico | 42% | Automoción, electrónica, maquinaria |

| Norteamérica | 27% | Aeroespacial, automoción, defensa |

| Europa | 21% | Automoción, automatización industrial |

| Resto del mundo | 10% | Mercados emergentes de América Latina y África |

Previsiones clave:

- Se prevé que el mercado del acero PM crezca a una TCAC del 10,2% (2024-2030)

- Se espera que la demanda de SBK1218 crezca especialmente en Asia-Pacífico debido a la expansión de la cadena de suministro de los OEM

Dadas estas tendencias, compradores a granel, fabricantes de equipos originales y distribuidores deberían plantearse establecer ahora relaciones fiables con los proveedores para asegurarse precios competitivos y entregas constantes.

5. Elección del proveedor de polvo SBK1218 adecuado: En qué fijarse

Cuando se adquiere polvo SBK1218 a granel, especialmente para aplicaciones B2B, es fundamental evaluar a los proveedores en función de factores clave de calidad, técnicos y logísticos.

Lista de comprobación para seleccionar un proveedor fiable de SBK1218

A. Capacidades técnicas:

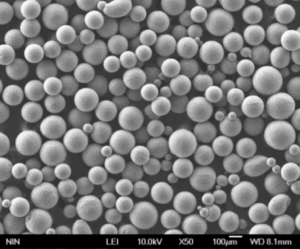

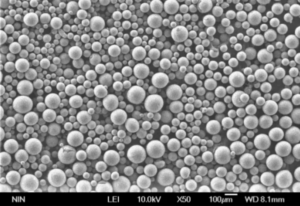

- ¿Ofrece el proveedor una distribución homogénea del tamaño de las partículas?

- ¿Son capaces de atomizar con agua o con técnicas de atomización híbridas?

- ¿Proporcionan fichas técnicas y certificados de aprobación?

B. Garantía de calidad:

- Procesos de fabricación con certificación ISO

- Sistemas avanzados de control de calidad, incluidas pruebas de propiedades químicas y mecánicas

- Trazabilidad de los lotes y documentación completa

C. Suministro a granel & Logística:

- Entrega puntual con apoyo logístico mundial

- Capacidad de producción escalable para las demandas de los OEM

- Gestión de inventarios y opciones JIT (Just-In-Time)

D. Asistencia y personalización:

- Asistencia técnica a petición para la optimización de la sinterización y el prensado

- Capacidad para adaptar las mezclas de polvos a las necesidades específicas de cada proyecto

Tabla de evaluación de proveedores

| Criterios de evaluación | Nivel de importancia | Preguntas |

|---|---|---|

| Método de atomización | Alta | ¿Agua o híbrido? Afecta a la compresibilidad y la densidad |

| Control del tamaño de las partículas | Alta | ¿Es constante el intervalo D50 en todos los lotes? |

| Plazo de entrega | Alta | ¿Puede el proveedor cumplir su calendario de producción? |

| Asistencia técnica | Medio | ¿Existe un equipo técnico o de I+D que apoye a su equipo? |

| Competitividad de precios | Medio | ¿Son favorables los precios y las condiciones de pago para los pedidos al por mayor? |

Para los compradores que buscan reducir el riesgo operativo y garantizar la continuidad del suministro, es esencial trabajar con un proveedor establecido y de confianza.

6. Top SBK1218 Polvo Proveedores en China

China alberga algunas de las instalaciones de producción de polvo de PM más avanzadas del mundo. A continuación se muestran cinco proveedores líderes de polvo SBK1218 conocidos por su calidad, consistencia y fiabilidad de la cadena de suministro.

| Nombre del proveedor | Ubicación | Destacados |

|---|---|---|

| Shanghai Truer Technology Co., Ltd | Shanghai | Uno de los proveedores de polvo de PM más profesionales de China, con capacidad de servicio completo |

| CNPC Powder Material Co., Ltd | Changzhou | Especializada en polvos atomizados por agua y por gas |

| Hunan 3D Materials S.L | Changsha | Ofrece una gama de polvos a base de hierro para Impresión 3d y PM |

| Foshan Powmet Metal Products Co. | Foshan | Centrado en el suministro de polvo de partículas para automoción |

| Fabricación aditiva Xi'an Sailong | Xi'an | Conocida por sus polvos metálicos de gran pureza y su apoyo a la investigación |

De estos, Tecnología Truer de Shanghai destaca por su integración vertical, su amplia cartera de productos y su compromiso con la innovación tanto en el sector de la fabricación aditiva como en el de la PM tradicional.

7. Por qué cada vez más compradores se decantan por los fabricantes chinos de PM en polvo

A medida que evolucionan las estrategias globales de aprovisionamiento, un número cada vez mayor de fabricantes de equipos originales, fabricantes por contrato y distribuidores recurren a proveedores chinos de pulvimetalurgia para obtener polvos de acero de alto rendimiento como el SBK1218.

Razones clave del cambio:

- Ventaja coste-rendimiento: Los proveedores chinos ofrecen precios competitivos en todo el mundo sin comprometer la calidad.

- Capacidades de fabricación avanzada: Proveedores como Truer utilizan tecnologías de atomización y mezcla de última generación.

- Proximidad a los centros de fabricación: La ubicación y las infraestructuras de China la convierten en un centro de producción de componentes industriales y de automoción.

- Personalización y flexibilidad: A diferencia de algunos proveedores occidentales, las empresas chinas suelen ser capaces de adaptar las fórmulas en polvo a las necesidades específicas del cliente.

Ventajas logísticas y de exportación:

- Acceso portuario estratégico (Shanghai, Shenzhen, Ningbo)

- Agilización de la documentación aduanera y de exportación

- Compatibilidad con embalajes y etiquetados específicos de OEM

Para los compradores internacionales, abastecerse en China representa un paso estratégico hacia la eficiencia de costes, la fiabilidad del suministro y la colaboración técnica.

Echa un vistazo Shanghai Truer’s Perfil de la empresa para saber más sobre sus capacidades y su reputación en el sector.

8. Por qué elegir Shanghai Truer Technology como su proveedor de SBK1218

Shanghai Truer Technology Co., Ltd es uno de los nombres más confiables de China en pulvimetalurgia. Fundada en 2009, Truer entró en el sector de la fabricación aditiva en 2019 y desde entonces ha crecido hasta convertirse en un proveedor de servicios completos tanto de polvos para impresión 3D como de polvos tradicionales de PM.

¿Qué diferencia a Truer?

✔️ Gama completa de polvos PM:

Desde SBK1218 hasta FN-0205 y FL-4605, Truer ofrece una completa selección de polvos de acero estructural PM.

✔️ Experiencia en atomización:

Polvos atomizados con agua, con gas y de tecnología combinada para satisfacer necesidades específicas de compresibilidad y resistencia.

✔️ Soluciones integrales de aditivos:

Una línea específica de aditivos:

- Lubricantes Lube-W, SUW-5000B

- SME-100 agentes de corte sin azufre

- Agentes de corte compuestos TD-8

- QH-150 aditivos magnéticos blandos

- Grados de grafito como TBC-400 y TBC-1000

✔️ Excelencia técnica:

Un equipo de I+D ayuda a los clientes a desarrollar, probar y optimizar sus fórmulas de PM para obtener un rendimiento real.

Capacidades de la SBK1218 de Truer:

| Característica | Ofrenda de Truer |

|---|---|

| Método de atomización | Agua atomizada (opciones personalizables) |

| Embalaje | 25kg, 50kg, bolsas jumbo disponibles |

| Mezclas personalizadas | Disponible previa petición |

| Control de calidad | Documentación completa, normas ISO |

| Logística de exportación | Envíos internacionales y asistencia aduanera |

Explore el catálogo completo de Productos en polvo PM que le ofrece Truer para su próximo ciclo de contratación.

9. Cómo pedir polvo SBK1218 al por mayor a China

Pedir polvo SBK1218 a granel a un proveedor de confianza como Shanghai Truer Technology es un proceso sencillo, especialmente para compradores B2B, OEM y distribuidores familiarizados con las compras internacionales. Truer está bien equipado para manejar pedidos de gran volumen y ofrece flexibilidad para especificaciones personalizadas, embalaje y condiciones de entrega.

Guía de pedidos al por mayor paso a paso

Paso 1: Investigación inicial

- Visite el Página de contacto en AM-Material.com

- Rellene los datos de su empresa, los requisitos del producto y el volumen de pedidos previsto

- Incluya especificaciones como el tamaño de las partículas, la preferencia de envasado y el lugar de entrega

Paso 2: Consulta técnica y presupuesto

- Reciba una respuesta en un plazo de 24-48 horas del equipo técnico-comercial de Truer

- Hable de la aplicación prevista: automoción, utillaje, piezas estructurales, etc.

- Truer proporciona un presupuesto detallado que incluye el precio unitario, la cantidad mínima de pedido y el plazo de entrega

Paso 3: Prueba de muestras (opcional)

- Solicite un lote de muestra (1-5 kg) para ensayos de sinterización o pruebas de calidad

- Truer admite pedidos de prueba para validar el rendimiento del polvo antes de la adquisición a granel

Paso 4: Confirmación del pedido a granel

- Confirme la cantidad y las especificaciones

- Firmar un acuerdo de compra que incluya las condiciones de pago (T/T, L/C, etc.) y los Incoterms (EXW, FOB, CIF)

Paso 5: Producción y rampa; control de calidad

- Comienza la producción con métodos de atomización en agua o híbridos

- Cada lote se somete a un riguroso control de calidad (composición química, granulometría, densidad)

Paso 6: Embalaje y envío

- Los polvos se envasan en bolsas selladas de 25 kg o 50 kg, o en bolsas grandes para granel

- Etiquetado y documentación conformes con las normas de exportación

- Envío por vía aérea o marítima en función de la urgencia y el volumen del pedido

Paso 7: Asistencia posventa

- Asistencia técnica posterior a la entrega para el prensado, la sinterización y la optimización de aplicaciones

- Asistencia en la realización de pedidos y planificación de suministros para compradores a largo plazo

Ejemplo de resumen de condiciones de compra

| Plazo | Detalles |

|---|---|

| MOQ (Cantidad mínima de pedido) | 100 kg (personalizable para primeros compradores) |

| Plazos de entrega | 7-15 días laborables para polvos estándar |

| Opciones de entrega | FOB Shanghai, CIF, DDP disponible |

| Condiciones de pago | T/T (30/70), L/C para grandes pedidos |

| Embalaje | Bolsas de PE selladas al vacío dentro de bidones de acero o de fibra |

| Asistencia técnica | Consulta en línea, ayuda a la formulación |

| Certificación | ISO 9001, COA, MSDS, RoHS (a petición) |

Para iniciar su proceso de compra al por mayor, póngase en contacto con Truer a través de la dirección oficial Página de contacto o navegar por los disponibles Productos en polvo PM para más opciones.

10. FAQs: Todo lo que debe saber sobre la compra de polvo SBK1218 al por mayor

A continuación se presentan algunas de las preguntas más comunes que los compradores B2B, distribuidores y fabricantes de equipos originales hacen cuando consideran el polvo SBK1218 para sus necesidades de fabricación.

P1: ¿Cuál es el tamaño típico de las partículas del polvo SBK1218?

A: La gama estándar de tamaños de partícula va de -100 malla a -200 malla, pero se pueden solicitar tamaños personalizados (por ejemplo, -325 malla). La distribución granulométrica influye en la compresibilidad y la densidad final de la pieza.

P2: ¿Puede utilizarse SBK1218 sin tratamiento térmico secundario?

A: Sí. SBK1218 es endurecible por sinterización, lo que significa que en muchos casos no requiere tratamiento térmico adicional. Esto reduce los costes de producción y la duración de los ciclos.

P3: ¿Cuál es la temperatura de sinterización recomendada?

A: SBK1218 suele sinterizarse bien a 1120-1150°C en atmósfera reductora. Los parámetros específicos pueden variar en función de la geometría de la pieza y la densidad del verde.

P4: ¿Cómo se compara SBK1218 con FL-4605 o FN-0205?

A: SBK1218 ofrece una composición equilibrada, proporcionando una mejor resistencia al desgaste que FN-0205 y una compactación más fácil que FL-4605. Es ideal para piezas estructurales de resistencia media-alta.

| Propiedad | SBK1218 | FL-4605 | FN-0205 |

|---|---|---|---|

| Dureza | Moderado | Alta | Moderado |

| Densidad Potencial | Alta | Alta | Moderado |

| Resistencia al desgaste | Alta | Muy alta | Medio |

| Facilidad de compactación | Alta | Moderado | Alta |

P5: ¿Ofrece Truer mezclas de polvos personalizadas?

A: Shanghai Truer ofrece servicios personalizados de aleación y mezcla para clientes que necesitan propiedades mecánicas o magnéticas específicas. Su equipo de I+D colabora en la formulación, las pruebas y la producción.

P6: ¿Cuál es la vida útil del polvo SBK1218?

A: Cuando se almacena en envases sellados y en condiciones secas, el polvo SBK1218 tiene una vida útil de 12-24 meses. Mantenga siempre el material en un entorno fresco y seco para evitar la oxidación o la contaminación.

P7: ¿Puede Truer ayudar con los parámetros de prensado y sinterización de piezas verdes?

A: Absolutamente. El equipo técnico de Truer ayuda a los clientes con directrices de fuerza de prensado, ciclos de sinterización e incluso recomendaciones de diseño de herramientas para garantizar un rendimiento óptimo de las piezas.

P8: ¿Exporta Truer a todo el mundo?

A: Sí, Shanghai Truer realiza envíos a Norteamérica, Europa, Sudeste Asiático y Oriente Medio. Proporcionan documentación completa para la exportación, incluyendo MSDS, COA y documentos de aduanas.

Notas finales & Enlaces internos

Si eres un comprador mayorista, distribuidoro OEM si busca un suministro fiable de polvo SBK1218 de alto rendimiento, Shanghai Truer Technology le ofrece la combinación ideal de calidad, asistencia técnica y rentabilidad. Tanto si está lanzando una nueva línea de productos como si está optimizando una ya existente, la experiencia en pulvimetalurgia de Truer puede ayudarle a seguir siendo competitivo.

más información Antecedentes de la empresa Truer y misión de la PM

🔗 Consulta la lista completa de Productos en polvo PM, incluido SBK1218

🔗 Empieza tu pedido visitando nuestro Página de contacto

más información sobre Capacidades pulvimetalúrgicas de Truer

Al asociarse con Shanghai Truer, tendrá acceso a uno de los proveedores de polvos de polimerización más profesionales de China, lo que garantizará que su empresa se mantenga a la vanguardia en calidad, ahorro de costes e innovación.