1. Introducción: Por qué el polvo FD-0200 es fundamental en pulvimetalurgia

El polvo FD-0200 es un polvo de acero aleado por difusión ampliamente utilizado en pulvimetalurgia (PM) para la producción de componentes estructurales de alta resistencia. Diseñado para aplicaciones que requieren un equilibrio entre resistencia, maquinabilidad y rentabilidad, el FD-0200 destaca en los sectores de la automoción, la industria y el utillaje.

Desde un punto de vista B2B, los fabricantes, OEM y fabricantes de componentes a granel valoran el FD-0200 por su:

- Alta resistencia sinterizada

- Excelente estabilidad dimensional

- Rendimiento constante en grandes series de producción

- Procesamiento rentable en la fabricación de grandes volúmenes

Para los compradores y distribuidores al por mayor, el abastecimiento de FD-0200 de un proveedor fiable y constante es fundamental para garantizar la integridad de las piezas y la estabilidad de la cadena de suministro.

2. Aplicaciones industriales del polvo FD-0200

El perfil metalúrgico del polvo FD-0200 lo hace adecuado para una amplia gama de aplicaciones en múltiples sectores. A continuación se indican los sectores clave y los componentes típicos fabricados con este acero de calidad PM:

| Industria | Ejemplos de aplicación | Requisitos clave |

|---|---|---|

| Automotor | Cubos de engranaje, cubos sincronizadores, piñones del árbol de levas, bujes | Alta resistencia a la fatiga y al desgaste |

| Herramientas eléctricas | Carcasas estructurales, soportes de motor | Integridad estructural, maquinabilidad |

| Maquinaria agrícola | Engranajes, bridas, componentes de transmisión | Durabilidad, resistencia a la corrosión |

| Electrónica de consumo | Sistemas de cierre mecánico, soportes | Precisión dimensional, baja porosidad |

| Equipamiento industrial | Soportes, bridas, piezas de bombas | Alta densidad, resistencia a la tracción |

Principales ventajas para fabricantes de equipos originales y distribuidores:

- Reducción del desperdicio de material gracias a la fabricación con forma casi neta

- Menores costes de utillaje y mecanizado

- Compatibilidad con líneas de compactación y sinterización de alta velocidad

- Suministro fiable a granel para la producción a gran escala

3. Propiedades principales y especificaciones técnicas

El FD-0200 se clasifica como polvo de acero aleado por difusión. Normalmente contiene hierro, cobre y carbono, prealeados o unidos por difusión para proporcionar una microestructura uniforme y una mejor respuesta de sinterización. A continuación se ofrece un desglose técnico de sus características típicas:

| Propiedad | Especificación |

|---|---|

| Composición básica | Hierro-cobre-carbono |

| Densidad (Verde) | ~6,6 g/cm³ |

| Densidad (Sinterizado) | ~7,2 - 7,4 g/cm³ |

| Dureza típica | 20-30 HRC |

| Resistencia a la tracción | 550-700 MPa |

| Límite elástico | 440-580 MPa |

| Alargamiento | ~2-4% |

| Cambio dimensional | Baja; buena estabilidad |

Compatibilidad con métodos de procesado:

- Prensa única, sinterización única

- Doble prensado, doble sinterizado

- Compactación en caliente para piezas de mayor densidad

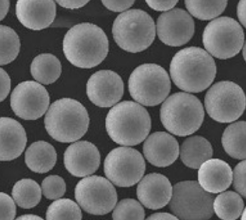

Características del polvo:

- Excelente fluidez

- Distribución uniforme del tamaño de las partículas

- Segregación mínima durante el transporte y el almacenamiento

Casos típicos de uso del FD-0200:

- Componentes de transmisión: La resistencia mecánica del polvo soporta las necesidades de carga de los engranajes y ruedas dentadas.

- Fijaciones y bujes: La precisión dimensional y la maquinabilidad lo hacen ideal para líneas de producción de alta velocidad.

- Piezas de bombas: La resistencia a la corrosión y la resistencia interna aumentan la vida útil en entornos expuestos a fluidos y aceites.

Para obtener datos técnicos más detallados y asistencia sobre el producto, visite la página web de Shanghai Truer FD-0200 Polvo Página de producto.

4. Demanda de mercado, tendencias y previsión de crecimiento del FD-0200

El mercado mundial de la pulvimetalurgia está en plena expansión, impulsado por la creciente demanda en los sectores de automoción, aeroespacial y maquinaria industrial. El polvo FD-0200 es uno de los más utilizados por su equilibrio entre rendimiento y coste, lo que lo convierte en un elemento básico en entornos de producción de gran volumen.

Principales tendencias del mercado que impulsan la demanda de FD-0200:

- Electrificación del automóvil: A medida que aumenta la adopción de vehículos eléctricos, se necesitan componentes PM ligeros y duraderos (como los fabricados con FD-0200) para motores, sistemas de engranajes y soportes estructurales.

- Rentabilidad de la producción en serie: Los fabricantes de equipos originales están sometidos a presiones para reducir costes. La fabricación de PM con FD-0200 ofrece eficiencia de materiales y menor coste total de producción en comparación con las piezas forjadas o mecanizadas.

- Impulso a la sostenibilidad: Con un desperdicio mínimo de material y una sinterización eficiente desde el punto de vista energético, los procesos de PM que utilizan FD-0200 se ajustan a los objetivos globales de sostenibilidad.

Previsiones de mercado:

| Región | CAGR (2024-2029) | Principales impulsores |

|---|---|---|

| Asia-Pacífico | 7.4% | Producción de automóviles, industrialización |

| Norteamérica | 5.9% | Aeroespacial, defensa, componentes de automoción |

| Europa | 6.2% | Crecimiento del VE, mandatos de fabricación ecológica |

FD-0200 Oportunidad para mayoristas:

- OEM y proveedores de primer nivel: Aumento de la demanda de piezas de gran volumen y resistencia.

- Fabricantes por contrato: Necesita un suministro de polvo constante y fiable para la producción por lotes.

- Distribuidores: Oportunidad de almacenar un material de gran demanda con tasas de reposición constantes.

5. Selección de un proveedor fiable de polvo FD-0200

Elegir al proveedor adecuado es fundamental para mantener la consistencia, la calidad y la fiabilidad de la producción de las piezas, especialmente cuando se trata de abastecerse en grandes cantidades para operaciones B2B.

Qué evaluar al elegir un proveedor:

| Factor | Importancia | Preguntas |

|---|---|---|

| Consistencia material | Alta | ¿La pólvora tiene certificación ISO? ¿Cuál es la tolerancia de desviación? |

| Capacidad de producción | Alta | ¿Puede el proveedor satisfacer mis necesidades de volumen a largo plazo? |

| Asistencia técnica | Medio | ¿Ofrecen asesoramiento técnico o mezclas personalizadas? |

| Fiabilidad de la entrega | Alta | ¿Cuál es el plazo de entrega? ¿Existen centros de distribución locales? |

| Precios y contratos | Medio | ¿Existen niveles de descuento por volumen o acuerdos de precios a largo plazo? |

| Reputación y experiencia | Alta | ¿Cuánto tiempo lleva el proveedor en la industria PM? |

Banderas rojas a evitar:

- Granulometría o uniformidad de mezcla incoherentes

- Falta de documentación o trazabilidad

- Sin equipo de asistencia B2B ni enlace técnico

- Capacidad de producción limitada o cadena de suministro inestable

Para una experiencia de aprovisionamiento B2B fiable, asegúrese de que su proveedor tiene una sólida experiencia en el sector, protocolos internos de control de calidad y la capacidad de personalizar soluciones en función de sus necesidades de producción.

6. Principales proveedores mundiales y distribuidores regionales

He aquí una comparativa de algunos de los nombres más fiables en el sector de la pólvora FD-0200:

| Compañía | Región | Puntos fuertes | Limitaciones |

|---|---|---|---|

| Höganäs AB | Europa | Alcance mundial, calidad constante | Precios especiales |

| Polvos metálicos de Río Tinto | Norteamérica | Gran capacidad, amplia línea de productos PM | Plazos de entrega más largos fuera de NA |

| Tecnología Truer de Shanghai | China | Precios competitivos, amplia gama de composición, tecnología avanzada | Lo mejor para los importadores B2B de Asia y el resto del mundo |

| Acero JFE | Japón | Polvos de hierro de alta calidad | Opciones de personalización limitadas |

| GKN Hoeganaes | Global | Amplia I+D, sólida red de PM | MOQ más elevados para pequeños compradores |

Por qué Shanghai Truer Technology está ganando cuota de mercado

Shanghai Truer Technology Co., Ltd está emergiendo como la opción preferida para el polvo FD-0200 entre los compradores B2B globales debido a:

- Experiencia acreditada: Más de 14 años en pulvimetalurgia y fabricación aditiva

- Gama completa de productos: Ofrece FD-0200 y docenas de otros polvos PM, incluidos aceros aleados por difusión, aceros inoxidables y grados híbridos de baja aleación

- Mezclas a medida y servicios de ingeniería: Capacidad de adaptar las soluciones de polvo para cumplir objetivos específicos de sinterización y densidad

- Tecnología de producción: Admite atomización por agua, atomización por gas y atomización combinada para una máxima flexibilidad

- Infraestructura de apoyo B2B: Gestión de cuenta dedicada, envío rápido y asistencia multilingüe

Los compradores pueden obtener más información sobre la historia y las capacidades de Truer en su Quiénes somos.

7. Por qué cada vez más compradores se decantan por proveedores chinos de FD-0200

En la última década, China ha emergido como líder mundial en la producción pulvimetalúrgica, ofreciendo avanzadas capacidades de fabricación y precios competitivos. Para los compradores B2B, especialmente mayoristas, fabricantes por contrato y OEM, abastecerse de polvo FD-0200 procedente de China presenta varias ventajas estratégicas.

Razones clave del cambio a proveedores chinos:

✅ Relación coste-eficacia

Los productores chinos de polvo de PM ofrecen precios significativamente más bajos sin comprometer la calidad, gracias a las economías de escala y a las cadenas de suministro integradas verticalmente.

✅ Capacidad de producción a gran escala

La industria china de fabricación de maquinaria permite la producción de grandes volúmenes con plazos de entrega rápidos, lo que resulta atractivo para los compradores de empresas que gestionan calendarios de fabricación ajustados.

✅ Procesos avanzados de fabricación

Los proveedores chinos modernos utilizan tecnologías de atomización de última generación (agua, gas, híbrida) y sólidos sistemas de control de calidad que rivalizan con los estándares occidentales.

✅ Flexibilidad de personalización

Los fabricantes chinos están más abiertos a mezclas personalizadas, variaciones de envasado y soluciones logísticas adaptadas a los compradores y distribuidores a granel.

✅ Cadenas de suministro más cortas en Asia-Pacífico

Para los compradores con sede en Asia-Pacífico, abastecerse en China reduce considerablemente el tiempo y los costes de envío en comparación con abastecerse en Norteamérica o Europa.

Errores comunes (desmentidos):

| Mito | Realidad |

|---|---|

| Los polvos chinos son de menor calidad | Los proveedores chinos de primer nivel, como Shanghai Truer, cumplen o superan las normas ISO |

| La comunicación es difícil | Muchos proveedores ofrecen asistencia multilingüe B2B |

| Los plazos de entrega son largos | Ciclos de producción rápidos y una logística de envío eficaz son la norma para los pedidos de exportación |

Si está evaluando un cambio en su estrategia de aprovisionamiento, ha llegado el momento de explorar el coste, la calidad y la flexibilidad de los proveedores chinos de polvo FD-0200.

8. Por qué elegir Shanghai Truer Technology como socio de FD-0200

Shanghai Truer Technology Co., Ltd no es un proveedor más, sino un socio estratégico B2B para empresas que buscan polvo FD-0200 fiable y de alto rendimiento en volúmenes al por mayor.

Visión general de la empresa:

- Fundada: 2009

- Lanzamiento de la División PM: 2019

- Especialización: Impresión 3d equipos de fabricación de polvo, polvo para fabricación aditiva y polvos PM

- Métodos de producción: Atomización con agua, atomización con gas, carbonilo, reducción y atomización combinada

Obtenga más información sobre las capacidades de PM y fabricación aditiva de Truer en su página de inicio.

Por qué Truer destaca entre los compradores B2B:

| Característica | Ventajas para los compradores |

|---|---|

| Amplia cartera de grados | FD-0200, FD-0208, FL-4605, FN-5000 y otros disponibles para pedidos al por mayor |

| Atomización flexible | Elija atomización por agua, gas o híbrida en función de las especificaciones de su pieza |

| Soporte técnico | Trabaje directamente con los metalúrgicos para optimizar el polvo para su aplicación |

| Producción con certificación ISO | Garantiza una calidad, trazabilidad y conformidad uniformes |

| Logística y embalaje | Opciones de embalaje personalizadas y apoyo a la exportación mundial para pedidos al por mayor |

Gama de productos más allá de FD-0200:

- Polvos PM de cobre-acero (Fe-Cu)

- Polvo de difusión de CuSn para cojinetes sinterizados y herramientas de diamante

- Aditivos de grafito como TBC-400, TBC-1000

- Lubricantes para prensado de polvo: Lube-W, SUW-5000B

- Agentes de corte avanzados: SME-100, sulfuro de manganeso, TD-8

Si sus operaciones requieren algo más que FD-0200, Truer puede agrupar varios tipos de polvo y aditivos en un solo envío, ahorrando tiempo y reduciendo la complejidad de la adquisición.

📌 Para hablar de sus necesidades específicas de abastecimiento, visite el Página de contacto y póngase en contacto con el equipo de ventas B2B de Truer.

9. Preguntas frecuentes: Compra de FD-0200 en polvo a granel

Éstas son las preguntas más frecuentes que se hacen los compradores B2B cuando se abastecen de polvo FD-0200:

P1: ¿Cuál es la cantidad mínima de pedido (MOQ) para el polvo FD-0200 de Truer?

👉 La MOQ estándar de Truer para FD-0200 es de 500 kg, pero los descuentos por volumen comienzan a partir de 1 tonelada. Hay opciones de MOQ personalizadas para contratos a largo plazo.

P2: ¿Puedo solicitar una mezcla personalizada o una formulación modificada?

👉 Sí. Truer ofrece consultas de ingeniería para desarrollar variantes de FD-0200 adaptadas a su proceso de sinterización o a sus necesidades de resistencia mecánica.

P3: ¿Cómo se envasa el FD-0200 para la exportación?

👉 El embalaje estándar incluye:

- sacos precintados de 25 kg

- súper sacos de 1 tonelada (FIBC)

- Envases al vacío para variantes sensibles a la humedad

Si lo desea, podemos personalizar el envase y el etiquetado.

P4: ¿Proporciona Truer documentos COA y MSDS?

👉 Absolutamente. Cada envío incluye:

- Certificado de análisis (COA)

- Ficha de datos de seguridad (FDS)

- Documentación de trazabilidad de los lotes

P5: ¿Cuánto tarda el envío?

👉 Para pedidos internacionales:

| Región | Plazo de entrega estimado |

|---|---|

| Asia-Pacífico | 5-10 días |

| Europa | 14-20 días |

| Norteamérica | 18-25 días |

Existen opciones de envío urgente y condiciones FOB/CIF.

P6: ¿Puede Truer ayudar con las pruebas de aplicaciones?

sí. El equipo metalúrgico de Truer puede ayudar con la dosificación de prueba, la sinterización de prueba y las evaluaciones de rendimiento específicas de la aplicación para FD-0200 y otros polvos PM.

Si está preparado para racionalizar su cadena de suministro y reducir costes sin sacrificar la calidad, el polvo FD-0200 de Shanghai Truer Technology es su solución ideal. Puede consultar su catálogo completo de polvo PM en la página web Página del producto PM Polvo.

✅ Resumen de los enlaces internos utilizados:

- Sobre nosotros - para obtener información sobre la empresa

- Página de inicio - para conocer la oferta completa de productos y servicios

- Contáctenos - para consultas y apoyo B2B

- PM Polvo Página de producto - para ver las especificaciones técnicas y la cartera de productos

- FD-0200 Polvo Página de producto - utilizado anteriormente para la navegación por productos específicos

¿Desea obtener más información sobre FD-0200 u obtener un presupuesto personalizado? Póngase en contacto con el equipo B2B de Truer hoy mismo y experimente una forma más inteligente de abastecerse de materiales pulvimetalúrgicos.