1. Introducción al polvo F0005 en pulvimetalurgia

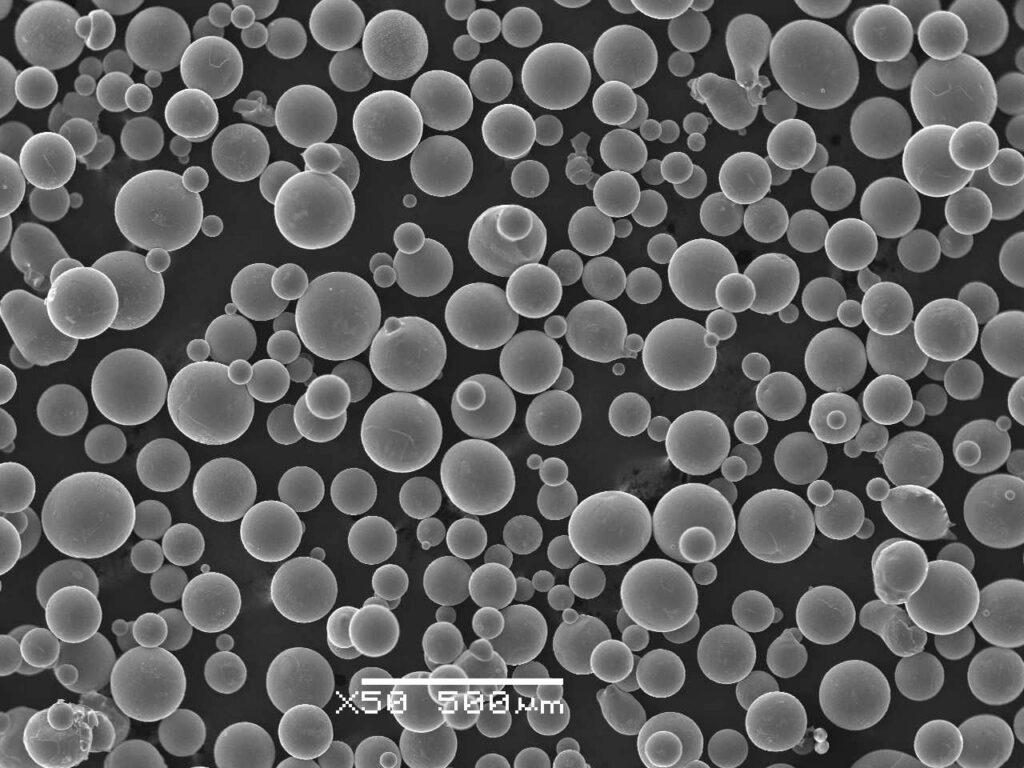

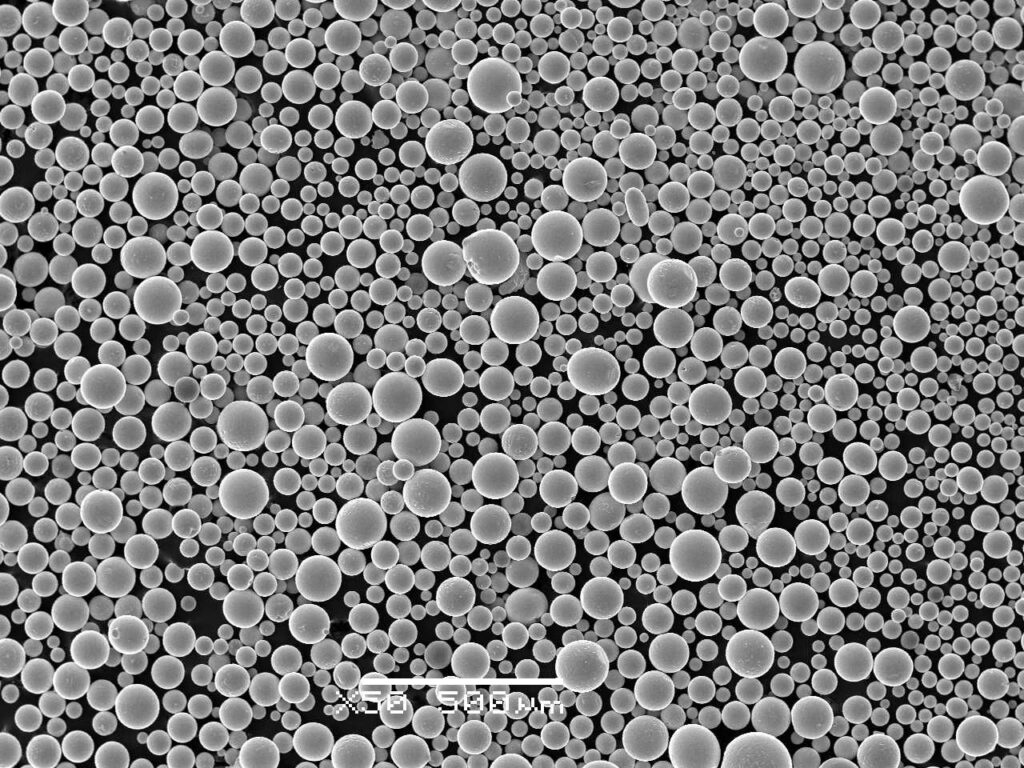

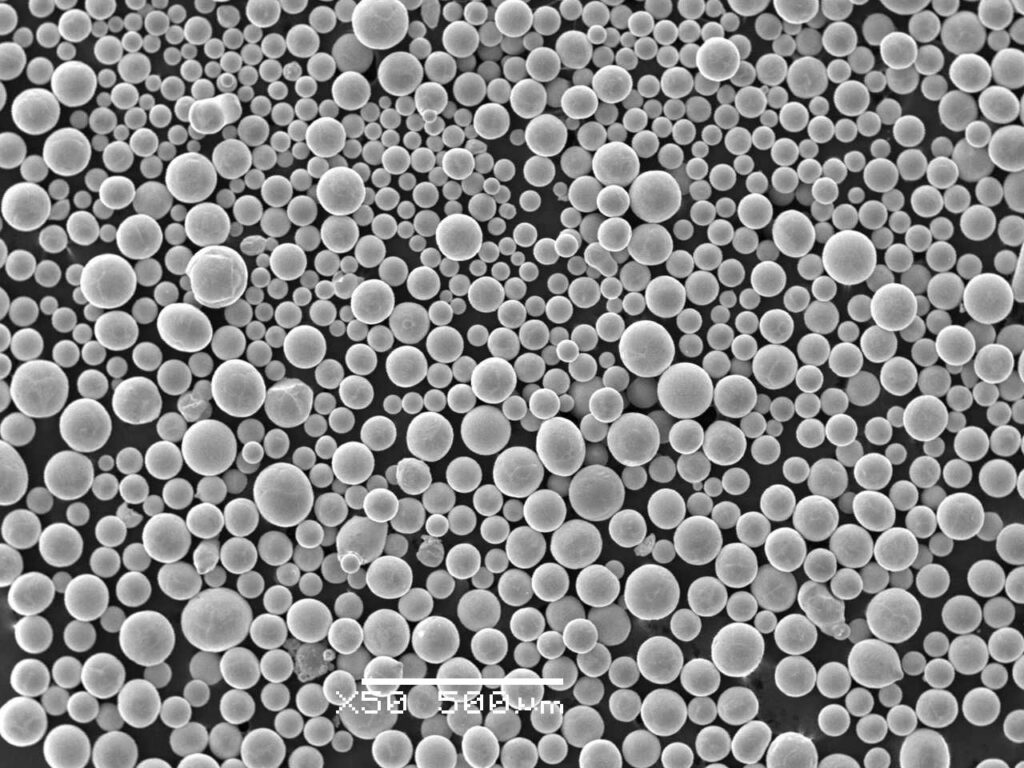

El polvo F0005 es un polvo ferroso utilizado en pulvimetalurgia (PM), compuesto normalmente de hierro puro con un estricto control del tamaño de las partículas y la composición química. Su denominación procede de las normas MPIF (Metal Powder Industries Federation), en las que “F” se refiere al hierro y “0005” indica un bajo contenido en carbono y un tamaño de partícula fino. Esto lo hace adecuado para una amplia gama de componentes estructurales y sinterizados en aplicaciones de automoción, aeroespaciales y maquinaria industrial.

Palabras clave B2B:

- Proveedores de polvo F0005

- venta al por mayor polvo de hierro F0005

- Polvo F0005 de grado PM

- polvo de hierro de gran pureza para sinterización

- F0005 polvo para uso industrial

Por qué el polvo F0005 es importante en la fabricación:

- Ofrece una excelente compresibilidad y resistencia en verde

- Produce piezas sinterizadas densas y de alta resistencia

- Ideal para formas complejas y aplicaciones de utillaje

- Solución rentable para la fabricación de grandes volúmenes

Industrias que utilizan polvo F0005:

| Industria | Aplicaciones comunes |

|---|---|

| Automotor | Cubos de engranajes, bujes, componentes del árbol de levas |

| Maquinaria | Rodamientos, piezas estructurales, acoplamientos |

| Aeroespacial | Componentes estructurales ligeros |

| Herramientas y matrices | Herramientas de prensado, insertos para matrices, punzones |

| Productos de consumo | Piezas de electrodomésticos, cerraduras y cierres |

2. Aplicaciones industriales del polvo F0005

El polvo F0005 es fundamental en la producción de diversos componentes sinterizados debido a su alta pureza y excelente estabilidad dimensional tras la sinterización. Su versatilidad lo convierte en la opción preferida de las empresas que buscan producir piezas de gran solidez y resistencia al desgaste.

Casos de uso comunes para el polvo F0005:

- Componentes de prensado y sinterización

- Aplicaciones magnéticas (en aleación)

- Piezas endurecidas superficialmente para resistir el desgaste

- Matrices de herramientas de diamante

Tabla de aplicación:

| Área de aplicación | Descripción | Método de tratamiento |

|---|---|---|

| Componentes de automoción | Engranajes y cubos sincronizadores de alta precisión | Prensa & Sinterización |

| Piezas estructurales | Piezas compactas y portantes en maquinaria | Conformado de hierro sinterizado |

| Matrices de herramientas de diamante | Agente aglomerante para abrasivos diamantados | Prensado en frío y sinterizado |

| Rodamientos & amp; Casquillos | Componentes porosos para un funcionamiento lubricado | Sinterizado impregnado de aceite |

| Componentes magnéticos | Bases de aleación magnética blanda (cuando están aleadas) | Aleación en polvo |

Por qué atrae a compradores mayoristas y distribuidores:

- Disponibilidad a granel a precios competitivos

- Compatibilidad con diversos procesos PM

- Puede alearse o mezclarse para conseguir propiedades específicas del material

3. Propiedades y ventajas del polvo F0005 para fabricantes

Para los fabricantes y compradores industriales, las propiedades mecánicas y químicas del polvo F0005 ofrecen importantes ventajas en la producción de grandes volúmenes de componentes metálicos.

Propiedades mecánicas clave:

| Propiedad | Valor típico |

|---|---|

| Densidad aparente | 2.5-3,0 g/cm³ |

| Caudal | 25-30 s/50g |

| Compresibilidad | Alta ( >7,0 g/cm³ de densidad verde) |

| Contenido de carbono | <0,005% |

| Densidad sinterizada | 6.8-7,2 g/cm³ |

*Los valores pueden variar en función de la transformación y del proveedor.

Ventajas para fabricantes de equipos originales y proveedores de primer nivel:

- Excelente resistencia en verde para la manipulación durante el prensado y la sinterización

- El bajo contenido en carbono reduce la distorsión durante la sinterización

- Buena maquinabilidad en estado postsinterizado

- Compatible con múltiples métodos de aleación (aleación por difusión, admixing)

Ventajas del uso de polvo F0005 en PM:

- ✅ Granulometría homogénea para una compactación uniforme

- ✅ Su gran pureza garantiza un rendimiento mecánico fiable

- ✅ Adecuado para líneas de producción automatizadas

- ✅ Admite geometrías complejas y piezas con forma casi de red

Para más especificaciones técnicas y opciones de compra, puede visitar la página PM polvo página de producto para explorar los datos detallados del producto y las calidades disponibles.

4. Demanda del mercado y tendencias mundiales de la cadena de suministro

En los últimos años, la demanda de polvos de hierro de gran pureza, como el F0005, ha crecido significativamente debido a la creciente adopción de la pulvimetalurgia en la automoción, la electrónica de consumo y las aplicaciones industriales. A medida que los fabricantes de equipos originales y los proveedores buscan alternativas rentables y de alto rendimiento al mecanizado tradicional, el polvo F0005 se ha convertido en un material de referencia para la producción en masa.

Perspectivas del mercado mundial

| Región | Principales impulsores | Oportunidades de mercado |

|---|---|---|

| Asia-Pacífico | Fabricación rápida de automóviles, rentabilidad | Abastecimiento de gran volumen en China e India |

| Europa | Ingeniería de precisión, objetivos de sostenibilidad | Demanda de metales ecológicos y reciclables |

| Norteamérica | Inversiones aeroespaciales y de defensa | I+D de materiales avanzados y desarrollo de aleaciones |

Principales tendencias del mercado del polvo F0005:

- Mayor uso en componentes de vehículos eléctricos: Dado que los vehículos eléctricos requieren componentes ligeros y de precisión, el F0005 se está adoptando en la producción de núcleos y carcasas de motores.

- Cambio hacia el aprovisionamiento localizado: Debido a las perturbaciones mundiales, muchos fabricantes están adoptando cadenas de suministro más localizadas, especialmente en Asia.

- Demanda de aleación personalizada: Los fabricantes de equipos originales solicitan mezclas de F0005 a medida para obtener propiedades de sinterización y prestaciones mecánicas específicas.

- Sostenibilidad & Reciclabilidad: La base de hierro de F0005 apoya los objetivos de sostenibilidad, ya que el hierro es uno de los metales más reciclables utilizados en la PM.

Palabras clave B2B de alta intención para esta sección:

- proveedores mundiales de polvo F0005

- compradores al por mayor de hierro en polvo

- Tendencias del mercado del polvo F0005 en 2024

- suministro personalizado de polvo PM

- Cadena de suministro B2B de pulvimetalurgia

5. Cómo seleccionar un proveedor fiable de polvo F0005

Elegir al proveedor de polvo F0005 adecuado es fundamental para garantizar la consistencia del producto, la eficacia de la producción y la rentabilidad. Los compradores de los sectores de automoción, aeroespacial y de herramientas dependen en gran medida de las especificaciones del polvo, la consistencia entre lotes y los plazos de entrega.

Factores clave a tener en cuenta:

- Consistencia del polvo & Control de calidad

Busque proveedores con certificación ISO 9001 y pruebas de control de calidad sólidas. La distribución del tamaño de las partículas, la densidad aparente y la fluidez deben controlarse rigurosamente. - Método de producción

El polvo F0005 puede producirse mediante atomización con agua o métodos de reducción. Dependiendo de su aplicación, puede preferir uno u otro. - Capacidad de suministro

Asegúrese de que el proveedor puede satisfacer su demanda mensual o trimestral, especialmente en el caso de grandes volúmenes de producción. - Servicios de personalización

Algunas aplicaciones requieren polvos a medida con lubricantesaditivos o componentes de aleación. - Logística & Plazos de entrega

Evalúe la velocidad de envío, el cumplimiento de las normas de exportación y las opciones de almacenamiento en su región.

| Lista de comprobación para la evaluación de proveedores F0005 | Sí/No |

|---|---|

| Ofrece fichas de datos técnicos (TDS/MSDS) | ✅ |

| Proporciona pedidos de muestras para pruebas | ✅ |

| Admite certificaciones OEM | ✅ |

| Experiencia con clientes B2B internacionales | ✅ |

| Personaliza el tamaño de las partículas o las aleaciones | ✅ |

Para conocer mejor las capacidades de los proveedores, visite la página Quiénes somos de Shanghai Truer para conocer cómo su experiencia en producción cumple las normas de calidad industrial.

6. Principales proveedores de Polvo F0005 en Asia y Europa

A continuación se ofrece una visión comparativa de los principales proveedores de polvo F0005 a nivel mundial, destacando sus regiones, puntos fuertes de producción y servicios.

Comparación de los principales proveedores

| Nombre de la empresa | Región | Puntos fuertes | Método de producción |

|---|---|---|---|

| Tecnología Truer de Shanghai | China | Amplia gama de polvos PM, aleación personalizada, asistencia OEM | Agua atomizada, reducción |

| Höganäs AB | Suecia | Alcance mundial, I+D, polvos de primera calidad | Agua/gas atomizado |

| Polvos metálicos de Río Tinto | Canadá | Polvos de gran pureza, enfoque automoción | Agua atomizada |

| Pometon S.p.A | Italia | Especializada en polvos de hierro y cobre, líneas ecológicas | Agua atomizada |

| JFE Steel Corporation | Japón | Metalurgia avanzada, polvos de precisión | Reducción |

Por qué destaca Shanghai Truer:

- Experiencia consolidada en gestión de proyectos: Desde 2009, Truer ha sido líder en pulvimetalurgia, expandiéndose a la fabricación aditiva en 2019.

- Amplia cartera de polvos: Ofrece más de 15 tipos de polvos PM ferrosos y no ferrosos, incluidos F0005, F0008 y FC-0208.

- Soluciones aditivas personalizadas: Su cartera de polvos incluye aditivos como el lubricante SUW-8000 y el agente de corte TD-8, esenciales para la sinterización y el mecanizado.

Servicios B2B-Friendly ofrecidos por Truer:

- Formulación de polvo OEM y ODM

- Precios al por mayor con acuerdos MOQ

- Asesoramiento técnico para diseñadores de piezas PM

- Envío rápido y atención al cliente multilingüe

Con una sólida reputación y una gran experiencia en la exportación, Shanghai Truer es la mejor opción para los compradores que buscan un suministro constante de polvo F0005.

7. Por qué más compradores eligen Polvo F0005 chino Fabricantes

En la última década, China ha emergido como líder mundial en la fabricación pulvimetalúrgica, ofreciendo materiales de alta calidad como el polvo F0005 a precios muy competitivos. Para compradores al por mayor, fabricantes de equipos originales y distribuidores, abastecerse directamente de fabricantes chinos ofrece varias ventajas estratégicas.

Principales ventajas de comprar polvo F0005 en China:

- Eficiencia de costes

Los menores costes de mano de obra y producción hacen que los proveedores chinos sean muy competitivos, especialmente en los pedidos a granel. - Producción escalable

Los fabricantes chinos suelen operar a mayor escala, ofreciendo mejores plazos de entrega y la capacidad de gestionar contratos de gran volumen. - Tecnología de fabricación avanzada

Unas modernas instalaciones equipadas con atomización de agua, hornos de reducción y sistemas de control de calidad garantizan unos estándares de calidad internacionales. - Formulaciones a medida y aditivos

Muchos proveedores chinos, entre ellos Shanghai Truer, ofrecen mezclas de polvos, lubricantes y aditivos a medida para aplicaciones especializadas. - Mejora de la logística y los servicios de exportación

Las fábricas chinas, que cuentan con líneas marítimas internacionales y procesos de documentación para la exportación, ofrecen hoy en día entregas internacionales sin problemas.

| Característica | Proveedores chinos de polvo F0005 | Proveedores de polvo Western F0005 |

|---|---|---|

| Precio por tonelada | Baja | Más alto |

| MOQ (Cantidad mínima de pedido) | Flexible | Fijado en bloque |

| Servicios de aleación a medida | Disponible | Limitado |

| Plazos de entrega | Más corto | Moderado |

| Certificación internacional | ISO, RoHS, etc. | ISO, ASTM |

Por qué los compradores B2B están cambiando:

- Los cambios económicos mundiales fomentan la diversificación de la cadena de suministro.

- Los compradores occidentales se enfrentan al aumento de los costes de las materias primas y la mano de obra.

- Los compradores B2B consideran que los proveedores chinos son más ágiles y responden mejor a las necesidades de los clientes.

Para obtener más información sobre la compra de F0005 en polvo en China, puede dirigirse a póngase en contacto con Shanghai Truer para solicitar presupuesto, muestras o asesoramiento técnico.

8. Por qué elegir Shanghai Truer como su socio de polvos F0005

Shanghai Truer Technology Co, Ltd se destaca como uno de los fabricantes de polvo F0005 más confiables y técnicamente avanzados de China. Fundada en 2009, la empresa no solo ha construido una base sólida en pulvimetalurgia, sino que también se ha expandido a la fabricación aditiva desde 2019.

Qué hace de Shanghai Truer un proveedor de confianza:

- Amplio catálogo de polvos PM

Shanghai Truer ofrece múltiples grados como F0005, F0008, FC-0208, FL-4605, etc., que satisfacen una amplia gama de casos de uso industrial. - Métodos de fabricación flexibles

Capaz de producir polvos mediante atomización con agua, reducción y métodos carbonílicos, según la aplicación. - Normas de alta calidad

Los estrictos procesos de inspección abarcan el análisis granulométrico, el caudal, la densidad aparente y la composición química. - Servicios de valor añadido

- Desarrollo de aleaciones personalizadas

- Asistencia técnica para sinterización y compactación

- Integración de lubricantes y aditivos (por ejemplo, SUW-8000, Lube-W)

- Excelente experiencia en exportación

Truer atiende a clientes de Asia, Europa y Norteamérica, con asistencia multilingüe y una eficaz logística global.

| Shanghai Capacidades más verdaderas | Descripción |

|---|---|

| Grados de polvo ofrecidos | F0005, F0008, FC-0208, FL-4605, FN-0205, etc. |

| Métodos de fabricación | Agua atomizada, reducción, técnicas híbridas |

| Aditivos disponibles | SUW-5000B, TD-8, QHP-330, TBC-1000, etc. |

| Aplicaciones compatibles | Automoción, utillaje, electrónica de consumo |

| Certificaciones | ISO 9001, RoHS, SGS |

Para conocer toda la gama de productos, visite sitio web oficial y explore las soluciones de polvos, lubricantes y aditivos PM adaptadas a las necesidades de su empresa.

9. FAQs: Compra al por mayor de polvo F0005 para uso industrial

A continuación encontrará las preguntas más frecuentes de los responsables de compras, ingenieros y compradores a la hora de adquirir polvo F0005 para uso industrial.

Q1: ¿Cuál es el MOQ para el polvo F0005 de Shanghai Truer?

A: La cantidad mínima de pedido es flexible, en función del volumen de su pedido y de sus necesidades de personalización. Disponemos de pequeñas cantidades de prueba.

P2: ¿Puedo solicitar granulometrías o mezclas de aleaciones personalizadas?

A: Sí. Shanghai Truer ofrece formulaciones personalizadas y puede ajustar la distribución del tamaño de las partículas, la fluidez y los elementos de aleación en función de su aplicación.

P3: ¿Qué opciones de embalaje hay para los pedidos al por mayor?

A: El polvo F0005 suele envasarse en bolsas selladas de 25 kg, con bidones de acero opcionales o bolsas de una tonelada para envíos de gran volumen. También hay envases antiestáticos y resistentes a la humedad.

P4: ¿Cuál es el plazo de entrega de los envíos internacionales?

A: El plazo de entrega estándar es de 2-3 semanas para pedidos al por mayor. Las opciones de producción y envío acelerados están disponibles bajo petición.

P5: ¿Se facilitan fichas técnicas y certificados de conformidad?

A: Sí. Truer proporciona documentación completa, incluidos los certificados TDS, MSDS, RoHS e ISO.

P6: ¿Puedo visitar la fábrica o solicitar muestras antes de hacer un pedido al por mayor?

A: Por supuesto. Se pueden organizar visitas a la fábrica, y hay muestras gratuitas de polvo F0005 disponibles para compradores cualificados y OEM.

🔗 Resumen de los enlaces de texto ancla internos

- PM polvo página de producto - Vinculado en la sección 3

- Quiénes somos - Vinculado en la sección 5

- Póngase en contacto con Shanghai Truer - Vinculado en la sección 7

- Sitio web oficial - Vinculado en la sección 8

- Catálogo de productos en polvo PM - Reutilizado en la sección 8 para referencia completa de la línea de productos

Al seleccionar estratégicamente un proveedor de confianza como Shanghai Truer, se asegura una calidad constante, precios competitivos y asistencia a largo plazo para sus operaciones pulvimetalúrgicas. Tanto si se abastece de polvo F0005 para automoción, herramientas o piezas de precisión, trabajar con un socio experimentado puede mejorar significativamente el rendimiento del producto y el retorno de la inversión.

¿Está listo para hablar de sus necesidades? Póngase en contacto con nosotros para un presupuesto personalizado o una consulta técnica.