Polvo de NiCrPSi es un material altamente especializado compuesto de níquel (Ni), cromo (Cr), fósforo (P) y silicio (Si). Está ganando cada vez más popularidad por sus notables propiedades y se utiliza en diversas aplicaciones industriales, desde entornos de alta temperatura hasta revestimientos de superficies. Si ha venido a conocer el polvo de NiCrPSi, probablemente esté buscando información sobre su composición, propiedades, usos y especificaciones. Exploremos en profundidad el polvo de NiCrPSi, sus variantes y todo lo que necesita saber

Visión general del polvo de NiCrPSi

El polvo de NiCrPSi es una aleación en polvo utilizada principalmente en industrias como la aeroespacial, la automovilística y la electrónica. Ofrece una excelente resistencia a la corrosión, la oxidación y el desgaste, por lo que es adecuado para aplicaciones de alto rendimiento. Gracias a su composición única de níquel, cromo, fósforo y silicio, puede soportar altas temperaturas y entornos difíciles.

Pero, ¿por qué debería interesarle el NiCrPSi? ¿Qué le hace destacar entre otros polvos metálicos? Veámoslo paso a paso.

Composición del polvo de NiCrPSi

¿De qué está hecho el polvo de NiCrPSi?

La composición del polvo NiCrPSi es una combinación de níquel, cromo, fósforo y silicio, cada uno de los cuales contribuye a sus características únicas. A continuación se explica con más detalle qué aportan estos elementos:

- Níquel (Ni): Proporciona fuerza, tenacidad y resistencia a la oxidación y la corrosión. La ductilidad del níquel es esencial para aplicaciones de alta temperatura.

- Cromo (Cr): Añade resistencia a la corrosión y al desgaste, aumentando la longevidad de los componentes.

- Fósforo (P): Reduce el punto de fusión y mejora la fluidez, lo que hace que el polvo sea ideal para revestimientos.

- Silicio (Si): Aumenta la dureza, mejora la resistencia a la oxidación y mejora la resistencia al desgaste.

| Elemento | Porcentaje (%) | Función |

|---|---|---|

| Níquel (Ni) | 50-60 | Solidez, resistencia a la oxidación, tenacidad |

| Cromo (Cr) | 20-30 | Resistencia al desgaste y a la corrosión |

| Fósforo (P) | 5-10 | Reduce el punto de fusión, mejora la fluidez |

| Silicio (Si) | 5-10 | Dureza, resistencia a la oxidación |

Características del polvo de NiCrPSi

Las propiedades de Polvo de NiCrPSi puede variar en función de la composición exacta y del proceso de fabricación. A continuación se indican algunas características clave:

- Resistencia a altas temperaturas: El polvo de NiCrPSi puede soportar temperaturas superiores a 1000°C sin descomponerse ni perder su integridad.

- Resistencia a la oxidación: Gracias a la presencia de cromo y silicio, este polvo es muy resistente a la oxidación, incluso a temperaturas extremas.

- Resistencia a la corrosión: El contenido de níquel garantiza que el polvo de NiCrPSi permanezca estable y resista la corrosión en entornos agresivos, incluidas condiciones marinas y ácidas.

- Dureza: La contribución del silicio garantiza que el polvo forme un revestimiento o componente duro y resistente al desgaste.

- Conductividad térmica: Con el níquel como base, este polvo ofrece una buena conductividad térmica, importante para aplicaciones que exigen disipación del calor.

Modelos y variantes de polvo de NiCrPSi

Existen varios modelos y tipos de polvos de NiCrPSi, cada uno adaptado a aplicaciones industriales específicas. Desglosemos algunos modelos populares:

- NiCrPSi 60/30/10

Un modelo con un 60% de níquel, un 30% de cromo y un 10% de silicio. Este tipo se utiliza en aplicaciones de alta temperatura, como álabes de turbinas y piezas de motores. - NiCrPSi 50/40/10

Este modelo presenta un mayor contenido de cromo para una mayor resistencia a la oxidación y la corrosión, lo que lo hace adecuado para entornos químicos agresivos. - NiCrPSi 55/30/15

Con un mayor contenido de silicio, este modelo ofrece una mayor dureza y resistencia al desgaste, ideal para entornos abrasivos como los equipos de minería. - NiCrPSi 60/25/15

Utilizado en aplicaciones aeroespaciales, este polvo tiene propiedades equilibradas de dureza, resistencia a la oxidación y conductividad térmica. - NiCrPSi 50/35/15

Esta variante se utiliza en revestimientos de superficies para equipos industriales, proporcionando una capa protectora duradera contra el desgaste y la corrosión. - NiCrPSi 45/40/15

Es conocido por su gran resistencia y dureza, lo que lo convierte en una elección popular para herramientas e instrumentos de corte. - NiCrPSi 65/25/10

Gracias a su alto contenido en níquel, este modelo destaca en hornos e intercambiadores de calor de alta temperatura. - NiCrPSi 55/35/10

Perfecta para aplicaciones que requieren resistencia a la corrosión y dureza moderada, como en la industria del petróleo y el gas. - NiCrPSi 50/40/10

Ideal para componentes de automoción, este modelo ofrece una excelente resistencia al desgaste en entornos de alta presión. - NiCrPSi 60/30/10

Utilizado con frecuencia en electrónica, este polvo es conocido por su conductividad térmica y su resistencia tanto a la oxidación como a la corrosión.

| Modelo | Ni (%) | Cr (%) | P (%) | Si (%) | Aplicaciones |

|---|---|---|---|---|---|

| NiCrPSi 60/30/10 | 60 | 30 | 5 | 5 | Álabes de turbina, piezas de motor |

| NiCrPSi 50/40/10 | 50 | 40 | 5 | 5 | Entornos químicos agresivos |

| NiCrPSi 55/30/15 | 55 | 30 | 5 | 10 | Equipos de minería, abrasivos |

| NiCrPSi 60/25/15 | 60 | 25 | 5 | 10 | Aplicaciones aeroespaciales |

| NiCrPSi 50/35/15 | 50 | 35 | 5 | 10 | Revestimientos de equipos industriales |

| NiCrPSi 45/40/15 | 45 | 40 | 5 | 10 | Herramientas, instrumentos de corte |

| NiCrPSi 65/25/10 | 65 | 25 | 5 | 5 | Hornos, intercambiadores de calor |

| NiCrPSi 55/35/10 | 55 | 35 | 5 | 5 | Aplicaciones en la industria del petróleo y el gas |

| NiCrPSi 50/40/10 | 50 | 40 | 5 | 5 | Componentes de automoción |

| NiCrPSi 60/30/10 | 60 | 30 | 5 | 5 | Electrónica, disipadores de calor |

Aplicaciones del polvo de NiCrPSi

¿Dónde puede utilizarse el polvo de NiCrPSi? Sus aplicaciones son tan variadas como las propias industrias. Desde la industria aeroespacial hasta la electrónica, el polvo de NiCrPSi desempeña un papel en muchos entornos exigentes y de alto rendimiento.

Aplicaciones clave

| Industria | Aplicaciones | Ventajas del uso de NiCrPSi en polvo |

|---|---|---|

| Aeroespacial | Álabes de turbina, componentes de motor | Resistencia a altas temperaturas, resistencia a la oxidación |

| Automotor | Sistemas de escape, turbocompresores | Resistencia al calor y al desgaste |

| Petróleo y gas | Equipos de perforación, tuberías | Resistencia a la corrosión, durabilidad en entornos difíciles |

| Electrónica | Placas de circuitos, disipadores térmicos | Conductividad térmica, resistencia a la oxidación |

| Marina | Hélices, revestimientos del casco | Resistencia a la corrosión en agua salada, longevidad |

| Minería | Trituradoras, cintas transportadoras, placas de desgaste | Resistencia a la abrasión, mayor vida útil |

| Herramientas | Herramientas de corte, moldes | Dureza, resistencia al desgaste, mecanizado de precisión |

Usos específicos

- Aplicaciones aeroespaciales: Polvo de NiCrPSigracias a su resistencia térmica y protección contra la oxidación, se utiliza ampliamente en motores a reacción, turbinas y otros componentes expuestos a temperaturas extremas. Imagine un motor a reacción que resista temperaturas constantes y abrasadoras de más de 1.000 °C: el NiCrPSi ayuda a hacerlo posible.

- Industria del automóvil: Los motores, turbocompresores y sistemas de escape de alto rendimiento se benefician de la capacidad del polvo de NiCrPSi para soportar el calor extremo y el desgaste. Mantiene el motor de su coche funcionando sin problemas incluso bajo una presión intensa.

- Petróleo y gas: En las perforaciones petrolíferas, donde los componentes están sometidos a presiones intensas y entornos corrosivos, se utiliza polvo de NiCrPSi para recubrirlos y protegerlos. Esto ayuda a mantener la integridad de los equipos, reduciendo el tiempo de inactividad y los costes de mantenimiento.

Ventajas del polvo de NiCrPSi frente a otros polvos metálicos

Cuando se compara el polvo de NiCrPSi con otros polvos metálicos, destaca claramente en varias áreas. Pero, ¿qué es exactamente lo que lo diferencia?

Comparación con otros polvos metálicos

| Característica | NiCrPSi Polvo | Otros polvos metálicos |

|---|---|---|

| Resistencia a altas temperaturas | Excelente (hasta 1000°C+) | Moderada a alta, dependiendo de la aleación |

| Resistencia a la corrosión | Excepcional, especialmente en ambientes ácidos/marinos | Varía mucho, de mala a buena |

| Resistencia a la oxidación | Alto (debido al Cromo & Silicio) | Varía en función de la composición |

| Resistencia al desgaste | Superior, especialmente en entornos abrasivos | Inferior a menos que esté especializado en dureza |

| Conductividad térmica | Bueno (con níquel como base) | Varía; algunos polvos ofrecen mejor conductividad |

| Dureza | Alto (debido al contenido de silicio) | Moderada a alta, dependiendo de la aleación |

Por qué el NiCrPSi es mejor para aplicaciones de alta temperatura

Comparado con otros polvos metálicos, el polvo de NiCrPSi ofrece un rendimiento superior en entornos de altas temperaturas. Mientras que otros polvos podrían empezar a degradarse u oxidarse a temperaturas extremas, el cromo y el silicio del NiCrPSi garantizan que permanezca estable e intacto. Es como tener una armadura para los componentes sometidos a altas temperaturas

Especificaciones y normas del polvo de NiCrPSi

Si desea comprar o utilizar polvo de NiCrPSi, es importante conocer sus especificaciones y las normas que cumple. Los distintos sectores pueden tener requisitos específicos de tamaño, composición o rendimiento.

Especificaciones

| Especificación | Gama/Detalles |

|---|---|

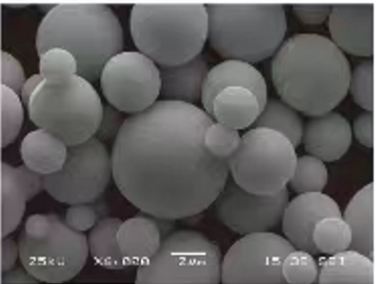

| Tamaño de partícula | 10-50 micras |

| Punto de fusión | 1200-1450°C |

| Densidad | 8.5 g/cm³ |

| Dureza | 600-750 HV |

| Conductividad térmica | 90 W/mK |

| Resistencia a la tracción | 450 MPa |

Normas

| Estándar | Descripción |

|---|---|

| ASTM B926 | Especificación normalizada de polvos metálicos para revestimientos |

| ISO 6208 | Especificaciones de los polvos metálicos utilizados en la pulverización térmica |

| AMS 4777 | Especificación de material aeroespacial para polvo de aleación de níquel |

Precios y proveedores de NiCrPSi en polvo

Polvo de NiCrPSi puede adquirirse a través de diversos proveedores de todo el mundo. Los precios pueden variar en función de la composición, la cantidad y la reputación del proveedor. He aquí un resumen:

Proveedores y precios

| Proveedor | Precio (por kg) | Disponibilidad | Ubicación |

|---|---|---|---|

| Materiales PowderCo | $300 | En stock | EE.UU. |

| Global Alloy Co. | $320 | Pedido especial | Alemania |

| TechSpray Metales | $280 | Pedidos al por mayor | China |

| AeroSpray Polvos | $350 | En stock | REINO UNIDO |

| NickelTech Ltd. | $310 | Existencias limitadas | Canadá |

Preguntas más frecuentes

| Pregunta | Respuesta |

|---|---|

| ¿Qué industrias utilizan más el polvo de NiCrPSi? | El polvo de NiCrPSi se utiliza ampliamente en las industrias aeroespacial, automovilística, petrolífera y del gas, electrónica, naval y de herramientas. |

| ¿Cómo se compara el NiCrPSi con otros polvos metálicos? | Ofrece una resistencia superior a las altas temperaturas y a la oxidación, por lo que es ideal para entornos que requieren materiales que soporten condiciones extremas. |

| ¿Es caro el polvo de NiCrPSi? | Puede ser más caro que otros polvos metálicos, pero sus propiedades únicas suelen justificar el coste para aplicaciones de alto rendimiento. |

| ¿En qué tamaños se presenta el polvo de NiCrPSi? | El tamaño de las partículas suele oscilar entre 10 y 50 micras, por lo que son adecuadas para diversos procesos industriales, como la pulverización térmica y la fabricación aditiva. |

| ¿Cuál es la principal ventaja de utilizar polvo de NiCrPSi? | Su excelente resistencia al calor, la corrosión y el desgaste, combinada con una buena conductividad térmica, lo hacen ideal para aplicaciones industriales exigentes. |

| ¿Se puede personalizar el polvo de NiCrPSi? | Sí, muchos proveedores ofrecen composiciones o granulometrías personalizadas para satisfacer requisitos específicos de distintas aplicaciones. |