El polvo de nitruro de aluminio (AlN) es un material versátil conocido por sus excepcionales propiedades térmicas y eléctricas. Sus aplicaciones abarcan la electrónica, la metalurgia y la cerámica, lo que lo convierte en un componente fundamental de la tecnología moderna. Esta guía ofrece una visión en profundidad del polvo de AlN, desde su composición y características hasta sus diversas aplicaciones y ventajas. También compararemos distintos modelos, analizaremos los pros y los contras y responderemos a las preguntas más frecuentes.

Visión general de Nitruro de aluminio en polvo

El nitruro de aluminio (AlN) es un material cerámico con propiedades únicas que lo diferencian de otros compuestos. Conocido por su alta conductividad térmica, su excelente aislamiento eléctrico y su estabilidad en condiciones extremas, el polvo de AlN es indispensable en industrias como la de los semiconductores, la aeroespacial y la energética.

Características principales del polvo de AlN

- Alta conductividad térmica: Disipación eficaz del calor.

- Aislamiento eléctrico: Ideal para aparatos electrónicos.

- Estabilidad química: Resistente a la corrosión y la oxidación.

- Banda ancha: Adecuado para aplicaciones electrónicas de alta potencia.

| Propiedad | Valor |

|---|---|

| Conductividad térmica | 170-200 W/mK |

| Resistividad eléctrica | >10ⁱ⁰ Ω-cm |

| Punto de fusión | 2,200°C |

| Densidad | 3,26 g/cm³ |

| Estructura cristalina | Wurtzita |

Tipos y modelos de polvo de AlN

Existen varios modelos de polvo de AlN adaptados a aplicaciones específicas. A continuación se muestra una lista de modelos populares con descripciones:

- Grado A-100: Polvo de gran pureza con bajo contenido en oxígeno, ideal para sustratos electrónicos de alto rendimiento.

- ThermaAlN-150: Diseñado para aplicaciones que requieren una conductividad térmica superior.

- NanoAlN-50: Partículas nanométricas para revestimientos y compuestos avanzados.

- EcoAlN-200: Opción respetuosa con el medio ambiente con métodos de producción sostenibles.

- Ultrafino-300: Polvo ultrafino para aplicaciones de precisión en semiconductores.

- AlN-XTreme: Aumento de la tenacidad de las cerámicas estructurales.

- SuperPure-500: Pureza ultra alta para investigación y usos especializados.

- IndustrialAlN-700: Opción rentable para aplicaciones a granel en industrias generales.

- PowderFlex-400: Granulometrías flexibles para aplicaciones diversas.

- DisipadorAlN-800: Específicamente diseñado para disipadores de calor y aplicaciones de gestión térmica.

| Nombre del modelo | Característica principal | Aplicación principal |

| Grado A-100 | Alta pureza, bajo contenido en oxígeno | Sustratos electrónicos |

| ThermaAlN-150 | Conductividad térmica superior | Disipación del calor |

| NanoAlN-50 | Partículas nanométricas | Recubrimientos, materiales compuestos |

| EcoAlN-200 | Producción sostenible | Uso industrial general |

| Ultrafino-300 | Grano ultrafino | Electrónica de precisión |

| AlN-XTreme | Mayor resistencia | Cerámica estructural |

| SuperPure-500 | Pureza ultra alta | Investigación, electrónica especializada |

| IndustrialAlN-700 | Rentable | Aplicaciones industriales a granel |

| PowderFlex-400 | Granulometría versátil | Aplicaciones diversas |

| DisipadorAlN-800 | Optimizado para disipadores de calor | Gestión térmica |

Composición del polvo de AlN

Nitruro de aluminio en polvo se compone principalmente de aluminio (Al) y nitrógeno (N). La composición suele incluir trazas de impurezas como oxígeno o carbono, según el proceso de producción.

| Elemento | Porcentaje |

| Aluminio (Al) | 50-55% |

| Nitrógeno (N) | 45-50% |

| Oxígeno (O) | <0,5% |

| Carbono (C) | <0,2% |

Los fabricantes consiguen una gran pureza mediante procesos como la reducción carbotérmica o la nitridación directa.

Características del polvo de AlN

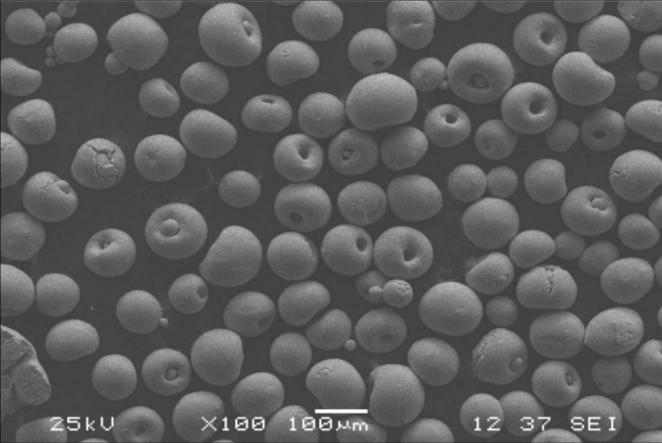

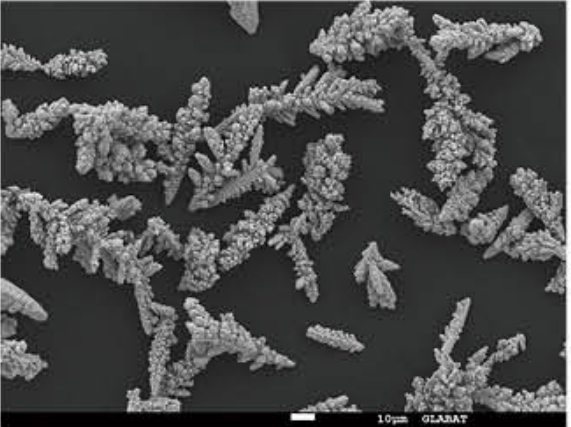

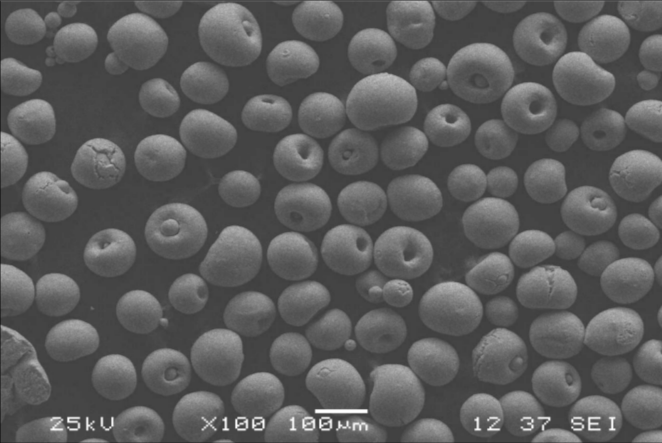

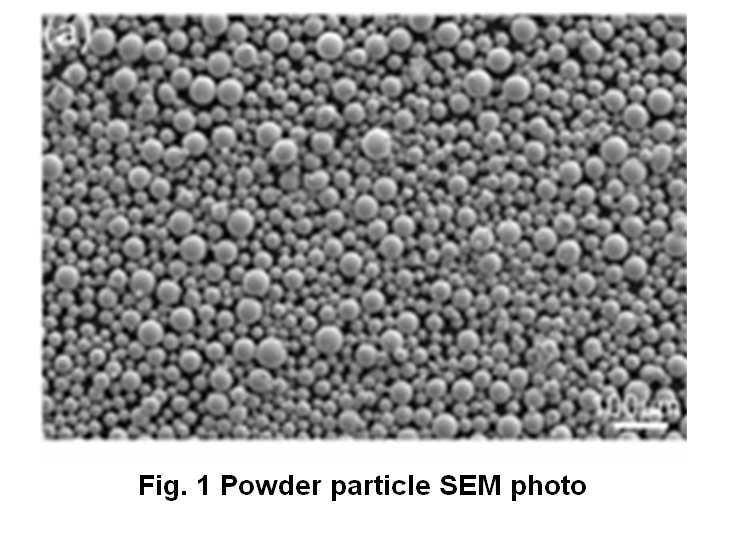

Propiedades físicas

- Densidad: 3,26 g/cm³

- Color: Gris claro o blanquecino

- Tamaño de las partículas: Rangos de nanómetros a micrómetros

Propiedades térmicas

- Coeficiente de dilatación térmica: 4.3 × 10-⁶ /°C

- Conductividad térmica: 170-200 W/mK

Propiedades eléctricas

- Constante dieléctrica: 8,6 a 1 MHz

- Resistividad eléctrica: >10ⁱ⁰ Ω-cm

Propiedades químicas

- Químicamente inerte en la mayoría de las condiciones

- Resistente a la corrosión y la oxidación

| Propiedad | Descripción |

| Densidad | 3,26 g/cm³ |

| Expansión térmica | Bajo, ideal para estructuras estables |

| Estabilidad química | Alta resistencia a la oxidación |

| Resistividad eléctrica | Excelentes propiedades aislantes |

Aplicaciones del polvo de AlN

Nitruro de aluminio en polvo se utiliza ampliamente en diversas industrias. Estas son algunas de sus aplicaciones más destacadas:

| Industria | Solicitud |

| Electrónica | Sustratos, disipadores térmicos, materiales de interfaz térmica |

| Cerámica | Componentes estructurales, revestimientos de alta temperatura |

| Aeroespacial | Sistemas de gestión térmica |

| Energía | Tecnología LED, sistemas fotovoltaicos |

| Metalurgia | Crisoles, auxiliares para el refinado de metales |

| Productos sanitarios | Cerámica biocompatible |

Especificaciones, tamaños, calidades y normas

El polvo de AlN se presenta en varios tamaños y grados para adaptarse a diferentes aplicaciones. A continuación encontrará una comparación detallada:

| Especificación | Rango/Valor |

| Tamaño de partícula | 0,1-10 micrómetros |

| Nivel de pureza | 95%-99.99% |

| Conductividad térmica | 170-200 W/mK |

| Contenido de oxígeno | <0,5% |

| Normas | ASTM C1685, ISO 9001 |

Proveedores y precios

El polvo de AlN está disponible en varios proveedores mundiales. El precio depende de la pureza, el tamaño de las partículas y la cantidad del pedido.

| Proveedor | Producto | Precio (USD/kg) | MOQ |

| Materion | Grado A-100 | $150-$200 | 1 kg |

| Cerámica avanzada | ThermaAlN-150 | $180-$250 | 5 kg |

| NanoMaterials Inc. | NanoAlN-50 | $300-$400 | 1 kg |

| Materiales GreenTech | EcoAlN-200 | $120-$170 | 10 kg |

Ventajas y limitaciones del polvo de AlN

Ventajas

- Alta conductividad térmica para una disipación eficaz del calor.

- Excelentes propiedades de aislamiento eléctrico.

- Químicamente estable y resistente a la oxidación.

Limitaciones

- Costes de producción relativamente elevados.

- Su fragilidad limita las aplicaciones mecánicas.

- Susceptibilidad a la hidrólisis en condiciones específicas.

| Aspecto | Ventajas | Limitaciones |

| Conductividad térmica | Alta | Ninguno |

| Propiedades eléctricas | Excelente aislamiento | No conductor |

| Coste | Las aplicaciones de gama alta justifican el coste | Caro para uso general |

Preguntas más frecuentes

| Pregunta | Respuesta |

| ¿Para qué se utiliza el polvo de AlN? | Se utiliza en las industrias electrónica, cerámica, aeroespacial, energética y médica. |

| ¿Por qué es caro el polvo de AlN? | El elevado coste se debe a los complejos procesos de producción y a los altos niveles de pureza. |

| ¿Cómo se produce el polvo de AlN? | Suele fabricarse mediante reducción carbotérmica o nitridación directa. |

| ¿Puede el polvo de AlN conducir la electricidad? | No, es un excelente aislante eléctrico. |

| ¿Es AlN respetuoso con el medio ambiente? | Sí, especialmente los grados ecológicos como EcoAlN-200. |