Introducción

CuAl10 Polvo es un polvo metálico de alto rendimiento fabricado a partir de una aleación de cobre (Cu) y aluminio (Al), que suele contener aproximadamente un 10% de aluminio en peso. Conocido por sus excelentes propiedades mecánicas y su resistencia a la corrosión, el polvo CuAl10 se utiliza ampliamente en diversos sectores, desde el aeroespacial hasta la electrónica y la fabricación aditiva. Si se pregunta por qué el CuAl10 es tan especial, siga leyendo: nos adentraremos en su composición, propiedades y aplicaciones únicas.

Composición del polvo CuAl10

Comprender la composición del polvo CuAl10 es clave para reconocer por qué es un material tan versátil. Esta aleación combina la conductividad del cobre con las propiedades de ligereza del aluminio, lo que la hace ideal para aplicaciones que requieren fuerza y resistencia a la corrosión sin demasiado peso añadido.

| Elemento | Porcentaje en peso | Propiedades aportadas |

|---|---|---|

| Cobre (Cu) | 90% | Proporciona conductividad, ductilidad |

| Aluminio (Al) | 10% | Añade resistencia y ligereza |

| Oligoelementos | <1% | Estabiliza y ajusta el rendimiento |

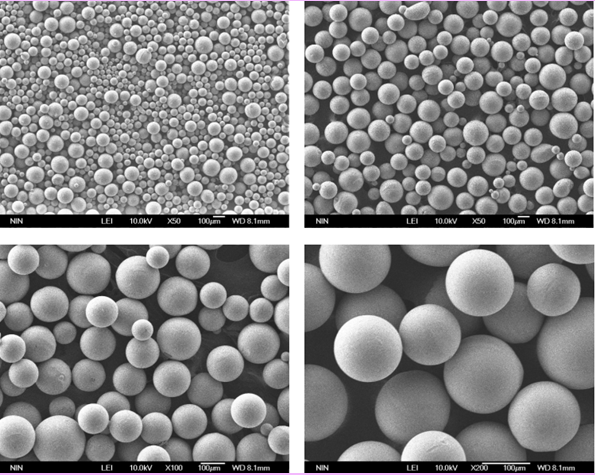

Proceso de fabricación del polvo CuAl10

Hay varias formas de fabricar CuAl10 en polvo, cada una de las cuales afecta a las características finales del material. Veamos los principales métodos de fabricación y cómo influyen en propiedades como el tamaño de las partículas, la densidad y la pureza.

| Método de fabricación | Descripción del proceso | Características resultantes |

|---|---|---|

| Atomización de gases | Aleación fundida CuAl10 rociada con gas inerte | Partículas finas y esféricas; gran pureza |

| Atomización del agua | Aleación rociada con agua a alta presión | Forma irregular; rentable; densa |

| Atomización por plasma | Aleación expuesta al arco de plasma para alta precisión | Partículas ultrafinas; tamaño muy controlado |

La elección del método de fabricación adecuado depende en gran medida de la aplicación prevista. Por ejemplo, el polvo atomizado por gas es el preferido para la impresión 3D por su forma esférica y su flujo uniforme.

Características del polvo CuAl10

La combinación única de cobre y aluminio en el polvo CuAl10 le confiere un equilibrio entre resistencia mecánica, resistencia a la corrosión y conductividad térmica. A continuación se indican algunas características clave que definen el rendimiento de esta aleación.

| Propiedad | Valor | Importancia |

|---|---|---|

| Densidad | ~7,3 g/cm³ | Suficientemente ligero para aplicaciones aeroespaciales |

| Punto de fusión | 1,030°C | Adecuado para entornos de alta temperatura |

| Resistencia a la tracción | Hasta 280 MPa | Proporciona durabilidad para usos estructurales |

| Conductividad térmica | ~125 W/mK | Excelente disipación del calor, útil en electrónica |

Estas propiedades hacen que el polvo CuAl10 sea ideal para aplicaciones en las que el equilibrio entre resistencia y peso es crucial, y en las que la disipación del calor desempeña un papel vital.

Tipos y modelos de CuAl10 Polvo

El polvo CuAl10 está disponible en varios modelos, cada uno de ellos adaptado a aplicaciones específicas mediante el ajuste de parámetros como el tamaño de las partículas y la pureza. A continuación se desglosan algunos de los modelos de CuAl10 Powder más utilizados.

| Modelo | Gama de tamaños de partículas | Nivel de pureza | Uso común |

|---|---|---|---|

| CuAl10-40S | 40-60 micras | 99% | Procesos de sinterización |

| CuAl10-25F | 25-45 micras | 99.5% | Moldeo por inyección de metales (MIM) |

| CuAl10-80M | 80-100 micras | 98% | Revestimientos por pulverización térmica |

| CuAl10-15P | 10-20 micras | 99.9% | impresión 3D, alta precisión |

| CuAl10-Nano | <1 micra | 99.8% | Tintas conductoras, electrónica |

| CuAl10-MAX300 | 250-300 micras | 98.5% | Aplicaciones estructurales |

| CuAl10-HF45 | 45-75 micras | 99.7% | Calentamiento inductivo de alta frecuencia |

| CuAl10-XP40 | 40-60 micras | 99% | Fabricación aditiva |

| CuAl10-BajoO2 | 40-60 micras | Baja oxidación | Aplicaciones sensibles a la oxidación |

| CuAl10-HP20 | 20-30 micras | 99.5% | Masilla de soldadura de alto rendimiento |

Cada modelo ofrece ventajas distintas en función de la aplicación, por lo que seleccionar la variante adecuada garantiza un rendimiento y una eficacia óptimos.

Aplicaciones y usos del polvo CuAl10

El polvo CuAl10 encuentra aplicaciones en diversos sectores gracias a sus versátiles propiedades. Desde complejos componentes aeroespaciales hasta la gestión térmica en electrónica, veamos cómo se aplica el polvo CuAl10 en diversos campos.

| Área de aplicación | Papel del polvo CuAl10 | Modelos destacados |

|---|---|---|

| Fabricación aditiva | Permite imprimir en 3D piezas precisas, ligeras y duraderas | CuAl10-P15, CuAl10-40S |

| Aeroespacial | Se utiliza en componentes que requieren alta resistencia y bajo peso | CuAl10-MAX300, CuAl10-25F |

| Electrónica | Excelente para disipadores de calor, tintas conductoras | CuAl10-Nano, CuAl10-LowO2 |

| Revestimientos por pulverización térmica | Proporciona capas protectoras térmicas resistentes a la corrosión | CuAl10-80M, CuAl10-40S |

| Moldeo por inyección de metales | Adecuado para crear formas pequeñas y complejas | CuAl10-25F, CuAl10-15P |

Tanto en la fabricación aditiva de vanguardia como en los recubrimientos por pulverización térmica, el polvo CuAl10 destaca por su resistencia y conductividad.

Especificaciones técnicas, tamaños y normas para CuAl10 Polvo

Cumplir las normas industriales es fundamental para polvos metálicos como el CuAl10. El cumplimiento de las especificaciones ASTM e ISO garantiza la calidad y la compatibilidad con otros materiales.

| Especificación | Norma (ISO/ASTM) | Tamaño de las partículas (micras) | Pureza |

|---|---|---|---|

| Fabricación aditiva | ISO/ASTM 52900 | 10-100 | 99.5% |

| Sinterización | ASTM B212 | 20-60 | 99% |

| Moldeo por inyección de metales | ASTM B243 | 25-45 | 99.5% |

| Revestimientos por pulverización térmica | ISO 14919 | 50-100 | 98% |

Proveedores, precios y disponibilidad

El polvo de CuAl10 es ofrecido por varios proveedores en todo el mundo, cada uno de los cuales atiende a diversas industrias y requisitos.

| Proveedor | Ubicación | Precios (USD/kg) | Plazos de entrega | Especialización |

|---|---|---|---|---|

| PowderMet Inc. | EE.UU. | $40-$60 | 2-4 semanas | Polvos de gran pureza |

| Global Alloys Co. | Alemania | $50-$70 | 3-6 semanas | Pedidos a granel de calidad industrial |

| Nippon Alloys Ltd. | Japón | $45-$65 | 2-3 semanas | Nanopolvos y polvos de alta precisión |

| EuroPowders GmbH | Alemania | $55-$75 | 4-6 semanas | Aplicaciones térmicas y estructurales |

El precio depende de factores como el modelo, la pureza y las cantidades de compra al por mayor. Los principales proveedores suelen ofrecer descuentos por pedidos al por mayor y tamaños especiales.

Ventajas y limitaciones del polvo CuAl10

El polvo CuAl10 ofrece numerosas ventajas, pero no está exento de dificultades. Comprender ambos puede ayudar a tomar decisiones de compra y aplicación con conocimiento de causa.

| Ventajas | Limitaciones |

|---|---|

| Fuerte y resistente a la corrosión | Más caro que las aleaciones básicas |

| Ligero pero duradero | No es ideal para la oxidación a alta temperatura |

| Excelente conductividad | Proveedores limitados de polvos nanométricos |

| Disponible en varios tamaños de partícula | Algunos modelos tienen un plazo de entrega más largo |

Comparación de CuAl10 Polvo a aleaciones similares

¿Tiene curiosidad por saber cómo se compara CuAl10 con aleaciones similares como CuAl8 o CuAl15? He aquí una rápida comparación:

| Aleación | Contenido en Cu | Al Contenido | Idoneidad de los casos de uso | Coste |

|---|---|---|---|---|

| CuAl10 | 90% | 10% | Aplicaciones equilibradas | Moderado |

| CuAl8 | 92% | 8% | Alta ductilidad, resistencia moderada | Baja |

| CuAl15 | 85% | 15% | Alta resistencia a la corrosión | Ligeramente superior |

Preguntas más frecuentes

| Pregunta | Respuesta |

| ¿Para qué se utiliza el polvo CuAl10? | El polvo CuAl10 se utiliza en impresión 3D, electrónica y aeroespacial por su resistencia, conductividad y resistencia a la corrosión. |

| ¿Cómo se fabrica el polvo CuAl10? | Se fabrica principalmente mediante atomización con gas, agua o plasma, y cada método produce partículas de características diferentes. |

| ¿Es caro el polvo CuAl10? | Los precios varían, pero suele ser más caro que las aleaciones más sencillas debido a sus propiedades especializadas. |

| ¿Puede utilizarse el polvo CuAl10 en soldadura? | Sí, algunos modelos como CuAl10-HP20 son adecuados para soldar materiales de aportación. |

| ¿En qué se diferencia el CuAl10 del cobre puro? | CuAl10 es más ligero y resistente gracias a su contenido en aluminio, pero ofrece una conductividad ligeramente inferior a la del cobre puro. |

Conclusión

CuAl10 Polvo sigue siendo un material muy solicitado por su durabilidad, resistencia a la corrosión y adaptabilidad a múltiples sectores. Desde la impresión 3D hasta la industria aeroespacial y electrónica, el polvo de CuAl10 es esencial en aplicaciones en las que la fuerza, la conductividad y la resistencia a la corrosión son fundamentales. A medida que evolucionan las técnicas de fabricación, la gama de modelos y aplicaciones del polvo de CuAl10 sigue creciendo, consolidando su lugar como aleación versátil y de alto rendimiento en la ingeniería moderna.