Polvos de baja aleación desempeñan un papel crucial en diversas industrias, desde la automovilística hasta la aeroespacial. Su versatilidad, combinada con unas propiedades únicas, los hace indispensables en la fabricación de componentes de alto rendimiento. En esta completa guía, exploraremos todo lo que necesita saber sobre el polvo de baja aleación, desde su composición hasta sus aplicaciones, propiedades y mucho más. Tanto si es un experto del sector como si es un lector curioso, este artículo está diseñado para proporcionarle conocimientos profundos sin dejar de ser ameno y ameno.

Polvo de baja aleación

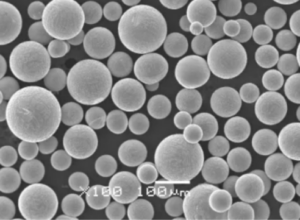

Los polvos de baja aleación son polvos metálicos de ingeniería que contienen un pequeño porcentaje de elementos de aleación como cromo, molibdeno o níquel. Estos polvos están diseñados específicamente para mejorar las propiedades mecánicas, la resistencia al desgaste y la tenacidad del metal base. Suelen utilizarse en pulvimetalurgia para fabricar piezas que requieren gran resistencia, durabilidad y dimensiones precisas.

Los polvos de baja aleación son populares en aplicaciones que exigen materiales con propiedades mecánicas superiores a las de los metales puros o los materiales de alta aleación. La cuidadosa selección de elementos de aleación en los polvos de baja aleación garantiza que el producto final pueda soportar condiciones extremas, como altas temperaturas, entornos corrosivos y cargas pesadas.

Detalles clave del polvo de baja aleación

| Parámetro | Descripción |

|---|---|

| Composición | Metal base con elementos de aleación 1-5% como Mo, Cr, Ni |

| Propiedades | Alta resistencia, resistencia al desgaste, mayor tenacidad y dureza |

| Aplicaciones comunes | Componentes de automoción, piezas aeroespaciales, herramientas y maquinaria pesada |

| Proceso de fabricación | Atomización, sinterización y prensado isostático en caliente (HIP) |

| Elementos de aleación típicos | Cromo, molibdeno, níquel, manganeso, vanadio, titanio |

| Ventajas | Propiedades mecánicas mejoradas, rentable, versátil |

Composición del polvo de baja aleación

Comprender la composición de los polvos de baja aleación es crucial para seleccionar el material adecuado para una aplicación específica. El metal base de estos polvos suele ser el hierro, pero también pueden utilizarse otros metales como el níquel y el titanio. Los elementos de aleación, añadidos en pequeñas cantidades, influyen significativamente en las propiedades del polvo.

Tabla: Elementos de aleación comunes en polvos de baja aleación

| Elemento de aleación | Concentración típica (%) | Propósito |

|---|---|---|

| Cromo (Cr) | 1-3% | Mejora la resistencia a la corrosión y la dureza |

| Molibdeno (Mo) | 0.5-2% | Mejora la resistencia a altas temperaturas y al desgaste |

| Níquel (Ni) | 1-5% | Aumenta la tenacidad y la ductilidad |

| Vanadio (V) | 0.1-1% | Mejora el refinamiento del grano y la resistencia al desgaste |

| Titanio (Ti) | 0.1-0.5% | Mejora la solidez y la resistencia a la corrosión |

| Manganeso (Mn) | 0.5-2% | Aumenta la templabilidad y la resistencia al desgaste |

¿Por qué estos elementos?

- Cromo (Cr): Conocido por su excelente resistencia a la corrosión, el cromo es un elemento clave en los polvos de baja aleación diseñados para entornos difíciles. También mejora la dureza, haciendo que el producto final sea más duradero.

- Molibdeno (Mo): Este elemento es crucial para las aplicaciones que requieren una gran resistencia a temperaturas elevadas. El molibdeno mejora la resistencia al desgaste, garantizando la longevidad de componentes como engranajes y ejes.

- Níquel (Ni): El níquel mejora la tenacidad y la ductilidad de los polvos de baja aleación, lo que los hace adecuados para piezas sometidas a tensiones o deformaciones importantes.

- Vanadio (V): El vanadio es esencial para el refinamiento del grano, que mejora las propiedades mecánicas generales del material, incluida la resistencia al desgaste.

- Titanio (Ti): La adición de titanio a los polvos de baja aleación aumenta la resistencia al tiempo que mantiene la resistencia a la corrosión, lo que lo hace ideal para aplicaciones aeroespaciales.

Características de Polvo de baja aleación

Las características de los polvos de baja aleación se adaptan mediante una cuidadosa selección de los elementos de aleación y un control preciso del proceso de fabricación. Estas características determinan la idoneidad del polvo para diversas aplicaciones.

Tabla: Características del polvo de baja aleación

| Característica | Descripción |

|---|---|

| Alta resistencia | Los polvos de baja aleación están diseñados para producir piezas con una resistencia superior. |

| Resistencia al desgaste | Mayor resistencia al desgaste gracias a la presencia de elementos como el Mo y el Cr. |

| Dureza | La mayor tenacidad permite un mejor rendimiento en aplicaciones exigentes. |

| Resistencia a la corrosión | Elementos de aleación como el Cr y el Ti proporcionan una excelente resistencia a la corrosión. |

| Estabilidad dimensional | Las piezas fabricadas con polvos de baja aleación mantienen sus dimensiones incluso bajo tensión. |

| Resistencia a la fatiga | Su excelente resistencia a la fatiga hace que estos polvos sean ideales para cargas cíclicas. |

Por qué son importantes estas características

- Alta resistencia: La resistencia es una consideración primordial en aplicaciones en las que las piezas están sometidas a cargas pesadas o presiones elevadas. Los polvos de baja aleación están diseñados para producir componentes que puedan soportar estas condiciones sin fallar.

- Resistencia al desgaste: En sectores como la automoción y el utillaje, las piezas sufren a menudo fricción y desgaste. La resistencia al desgaste de los polvos de baja aleación garantiza que los componentes duren más, reduciendo la necesidad de sustituciones frecuentes.

- Dureza: La tenacidad es la capacidad de un material para absorber energía y deformarse sin romperse. Esta propiedad es esencial para las piezas que deben soportar impactos o tensiones sin fracturarse.

- Resistencia a la corrosión: La corrosión puede reducir considerablemente la vida útil de un componente. Los polvos de baja aleación con elementos como el cromo ofrecen una resistencia superior a la corrosión, lo que los hace ideales para su uso en entornos difíciles.

- Estabilidad dimensional: Mantener unas dimensiones precisas es fundamental en sectores como el aeroespacial y la automoción, donde incluso pequeñas desviaciones pueden provocar problemas importantes. Los polvos de baja aleación garantizan la estabilidad de las piezas en condiciones variables.

- Resistencia a la fatiga: La resistencia a la fatiga es vital para los componentes que se someten a ciclos de carga repetidos. Los polvos de baja aleación están diseñados para soportar estas condiciones sin sucumbir al fallo por fatiga.

Aplicaciones del polvo de baja aleación

Los polvos de baja aleación son increíblemente versátiles y se utilizan en una amplia gama de industrias. Su capacidad para mejorar las propiedades mecánicas los hace ideales para aplicaciones que requieren resistencia, durabilidad y precisión.

Tabla: Aplicaciones comunes del polvo de baja aleación

| Industria | Solicitud | Beneficios |

|---|---|---|

| Automotor | Engranajes, cojinetes, árboles de levas, bielas | Alta resistencia, resistencia al desgaste, resistencia a la fatiga |

| Aeroespacial | Álabes de turbina, componentes de motor, piezas estructurales | Ligereza, alta resistencia, resistencia a la corrosión |

| Herramientas | Herramientas de corte, moldes, matrices | Resistencia al desgaste, tenacidad, precisión |

| Maquinaria pesada | Cajas de cambios, componentes hidráulicos | Solidez, durabilidad, resistencia a la corrosión |

| Petróleo y gas | Brocas, válvulas, tuberías | Alta resistencia al desgaste y a la corrosión |

| Médico | Implantes, herramientas quirúrgicas | Biocompatibilidad, solidez, resistencia a la corrosión |

| Defensa | Vehículos blindados, sistemas de armas | Dureza, resistencia al desgaste, resistencia |

| Electrónica | Conectores, carcasas | Estabilidad dimensional, resistencia a la corrosión |

| Energía | Componentes de turbinas eólicas, piezas de reactores nucleares | Resistencia, resistencia a la fatiga, resistencia a la corrosión |

| Marina | Hélices, componentes del motor | Resistencia a la corrosión, resistencia al desgaste, tenacidad |

Ejemplos reales

- Automotor: En la industria del automóvil, los polvos de baja aleación se utilizan para fabricar componentes críticos como engranajes y árboles de levas. Estas piezas requieren una gran solidez y resistencia al desgaste para soportar las tensiones del funcionamiento del motor.

- Aeroespacial: Los álabes de turbina de los motores a reacción suelen fabricarse con polvos de baja aleación debido a su capacidad para mantener la resistencia y la estabilidad a altas temperaturas, lo que garantiza un funcionamiento seguro y eficaz.

- Médico: Las herramientas quirúrgicas y los implantes deben ser a la vez resistentes y biocompatibles. Los polvos de baja aleación con titanio se utilizan habitualmente para cumplir estos requisitos, proporcionando dispositivos médicos duraderos y seguros.

Ventajas del polvo de baja aleación

Los polvos de baja aleación ofrecen una combinación única de propiedades que los hacen muy ventajosos en diversas aplicaciones. Veamos las ventajas específicas que distinguen a estos polvos de otros materiales.

Tabla: Ventajas del polvo de baja aleación

| Ventaja | Descripción |

|---|---|

| Relación coste-eficacia | Los polvos de baja aleación suelen ser más asequibles que las alternativas de alta aleación. |

| Versatilidad | Adecuado para una amplia gama de aplicaciones en diferentes industrias. |

| Propiedades mecánicas mejoradas | Mayor solidez, resistencia al desgaste y tenacidad en comparación con los metales puros. |

| Adaptabilidad | La composición puede ajustarse a los requisitos específicos de cada aplicación. |

| Precisión dimensional | Ideal para fabricar piezas con dimensiones precisas y tolerancias ajustadas. |

| Resistencia medioambiental | Ofrece una excelente resistencia a la corrosión, el calor y el desgaste en entornos difíciles. |

Por qué son importantes estas ventajas

- Relación coste-eficacia: Los polvos de baja aleación son una solución rentable para fabricar componentes de alto rendimiento. En comparación con los polvos de alta aleación, ofrecen ventajas similares a un precio inferior, lo que los convierte en una opción atractiva para las industrias preocupadas por los costes.

- Versatilidad: La posibilidad de utilizar polvos de baja aleación en una gran variedad de sectores, desde el automovilístico hasta el aeroespacial, demuestra su versatilidad. Esto los convierte en un material de referencia para los fabricantes que buscan optimizar el rendimiento en distintas aplicaciones.

- Propiedades mecánicas mejoradas: La adición de elementos de aleación mejora significativamente las propiedades mecánicas del metal base. El resultado son componentes más resistentes y duraderos, capaces de soportar condiciones exigentes.

- Adaptabilidad: Una de las principales ventajas de los polvos de baja aleación es la posibilidad de adaptar su composición a requisitos específicos. Esto permite a los fabricantes optimizar el material para aplicaciones concretas, ya sea para mejorar la resistencia al desgaste, aumentar la solidez o mejorar la resistencia a la corrosión.

- Precisión dimensional: Los polvos de baja aleación son ideales para producir piezas con tolerancias estrechas y dimensiones precisas. Esto es especialmente importante en industrias como la aeroespacial y la automovilística, donde incluso pequeñas desviaciones pueden provocar problemas importantes.

- Resistencia medioambiental: En aplicaciones en las que los componentes están expuestos a entornos difíciles, como altas temperaturas o sustancias corrosivas, los polvos de baja aleación ofrecen una resistencia superior, garantizando una mayor vida útil y reduciendo los costes de mantenimiento.

Desventajas y limitaciones del polvo de baja aleación

Aunque los polvos de baja aleación ofrecen numerosas ventajas, también presentan ciertas limitaciones que deben tenerse en cuenta a la hora de seleccionar materiales para aplicaciones específicas.

Tabla: Desventajas y limitaciones del polvo de baja aleación

| Desventaja | Descripción |

|---|---|

| Gama limitada de elementos de aleación | El porcentaje de elementos de aleación es limitado, lo que puede restringir las propiedades. |

| No apto para entornos extremos | Pueden necesitarse polvos de alta aleación para condiciones más extremas. |

| Complejidad de procesamiento | Requiere un control preciso durante la fabricación para conseguir las propiedades deseadas. |

| Potencial de fragilidad | Algunos polvos de baja aleación pueden volverse quebradizos si no se procesan correctamente. |

| Resistencia limitada a la corrosión | Aunque mejorada, la resistencia a la corrosión puede no igualar la de los aceros inoxidables. |

Por qué son importantes estas limitaciones

- Gama limitada de elementos de aleación: La gama de elementos de aleación en los polvos de baja aleación se limita a unos 1-5%. Esto puede restringir la capacidad del material para alcanzar ciertas propiedades, especialmente en comparación con los polvos de alta aleación que pueden contener porcentajes más altos de elementos de aleación.

- No apto para entornos extremos: Para aplicaciones en condiciones extremadamente duras, como entornos de alta temperatura o atmósferas altamente corrosivas, los polvos de alta aleación pueden ser una mejor opción. Los polvos de baja aleación pueden no proporcionar la protección o el rendimiento necesarios en estos escenarios.

- Complejidad de procesamiento: El proceso de fabricación de polvos de baja aleación requiere un control preciso para conseguir las propiedades deseadas. Cualquier desviación en el proceso puede dar lugar a un producto que no cumpla las especificaciones requeridas, lo que puede provocar fallos o reducir el rendimiento.

- Potencial de fragilidad: Si no se procesan correctamente, los polvos de baja aleación pueden volverse quebradizos, haciéndolos propensos a agrietarse o romperse bajo tensión. Esto es especialmente preocupante en aplicaciones en las que la tenacidad es crítica.

- Resistencia limitada a la corrosión: Aunque los polvos de baja aleación ofrecen una mayor resistencia a la corrosión que los metales puros, es posible que no alcancen la protección que ofrecen materiales como el acero inoxidable, sobre todo en entornos muy corrosivos.

Modelos específicos de polvo metálico

Los polvos de baja aleación vienen en varios modelos, cada uno diseñado para satisfacer requisitos específicos. He aquí diez ejemplos de modelos populares de polvo de baja aleación, junto con sus descripciones y aplicaciones.

Tabla: Modelos populares de polvo de baja aleación

| Modelo | Composición | Propiedades | Aplicaciones |

|---|---|---|---|

| FeMo10 | Fe + 10% Mo | Alta resistencia, excelente resistencia al desgaste | Engranajes de automoción, componentes aeroespaciales |

| FeNi5 | Fe + 5% Ni | Mayor tenacidad y ductilidad | Piezas estructurales, conectores |

| FeCr3 | Fe + 3% Cr | Mayor resistencia a la corrosión, buena dureza | Componentes marinos, herramientas |

| FeV1 | Fe + 1% V | Mayor resistencia al desgaste, refinamiento del grano | Herramientas de corte, piezas sometidas a grandes esfuerzos |

| FeMn2 | Fe + 2% Mn | Mejor templabilidad, resistencia al desgaste | Rodamientos, ejes, engranajes |

| FeMo2Ni4 | Fe + 2% Mo + 4% Ni | Resistencia y dureza equilibradas | Piezas estructurales aeroespaciales, automoción |

| FeCrMoNi | Fe + Cr + Mo + Ni (proporciones personalizables) | Propiedades versátiles, adaptadas a aplicaciones específicas | Multitud de industrias |

| FeTi0,5 | Fe + 0,5% Ti | Mayor resistencia, buena resistencia a la corrosión | Fijaciones aeroespaciales, implantes médicos |

| FeMnCrNiV | Fe + Mn + Cr + Ni + V (mezcla personalizada) | Mayor resistencia al desgaste, tenacidad y resistencia a la corrosión | Componentes de alto rendimiento |

| FeMoCrNi2V1 | Fe + Mo + Cr + Ni + V | Alta resistencia, excelente resistencia al desgaste y a la corrosión | Petróleo y gas, componentes aeroespaciales |

Descripciones detalladas

- FeMo10: Este modelo incorpora hierro con molibdeno 10%, que ofrece una gran solidez y una excelente resistencia al desgaste. Se utiliza habitualmente en los sectores de automoción y aeroespacial para componentes como engranajes y piezas estructurales que deben soportar grandes esfuerzos y desgaste.

- FeNi5: Compuesto de níquel 5%, el FeNi5 proporciona una mayor tenacidad y ductilidad, por lo que es ideal para piezas estructurales y conectores que requieren durabilidad y flexibilidad.

- FeCr3: Con cromo 3%, este modelo ofrece una mayor resistencia a la corrosión y una buena dureza. Es muy adecuado para componentes marinos y herramientas que deban soportar entornos corrosivos.

- FeV1: Con vanadio 1%, el FeV1 mejora la resistencia al desgaste y favorece el refinamiento del grano, por lo que es una opción popular para herramientas de corte y piezas sometidas a grandes esfuerzos.

- FeMn2: Este modelo incluye manganeso 2%, que mejora la templabilidad y la resistencia al desgaste. Suele utilizarse en cojinetes, ejes y engranajes donde estas propiedades son cruciales.

- FeMo2Ni4: Una mezcla equilibrada de molibdeno 2% y níquel 4%, este modelo proporciona un buen equilibrio de resistencia y tenacidad, por lo que es adecuado para piezas estructurales aeroespaciales y aplicaciones de automoción.

- FeCrMoNi: Este modelo personalizable permite adaptar las propiedades ajustando las proporciones de cromo, molibdeno y níquel. Se utiliza en múltiples sectores en los que se requieren propiedades específicas.

- FeTi0,5: Con titanio 0,5%, este modelo ofrece una mayor resistencia y una buena resistencia a la corrosión, por lo que es ideal para fijaciones aeroespaciales e implantes médicos.

- FeMnCrNiV: Una mezcla personalizada de manganeso, cromo, níquel y vanadio, este modelo proporciona una resistencia superior al desgaste, tenacidad y resistencia a la corrosión, adecuado para componentes de alto rendimiento.

- FeMoCrNi2V1: Combinando molibdeno, cromo, níquel y vanadio, este modelo ofrece una gran solidez y una excelente resistencia al desgaste y la corrosión, por lo que es perfecto para aplicaciones exigentes en los sectores del petróleo y el gas y aeroespacial.

Especificaciones, tamaños y normas

Los polvos de baja aleación están disponibles en varios tamaños y grados, y se ajustan a las normas de la industria para garantizar su calidad y consistencia. Las especificaciones de estos polvos son cruciales para determinar su idoneidad para aplicaciones específicas.

Tabla: Especificaciones, tamaños y normas de los polvos de baja aleación

| Especificación | Descripción |

|---|---|

| Tamaño de partícula | De 10 a 150 micras, según la aplicación |

| Pureza | Normalmente >99%, con un control estricto de las impurezas |

| Grado | Varía según la aplicación, incluidos los grados estándar como ASTM F75 |

| Densidad | Normalmente 7,8 g/cm³ para polvos a base de hierro |

| Fluidez | Medido con caudalímetro Hall, normalmente 30-50 s/50g |

| Normas | ASTM B213, ASTM B962, ISO 4497, ISO 3923 |

| Embalaje | Disponible en sacos de 25 kg, bidones o envases personalizados |

Por qué son importantes las especificaciones

- Tamaño de partícula: El tamaño de las partículas de polvo es fundamental para determinar cómo se comportará el polvo durante el procesamiento. Las partículas más pequeñas se utilizan normalmente para aplicaciones que requieren detalles más finos y precisión, mientras que las partículas más grandes pueden ser preferibles para componentes más voluminosos.

- Pureza: Una alta pureza es esencial para garantizar que el polvo funcione como se espera, especialmente en aplicaciones críticas como la aeroespacial o los dispositivos médicos. Las impurezas pueden provocar defectos o fallos en el producto final.

- Grado: El grado del polvo determina su idoneidad para aplicaciones específicas. Por ejemplo, ASTM F75 es una norma común para las aleaciones de cobalto-cromo-molibdeno utilizadas en implantes médicos.

- Densidad: La densidad del polvo afecta a su comportamiento de empaquetado y a la densidad final del producto sinterizado. Una densidad constante es importante para conseguir propiedades uniformes en la pieza acabada.

- Fluidez: La fluidez es una medida de la facilidad con la que el polvo fluye a través de las tolvas y otros equipos. Una buena fluidez es crucial para un procesamiento uniforme y productos finales de alta calidad.

- Normas: El cumplimiento de las normas industriales garantiza que el polvo cumpla los requisitos de calidad y rendimiento necesarios. Esto es especialmente importante en industrias reguladas como la aeroespacial y la de dispositivos médicos.

- Embalaje: Un embalaje adecuado es importante para proteger el polvo durante el transporte y el almacenamiento. También garantiza que el polvo se entregue en un estado listo para su uso.

Proveedores y precios

Elegir el proveedor adecuado para polvo de baja aleación es esencial para garantizar la calidad, la coherencia y la fiabilidad. He aquí algunos de los principales proveedores y un

visión general de las tendencias de precios.

Tabla: Proveedores y precios

| Proveedor | Ubicación | Modelos disponibles | Precio (por kg) | Cantidad mínima de pedido |

|---|---|---|---|---|

| Höganäs AB | Suecia | FeMo10, FeCr3, FeV1 | $25-$40 | 100 kg |

| Pulvimetalurgia GKN | REINO UNIDO | FeNi5, FeMn2, FeMoCrNi | $30-$50 | 200 kg |

| Tecnología Carpenter | EE.UU. | FeMo2Ni4, FeTi0,5 | $35-$55 | 50 kg |

| Sandvik AB | Suecia | FeMnCrNiV, FeMoCrNi2V1 | $40-$60 | 100 kg |

| ATI Polvos Metálicos | EE.UU. | FeCrMoNi, FeV1 | $30-$45 | 150 kg |

| Kennametal | EE.UU. | FeCr3, FeMo10 | $35-$50 | 100 kg |

Comprender los precios

- Variación de precios: El precio de los polvos de baja aleación puede variar significativamente en función de factores como la composición, la pureza y la ubicación del proveedor. Los porcentajes más altos de elementos de aleación como el molibdeno o el níquel suelen aumentar el precio.

- Cantidad mínima de pedido (MOQ): El MOQ es un factor importante para las empresas, sobre todo para las más pequeñas. Los proveedores suelen exigir pedidos más grandes para justificar el coste de producción y envío, pero algunos ofrecen más flexibilidad con MOQ más bajos.

- Consideraciones geográficas: La ubicación del proveedor también puede afectar a los precios debido a los gastos de envío, los aranceles de importación y exportación y la normativa local. Por ejemplo, los proveedores europeos pueden tener precios más altos debido a una normativa medioambiental más estricta.

Comparación de los pros y los contras de las opciones de polvo de baja aleación

A la hora de elegir un polvo de baja aleación, es esencial sopesar los pros y los contras de los distintos modelos. Aquí tienes una comparativa que te ayudará a tomar una decisión informada.

Tabla: Comparación de las opciones de polvo de baja aleación

| Modelo | Pros | Contras |

|---|---|---|

| FeMo10 | Alta resistencia, excelente resistencia al desgaste | Mayor coste debido al contenido de molibdeno |

| FeNi5 | Mayor tenacidad y ductilidad | Menor resistencia a la corrosión que los modelos FeCr |

| FeCr3 | Buena resistencia a la corrosión, dureza | Tenacidad limitada, puede requerir aleación adicional |

| FeV1 | Mayor resistencia al desgaste, refinamiento del grano | Puede ser quebradizo si no se procesa correctamente |

| FeMn2 | Mayor resistencia y rentabilidad | Menor resistencia en comparación con los modelos FeMo o FeNi |

| FeMo2Ni4 | Resistencia y dureza equilibradas | Precio medio, puede no ofrecer una resistencia extrema a la corrosión |

| FeCrMoNi | Propiedades personalizables, aplicación versátil | Procesamiento complejo, mayor coste |

| FeTi0,5 | Mayor resistencia, buena resistencia a la corrosión | Limitado a aplicaciones que requieren menor tenacidad |

| FeMnCrNiV | Resistencia superior al desgaste y la corrosión | Mayor coste, procesamiento complejo |

| FeMoCrNi2V1 | Alta resistencia, excelente resistencia al desgaste y a la corrosión | Tratamiento más caro y complejo |

¿Qué modelo le conviene?

- Si necesita alta resistencia y resistencia al desgasteconsidera FeMo10. Sin embargo, prepárese para un coste ligeramente superior debido al contenido de molibdeno.

- Para aplicaciones que requieren tenacidad y ductilidad, FeNi5 es una opción sólida, aunque puede no ofrecer el mismo nivel de resistencia a la corrosión que los modelos con mayor contenido de cromo.

- ¿Busca resistencia a la corrosión? FeCr3 es una opción excelente, aunque es posible que deba considerar una aleación adicional si necesita una mayor tenacidad.

- Si su principal preocupación es la resistencia al desgaste, FeV1 ofrece un mejor rendimiento, pero hay que tener cuidado con la fragilidad si no se procesa correctamente.

- Para una solución rentable con buena templabilidad, FeMn2 merece la pena tenerlo en cuenta, aunque puede que no alcance la resistencia de modelos más caros.

Preguntas más frecuentes

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el polvo de baja aleación? | Los polvos de baja aleación se utilizan en industrias como la automovilística, la aeroespacial y la de herramientas para fabricar componentes duraderos y de alta resistencia. |

| ¿Cómo se fabrica el polvo de baja aleación? | Los polvos de baja aleación suelen fabricarse mediante atomización, seguida de sinterización o prensado isostático en caliente (HIP). |

| ¿Cuáles son las ventajas de utilizar polvo de baja aleación? | Entre sus ventajas se incluyen la mejora de las propiedades mecánicas, la rentabilidad y la versatilidad en diversas aplicaciones. |

| ¿Cuáles son las limitaciones del polvo de baja aleación? | Las limitaciones incluyen una gama restringida de elementos de aleación, fragilidad potencial e idoneidad limitada para entornos extremos. |

| ¿Cómo elegir el polvo de baja aleación adecuado? | Tenga en cuenta factores como la resistencia necesaria, la resistencia al desgaste, la resistencia a la corrosión y el coste a la hora de seleccionar un polvo de baja aleación. |

| ¿Pueden personalizarse los polvos de baja aleación? | Sí, los polvos de baja aleación pueden adaptarse ajustando la composición de los elementos de aleación para satisfacer requisitos específicos. |

| ¿Son caros los polvos de baja aleación? | El precio varía en función de la composición y el proveedor, pero los polvos de baja aleación suelen ser más asequibles que las alternativas de alta aleación. |

| ¿Qué industrias utilizan polvo de baja aleación? | Entre los principales sectores se encuentran la automoción, la industria aeroespacial, el petróleo y el gas, las herramientas y los productos sanitarios. |

| ¿Es el polvo de baja aleación adecuado para entornos difíciles? | Aunque ofrecen una mayor resistencia al desgaste y la corrosión, los polvos de baja aleación pueden no ser adecuados para entornos extremadamente duros, en los que podrían ser necesarios polvos de alta aleación. |

| ¿Cómo se garantiza la calidad del polvo de baja aleación? | La calidad se garantiza mediante el cumplimiento de normas industriales como ASTM e ISO, así como un estricto control de la pureza y el tamaño de las partículas. |

Conclusión

Polvos de baja aleación son un material indispensable en la fabricación moderna, ya que ofrecen una combinación única de propiedades que los hacen adecuados para una amplia gama de aplicaciones. Desde piezas de automoción hasta componentes aeroespaciales, estos polvos proporcionan la resistencia, durabilidad y precisión necesarias en las industrias actuales de alto rendimiento.

Si conoce la composición, las características y las aplicaciones de los polvos de baja aleación, así como las ventajas y limitaciones de los distintos modelos, podrá tomar decisiones informadas sobre qué material se adapta mejor a sus necesidades específicas. Tanto si busca optimizar el rendimiento, reducir costes o garantizar la longevidad, los polvos de baja aleación ofrecen una solución versátil que puede adaptarse a sus requisitos.

Recuerde tener en cuenta todos los factores, incluidos la composición, el coste, la fiabilidad del proveedor y las necesidades específicas de la aplicación, a la hora de elegir el polvo de baja aleación adecuado para su proyecto. Con la elección correcta, puede lograr resultados superiores y alcanzar el éxito en sus esfuerzos de fabricación.